Multi-layer-color denture and base integrated carving block as well as manufacturing and use methods thereof

A denture base, denture technology, applied in the direction of dental prosthesis, medical science, dentistry, etc., can solve the problem that the status quo of the denture base cannot be completely changed, and achieve the reduction of the number of residual monomers, saving time and money, and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

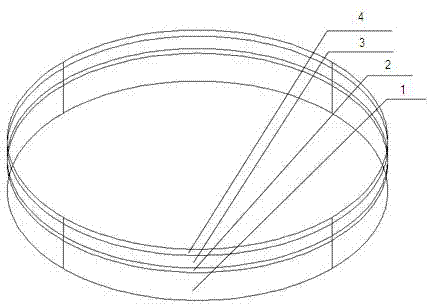

[0031] Embodiment 1: A general-purpose CAD / CAM three-layer denture and base integrally formed engraving block and its manufacturing method.

[0032] A general-purpose CAD / CAM three-layer denture and base integrally formed engraving block, such as figure 1 As shown, it consists of a four-layer resin block with a diameter of 100mm and a thickness of 33mm. methacrylate, 1.0wt% iron oxide red, 1.0wt% cobalt blue, 1.0wt% titanium yellow, 1.0wt% red nylon fiber, the thickness of the neck layer is 3mm, and it is composed of 98.0wt% polymethyl methacrylate- Composed of acrylic acid copolymer, 2.0wt% denture layer colorant, dentin layer thickness is 8mm Composed of 98.9wt% polymethyl methacrylate-acrylic acid copolymer, 1.1wt% denture layer colorant, enamel layer thickness is 4mm It is composed of 99.6wt% polymethyl methacrylate-acrylic acid copolymer and 0.4wt% denture layer coloring agent. The denture layer coloring agent is composed of 50.0wt% iron oxide red, 25.0wt% cobalt blue, ...

Embodiment 2

[0042] Embodiment 2, a universal CAD / CAM single-layer colored denture and base integrally formed engraving block and its manufacturing method.

[0043] A universal CAD / CAM single-layer color denture and base integrally formed engraving block, which is composed of a resin block with a diameter of 100 mm and a thickness of 33 mm, which is divided into two layers. Composition of methyl methacrylate-acrylic acid copolymer, 36.0wt% polymethyl methacrylate, 1.0wt% iron oxide red, 1.0wt% cobalt blue, 1.0wt% titanium yellow, 1.0wt% red nylon fiber, denture layer thickness 15mm is composed of 98.0wt% polymethyl methacrylate-acrylic acid copolymer, 2.0wt% denture layer coloring agent, wherein the denture layer coloring agent consists of 50.0wt% iron oxide red, 25.0wt% cobalt blue, 25.0wt% titanium yellow composition.

[0044] The preparation method step of above-mentioned product is.

[0045] (A) Coloring of the base layer: put polymethyl methacrylate-acrylic acid copolymer particles,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com