Decarburization and recarburization determination method for bolt under quenched state

A measurement method and technology of bolts, which are applied in the field of carburization measurement and debonding of bolts in the quenched state, can solve the problems of long time consumption and economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

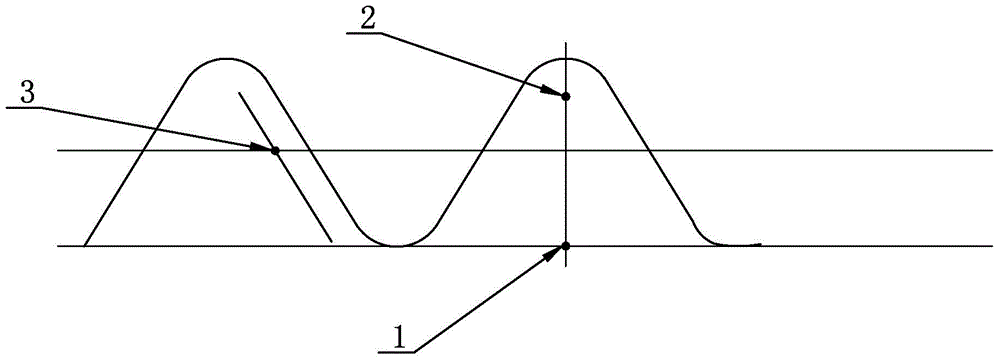

[0015] Such as figure 1 Shown, a kind of decarburization measuring method under the quenched state of bolt is characterized in that, comprises the following steps:

[0016] (1) At the corresponding threaded part of the bolt in the quenched state, cut a cross-sectional sample along the axial direction perpendicular to the bolt and a nominal diameter away from the end of the bolt;

[0017] (2) Grinding and polishing the intercepted sample until the surface roughness of the sample is 0.6-1.0um;

[0018] (3) Take three points on the sample for hardness testing, among which, the first point 1 is the bottom of the thread, the second point 2 is the movement of the crest of the thread to the bottom of the thread by 0.20mm perpendicular to the axial direction of the bolt, and the second point Three points 3 are the points where the thread flanks are translated 0.12mm inwardly and intersect with the pitch line of the thread. When the hardness value of the first point 1 minus the hardne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com