Metal anti-color changing method using self-assembling monomolecular film

A self-assembled single-molecule, anti-discoloration technology, which is applied in the coating process of metal materials, etc., can solve the problems of high toxicity, threats to the health of operators and the environment, improve anti-discoloration ability, and avoid the use of toxic chemicals , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Get copper sheet (10 * 10 * 1mm) copper-containing 99.9%, adopt following steps to process:

[0028] (1) Degreasing:

[0029] After degreasing with alkali (sodium hydroxide) solution, rinse with deionized water;

[0030] (2) Polishing:

[0031] Use sandpaper to polish the degreased and cleaned copper sheet to 2000#;

[0032] (3) Activation:

[0033] Nitric acid: 7mol / L,

[0034] Time: 30s,

[0035] Temperature: room temperature;

[0036] (4) Surface treatment:

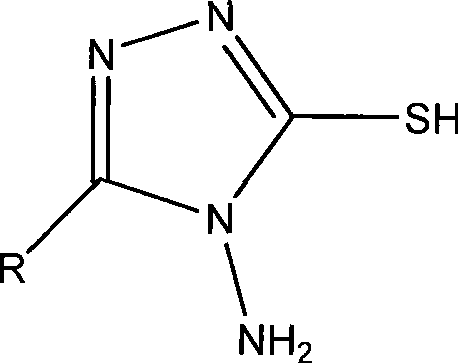

[0037] Active substance: 3-Undecyl-4-amino-5-mercapto-1,2,4-s-triazole,

[0039] Concentration: 10 -3 mol / L,

[0040] Time: 24h,

[0041] Temperature: room temperature;

[0042] (5) Cleaning:

[0043] After ultrasonically oscillating in ethanol for 10 min, rinse off residual ethanol with deionized water;

[0044] (6) Drying: For metals with residual solution on the surface, dry them with hot air after washing with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com