Gold-bearing imitation-gold copper alloy and preparation method thereof

A technology of copper alloy and imitation gold, which is applied in the field of gold-containing gold-imitation copper alloy and its preparation, and imitation gold-copper alloy. Not easy to cut and other problems, to improve the use value, easy to process, and conducive to processing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

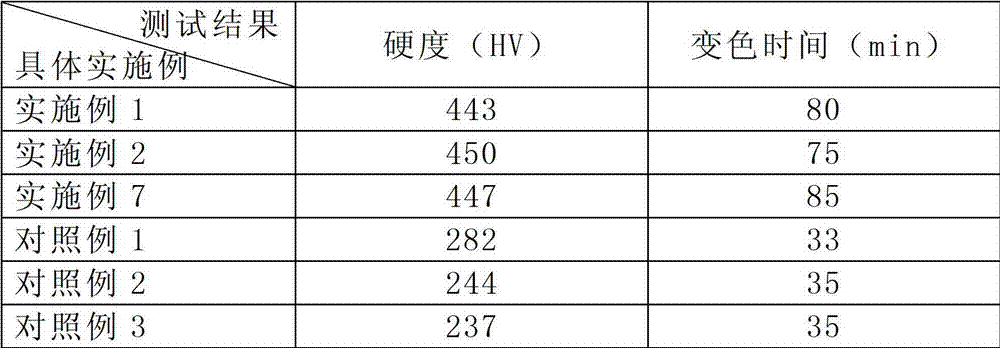

Examples

Embodiment 1

[0032] A gold-containing imitation gold-copper alloy, the alloy is mainly composed of the following raw materials in weight percentage:

[0033] Au: 0.5%; Zn: 25%; Al: 2.0%; Si: 0.05; the balance is Cu, and the sum of weight percentages of all elements is 100%.

[0034] The described gold-containing imitation gold-copper alloy is prepared according to the following method:

[0035] A. Smelting: Weigh each raw material according to the above weight percentage, clean the above raw materials with acid, which can effectively remove the oxide layer on the metal surface, dry it after cleaning with acid, and then load it in batches In the crucible of the vacuum medium-frequency induction melting furnace, the temperature is controlled at 1225°C to melt to clear liquid, then melted and stirred for 30 minutes, and then poured into a Ф60 water-cooled red copper crystallizer to obtain gold-containing imitation gold alloy ingots;

[0036] B, annealing treatment: under the condition that t...

Embodiment 2

[0039] A gold-containing imitation gold-copper alloy, the alloy is mainly composed of the following raw materials in weight percentage:

[0040] Au: 0.5%; Zn: 25%; Al: 5%; In: 0.4%; Ni: 1%; the balance is Cu, and the sum of the weight percentages of all elements is 100%.

[0041] The described gold-containing imitation gold-copper alloy is prepared according to the following method:

[0042] A. Smelting: Weigh each raw material according to the above weight percentage, clean the above raw materials with acid, which can effectively remove the oxide layer on the metal surface, dry it after cleaning with acid, and then load it in batches In the crucible of the vacuum intermediate frequency induction melting furnace, the temperature is controlled at 1200 ° C to melt to clear liquid, then melt and stir for 60 minutes, and then pour it into a Ф70 water-cooled red copper crystallizer to obtain gold-containing imitation gold alloy ingots;

[0043] B, annealing treatment: under the co...

Embodiment 3

[0046] A gold-containing imitation gold-copper alloy, the alloy is mainly composed of the following raw materials in weight percentage:

[0047] Au: 10%; Zn: 0.4%; toner: 1%, the toner is selected from one of aluminum, indium, nickel, tin; RE: 1%; Si: 1%; the balance is Cu, the sum of weight percentages of all elements is 100%.

[0048] The described gold-containing imitation gold-copper alloy is prepared according to the following method:

[0049] A. Smelting: Weigh each raw material according to the above weight percentage, clean the above raw materials with acid, which can effectively remove the oxide layer on the metal surface, dry it after cleaning with acid, and then load it in batches In the crucible of the vacuum intermediate frequency induction melting furnace, the temperature is controlled at 1300 ° C to melt to clear liquid, then melt and stir for 10 minutes, and then pour it into a Ф70 water-cooled red copper crystallizer to obtain gold-containing imitation gold a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com