Automatic oil coating machine

An automatic coating and grease technology, applied in the direction of coating, liquid coating device on the surface, etc., to achieve the effect of ensuring accuracy, reducing fixture cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

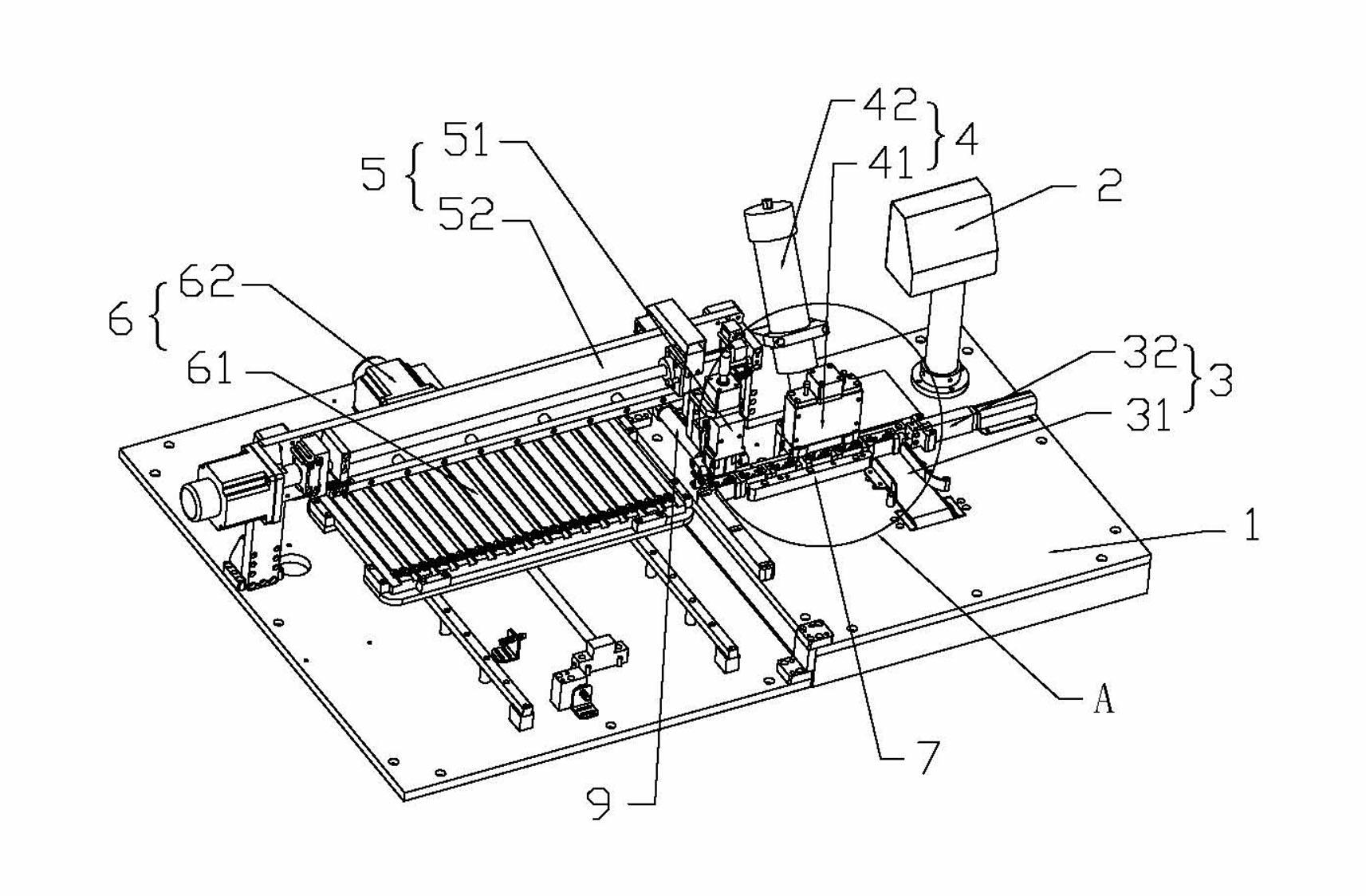

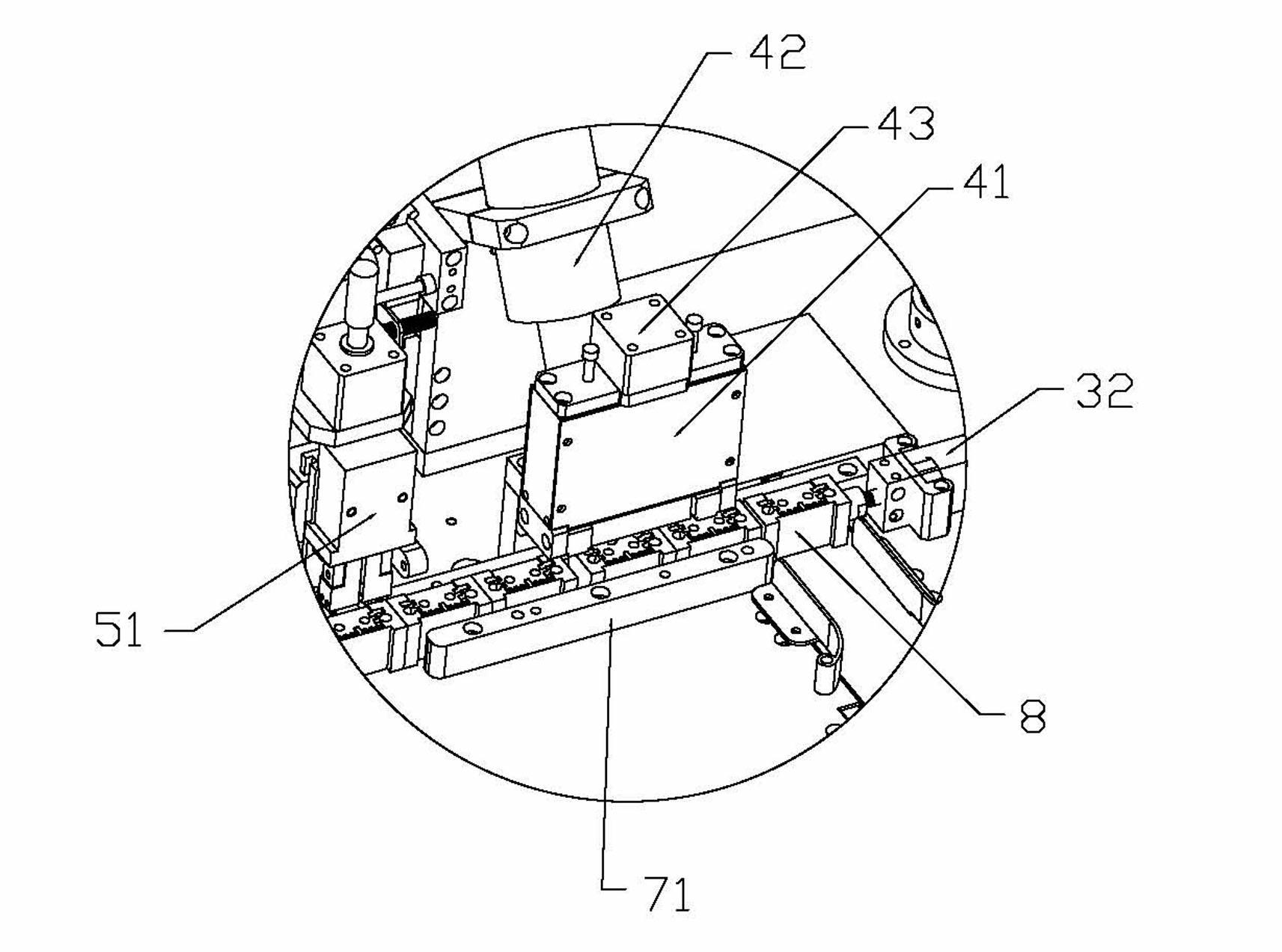

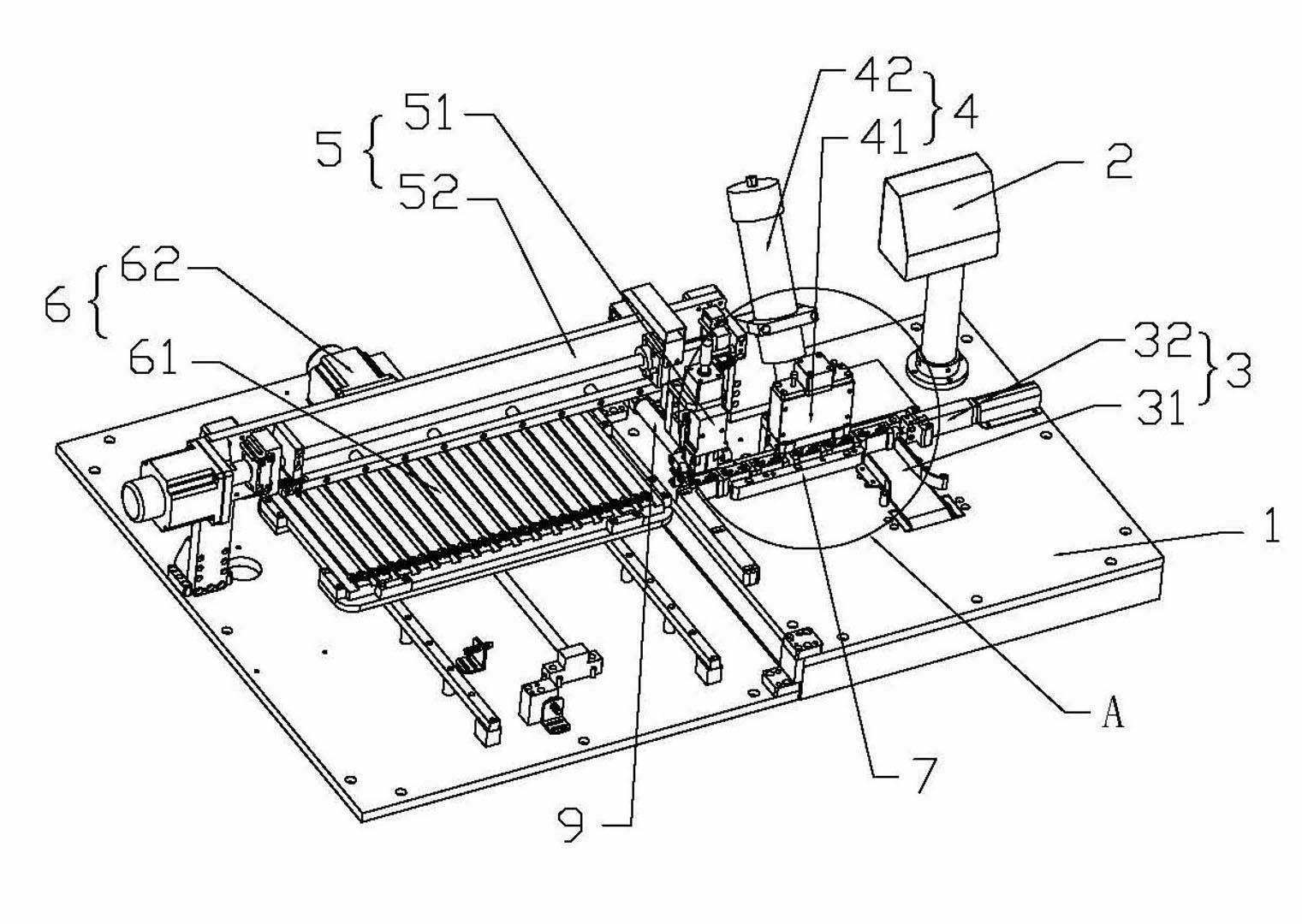

[0021] refer to figure 1 and figure 2 , an automatic grease coating machine, comprising a frame 1, a PLC controller and a touch screen 2, a feeding mechanism 3, a coating mechanism 4, a swing mechanism 5 and a tray mechanism 6 are sequentially arranged on the table of the frame 1 , a material guide belt 7 is provided between the feeding mechanism 3 and the tray mechanism 6, and an auxiliary feeding clamp 8 and a pushing clamp device 9 are also provided on the frame 1; the PLC controller controls the action of each electrical device of the coating machine , and the touch screen 2 is connected to the PLC controller for signal input and display.

[0022] The fixture 8 is a plurality of independent standard squares with clamping holes for carrying workpieces.

[0023] The feeding mechanism 3 includes a vertical conveyor belt 31 and a cylinder pushing device 32 , the cylinder pushing device 32 is used to push the clamp 8 on the conveyor belt 31 to the material guide belt 7 step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com