Method for manufacturing hard gold jewelry

A hard gold and jewelry technology, applied in jewelry, clothing, electrolysis process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

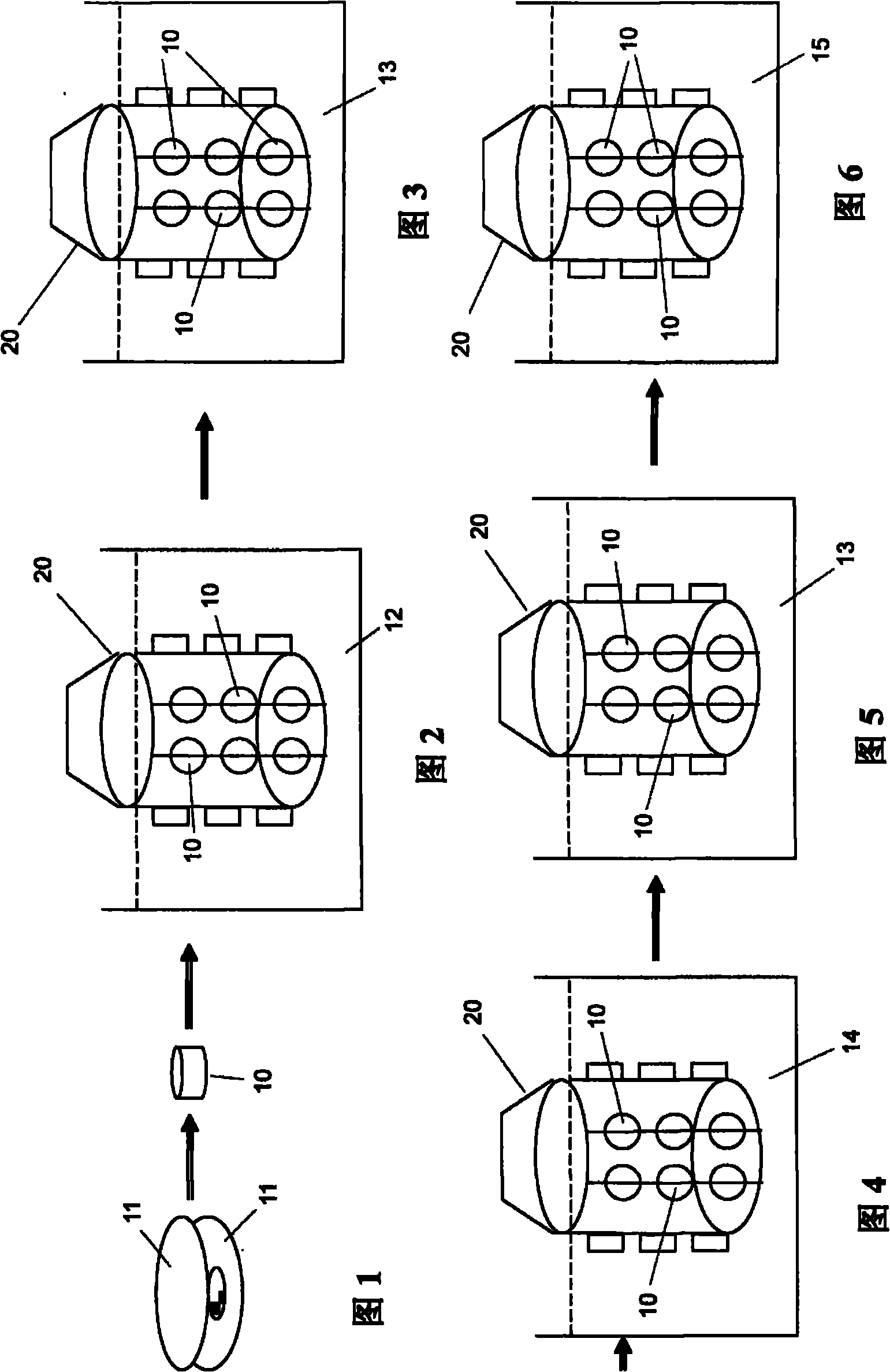

[0032] In the accompanying drawings, the various steps of forming a hollow gold piece suitable for use in jewelry are schematically depicted. The method typically produces gold jewelry with a purity greater than 99.9% and a microhardness greater than 100 Hv.

[0033] through such as figure 1 The silicon rubber mold 11 shown is spin casted to produce the mandrel 10 of the low melting point alloy.

[0034] After casting, the mandrel 10 is placed in a drum to remove thorns or any parting lines. Additionally, grinding and polishing may also be required to smooth the surface of the mandrel.

[0035] As an alternative to low melting point alloys, wax can be used to form the mandrel. If wax is used, the wax should be removed before the mandrel is placed in the bath since the temperature of the bath is typically above the melting point of the wax.

[0036] The mandrel 10 is then attached to the clamp 20 of the plating rack. Such as figure 2 As shown, the mandrel 10 is cleaned i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com