Nano-SiO2 modified aluminium section bar superior atmospheric corrosion resisting polyester powder paint and preparation method thereof

A technology of polyester powder and aluminum profiles, applied in polyester coatings, powder coatings, coatings, etc., can solve the problems of poor bonding force, interface defects, and high specific surface energy, improve performance and service life, and improve durability. Ability to irradiate ultraviolet rays and improve dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

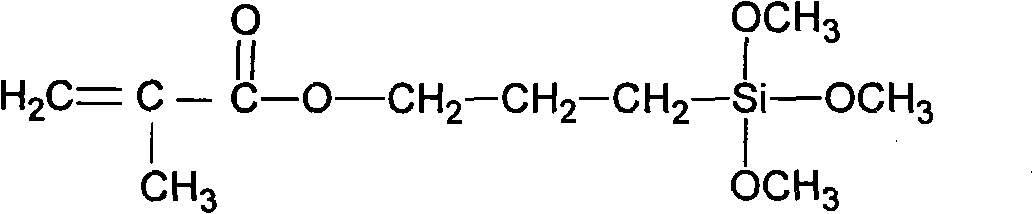

[0033] Nano SiO of the present invention 2 Modified aluminum profile high weather resistance polyester powder coating, on nano-SiO 2 The surface introduces a reactive silane coupling agent, when using an acryloxy silane coupling agent:

[0034]

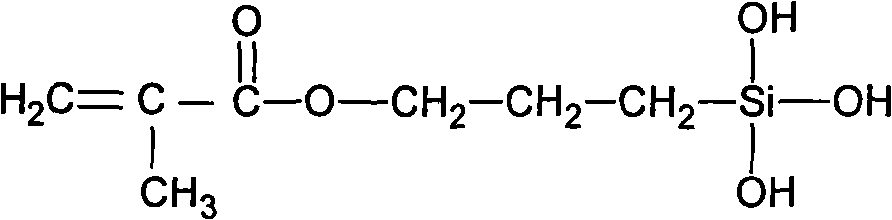

[0035] Hydrolyzed into the following forms:

[0036]

[0037] nano-SiO 2 Both the surface and the hydrolyzed silane coupling agent contain hydroxyl groups, so a strong bond is easily formed between the two, including the dehydration of Si-OH groups and Si-OH groups, hydrogen bonds and van der Waals interactions.

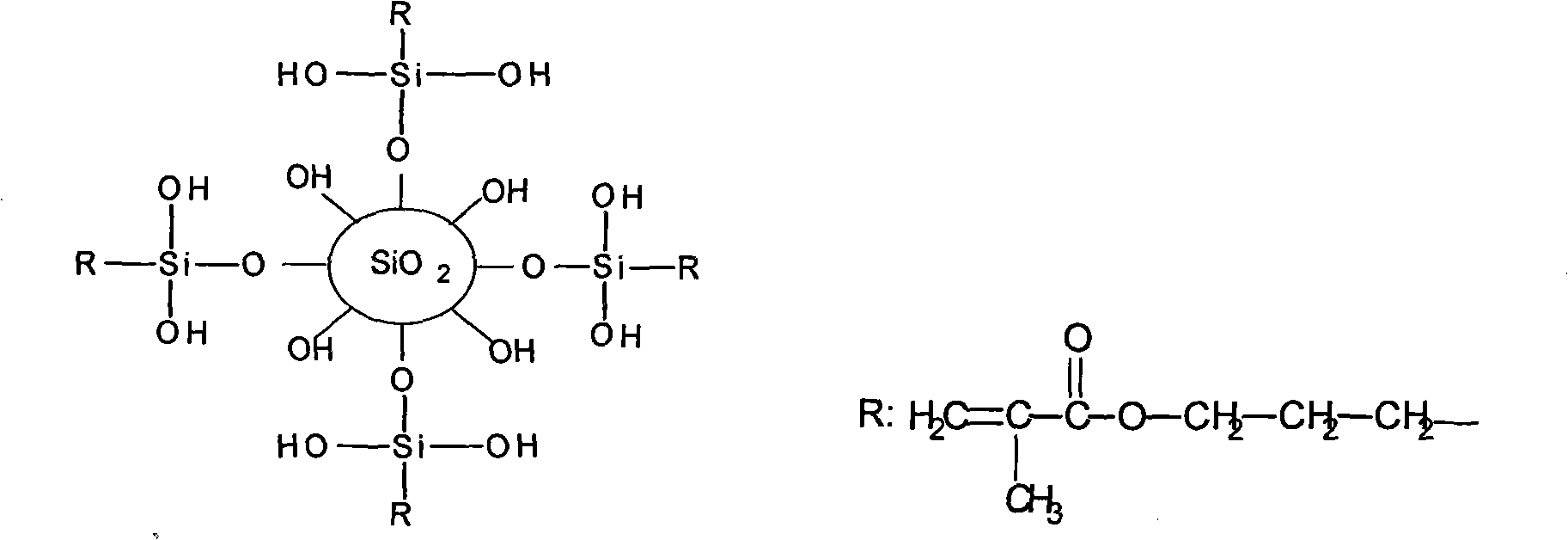

[0038] nano-SiO 2 The other end of the surface-bound coupling agent contains a polymerizable double bond, which provides conditions for the polymerization of acrylic monomers. The reaction structure is as follows:

[0039]

[0040] Therefore, the double bond of polymethacrylic acid is polymerized in situ at the double bond at the other end of the coupling agent, and the nano-SiO 2 Surface coated with graft poly...

Embodiment 2

[0051] The difference between this embodiment and the above-mentioned embodiment lies in that the silane coupling agent used is vinyltrimethoxysilane, and the initiator is diacetyl peroxide. The hydrolysis time of the silane coupling agent is 2 hours, and the silane coupling agent and nano-SiO 2 The reaction time is 3h; SiO modified by methacrylic acid monomer and silane coupling agent 2 The reaction temperature is 70°C, and the reaction time is 6h. According to 1.5% nano-SiO 2 The amount of addition, the preparation of nano-SiO 2 Modified polyester powder coating, the aging resistance of the coating is: the artificial accelerated weather resistance of ultraviolet lamp (QUV-B lamp, wavelength 313nm) is greater than 400h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com