Quartz glass rod flame polishing and annealing device and method thereof

A quartz glass rod, flame polishing technology, applied in glass production and other directions, can solve the problems of excessive bending, low production efficiency, increase heating time of quartz glass rod, etc., and achieve the effect of stable clamping method and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

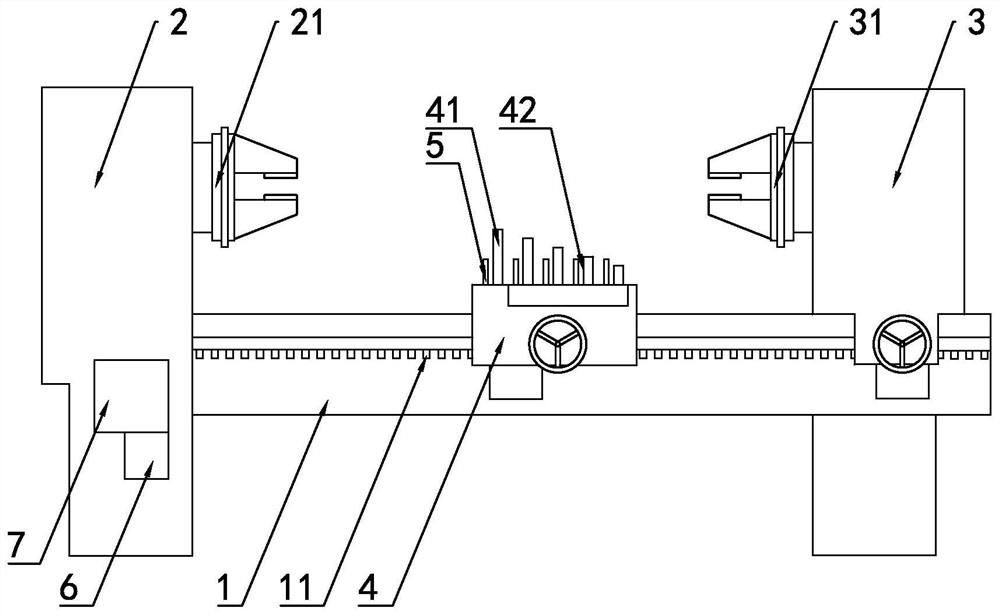

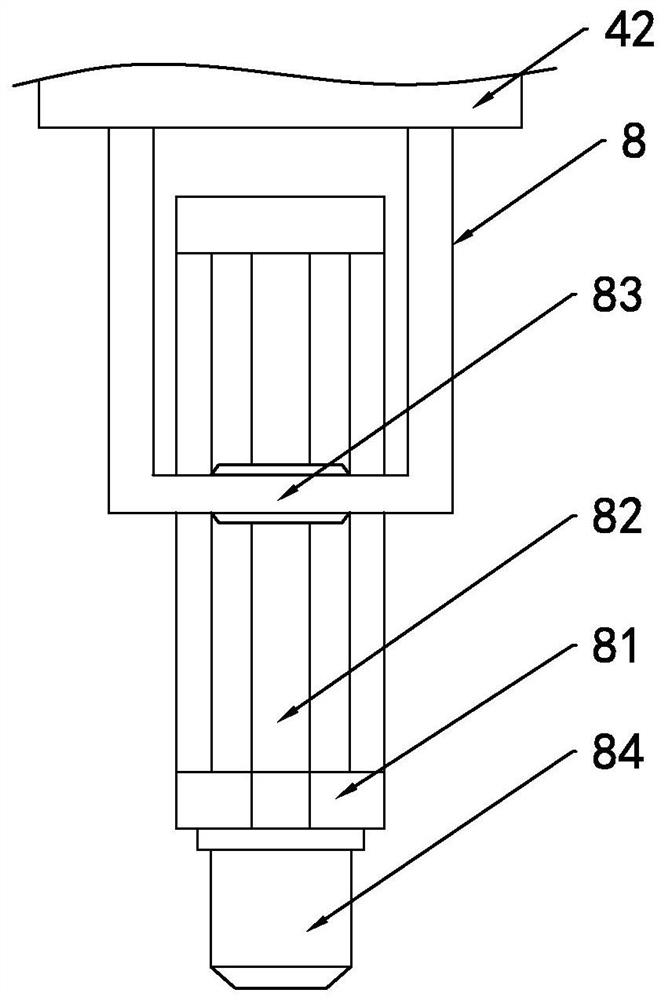

[0033] Such as Figure 1-2 As shown, the present invention discloses a device for flame polishing and annealing of quartz glass rods, which includes a bed 1 with a rack slide 11, a fixed bed head 2 arranged at one end of the bed 1, and a bed transverse to the rack slide 11. Slidingly connected mobile bedside 3; the bed 1 between the fixed bedside 2 and the mobile bedside 3 is provided with a flame operating table 4 slidingly provided with the rack slideway 11, and the fixed bedside 2 and the mobile bedside The head of the bed 3 is respectively provided with a left part chuck 21 and a right part chuck 31 which are all facing the flame operation platform 4. In a specific embodiment of the present invention, a main burner 41 and several The auxiliary burners 42 arranged at equal intervals, the main burner 41 and the auxiliary burner 42 are located on the same horizontal line, and the combustion temperature is uniformly reduced from the main burner 41 to the auxiliary burner 42 si...

Embodiment 2

[0045] In addition, the present invention also discloses a flame polishing and annealing method for a quartz glass rod, which is characterized in that it includes the following steps:

[0046] S1 loading at the mobile end: first clamp the quartz glass rod on the right chuck at the head of the mobile bed; start the driver to drive the right chuck to rotate at a constant speed;

[0047] S2 Preheating: Turn on the main burner and control the supply flow, direction and angle of the external hydrogen and oxygen supply devices, turn on the servo motor, adjust the displacement speed controller, control the horizontal reciprocating operation of the flame operating table, and preheat the quartz glass rod ;

[0048] S3 polishing and annealing: move the flame to near the middle of the quartz glass rod, adjust the height and angle of the auxiliary flame nozzle and the supply of hydrogen and oxygen in the auxiliary heating area in advance, and turn on each auxiliary flame nozzle. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com