Optical frame PU foaming mould

A technology for foaming molds and mirror frames, which can be applied to frames, household appliances, and other household appliances, etc. It can solve the problems of not being able to fit tightly, mold gaps, inconvenience, etc., and achieve the effect of ensuring no abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

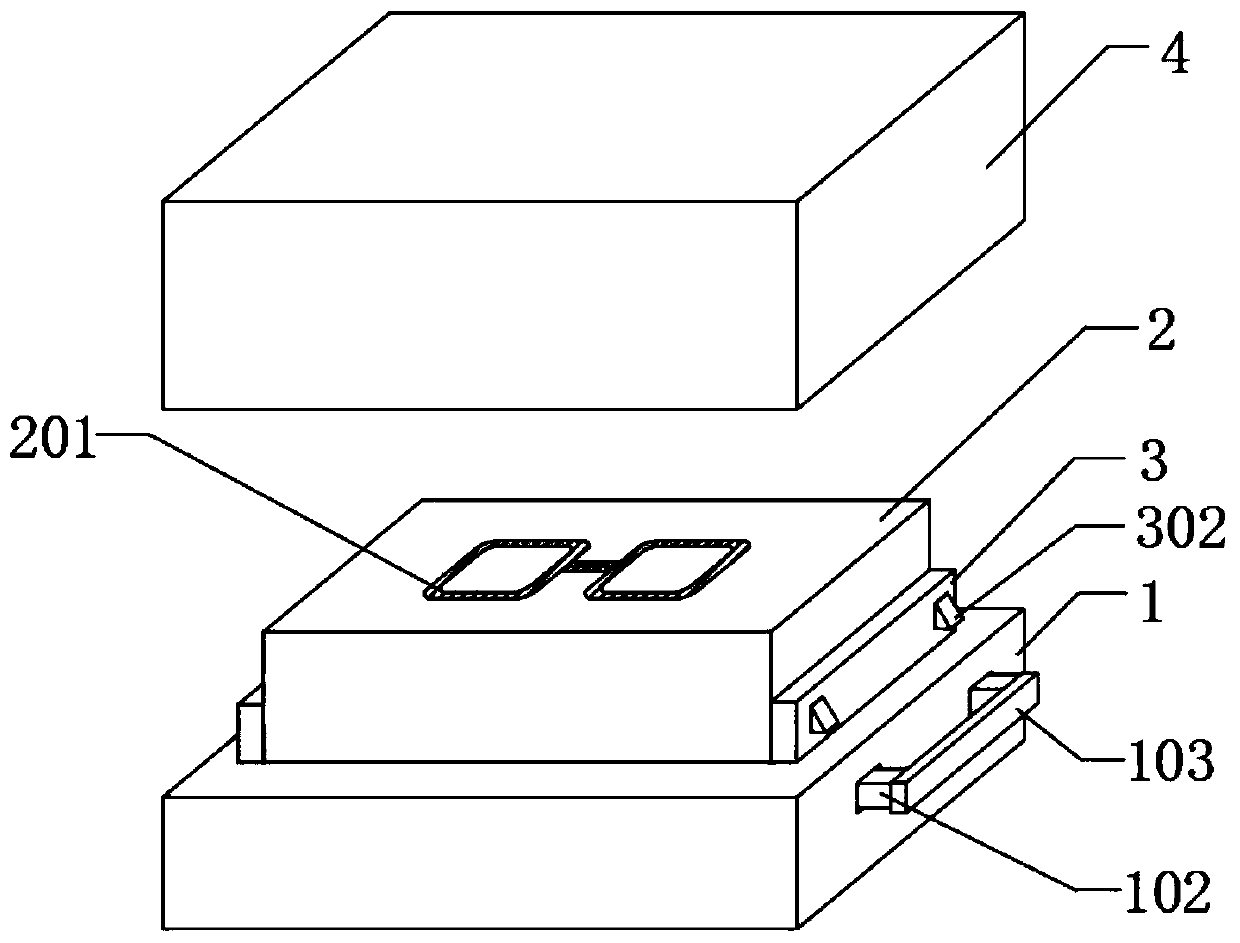

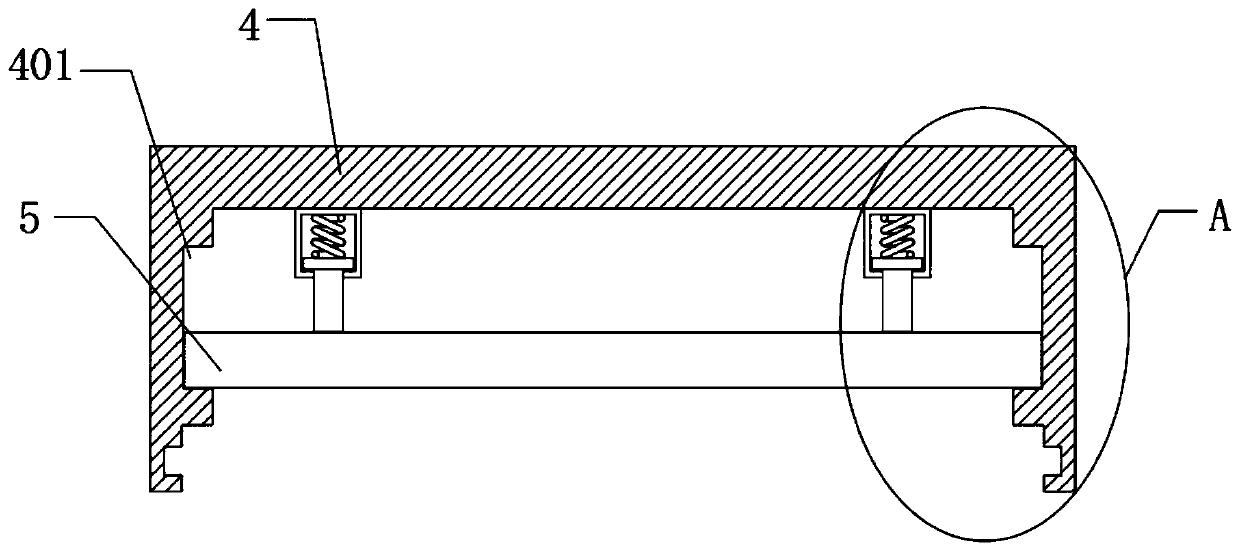

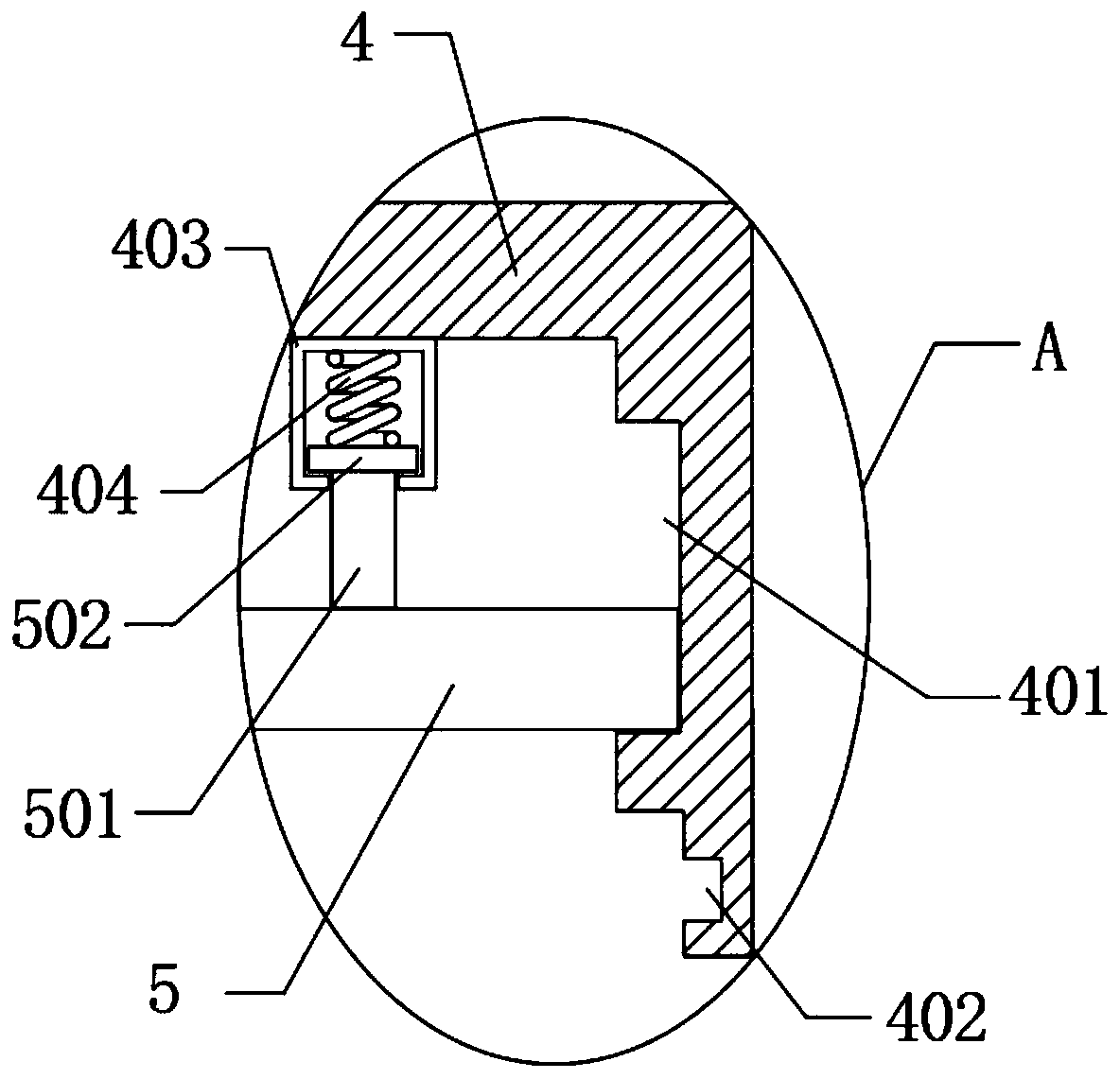

[0025] Embodiments of the present invention provide a PU foam mold for mirror frames, such as Figure 1-5 As shown, it includes a base 1, a mold table 2 and an upper cover shell 4, the mold table 2 is fixedly connected to the top of the base 1, the upper cover shell 4 is clamped on the top of the base 1, and the top of the base 1 is fixedly connected with a fixed block 3. The fixed block 3 is also fixed on the side wall of the mold table 2. The upper surface of the mold table 2 is provided with a frame groove 201, and the upper cover shell 4 is provided with a pressure plate 5. The top of the pressure plate 5 is provided with a pressing device. The upper cover The inner wall of the housing 4 is provided with a card slot 402, the side wall of the base 1 is provided with a first chute 101, the side wall of the fixed block 3 is provided with a second chute 301, the first chute 101 and the second chute 301 A snap-in component matching the slot 402 is provided.

[0026] This devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com