Drying and disinfecting device for production of cosmetic bottles

A disinfection device and cosmetic bottle technology, which is applied in the field of cosmetic bottles, can solve the problems of uneven heating of cosmetic bottles, poor air flow, deformation of cosmetic bottles, etc., and achieve the effects of avoiding uneven heating, rapid drying and disinfection, and uniform drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

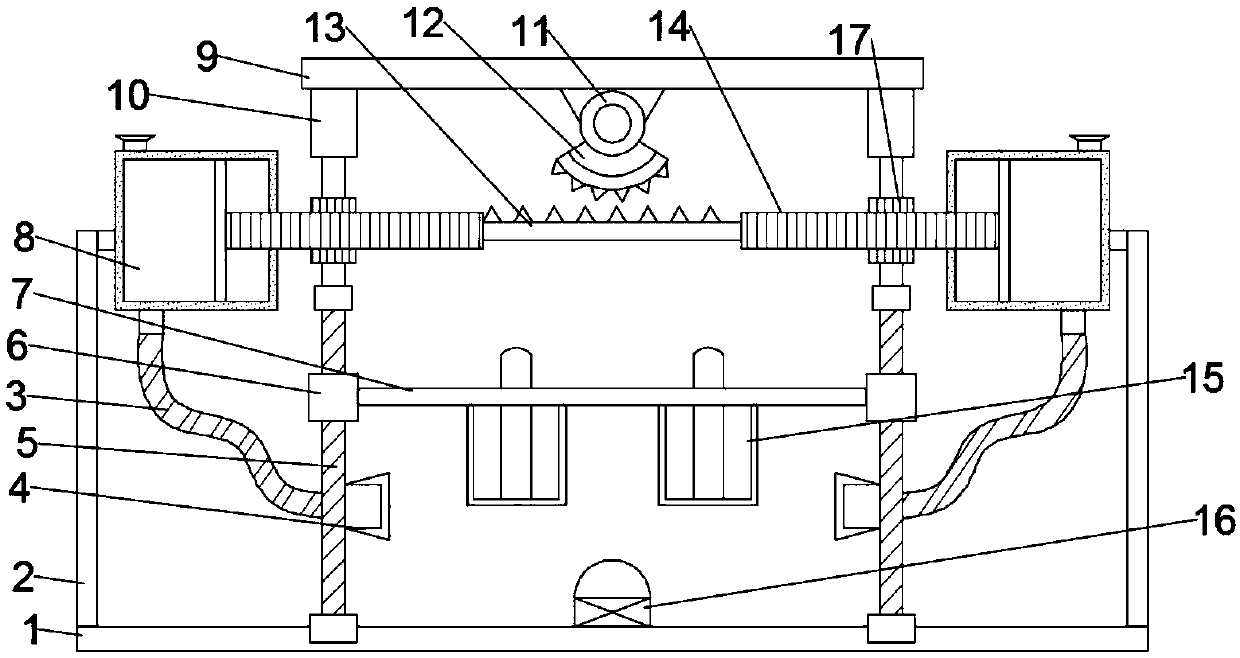

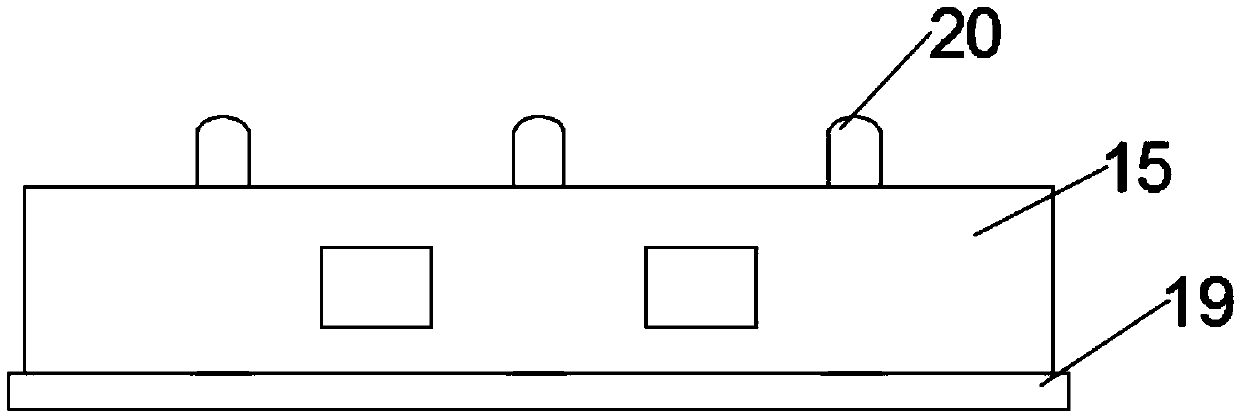

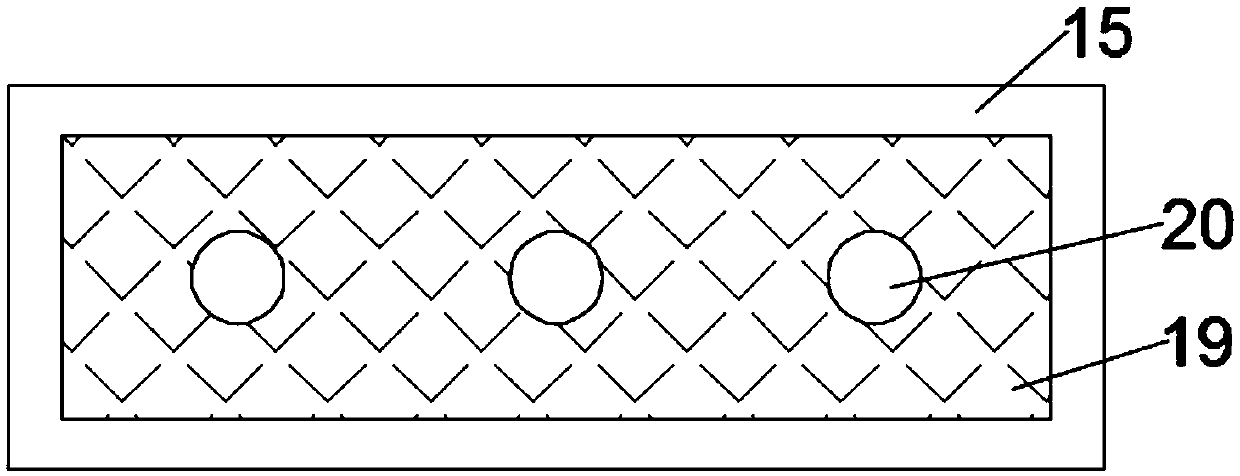

[0020] see Figure 1~4 , in the embodiment of the present invention, a drying and disinfection device for the production of cosmetic bottles, including a base 1, a vertical plate 2, a screw rod 5 and a placement frame 15, the upper surface of the base 1 is symmetrically welded with two vertical plates 2, the vertical plate The upper end of the plate 2 is fixed with a welding steam release chamber 8, two screw rods 5 are arranged symmetrically on one side of the vertical plate 2, and the lower end of the screw rod 5 is connected to the upper surface of the base 1 by rotation, and the upper end of the screw rod 5 is rotated Connect the bearing seat 10, the bearing seat 10 is fixedly installed on the support horizontal plate 9 by bolts, the support horizontal plate 9 is arranged in parallel above the base 1, and the screw rod 5 is threaded with a threaded block 6, The threaded blocks 6 are connected by connecting rods 7, and the lower part of the connecting rods 7 is fixedly conn...

Embodiment 2

[0028] A cosmetic bottle processing device, comprising the cosmetic bottle production drying and disinfection device as described in embodiment 1.

[0029] The working principle of the present invention is: install the cosmetic bottle that needs to be dried and sterilized on the limit post 20, and then start the drive motor 11, and the drive motor 11 starts to drive the incomplete gear 12 to rotate, and the incomplete gear 12 rotates. The complete gear 12 drives the first rack 13 and the second rack 14 to slide left and right, so that the second rack 14 drives the complete gear 17 and the screw mandrel 5 to rotate, realizing the synchronous driving of the screw mandrel 5 The threaded block 6, the connecting rod 7 and the placement frame 15 move up and down, realizing the cutting of the steam flow, increasing the flow of the steam, and ensuring the uniform drying of the cosmetic bottle; the second rack 14 slides left and right to push The piston plate 18 slides left and right, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com