Filtrating type vapor-liquid separating device

A vapor-liquid separation and filtration technology, applied in separation methods, charging systems, and liquid degassing, etc., can solve the problems of fuel injector safety hazards, inhaled gas, and impact on working stability, to protect normal work and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

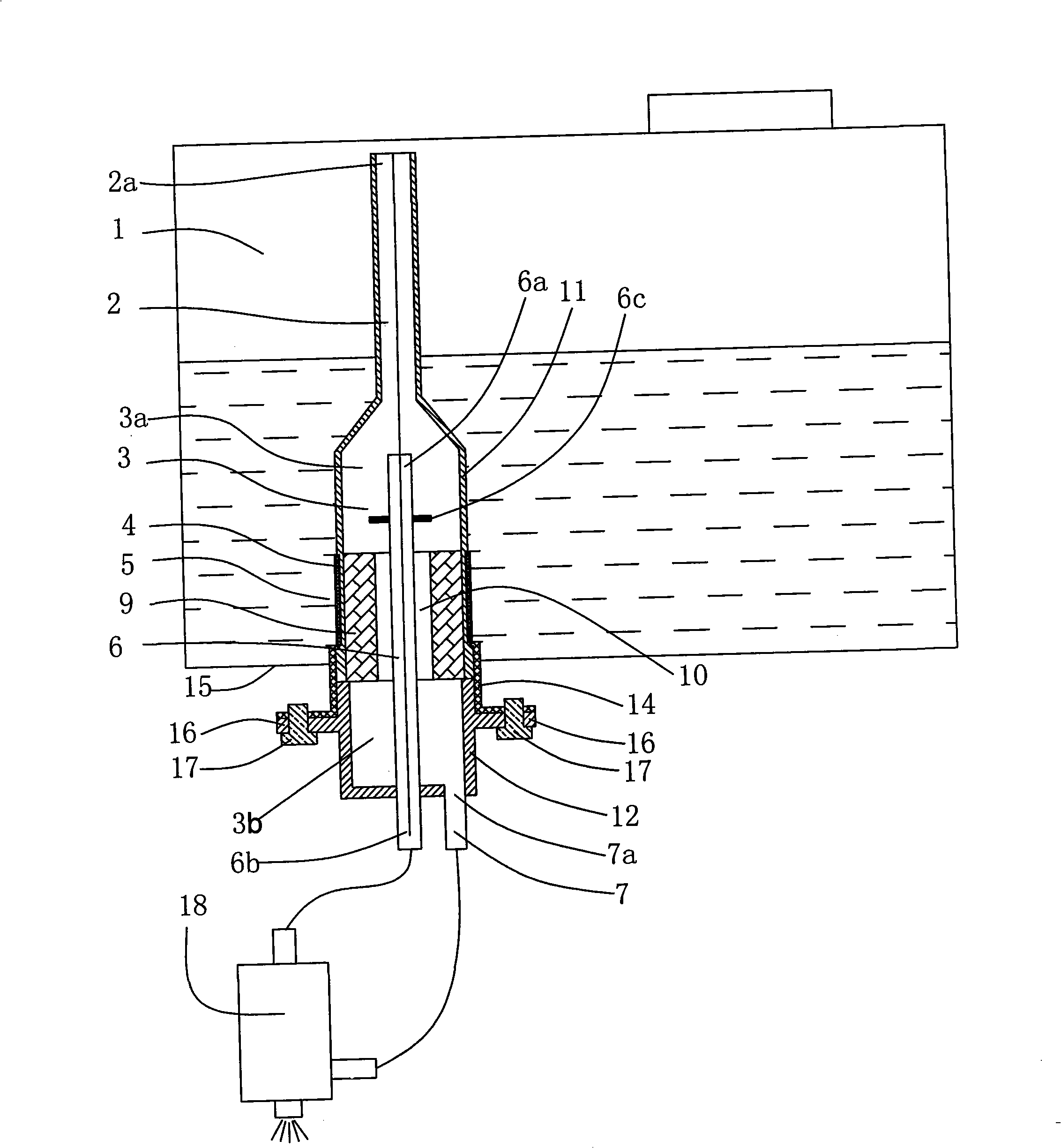

[0033] figure 1It is an embodiment of the filter type vapor-liquid separation device of the present invention. As shown in the figure, the device has a first fuel filter 4 and a second fuel filter 9 placed inside the fuel tank, and the fuel outlet pipe 7. An oil return pipe 6, an oil inlet 5 and an exchange volume composed of the upper body 11 and the lower body 12. 3. The upper body 11 and the lower body 12 are pressed against each other through the thread 13, and the second filter 9 is fixed at the same time In the exchange volume 3.

[0034] The first fuel filter 4 is made of mesh material, located on the periphery of the exchange volume 3 , and the mesh gap is formed as an oil inlet 5 .

[0035] The columnar hollow second fuel filter 9 divides the exchange volume 3 into an upper volume 3 a and a lower volume 3 b, wherein the cavity forms an intermediate oil passage 10 . The oil return pipe 6 passes through the lower volume 3b and leads to the upper volume 3a through the ...

Embodiment 2

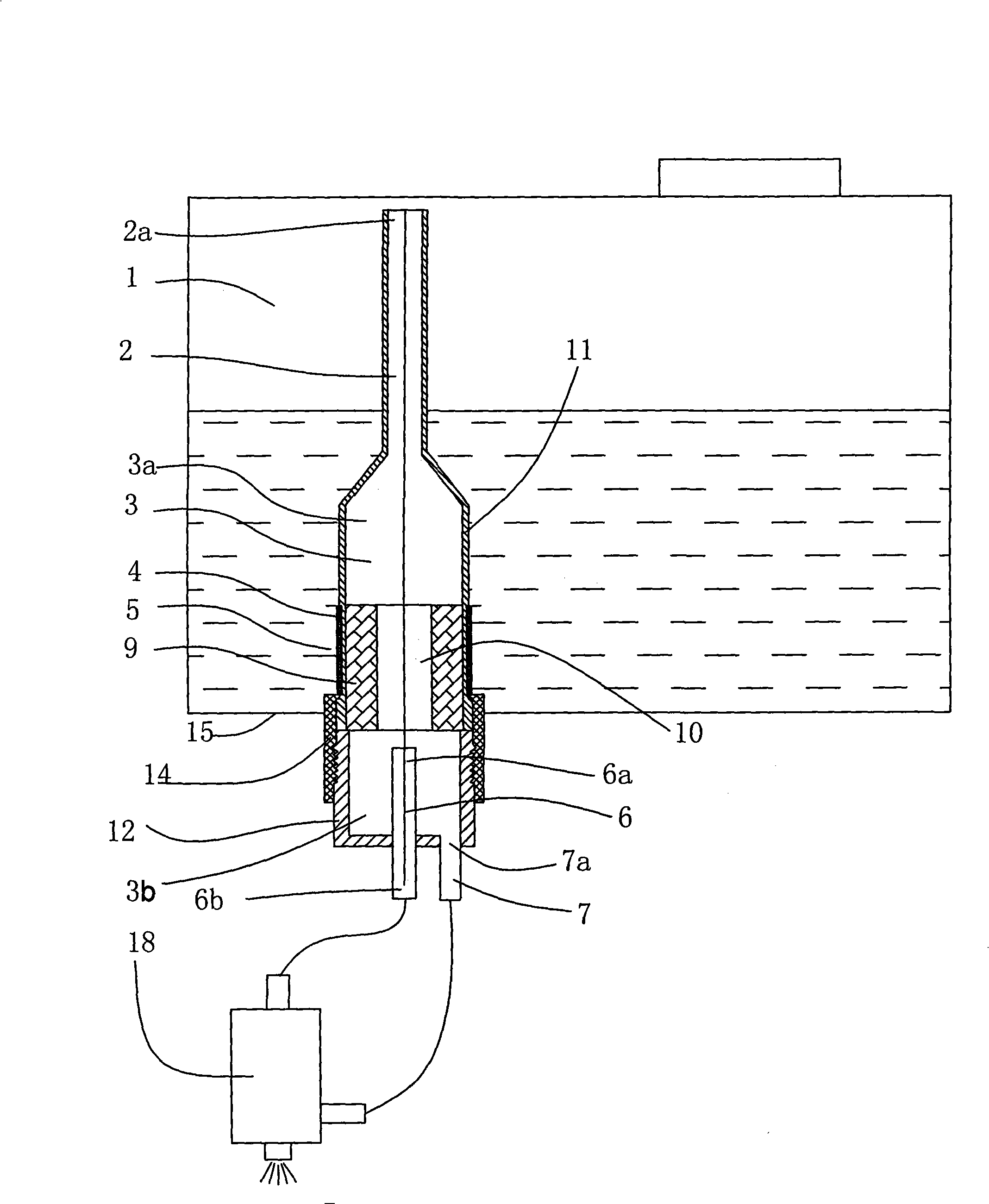

[0042] figure 2 It is another embodiment of the filter type gas-liquid separation device of the present invention, as shown in the figure, the difference from Embodiment 1 is that firstly the oil return pipe 6 does not pass through the middle oil passage 10 to reach the upper volume 3a , and only reach the position where the lower volume 3b is close to the middle oil passage 10; secondly, the lower body 12 has no protruding outer edge, and the upper body 11 and the second A fuel filter 9 is fixed in the exchange volume 3 . The oil return of the fuel injector 18 directly enters the lower volume 3b from the oil return pipe 6, the liquid fuel discharged from the oil return pipe 6 directly enters the oil outlet pipe 7 downwards, and participates in the circulation flow again, and the air bubbles discharged from the oil return pipe 6 are discharged from the middle oil passage 10 Enter the upper volume 3a, and finally enter the fuel tank 1 through the exhaust passage 2.

Embodiment 3

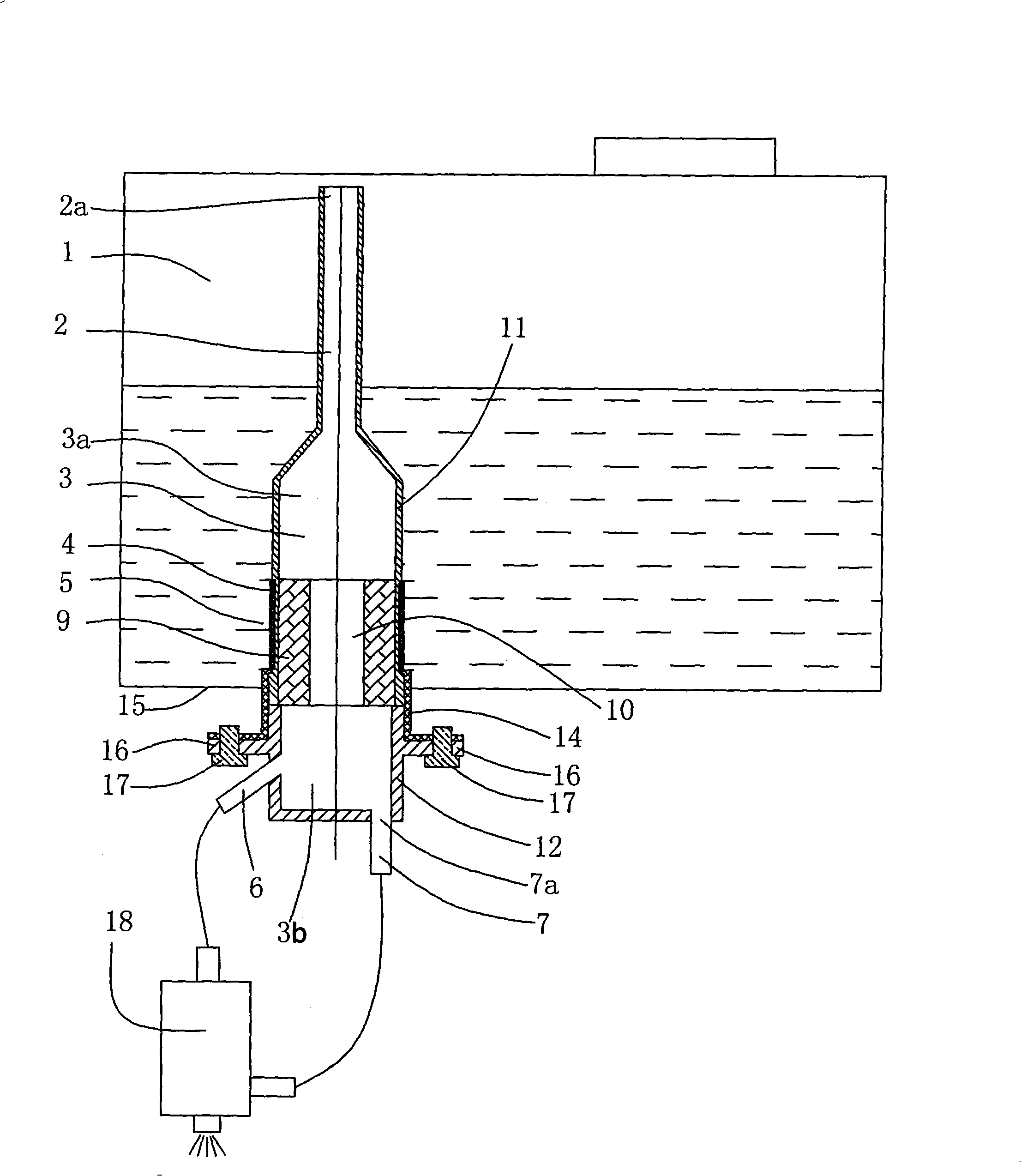

[0044] image 3 Another implementation example of the filter-type gas-liquid separation device of the present invention, as shown in the figure, differs from Embodiment 1 in that: the oil return pipe 6 is an oil return nozzle extending outward on the lower body 12, and its The axis and the axis of the oil outlet pipe 7 may form a certain angle. The oil return of the fuel injector 18 directly enters the lower volume 3b from the oil return pipe 6, the liquid fuel discharged from the oil return pipe 6 directly enters the oil outlet pipe 7 downwards, and participates in the circulation flow again, and the air bubbles discharged from the oil return pipe 6 are discharged from the middle oil passage 10 Enter the upper volume 3a, and finally enter the fuel tank 1 through the exhaust passage 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com