Gold jewelry five-axis turning and milling integrated machining center

A processing center and jewelry technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems that the processing surface finish is difficult to meet the high-gloss requirements, cannot be separated from people, and the size of jewelry is large, so as to ensure processing accuracy and high-gloss effect Requirement, reduction of gravity inertia error, effect of small size of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

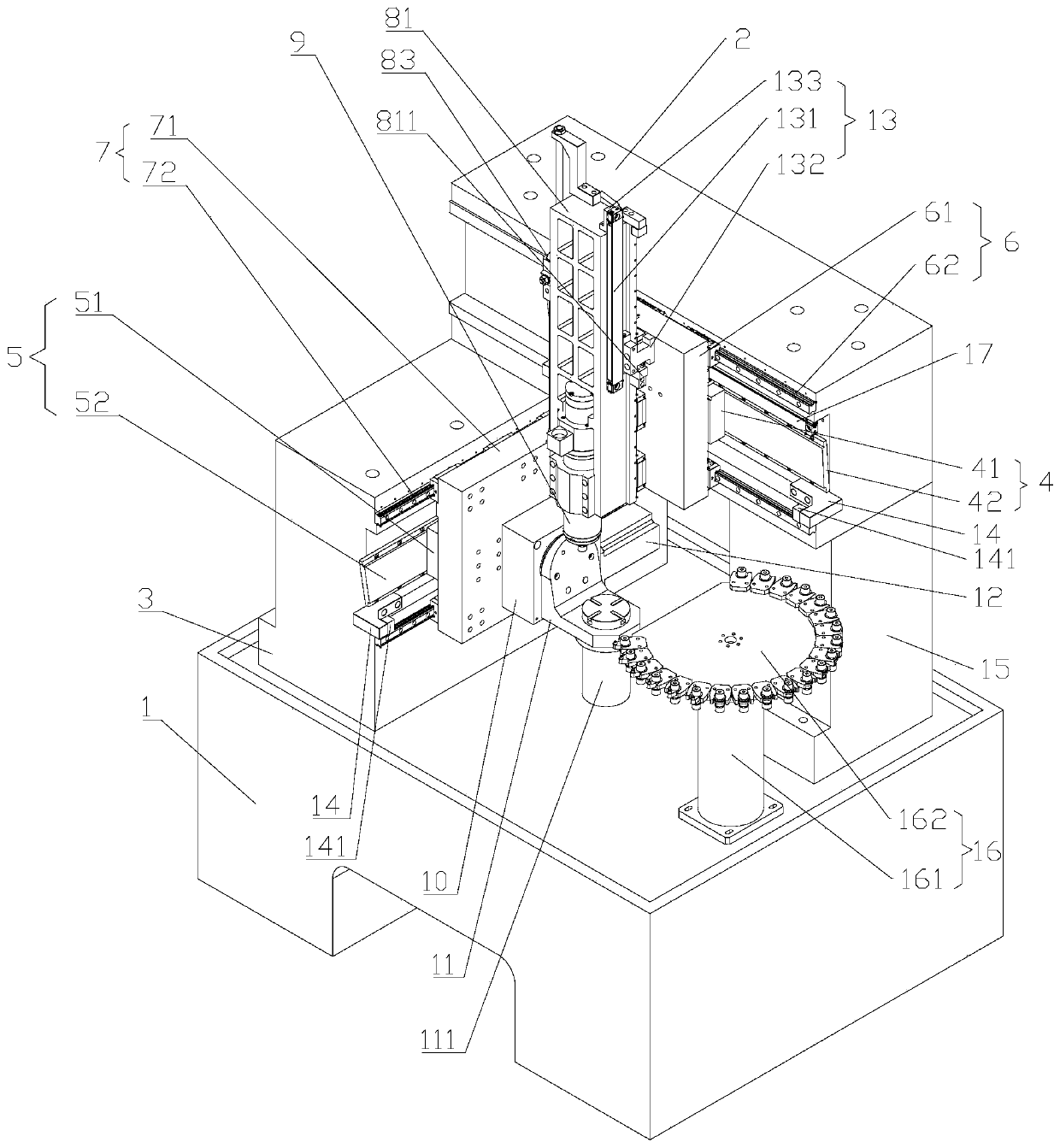

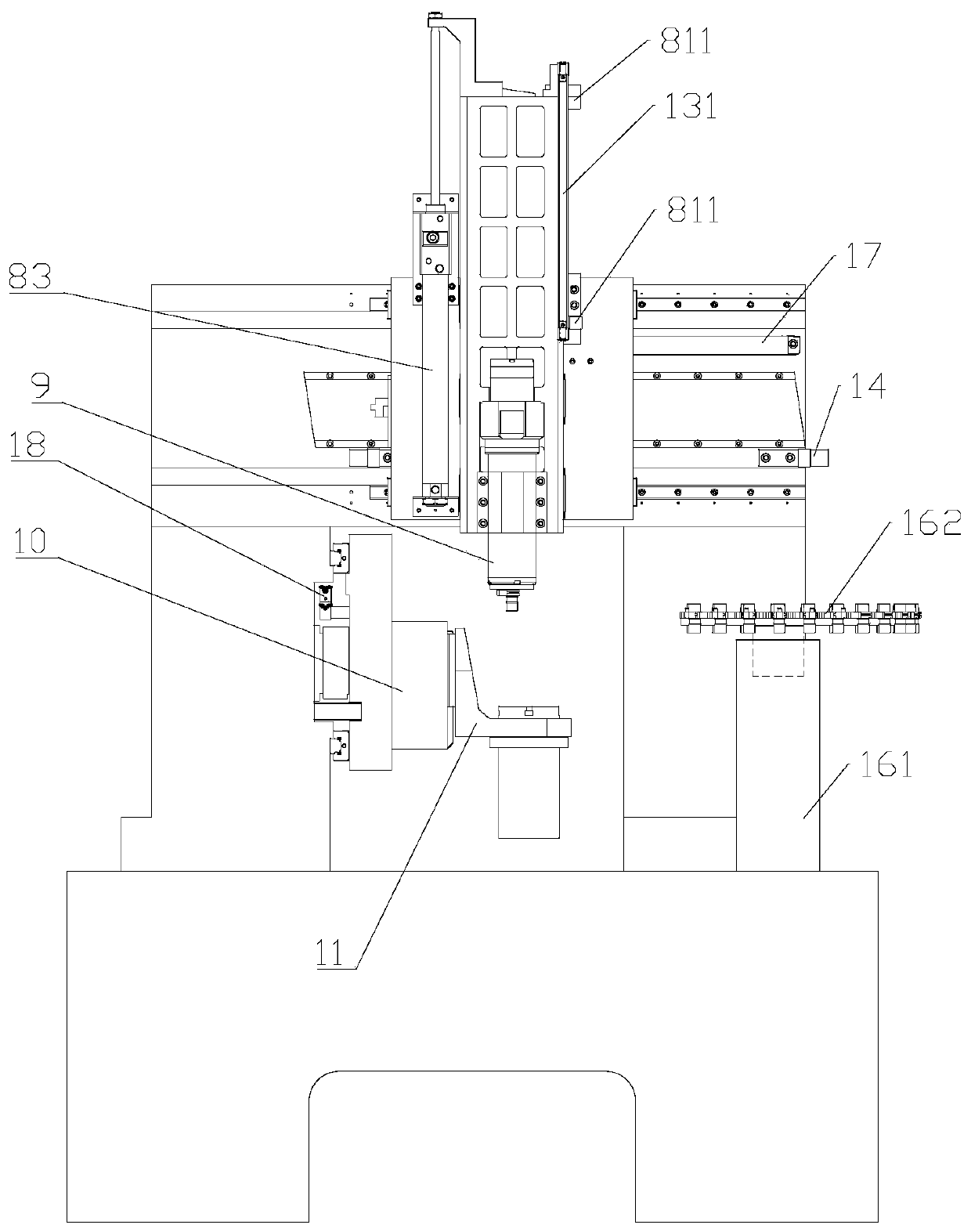

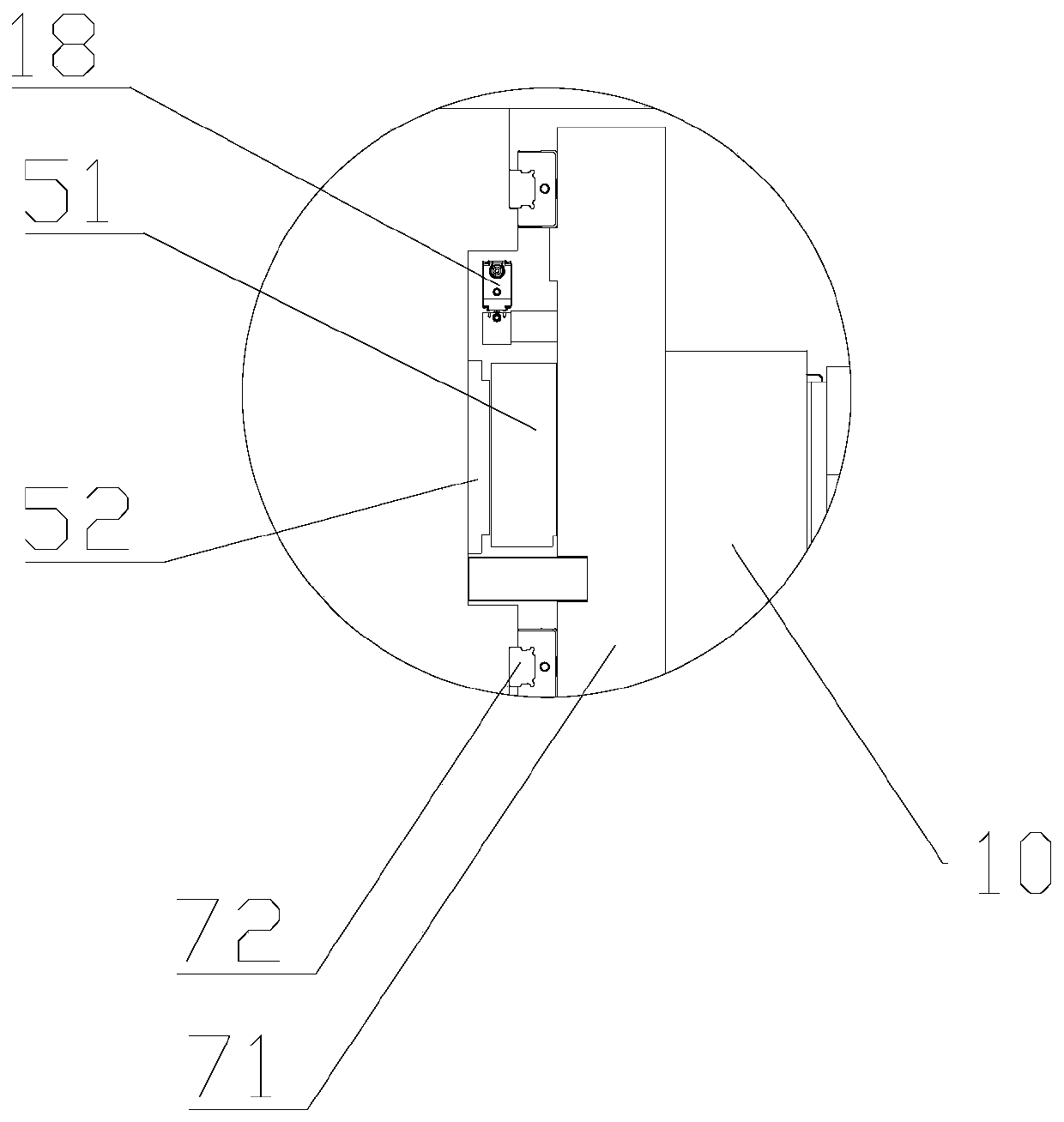

[0034] This embodiment provides a gold jewelry five-axis turning and milling integrated machining center, such as Figure 1-5 As shown, it includes: bed 1; Y-axis mounting base 2, Y-axis mounting base 2 is fixed on the top of bed 1; X-axis mounting base 3, X-axis mounting base 3 is fixed on the top of Y-axis mounting base 2; The X-axis mounting base 3 is provided with an X-axis moving assembly 6, a Z-axis moving assembly 8, and a spindle 9 assembly for processing; a Y-axis moving assembly 7, and the Y-axis moving assembly 7 is arranged on the Y-axis mounting base 2; the Y-axis moving The assembly 7 includes a second carriage 71 for reciprocating movement along the Y axis; the second carriage 71 is provided with a turntable 11 that rotates around the C axis and a first reducer 10 that makes the turntable 11 rotate around the A axis. The reducer 10 is fixed on the second carriage 71 , and the turntable 11 is fixedly connected to the output end of the first reducer 10 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com