Cyanide-free 18k gold electrocasting solution and preparation method and application thereof

A technology of electroforming solution and solution, which is applied in the direction of electroforming and electrolysis, can solve the problems affecting the quality of 18K gold jewelry, the threat to workers and the environment, and the impact on production efficiency, so as to achieve easy control of gold content, reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of cyanide-free 18k gold ornaments, characterized in that: comprising the following steps in sequence:

[0025] 1) Plate making: Carve the design drawing into a wax plate or 3D print the design drawing into a wax plate, cast it into a silver plate through lost wax, and then trim the silver plate as a master;

[0026] 2) Molding, mold opening, and mold inversion: The film pressing steps are: insert the prepared master plate between two semi-raw vulcanized rubbers, and apply a release agent (Datian brand oil-based release agent) between the two semi-raw vulcanized rubbers. ORDA-350A), under the condition of 150 ℃, press for 10 hours to fully mature and shape, and complete the film; the mold opening step is: after the mold is completed, take out the master plate, and engrave the liquid alloy backflow groove on the two semi-raw vulcanized rubber And the exhaust fine groove, complete the mold opening, and obtain the film; the step of pouring the mold is:...

Embodiment 8

[0051] Basically the same as Example 2, the difference is: in the preparation of the electroforming solution, in step A, keep warm for 25min, the consumption of aqua regia is 10mL per gram of gold, and the mass concentration of sodium sulfite solution is 15%; in step B, Stirring speed is 400r / min, continue to stir and keep warm for 15min after feeding; in step C, stir speed is 700r / min, continue stirring and keeping warm for 8min after adding; in step D, stir speed is 700r / min.

Embodiment 9

[0053] It is basically the same as Example 2, except that: in the preparation of the electroforming solution, in step A, keep warm for 60min, the consumption of aqua regia is 18mL per gram of gold, and the mass concentration of sodium sulfite solution is 25%; in step B, Stirring speed is 800r / min, continue to stir and keep warm for 40min after feeding; in step C, stirring speed is 1200r / min, continue stirring and keeping warm for 25min after adding; in step D, stirring speed is 1200r / min.

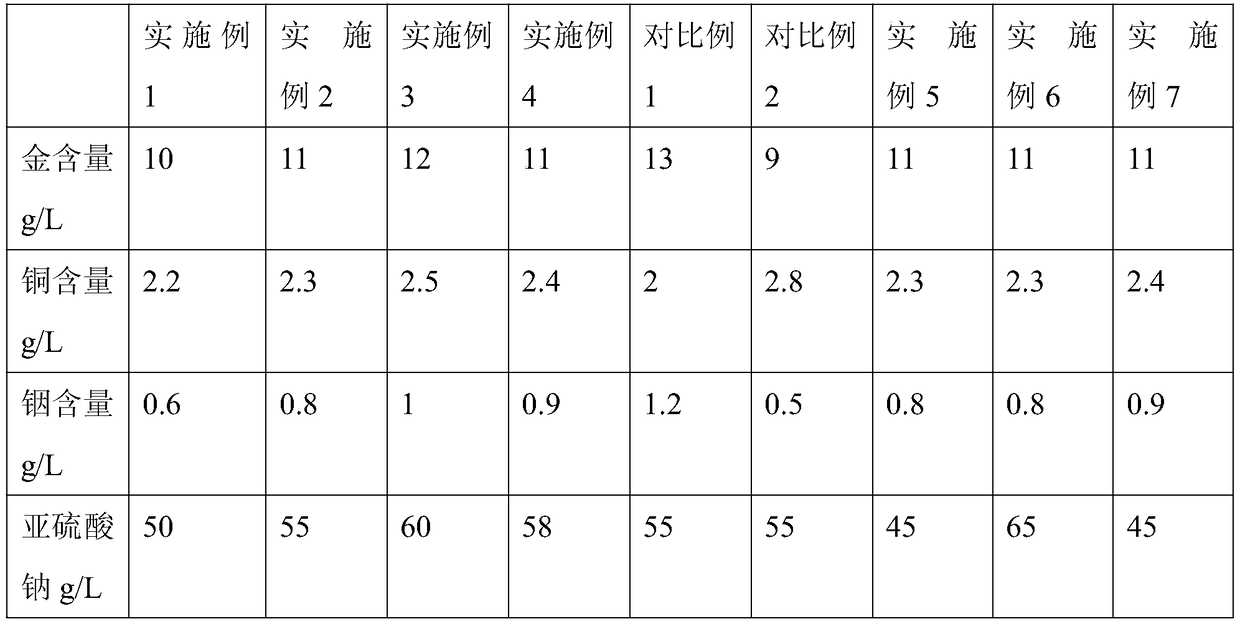

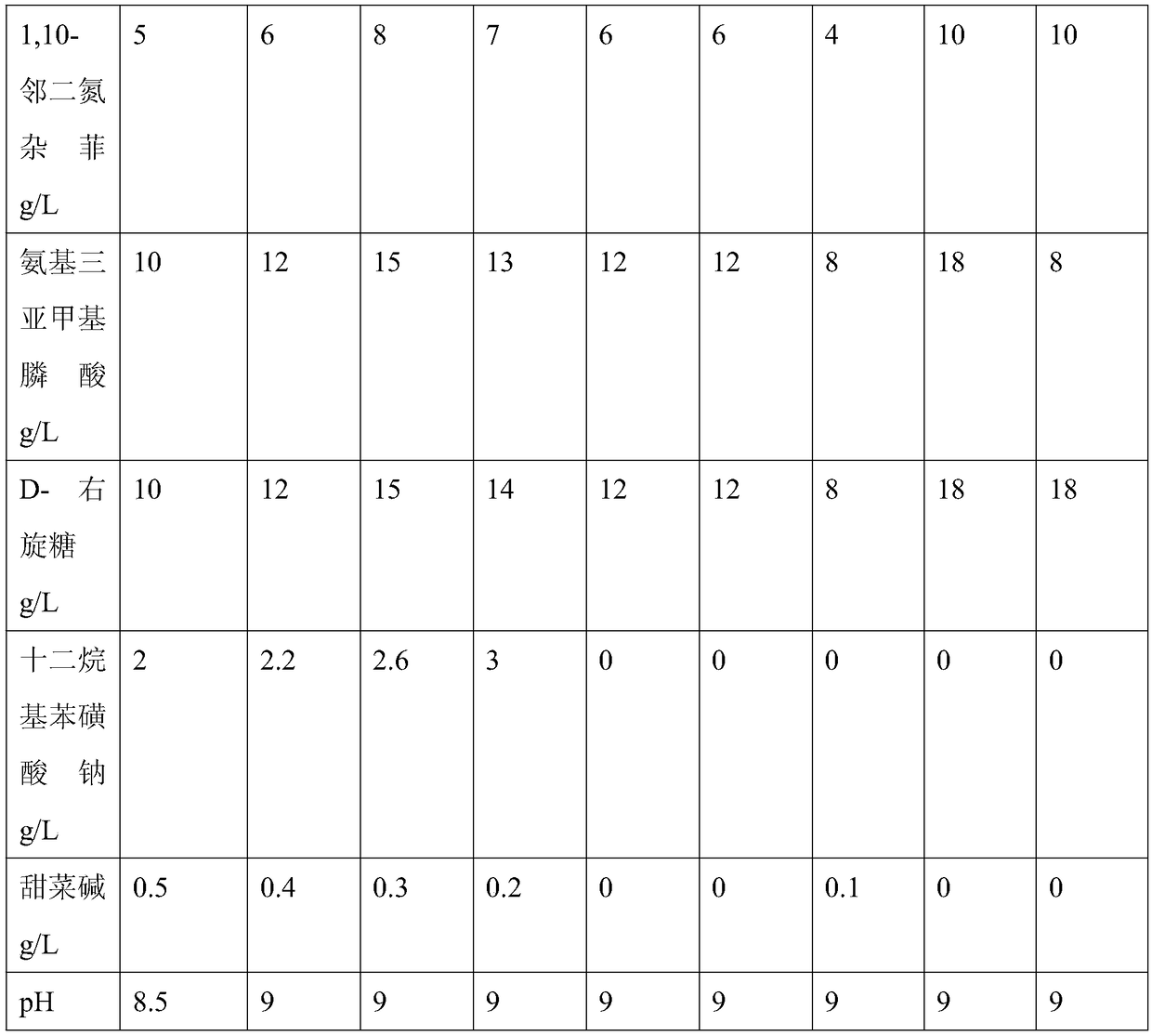

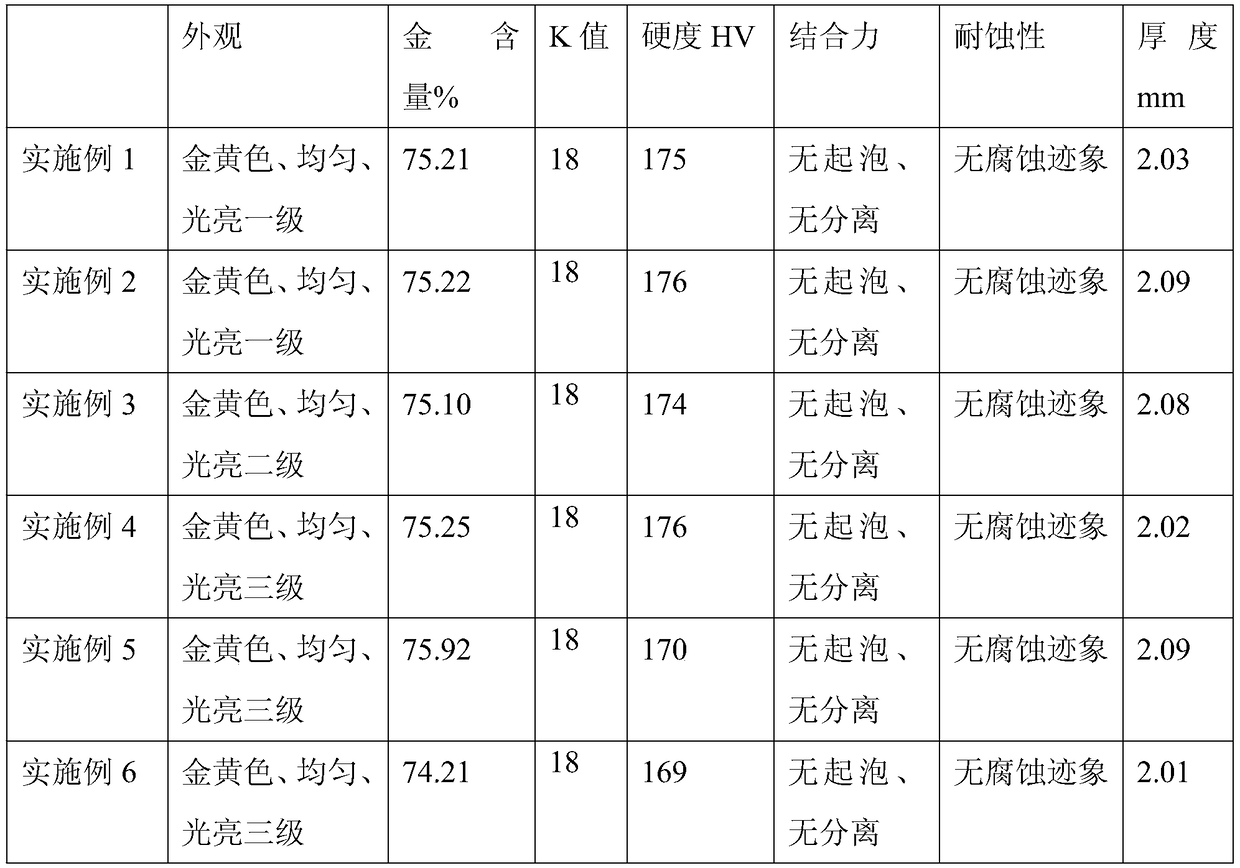

[0054] The performance table of each embodiment gained electroplating solution of table 2

[0055]

Stability / month

Dispersion ability / %

Deep Plating Ability

Example 1

>12

87

6.5

Example 2

>12

88

6.8

Example 3

>12

85

6.2

Example 4

>12

87.2

6.7

Example 5

5

80

5

Example 6

6

80

4.9

Example 7

5

79

4.8

Example 8

10

82

5.9

Example 9

10.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com