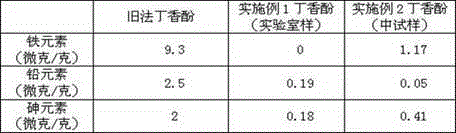

Production process of eugenol for flavoured product

A production process and eugenol technology, applied in the field of eugenol production technology, can solve problems such as poor anti-discoloration performance, and achieve the effects of improving anti-discoloration performance and being widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A. Get 50g clove leaf oil and place it in a vacuum distillation device for vacuum distillation, vacuum decolorization at -0.098MPa, collect the fraction at 120°C-160°C, and score 46.6g of white clove leaf oil;

[0020] B, get 40g of the clove leaf oil that A obtains, add 267g of 3%NaOH solution, stir reaction, leave standstill liquid separation, water layer extracts with 2g cyclohexane, liquid separation obtains water layer and is sodium eugenol aqueous solution;

[0021] C, the sodium eugenol aqueous solution that B obtains with 20% H 2 SO 4 The solution is neutralized until the pH of the water layer is 5-7, and the liquid is separated by standing to obtain the lower layer, which is the crude eugenol a;

[0022] D, add 0.1% EDTA-2Na solution equal to the volume of eugenol crude product a to the eugenol crude product a obtained in C, stir for 15 minutes, leave to stand for liquid separation, and wash to obtain the separation of lower layer eugenol crude product b;

[...

Embodiment 2

[0025] A, 1000g clove leaf oil is added to the distillation pot, vacuum decolorization is carried out under vacuum 760mmHg, the fraction under 120 ℃-160 ℃ is collected, and white clove leaf oil is scored 965g;

[0026] B, get 960g of the clove oil that A obtains, add 10%NaOH solution of 1920g, stir reaction, leave standstill liquid separation, water layer extracts with 48g cyclohexane, liquid separation obtains water layer and is sodium eugenol aqueous solution;

[0027] C, the sodium eugenol aqueous solution that B obtains with 50% H 2 SO 4 The solution is neutralized until the pH of the water layer is 5-7, and the liquid is separated by standing to obtain the lower layer, which is the crude eugenol a;

[0028] D, add 0.5% EDTA-2Na solution equal to the volume of eugenol crude product a to the eugenol crude product a obtained in C, stir for 15 minutes, leave to stand for liquid separation, wash with water to separate the lower layer of eugenol crude product b;

[0029] E. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com