Preparation method for discoloration tolerant antibacterial material of silver-loaded titanium phosphate

A technology of silver-loaded phosphoric acid and antibacterial materials, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve problems such as affecting the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

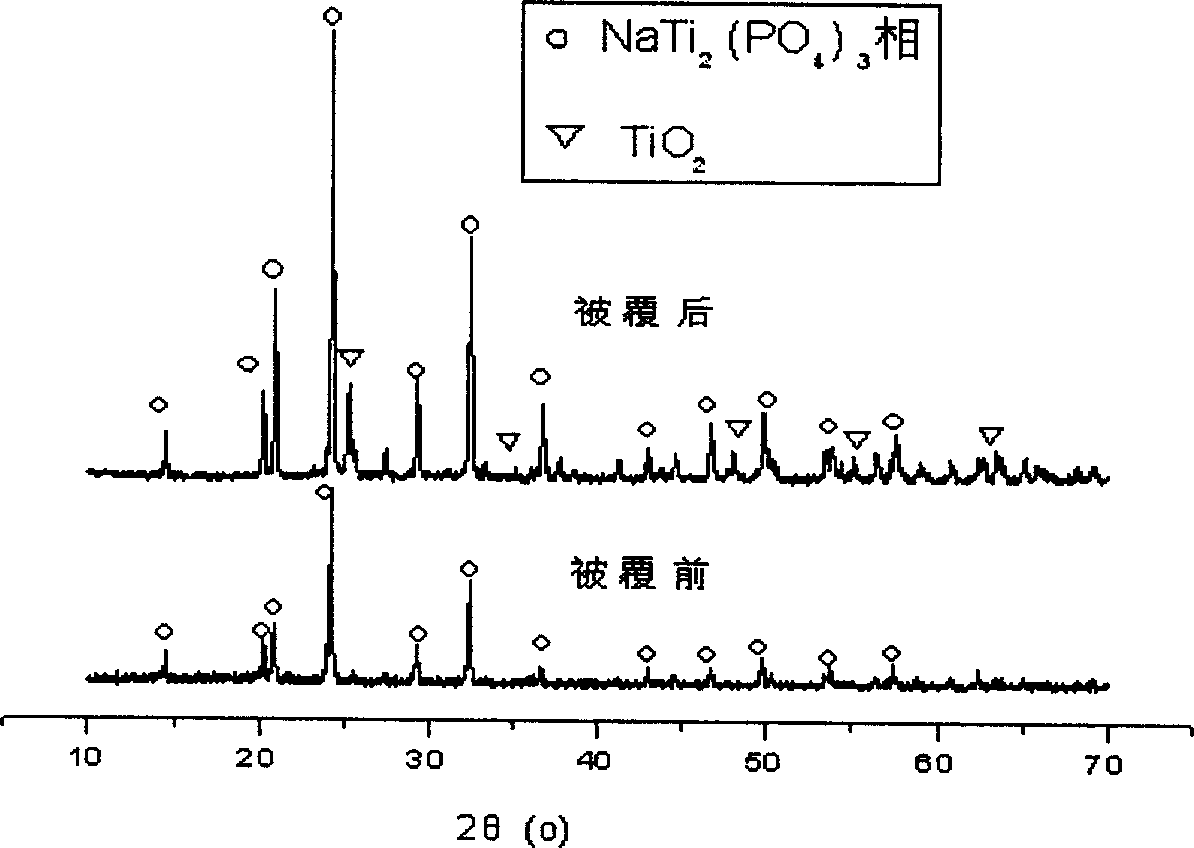

[0014] Example 1. Dissolve 2.5 g of titanium sulfate and 0.061 g of urea in water, add 10 g of sodium titanium phosphate block, put it in a 50°C water bath, and stir the solution for 6 hours. After drying the coated sodium titanium phosphate block, heat and keep it at 600°C for 1h in the atmosphere, and then exchange it with 1.0% silver nitrate solution at 20°C for 0.5h. 1%. The silver-loaded sodium titanium phosphate block was heated and kept at 600° C. for 6 hours in the atmosphere. Expose the block under direct sunlight for 48 hours, and measure it with a SBD-1 digital whiteness meter. The whiteness of the block is 89%. The antibacterial performance of the sodium titanium phosphate block is tested by the oscillation method. The antibacterial rate can be Reach 99%.

example 2

[0015] Example 2. Dissolve 1.83 g of titanyl sulfate and 0.061 g of urea in water, add 10 g of titanium calcium phosphate blocks, put in a 70°C water bath, and stir the solution for 3 hours. After drying the coated titanium calcium phosphate block, heat and keep it at 500°C for 4h in the atmosphere, then use 4.0% silver nitrate solution at 50°C for silver ion exchange, after 0.5h exchange the amount of silver loaded up to 3%. The silver-loaded calcium titanium phosphate block was heated and kept at 800° C. for 0.5 h under atmospheric atmosphere. This block is exposed to the sun for 48h under direct sunlight, measured according to the same method as in Example 1, the whiteness of the block is 90%, and the antibacterial performance of the calcium titanium phosphate block is tested by the oscillation method, and its antibacterial rate can reach 99%.

example 3

[0016] Example 3. Dissolve 2.5 g of titanium sulfate and 0.305 g of urea in water and mix well, add 10 g of lithium titanium phosphate block, put in a 90°C water bath, and stir the solution for 6 hours. After drying the coated lithium titanium phosphate block, heat it at 700°C for 1h in the atmosphere, and then exchange it with 20% silver nitrate solution at 30°C for 0.5h. 10%. The silver-loaded lithium titanium phosphate block was heated and kept at 1000° C. for 6 hours in the atmosphere. The block was exposed to the sun for 48 hours under direct sunlight, measured according to the same method as Example 1, the whiteness of the block was 90%, and the antibacterial performance of the lithium titanium phosphate block was tested by the oscillation method, and the antibacterial rate could reach 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum inhibitory concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com