Reconfigurable microwave low-pass filter containing MEMS switch and its manufacturing method

A low-pass filter and switch technology, which is applied in the field of micro-mechanical systems and microwave crossover, can solve the problems of large filter insertion loss, unfavorable IC process integration, and large size, and achieve low insertion loss, low power consumption, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

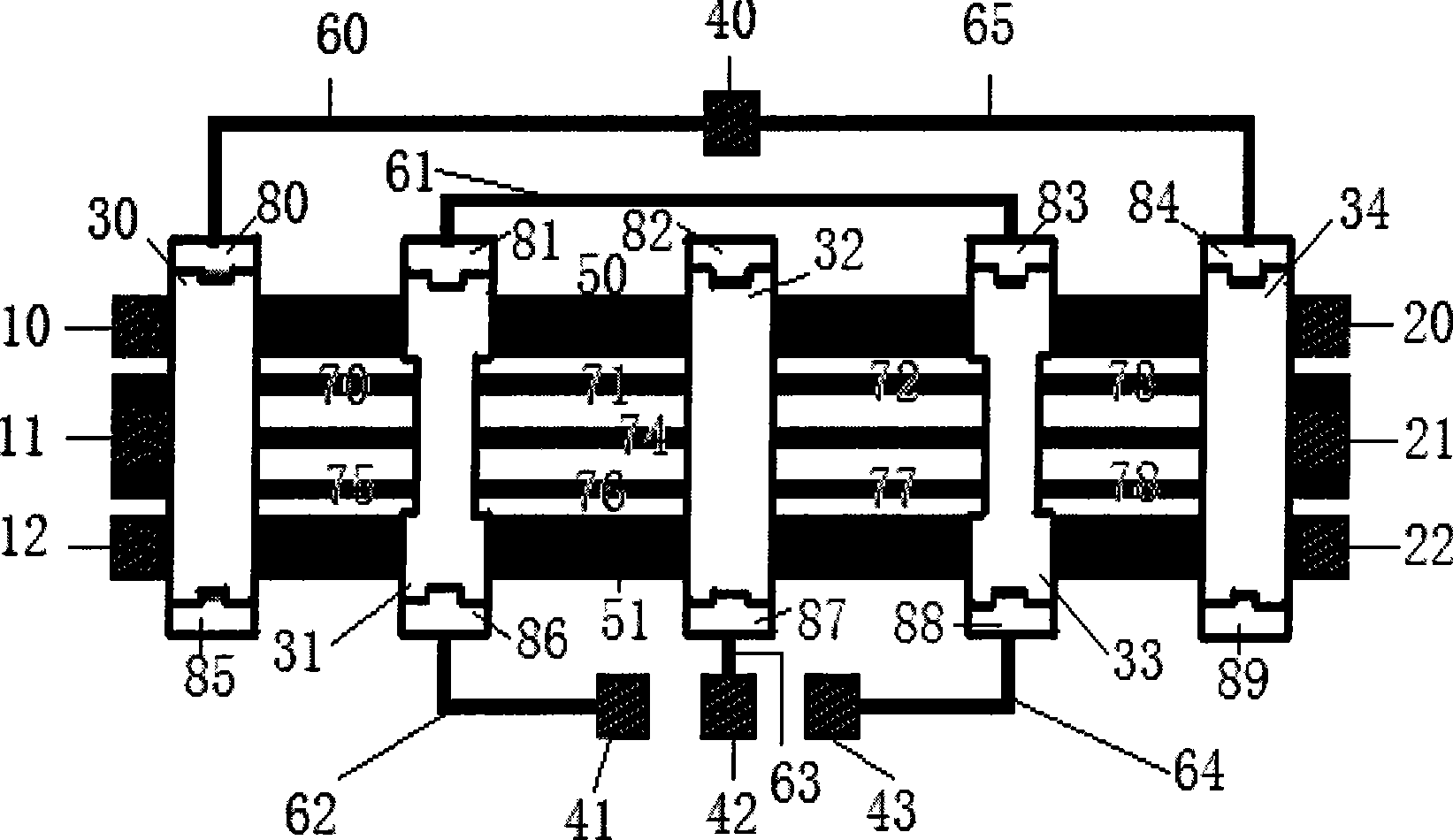

[0055] The low-pass filter involved in this embodiment has exactly the same structure as the low-pass filter described in "Summary of the Invention", and details are not repeated here. The 3dB cut-off frequencies of the filter before and after reconstruction are 21GHz and 12GHz, respectively.

[0056] The working principle of this embodiment.

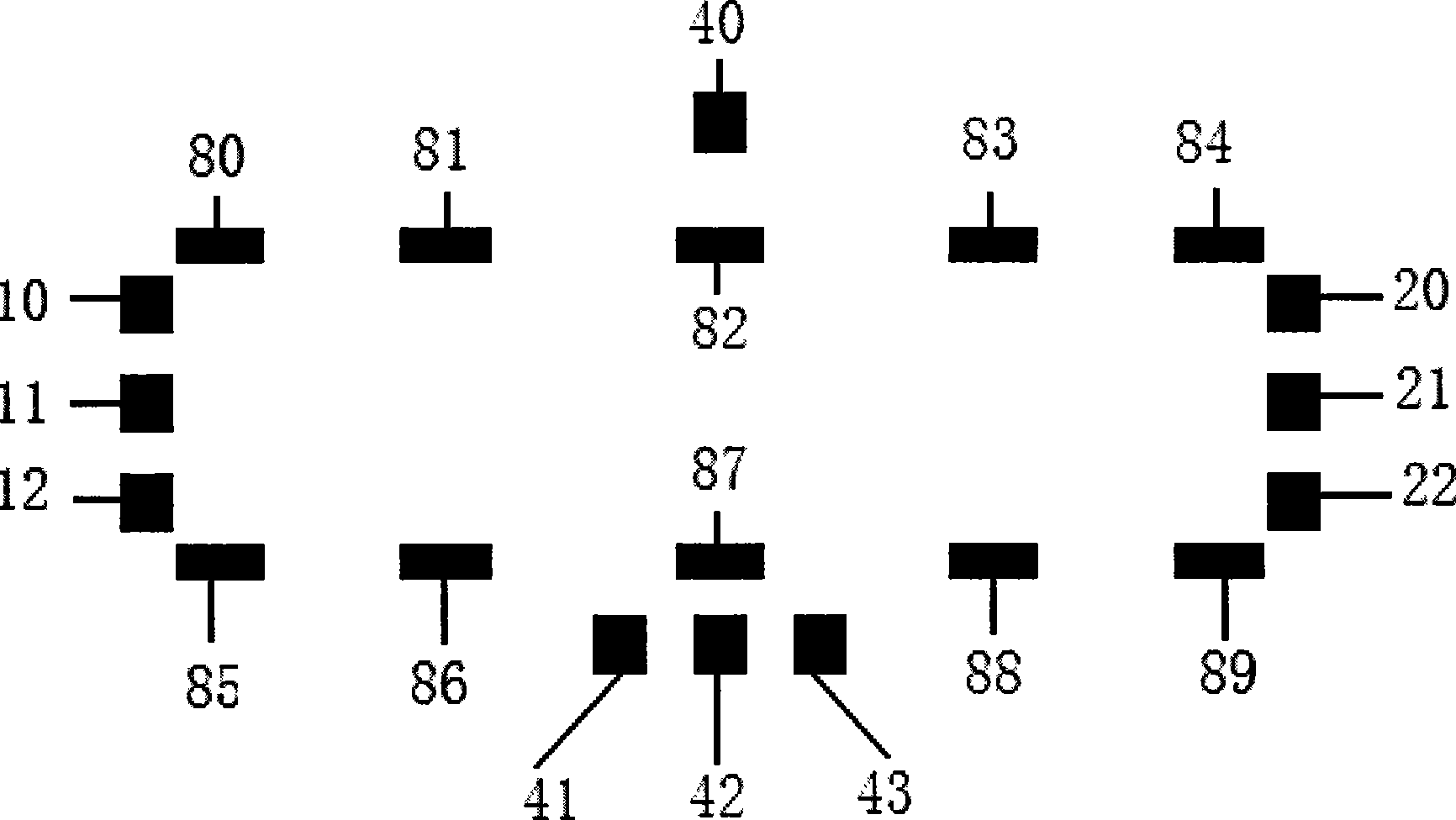

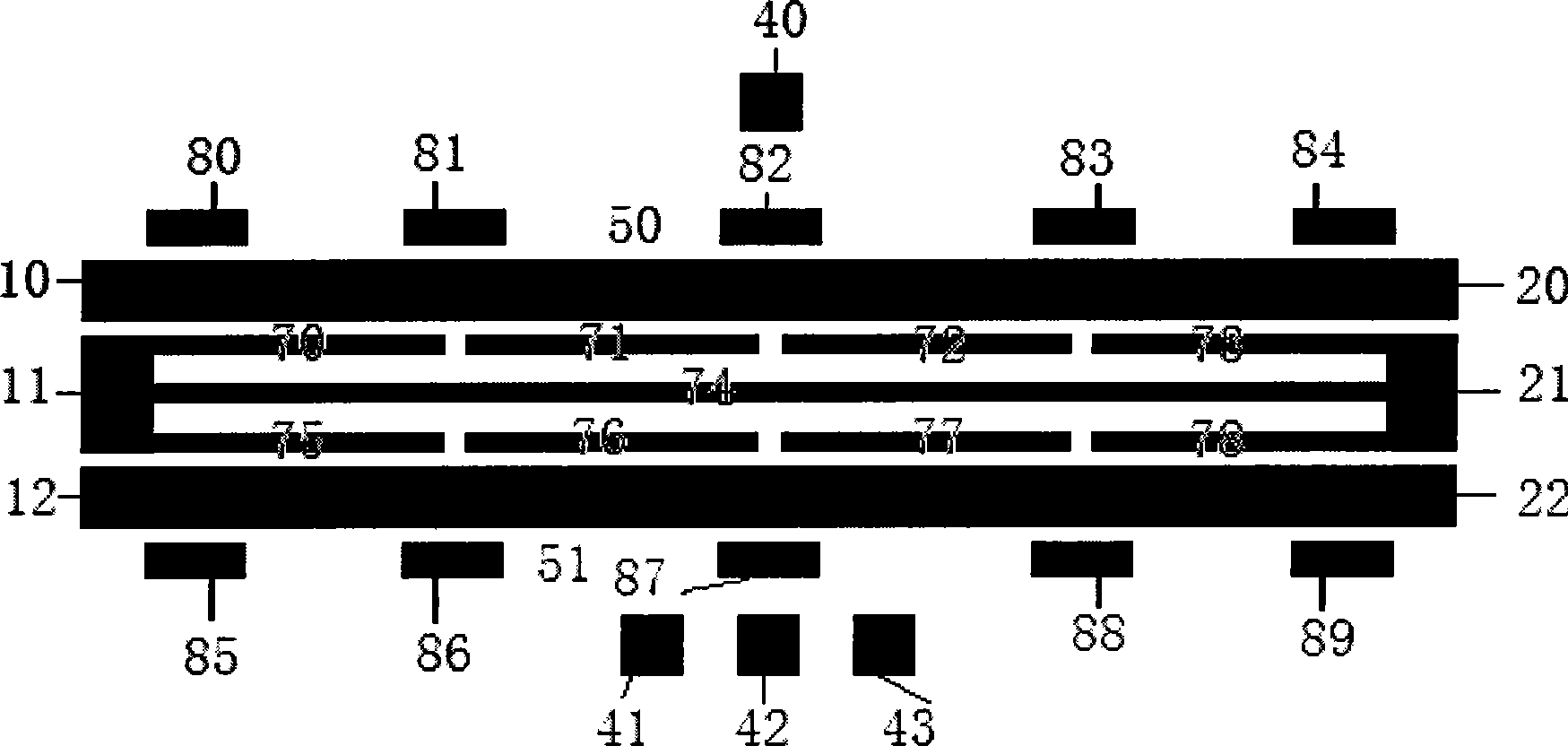

[0057] The reconfigurable low-pass filter obtains reconfigurable functions by turning off and on five MEMS switches, such as figure 1 As shown, before reconfiguration, one end of the 30V voltage is applied to the first ground wire 50 and the second ground wire 51, and the other end is applied to the first bias pad 40 and the third bias pad 42, then due to the electrostatic effect of the first The MEMS membrane bridge 30, the third MEMS membrane bridge 32 and the fifth MEMS membrane bridge 34 are closed, the second MEMS membrane bridge 31 and the fourth MEMS membrane bridge 33 are opened, ignoring the parasitic effect of opening the MEM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com