Manufacturing method of 18K gold and 18K gold jewelry

A production method and technology for gold jewelry, applied in clothing, jewelry, applications, etc., can solve the problems of easily revealing the original color of K gold, easy fading of jewelry, poor gloss, etc., and achieve easy decolorization, pure color, and good oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

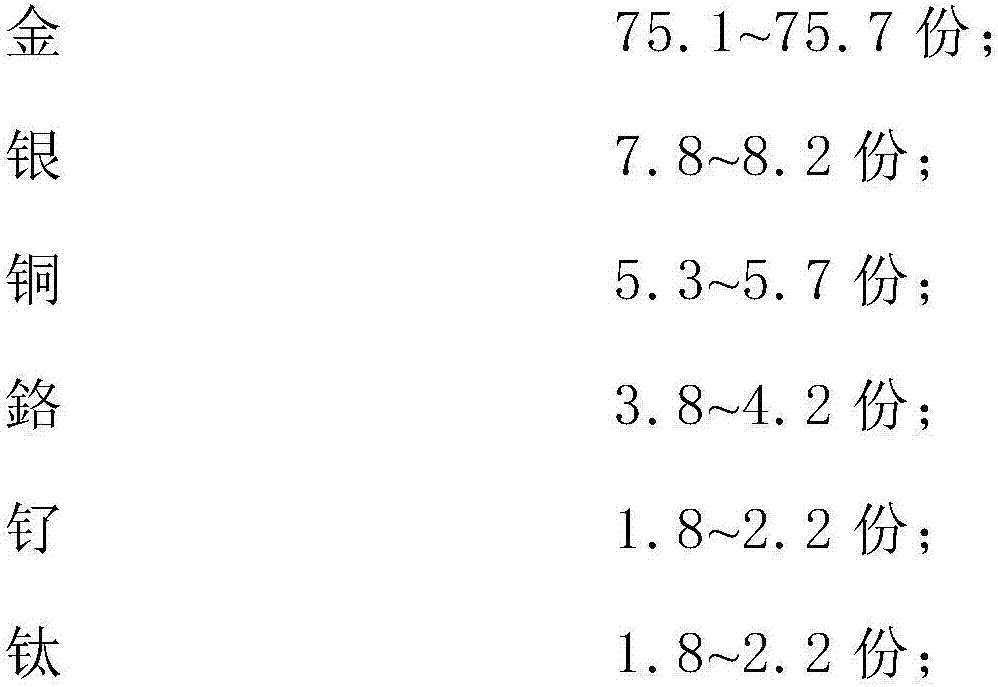

[0029] An 18K gold made from the following raw materials by weight:

[0030]

[0031] Further, the more specific parts by weight of the above raw materials are as follows:

[0032]

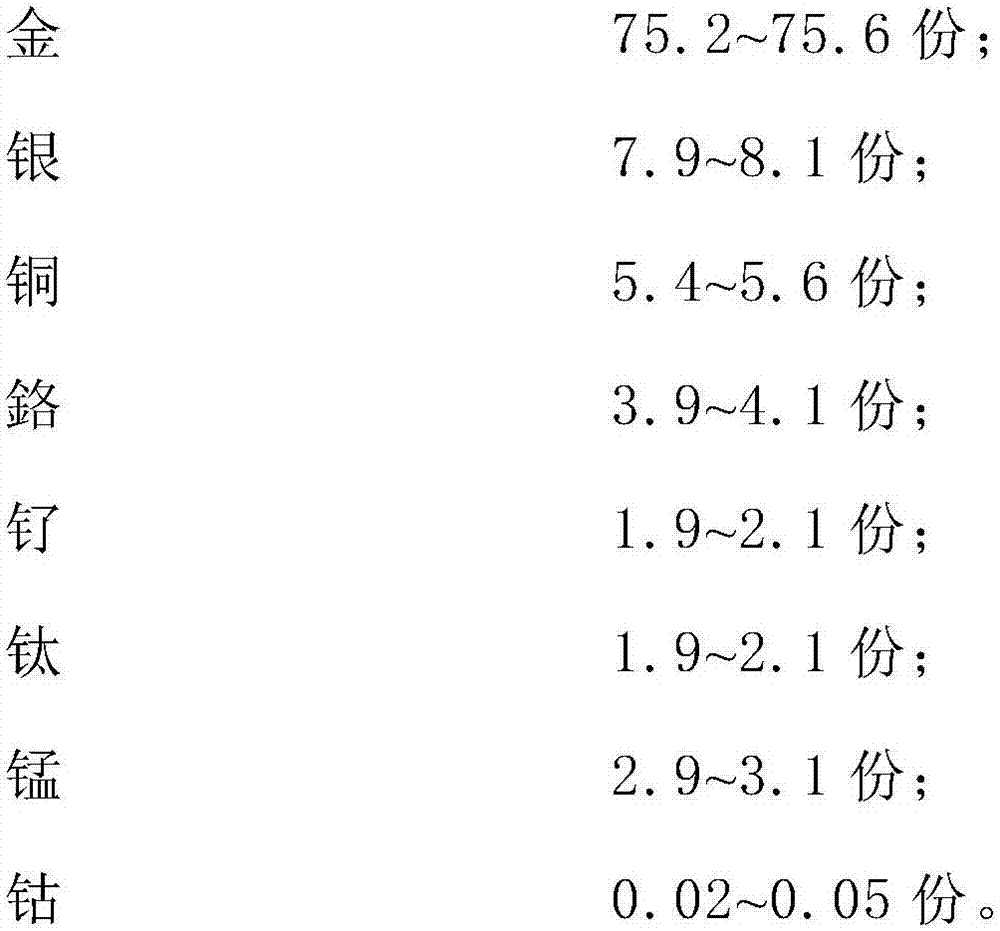

[0033] Furthermore, the more specific parts by weight of the above raw materials are as follows:

[0034]

[0035]

[0036] To sum up: the above-mentioned metal raw materials are used to make 18K gold. The 18K gold produced is pure in color and has very good gloss. It is not easy to fade after long-term use. It does not change color when burned with an open flame. It has excellent oxidation resistance. it is good.

Embodiment 2

[0038] A method for making 18K gold jewelry includes the following steps:

[0039] a. Prepare the raw materials according to the metal components and their weight parts ratio as in Example 1;

[0040] b. The raw materials are smelted under the protection of inert gas;

[0041] c. Pour the molten metal liquid into a forming mold under the protection of inert gas, and cast it to form a blank;

[0042] d. Carry out fine clamping, laser welding, repairing and shaping, fine grinding and polishing of the blank to make semi-finished jewelry;

[0043] e. Electroplating of semi-finished jewelry products to restore the external color to the true color of gold;

[0044] f. Surface treatment of semi-finished jewelry after electroplating to form finished jewelry.

[0045] Preferably, in step b and step c, the inert gas is nitrogen, helium or argon, or a mixture of nitrogen and argon, or a mixture of helium and argon; the mixture of nitrogen and argon consists of 7-9 parts by weight of nitrogen and 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com