Permeameter for realizing multi-field coupling and in-situ dry-wet cycle

A dry-wet cycle and permeameter technology, applied in the direction of permeability/surface area analysis, instruments, scientific instruments, etc., can solve the problems of inability to achieve multi-field coupling, affect the accuracy of sample penetration, and cannot effectively reflect the actual situation. To achieve the effect of ensuring identity, improving operation convenience and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

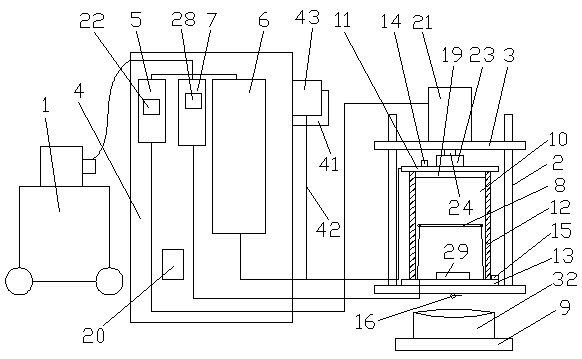

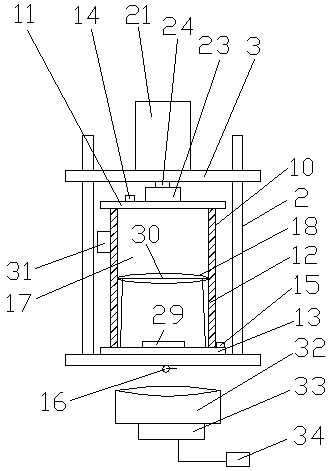

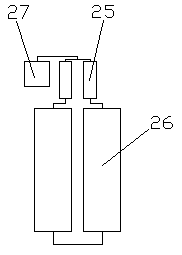

[0036] A permeameter for realizing multi-field coupling and in-situ dry-wet cycle, including an air compressor 1 and a frame 2, the frame 2 is provided with a moving beam 3, and also includes an air control cabinet 4, an axial pressure loading device 5, and a hole Pressure loading device 6, confining pressure loading device 7, in-situ drying device 8, metering device 9 and a pressure chamber 10 for placing samples, the pressure chamber 10 includes a top cover 11, a plexiglass pressure-bearing cylinder 12 and a base 13. The top cover 11 is detachably connected to the upper end of the plexiglass pressure-bearing cylinder 12, the base 13 is detachably connected to the lower end of the plexiglass pressure-bearing cylinder 12, and the top cover 11 is connected with a first exhaust valve 14, A seepage outlet is opened on the base 13, a second exhaust valve 15 is connected to the base 13, a water outlet valve 16 is connected to the seepage outlet, and the space between the inner wall ...

Embodiment 2

[0039]A permeameter for realizing multi-field coupling and in-situ dry-wet cycle, including an air compressor 1 and a frame 2, the frame 2 is provided with a moving beam 3, and also includes an air control cabinet 4, an axial pressure loading device 5, and a hole Pressure loading device 6, confining pressure loading device 7, in-situ drying device 8, metering device 9 and a pressure chamber 10 for placing samples, the pressure chamber 10 includes a top cover 11, a plexiglass pressure-bearing cylinder 12 and a base 13. The top cover 11 is detachably connected to the upper end of the plexiglass pressure-bearing cylinder 12, the base 13 is detachably connected to the lower end of the plexiglass pressure-bearing cylinder 12, and the top cover 11 is connected with a first exhaust valve 14, A seepage outlet is opened on the base 13, a second exhaust valve 15 is connected to the base 13, a water outlet valve 16 is connected to the seepage outlet, and the space between the inner wall o...

Embodiment 3

[0045] A permeameter for realizing multi-field coupling and in-situ dry-wet cycle, including an air compressor 1 and a frame 2, the frame 2 is provided with a moving beam 3, and also includes an air control cabinet 4, an axial pressure loading device 5, and a hole Pressure loading device 6, confining pressure loading device 7, in-situ drying device 8, metering device 9 and a pressure chamber 10 for placing samples, the pressure chamber 10 includes a top cover 11, a plexiglass pressure-bearing cylinder 12 and a base 13. The top cover 11 is detachably connected to the upper end of the plexiglass pressure-bearing cylinder 12, the base 13 is detachably connected to the lower end of the plexiglass pressure-bearing cylinder 12, and the top cover 11 is connected with a first exhaust valve 14, A seepage outlet is opened on the base 13, a second exhaust valve 15 is connected to the base 13, a water outlet valve 16 is connected to the seepage outlet, and the space between the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com