Water heater with interlinked air intake regulator and its operation process

A technology for air intake adjustment and water heater, which is applied in the direction of adjusting fuel supply, combustion method, water heater, etc., which can solve the problems of incomplete combustion of gas and air mixture, difficult transportation and installation, and large volume, so as to avoid combustion problems. Complete, reduce overall volume, avoid bulky effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

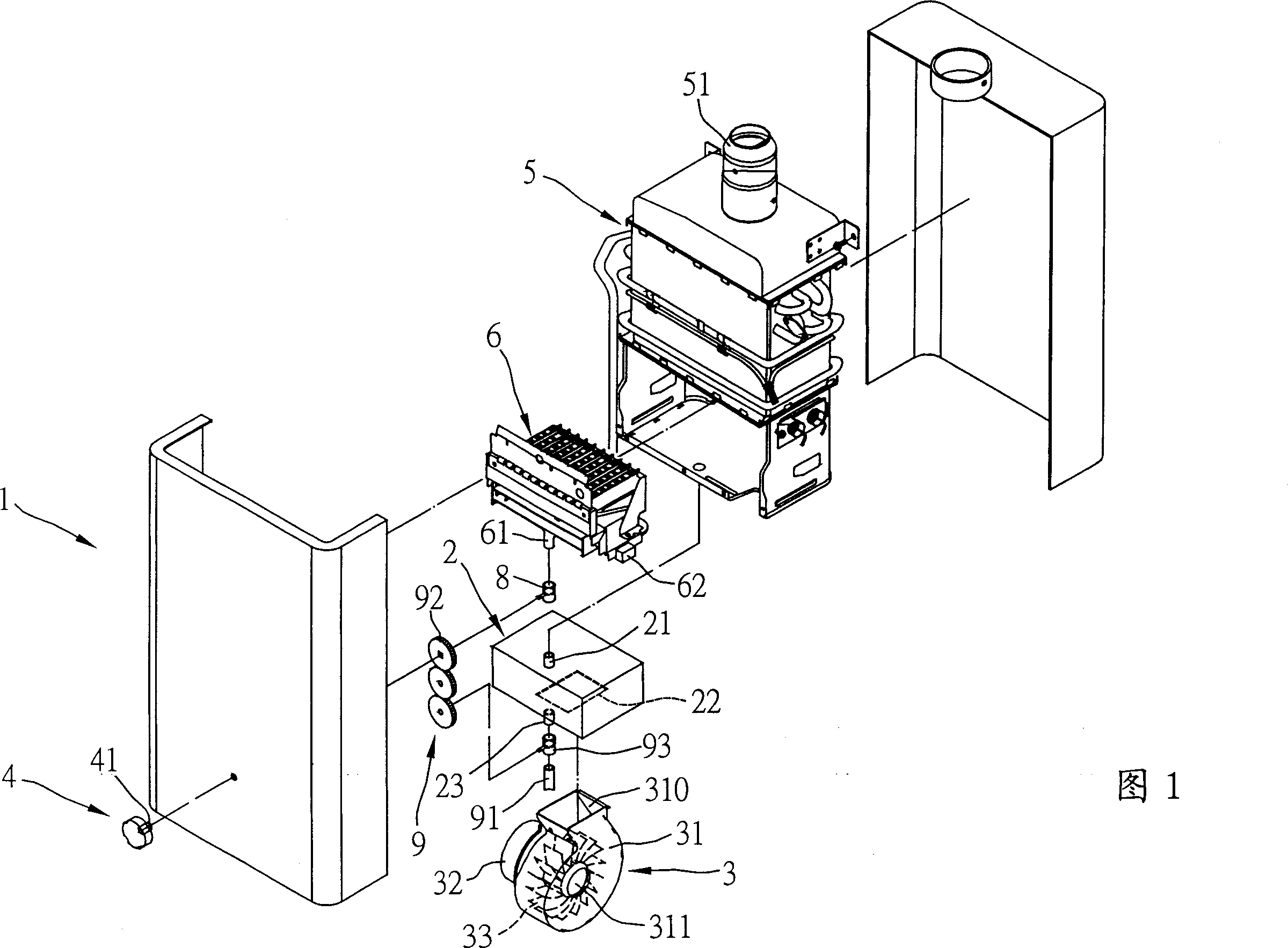

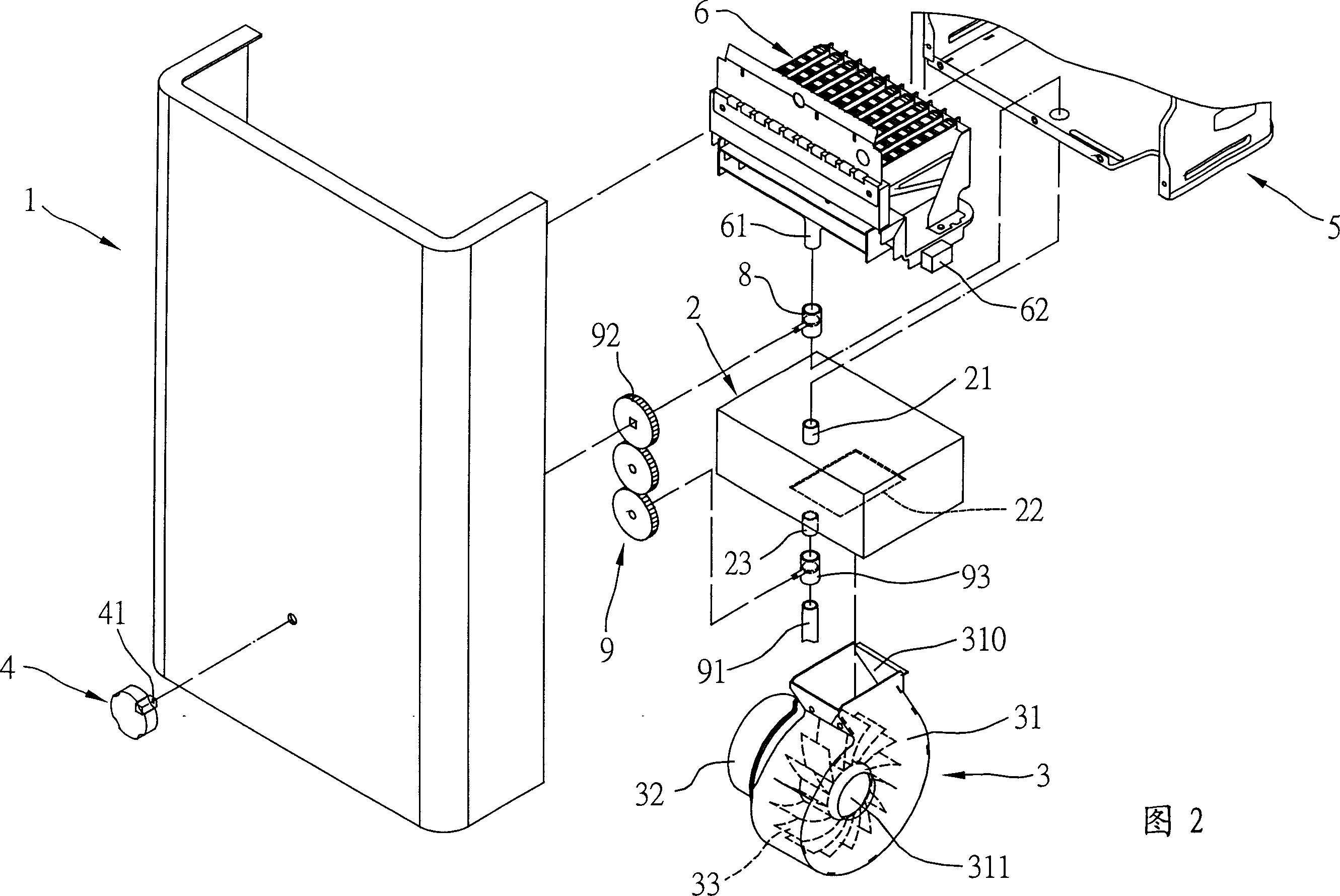

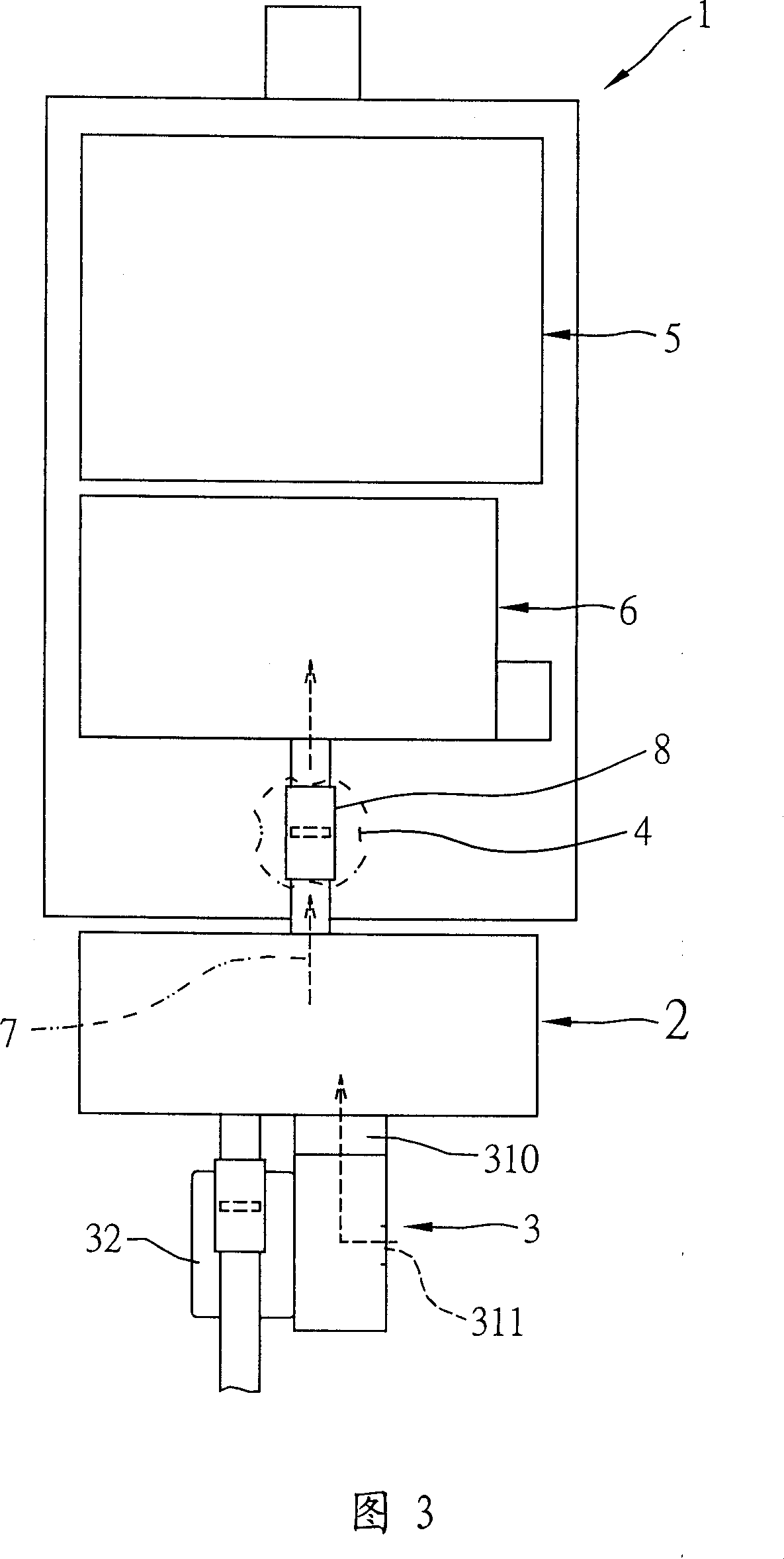

[0048] Please refer to Figure 1 and Figure 4, the present invention provides a water heater with interlocking air intake adjustment device, including a body 1, a pre-mixing tank 2, an intake air supply mechanism 3 and a fuel regulator 4.

[0049] The main body 1 is roughly a rectangular shell, inside which is provided with a heat exchanger 5 and a fire row burner 6, the fire row burner 6 is located below the heat exchanger 5, and an exhaust pipe 51 is installed above the heat exchanger 5 , to provide exhaust gas discharge, a gas pipe 61 is provided under the fire row burner 6, and the fire row burner 6 can be further connected to an electronic controller 62, which is located in the body 1 and can be used to sense And control the size of this fire row burner 6 fire quantities.

[0050] The pre-mixing tank 2 is roughly in the shape of a hollow box and is arranged in the body 1. The pre-mixing tank 2 has an air supply pipe 21, an air inlet 22 and a fuel intake pipe 23, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com