Ammonia distillation reboiler for supercritical water oxidation system and its processing method and use method

An oxidation system and supercritical water technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as high-temperature and high-pressure fluid leakage, component damage, etc., to increase the working space and improve Effect of service life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in further detail below in conjunction with accompanying drawing:

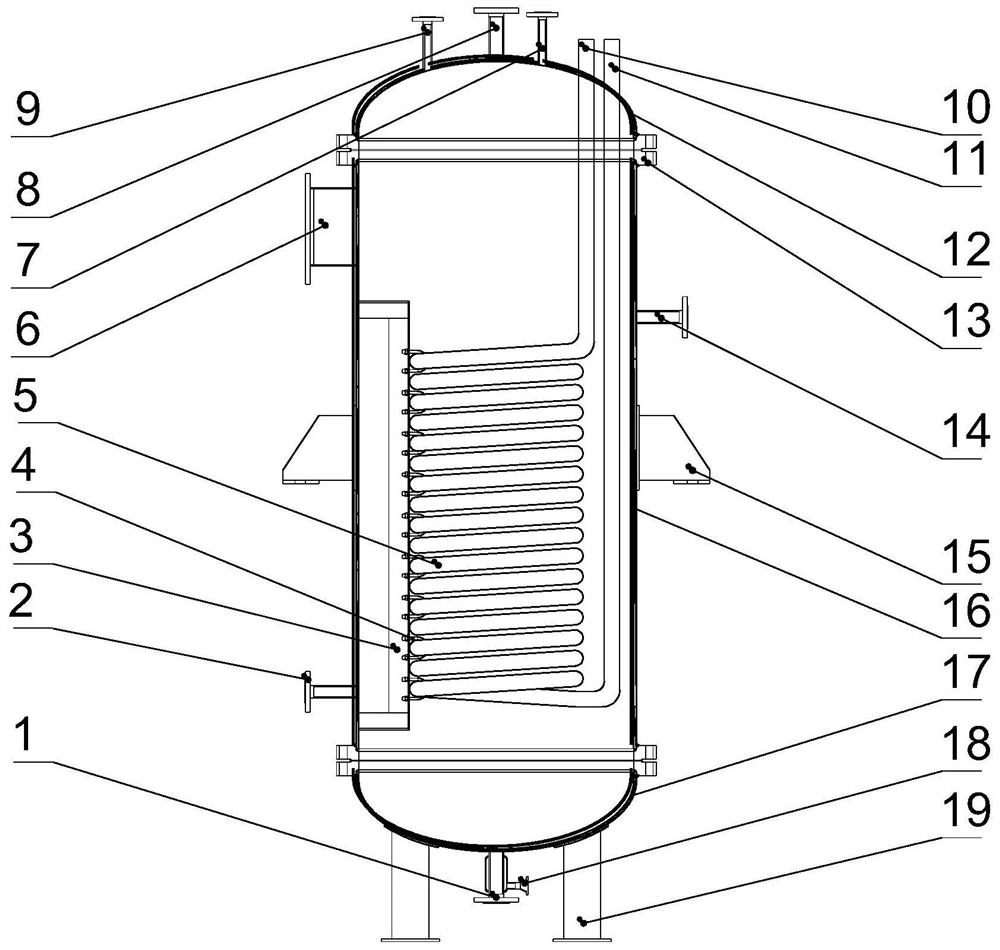

[0042] see figure 2 , a kind of ammonia distiller reboiler for supercritical water oxidation system of the present invention comprises cylinder body 16, upper seal head 12 and lower seal head 17, and cylinder body 16 is fixed with upper seal head 12, lower seal head 17 respectively connected to form an ammonia distillation reboiler cavity, a heating coil 5 is fixed inside the cylinder 16, and an opening for heating the heating coil inlet 11 and the heating coil outlet 10 is provided on the top wall of the upper head 12 Holes; a steam outlet 8 is provided on the top of the upper head 12, a sewage inlet 1 and a bottom sewage outlet 18 are provided at the bottom of the lower head 17, and a sampling port 2 and a side sewage outlet 14 are provided on the side wall of the cylinder 16.

[0043] Preferably, a coil support frame 3 is welded on one inner wall of the cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com