Continuous punching die for automobile supporting frame

A car bracket and punching technology, which is applied in the direction of piercing tools, manufacturing tools, metal processing equipment, etc., can solve the problems of cumbersome operation, high product failure rate, and cost increase, so as to reduce the failure rate, improve product quality, The effect of guaranteeing identity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

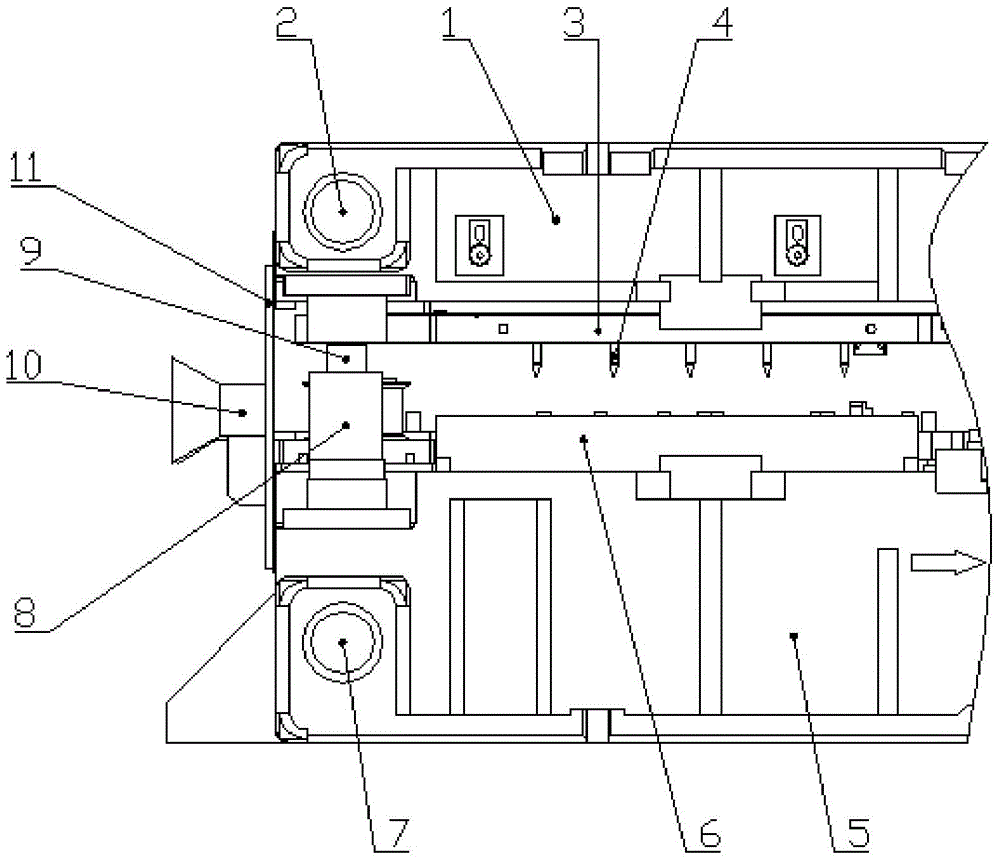

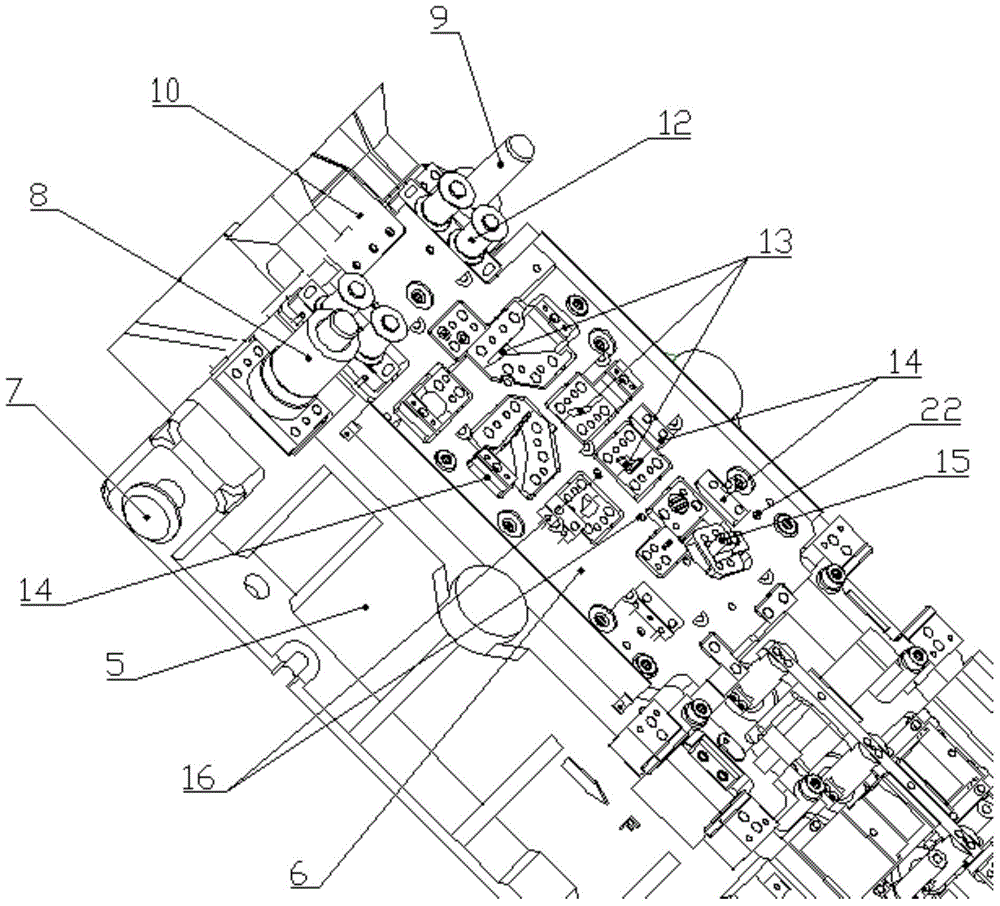

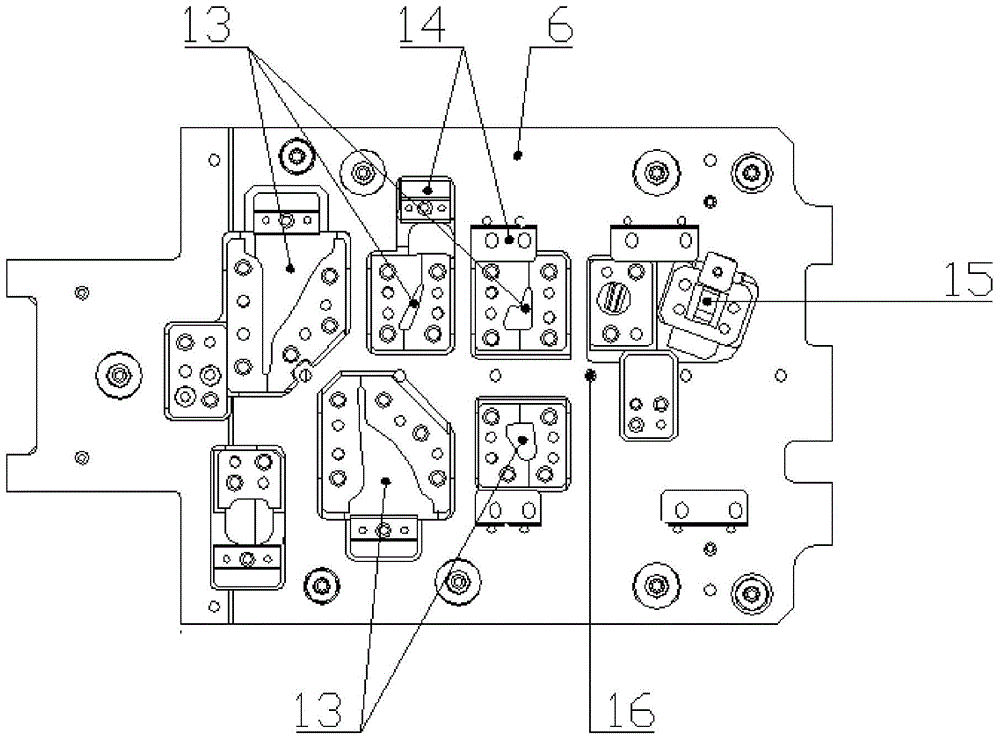

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a mold for continuous punching of automobile brackets, including an upper mold and a lower mold.

[0028] The lower mold includes a lower mold base 5 and a lower pressing plate 6 arranged in the lower mold base 5, and a spring guide column (not shown in the figure) is arranged between the lower pressing plate 6 and the lower mold base 5 to buffer the upper mold against the lower Die impact. One end of lower mold base 5 is provided with transmission mechanism, and this transmission mechanism comprises feeding plate 10 and the feeding roller 12 that is positioned at the both sides of feeding plate 10, carries out feeding by feeding plate 10 and feeding roller 12, upper The material transfer roller 12 is driven by a stepper motor. The lower pressing plate 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com