Patents

Literature

179results about "Burner manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

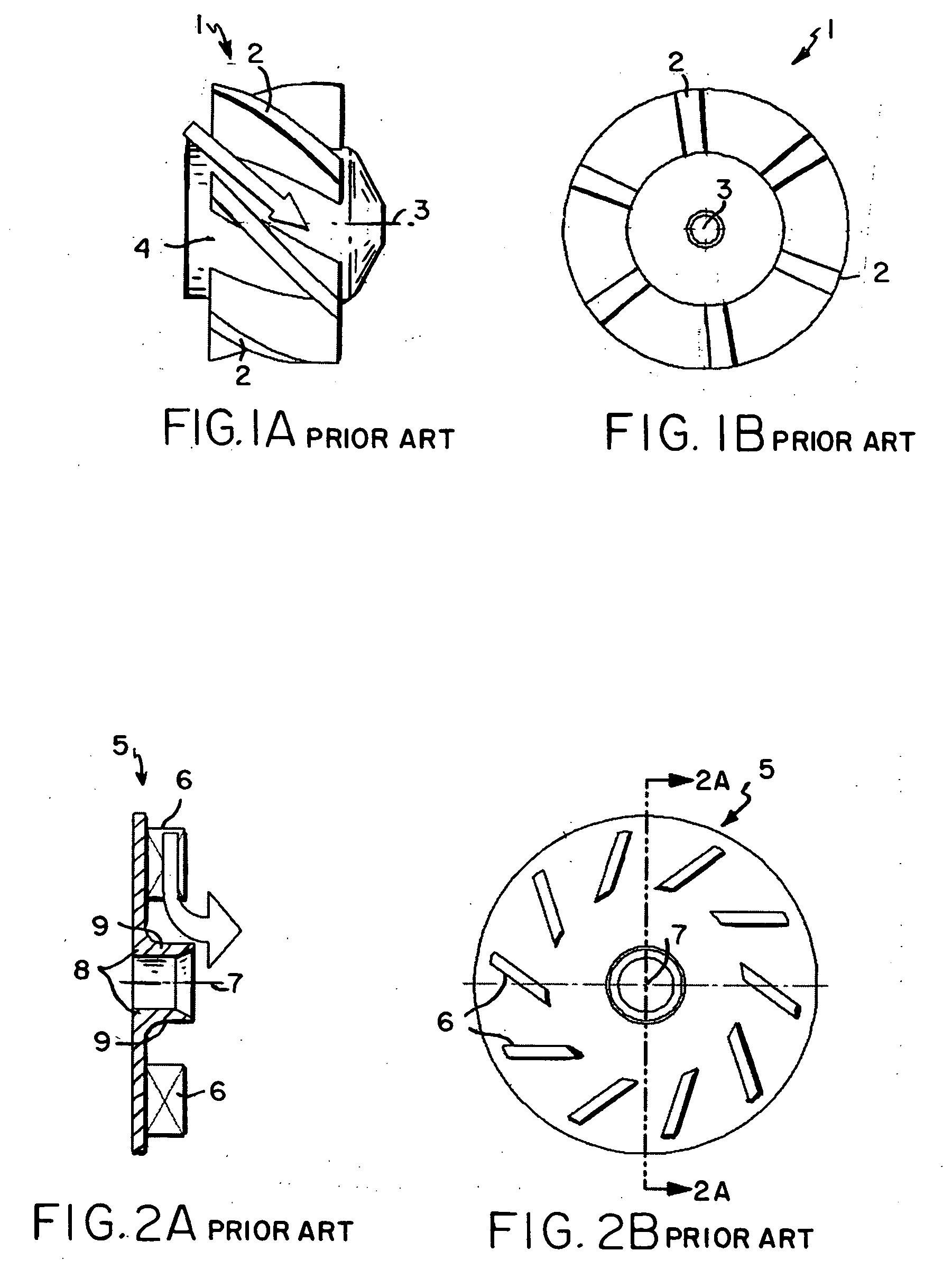

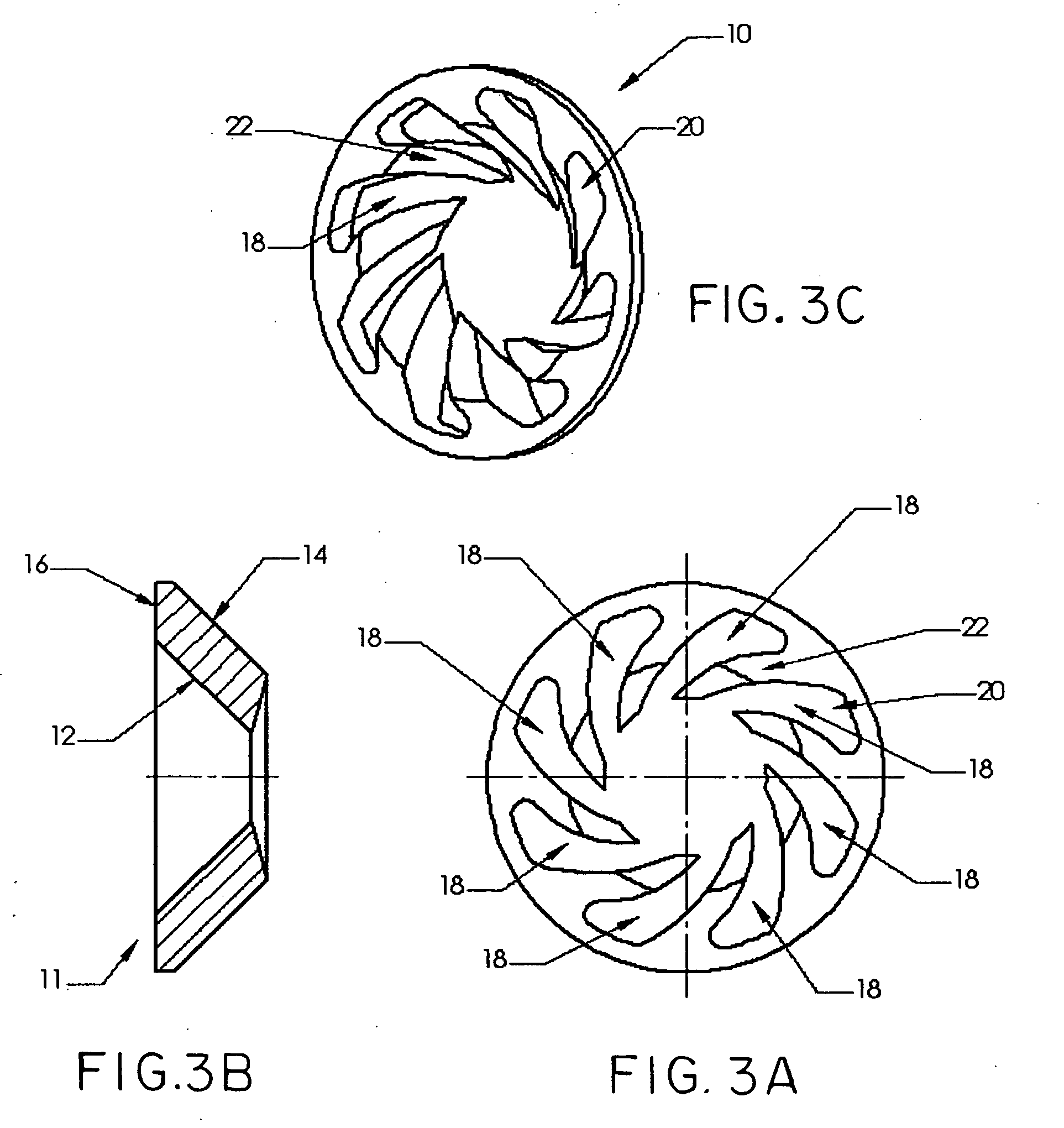

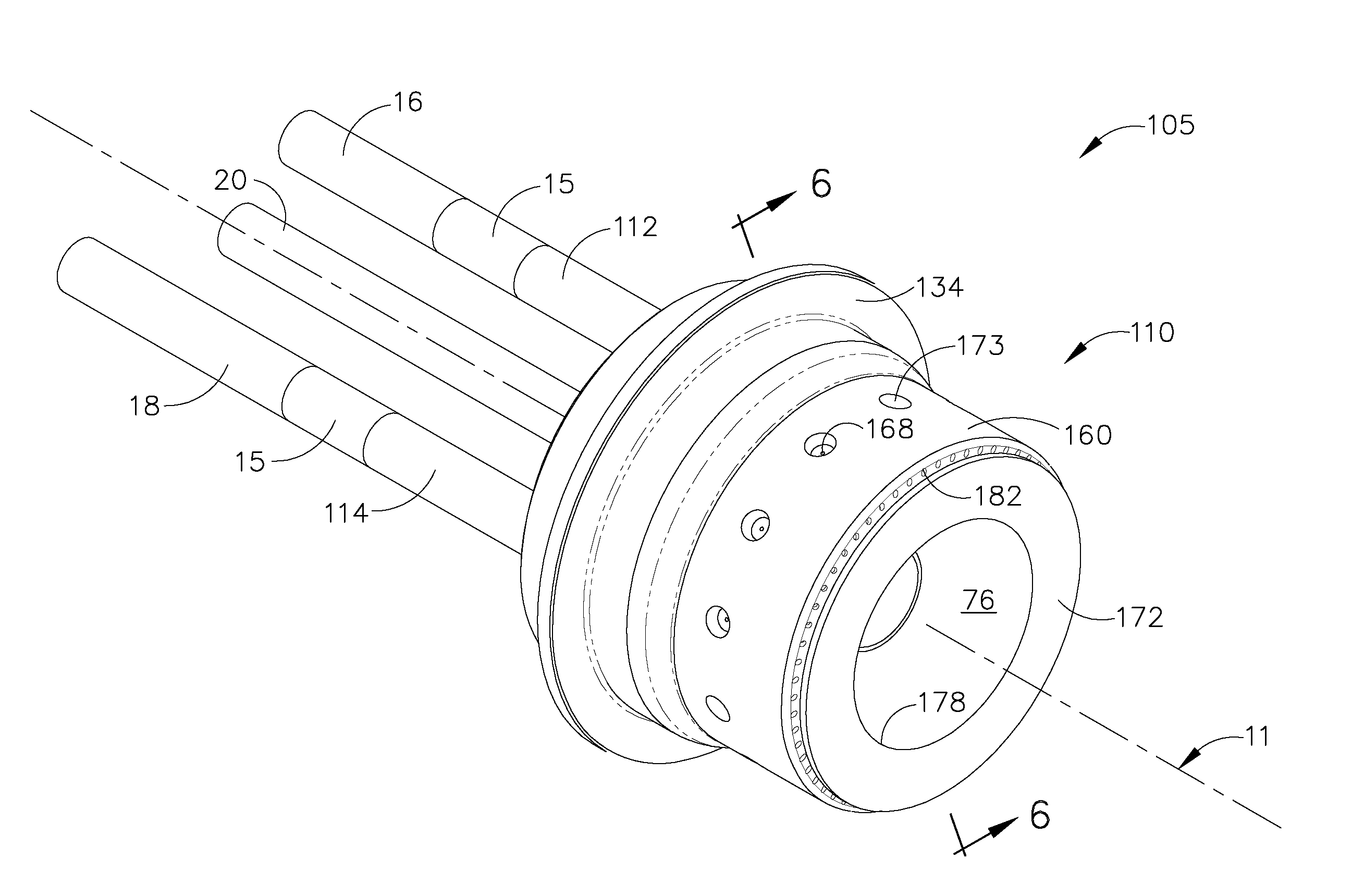

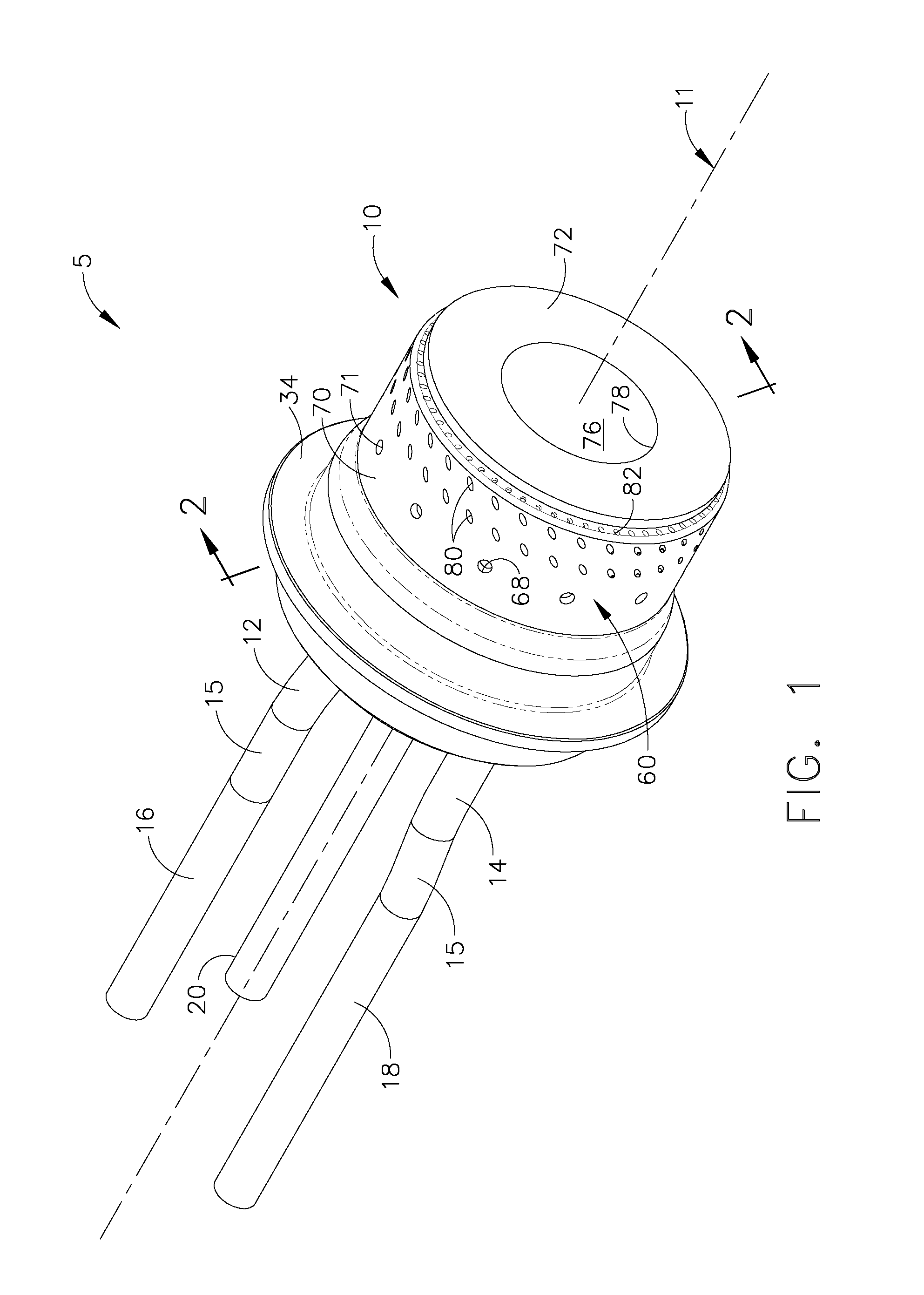

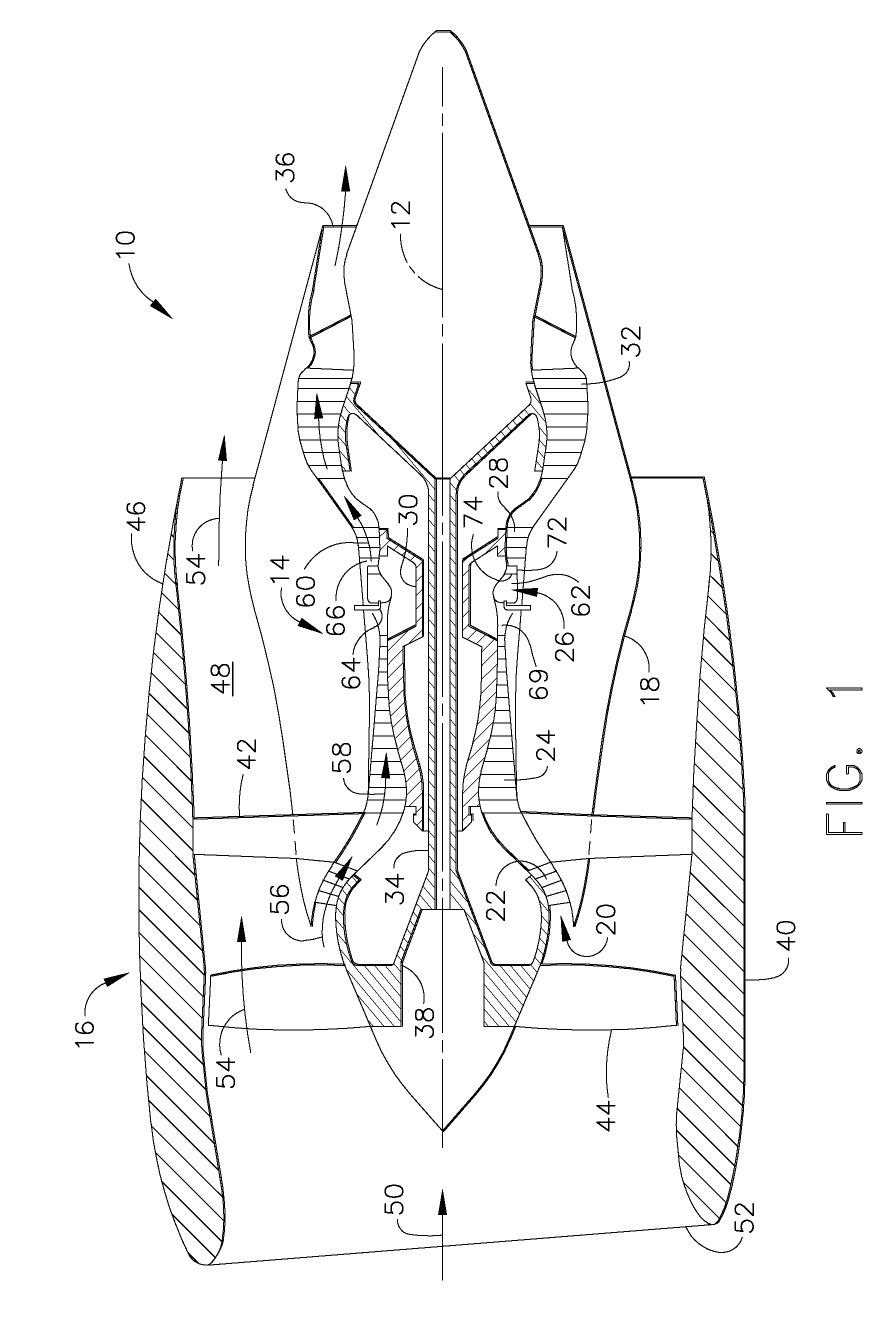

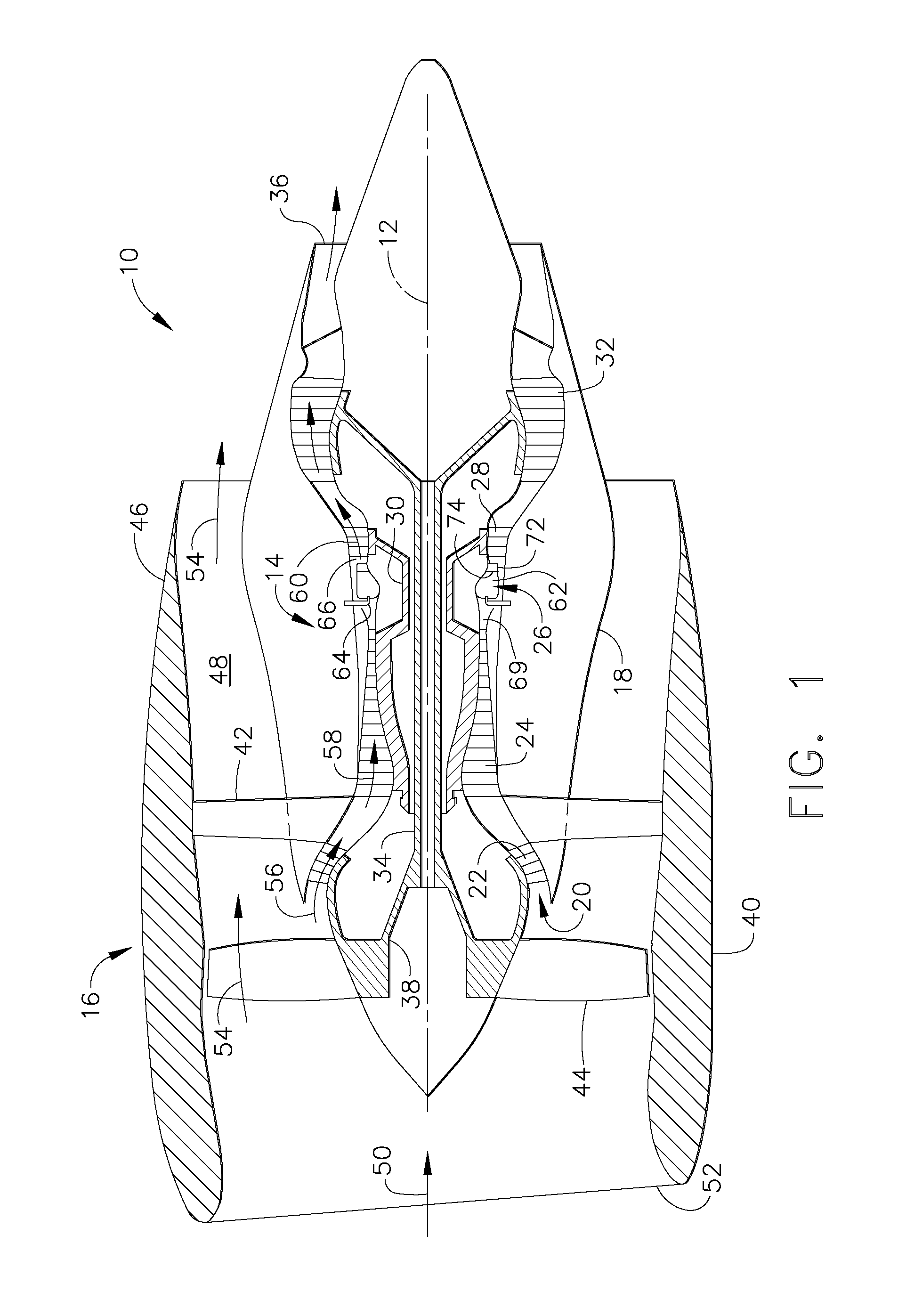

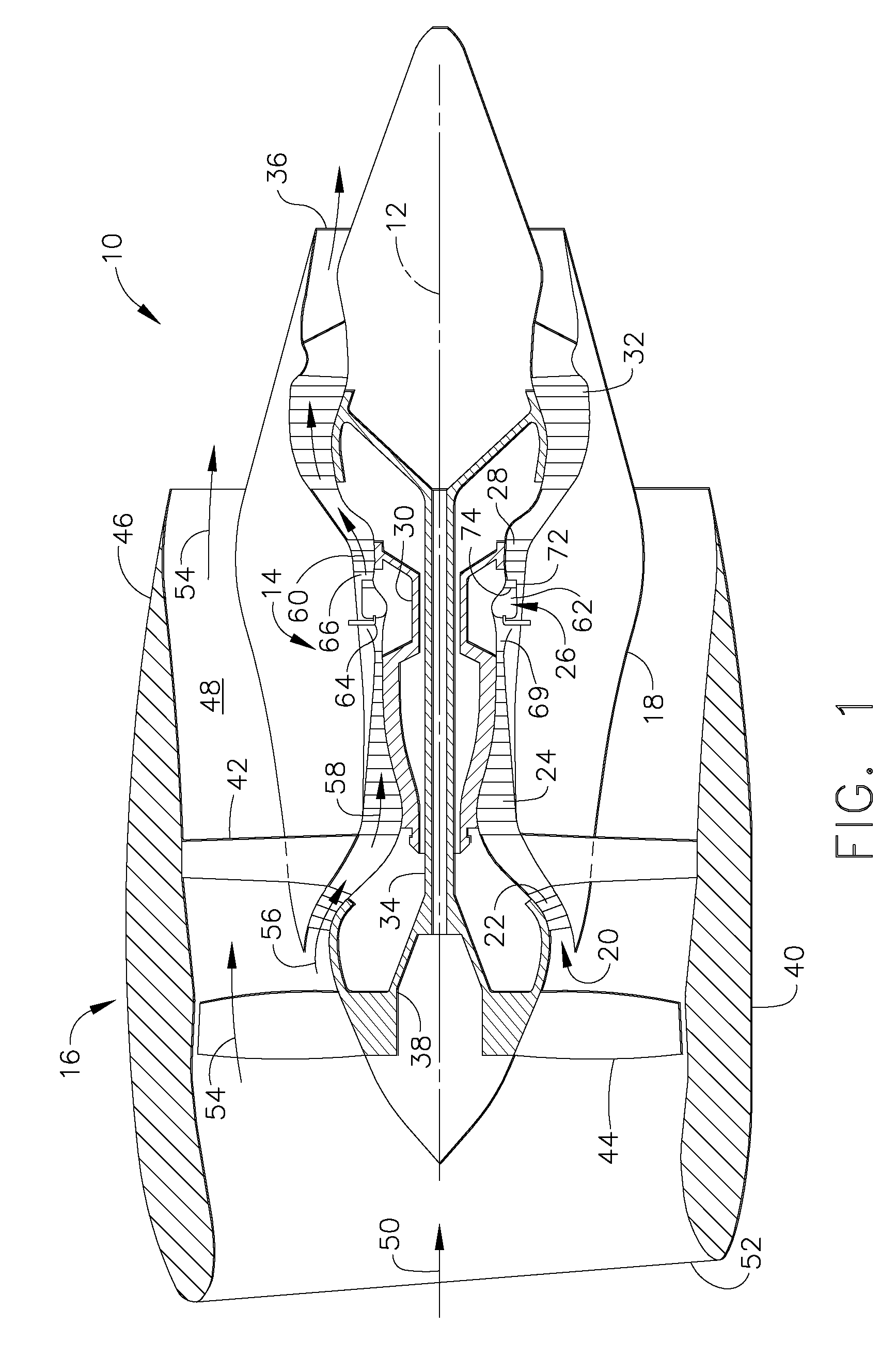

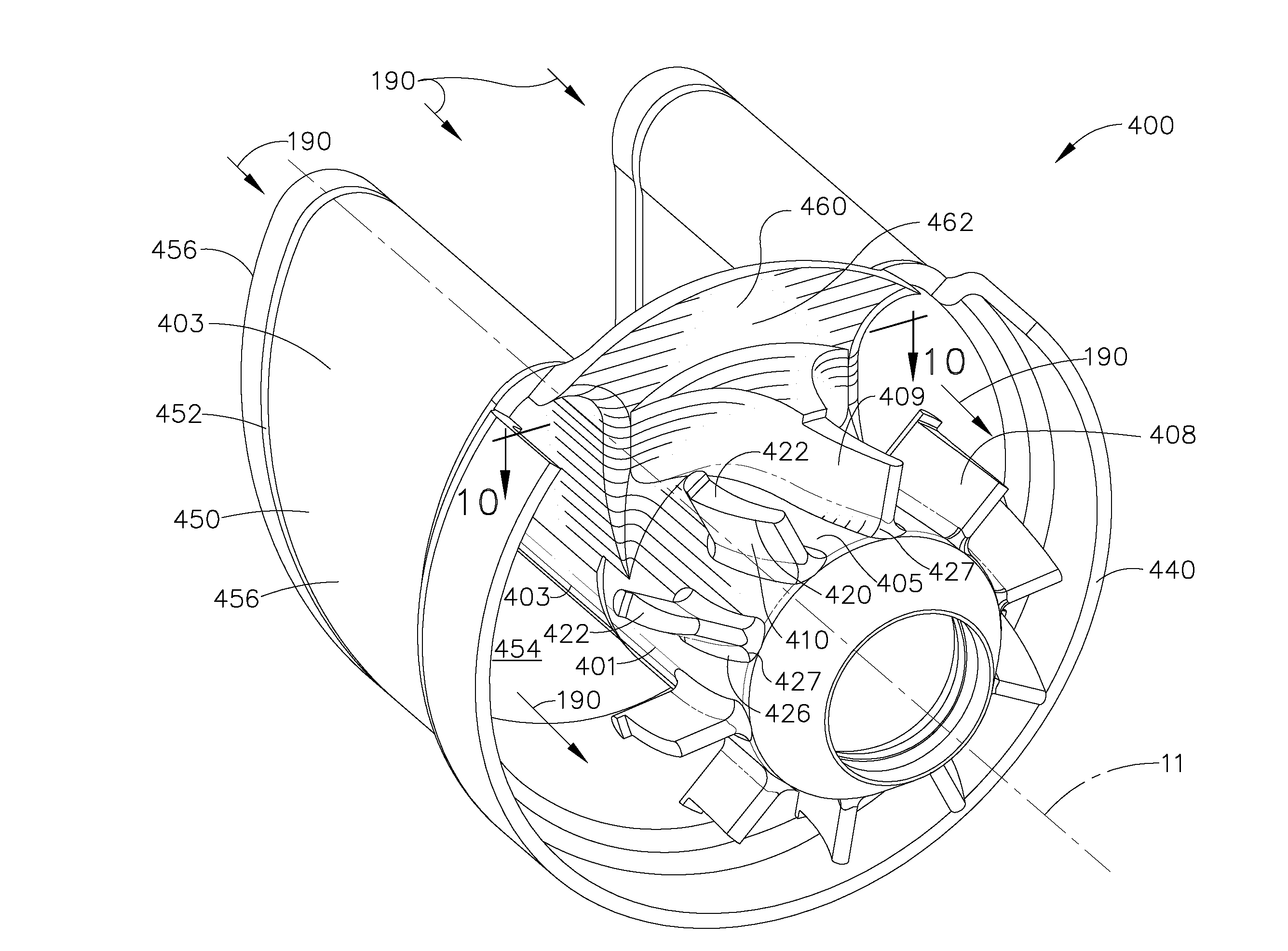

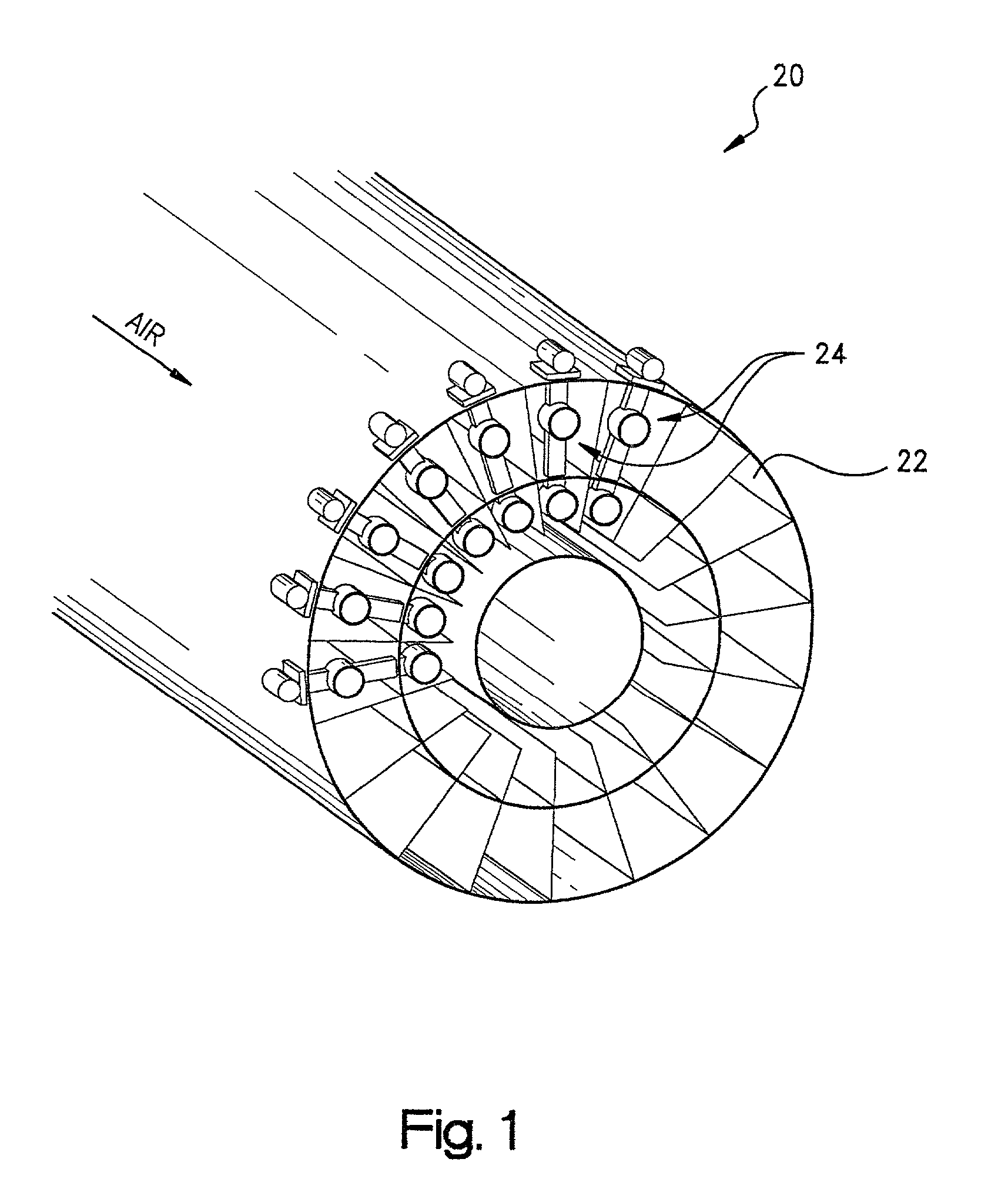

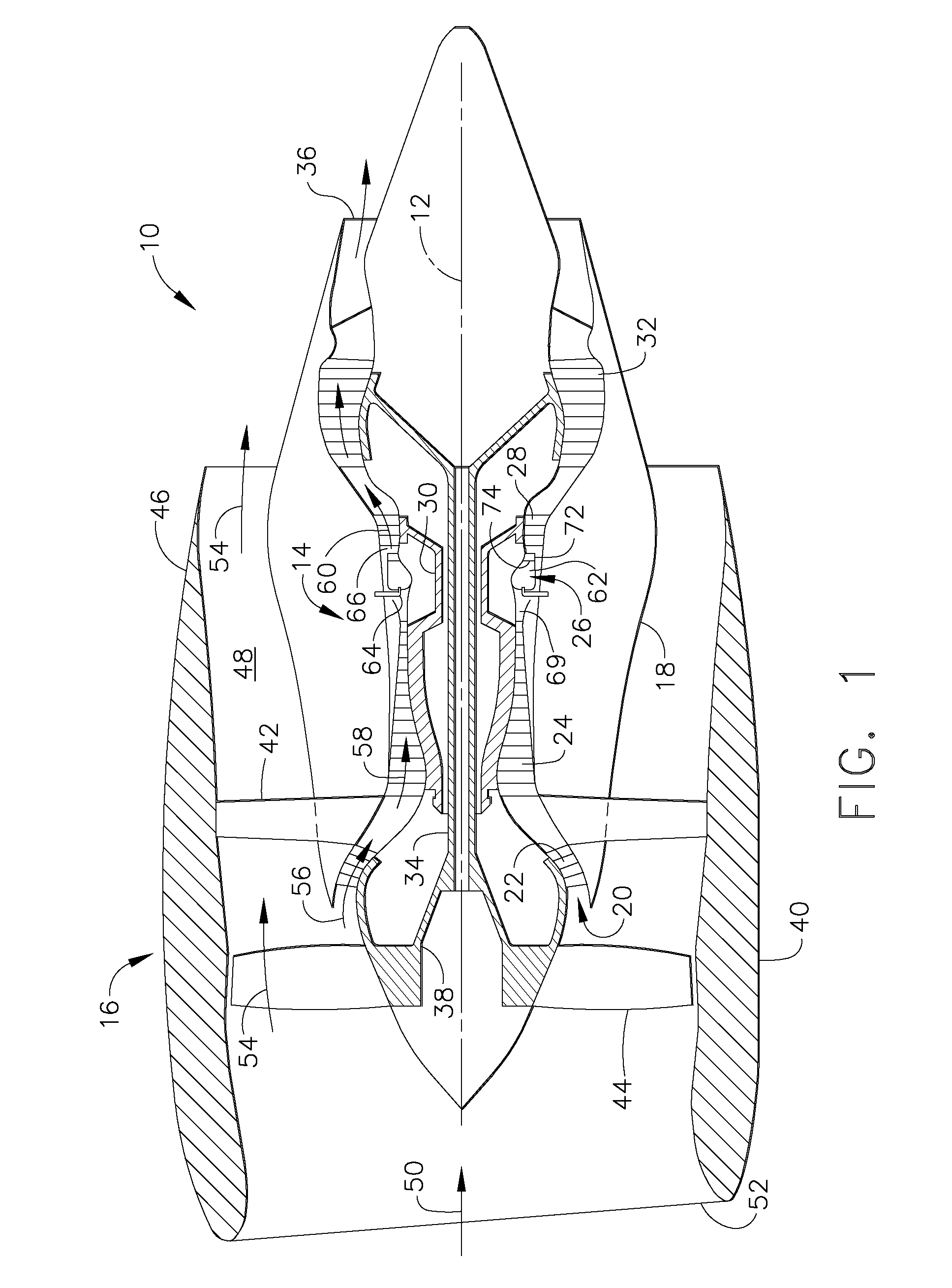

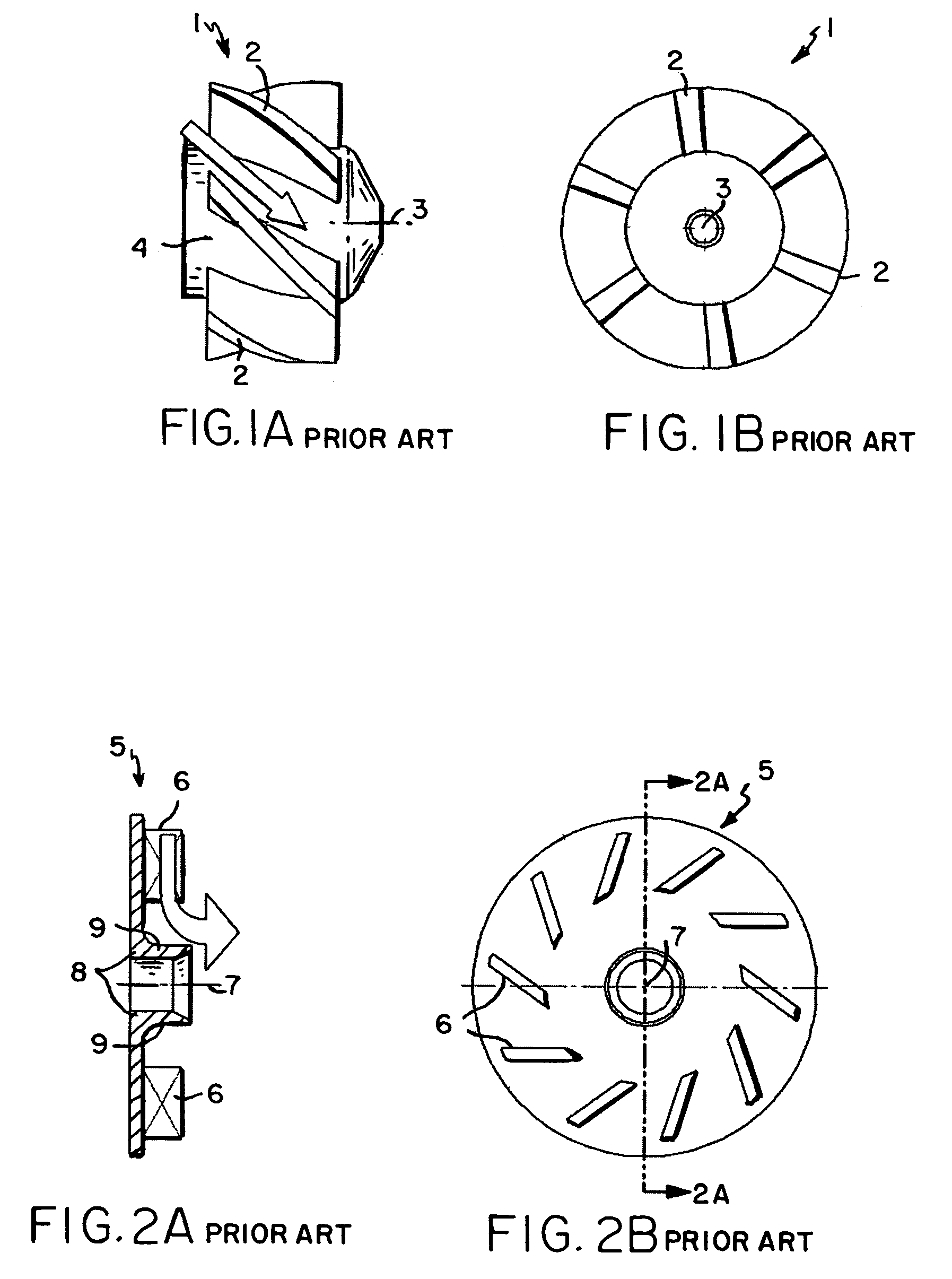

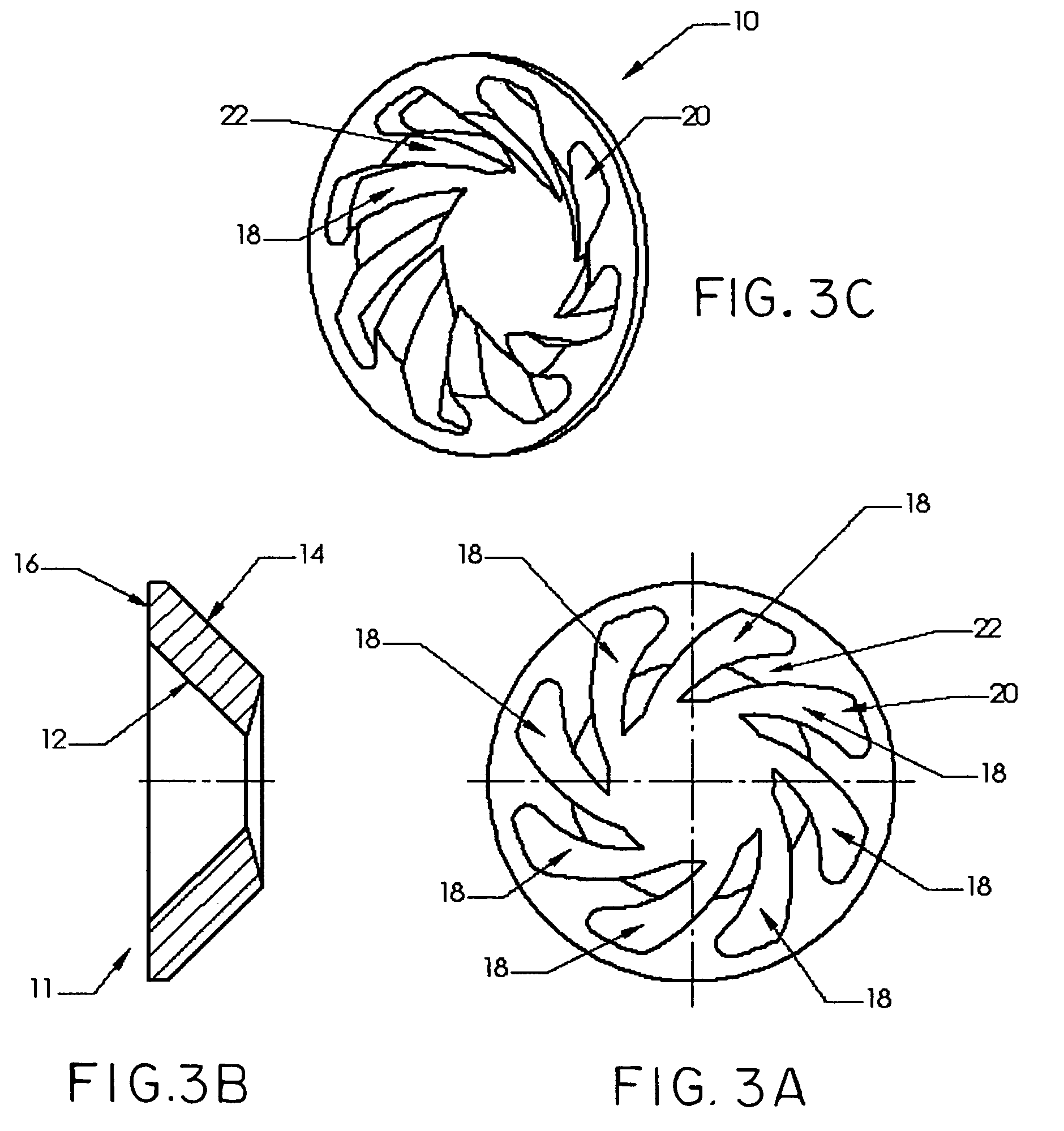

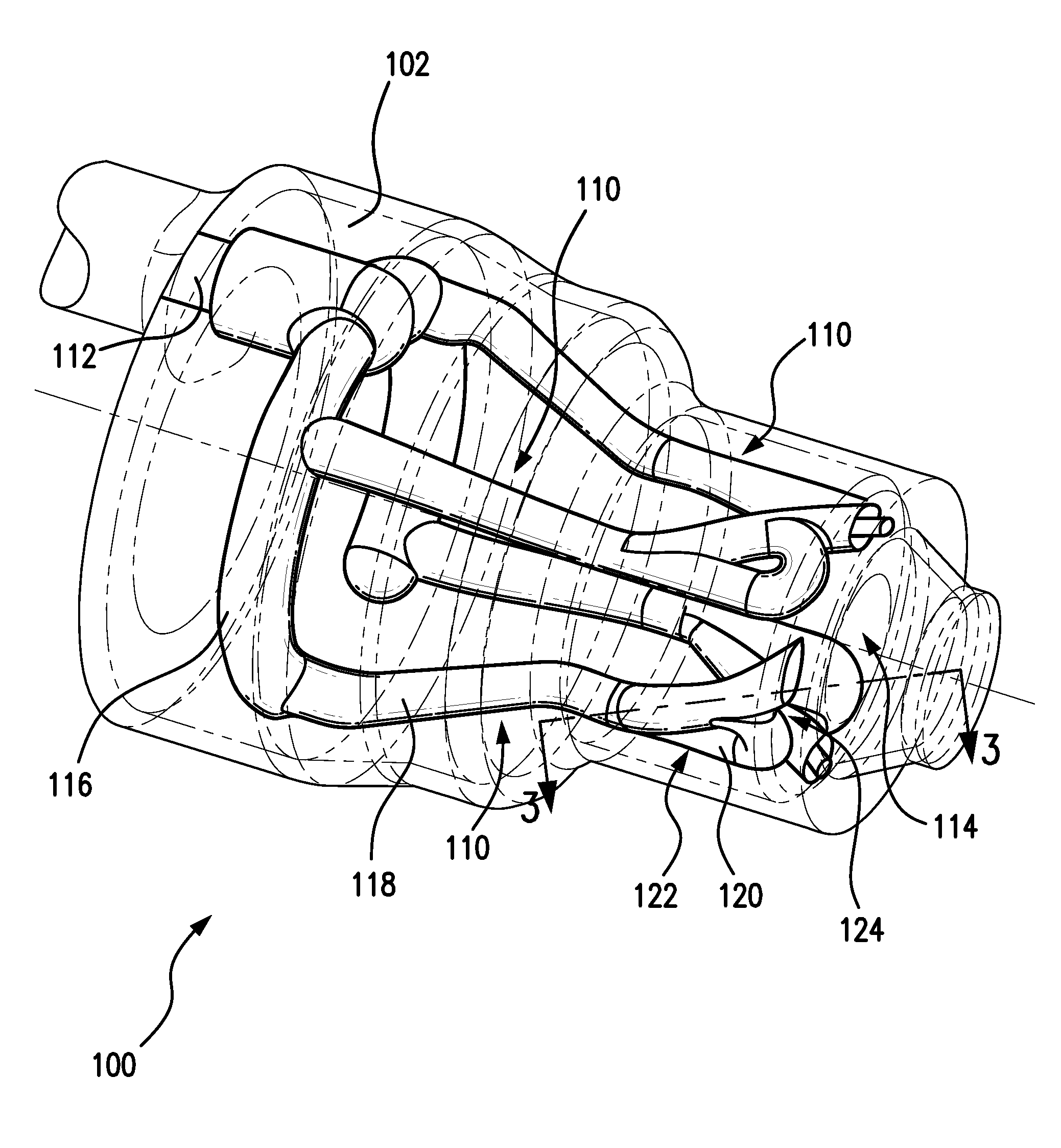

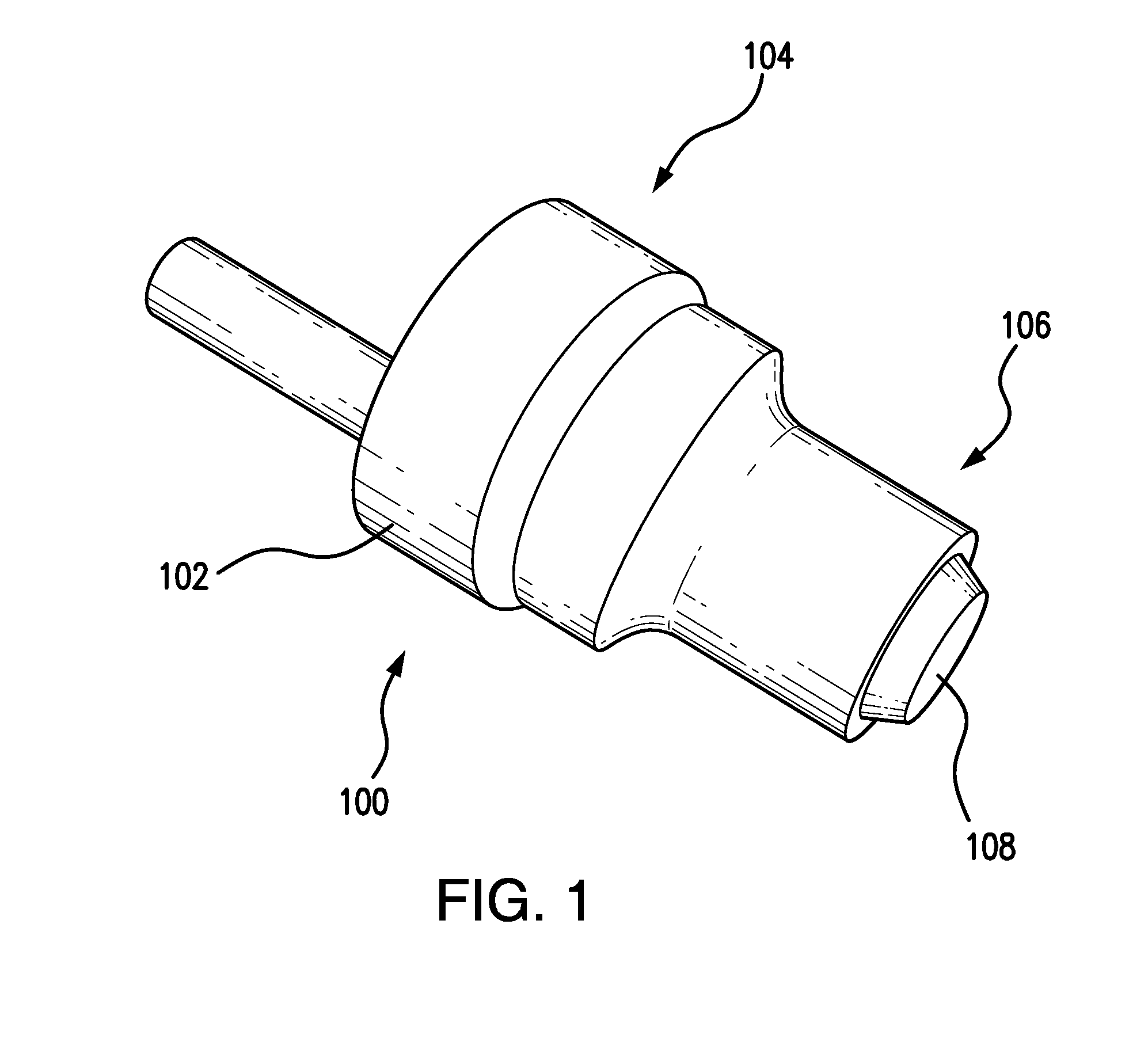

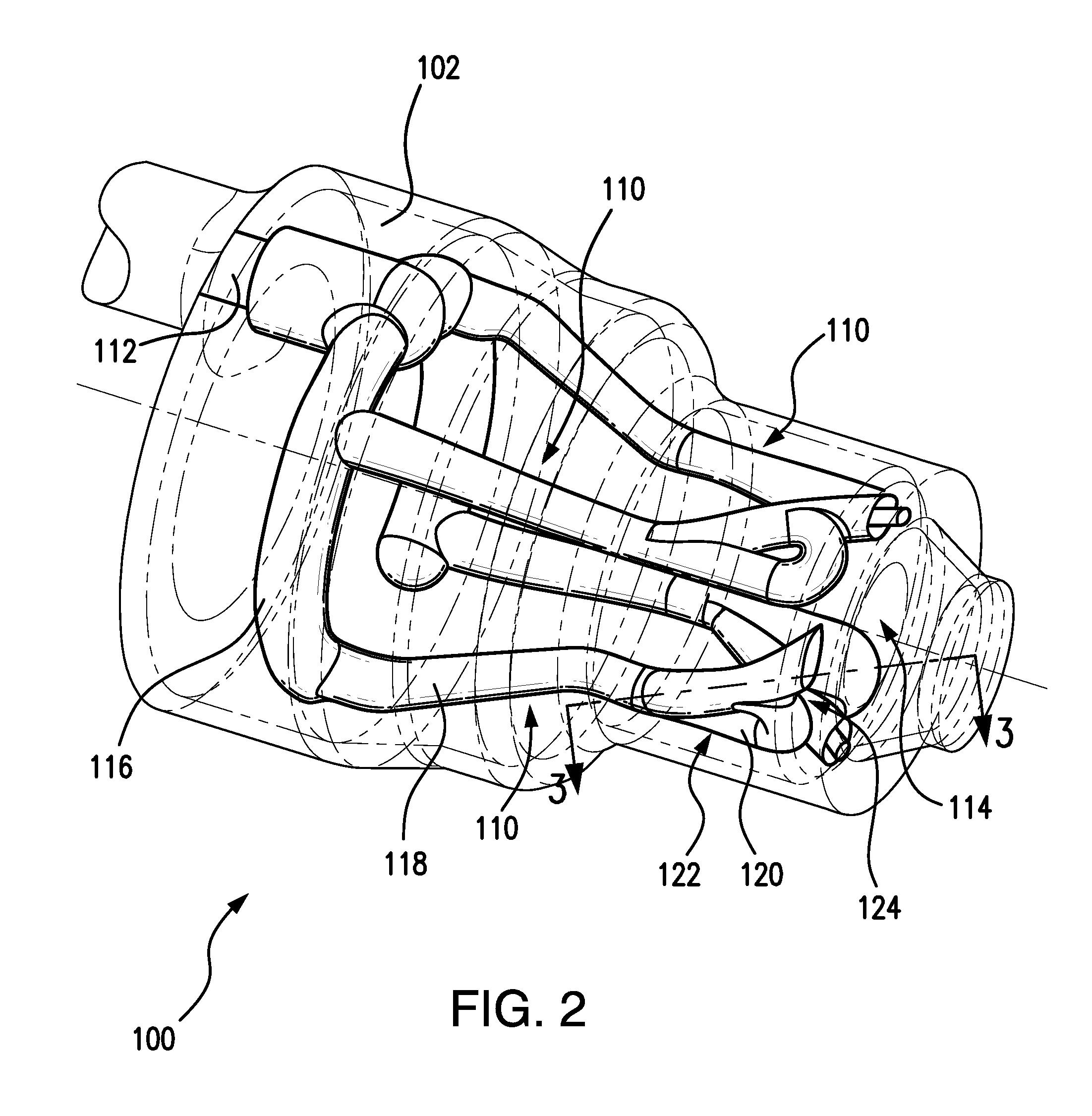

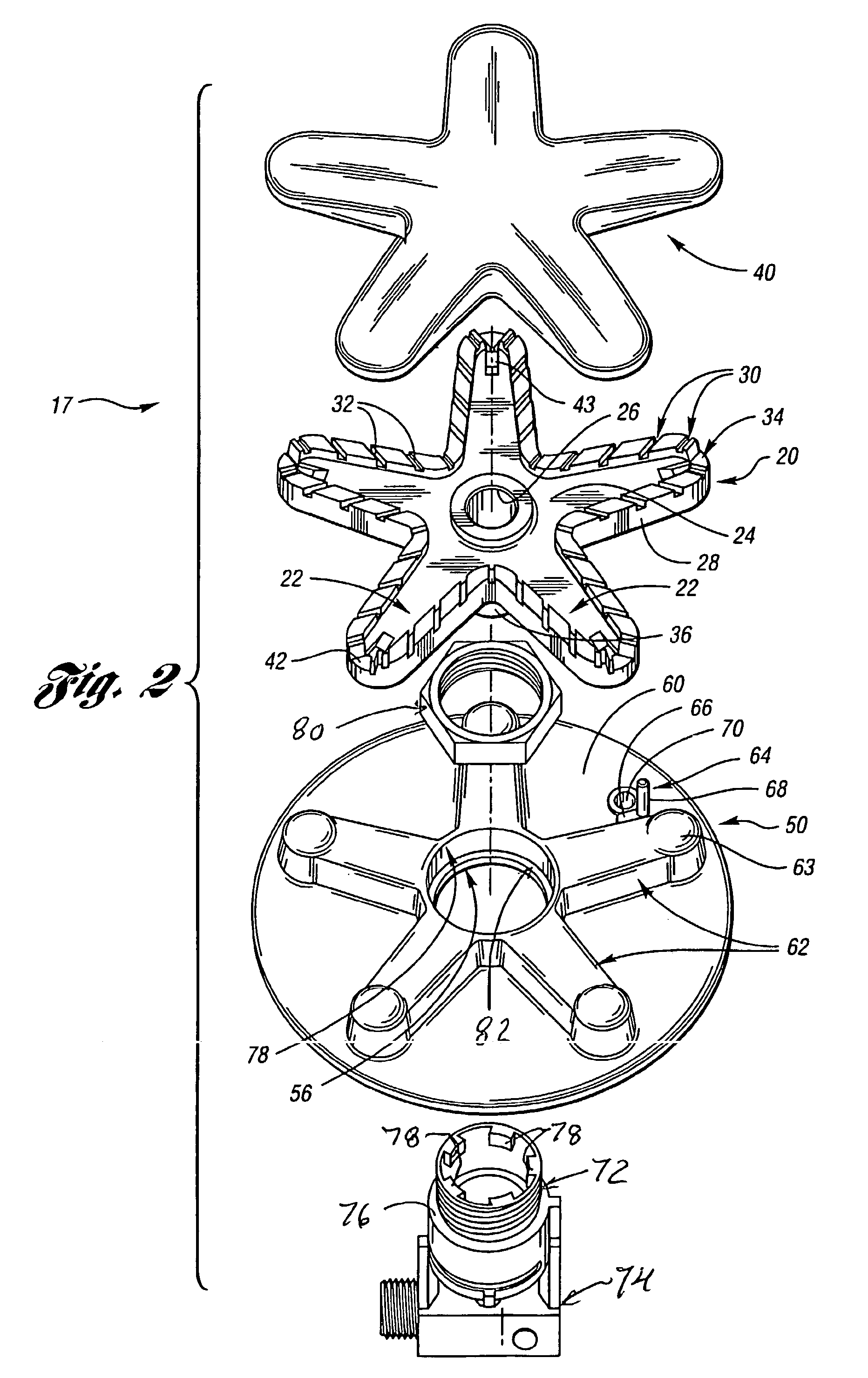

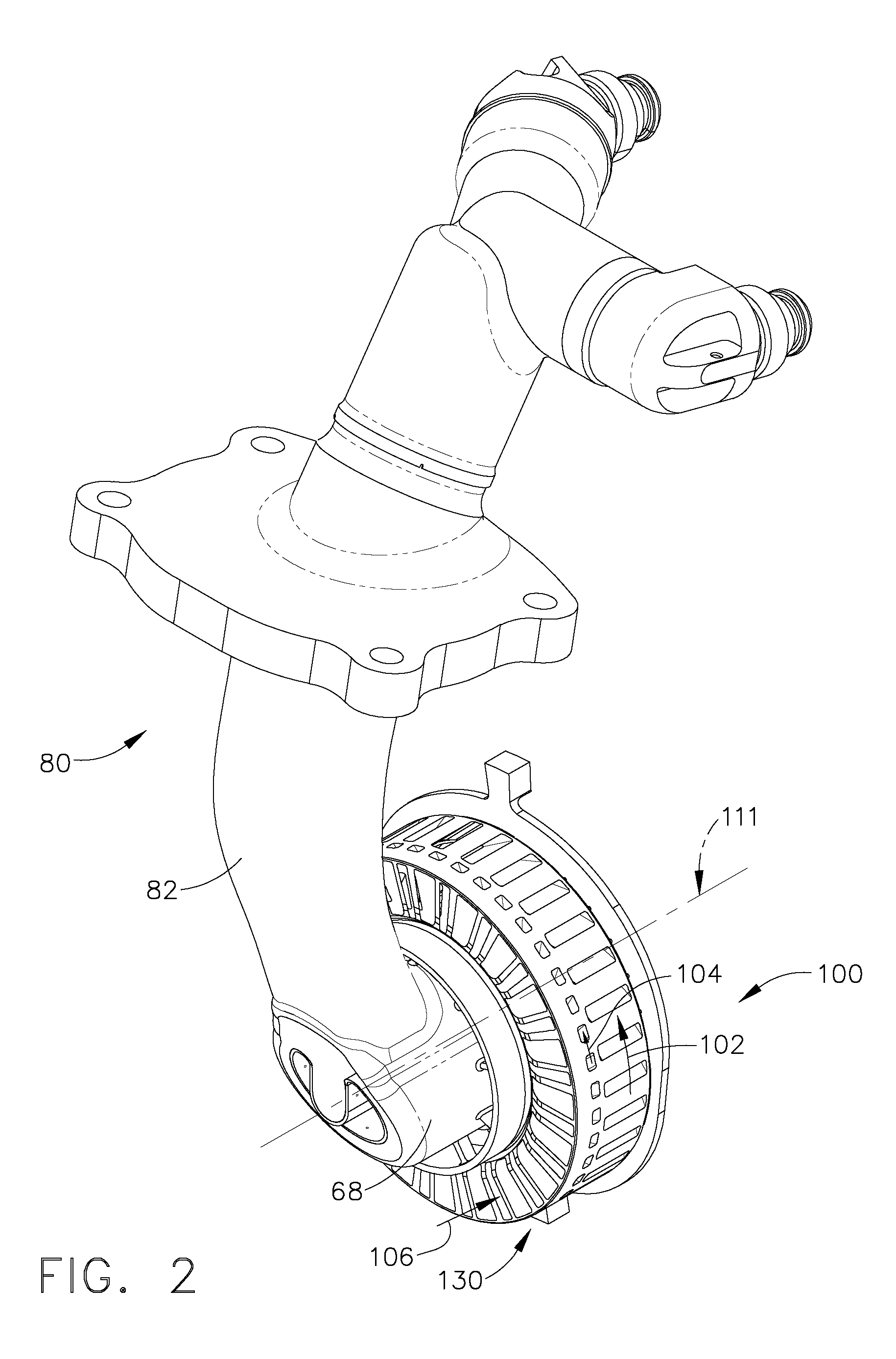

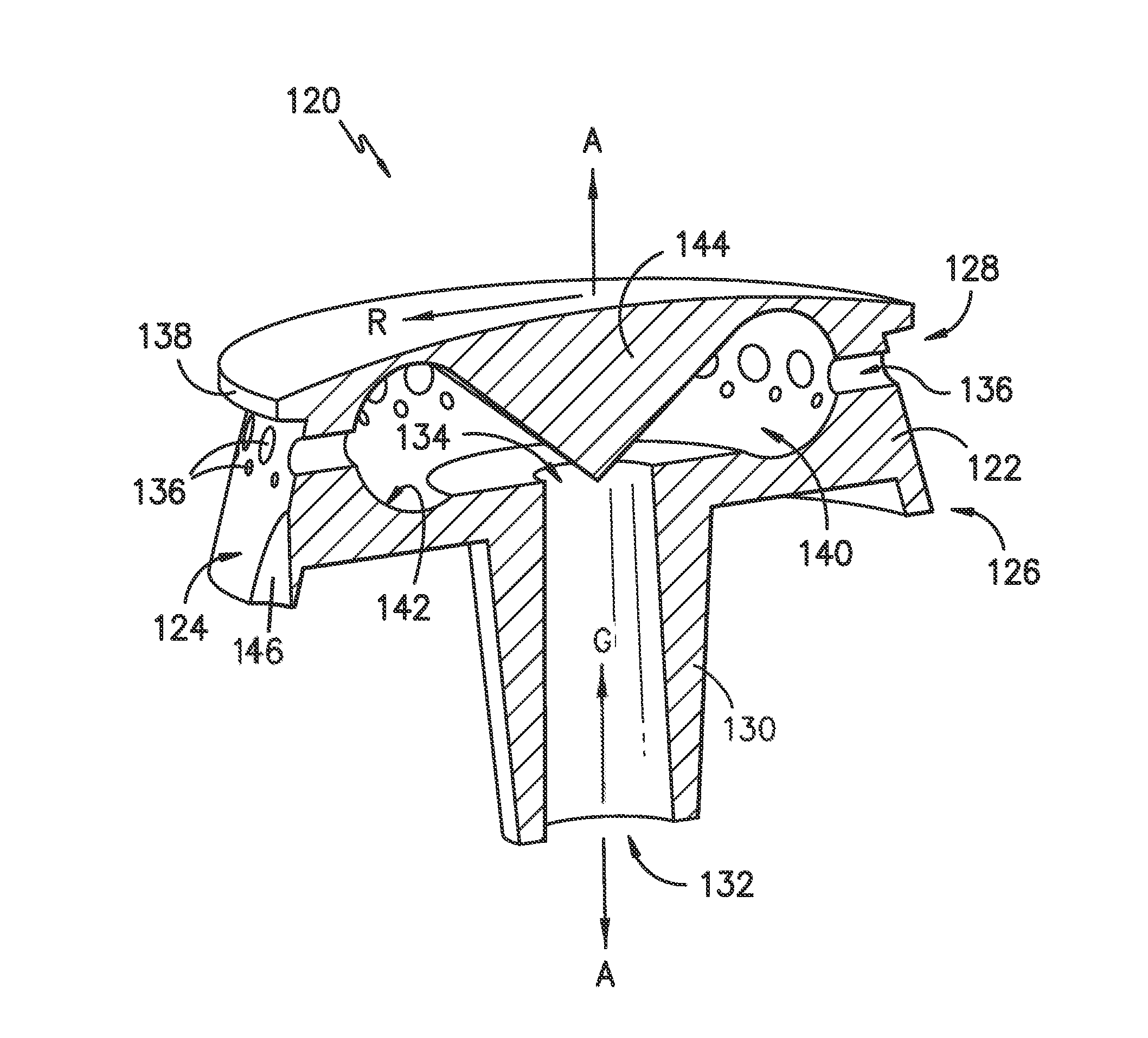

Conical swirler for fuel injectors and combustor domes and methods of manufacturing the same

ActiveUS20050279862A1Area minimizationReduced frontal surface areaContinuous combustion chamberSpray nozzlesCombustorCombustion chamber

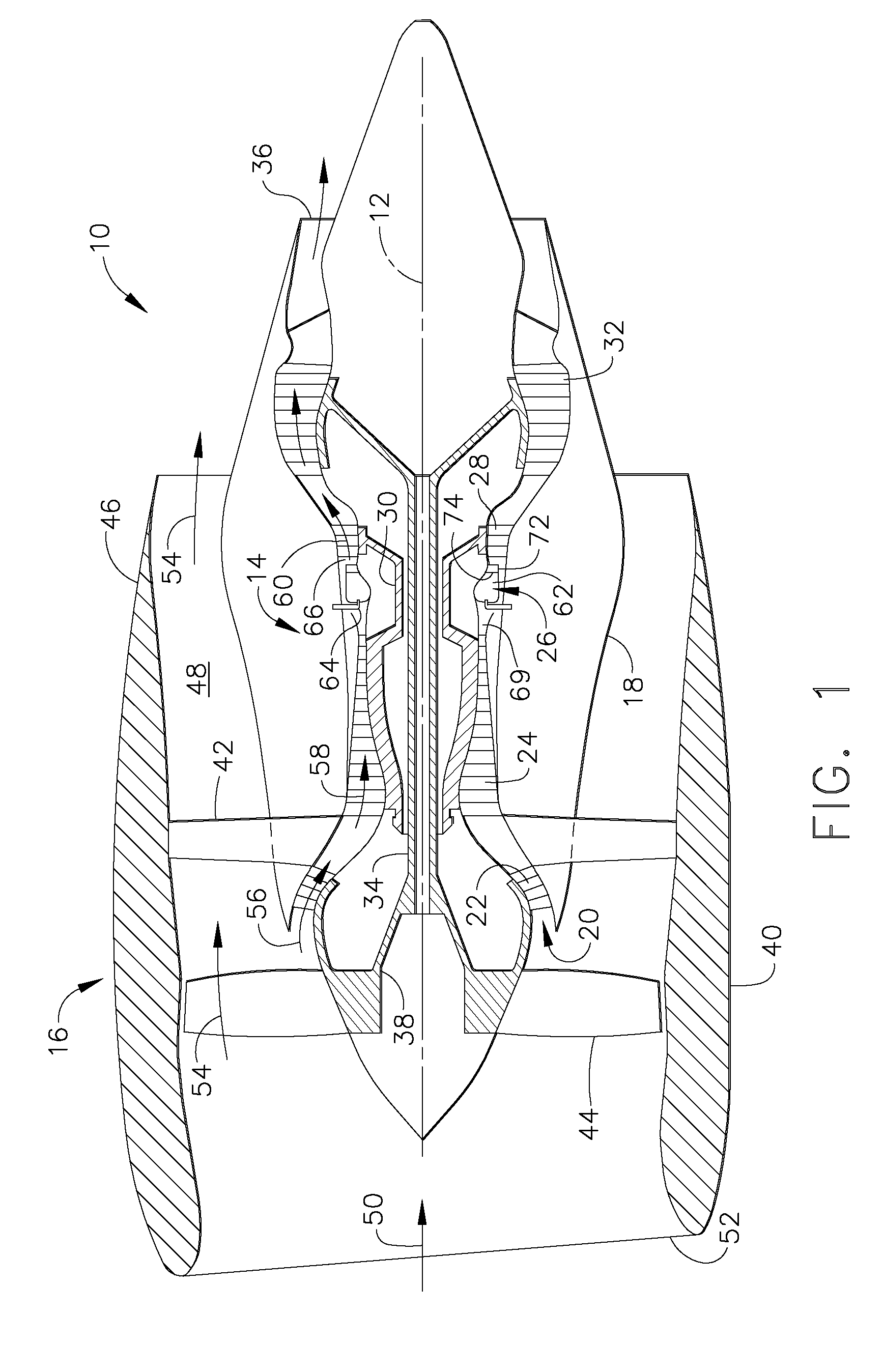

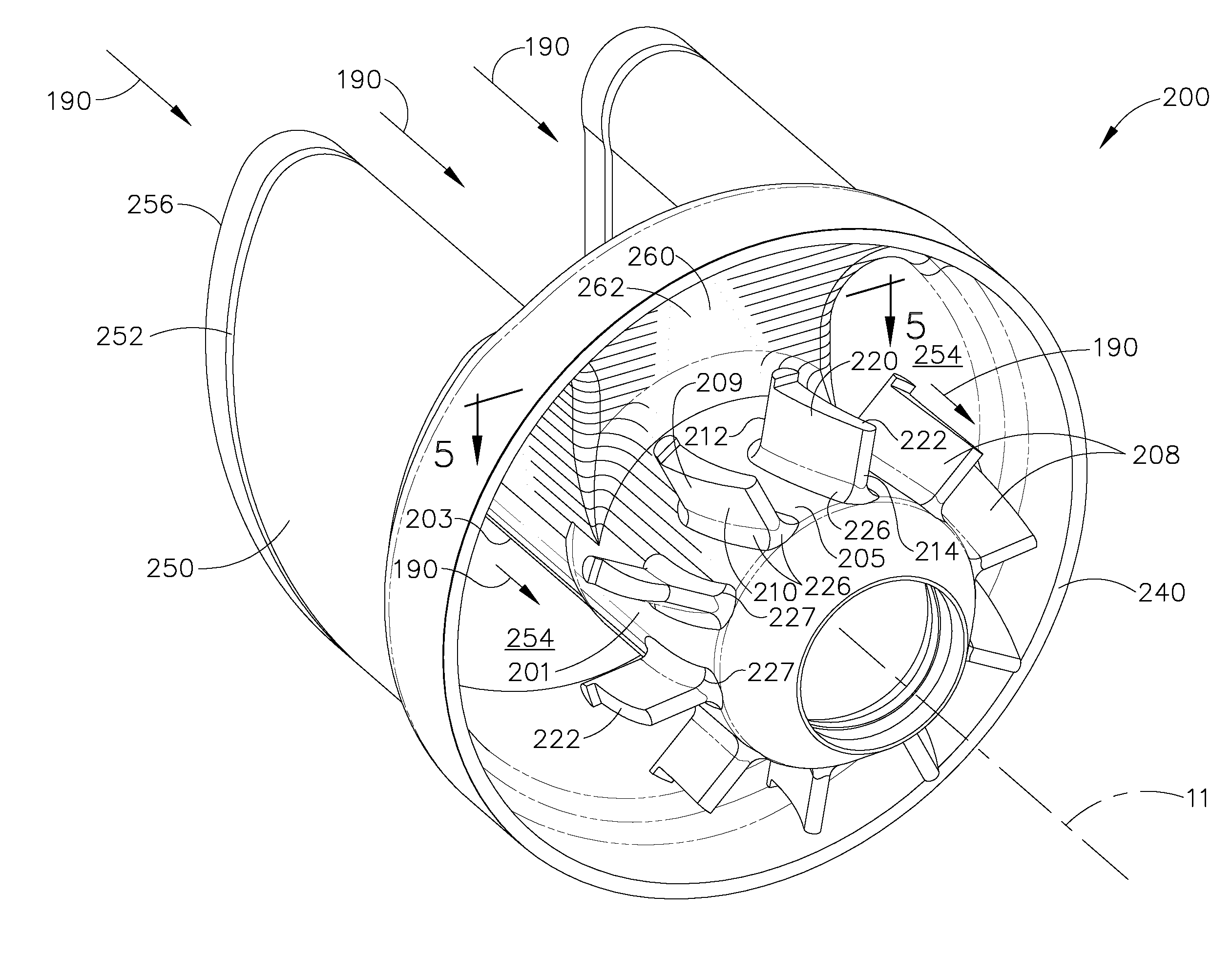

A method of manufacturing gas and / or fuel swirlers for fuel injectors and combustor domes and cone-shaped swirlers so manufactured are disclosed. The disclosed conical swirlers feature cut-through slots on a cone-shaped body. The contour and spacing of the slots are configured and arranged to accommodate a wide range of requirements for fluid flow areas and swirl strengths. Preferably, the cone-shaped swirlers can be manufactured by wire EDM processing. More preferably, multiple cone-shaped swirlers can be manufactured simultaneously by nesting swirler blanks in a stack and wire EDM processing the stack as a unit. The cone-shaped pinwheel swirler fits well into various fuel injector heads, enabling the injectors to reduce the frontal surface area and flat area for minimal potential of carbon formation.

Owner:COLLINS ENGINE NOZZLES INC

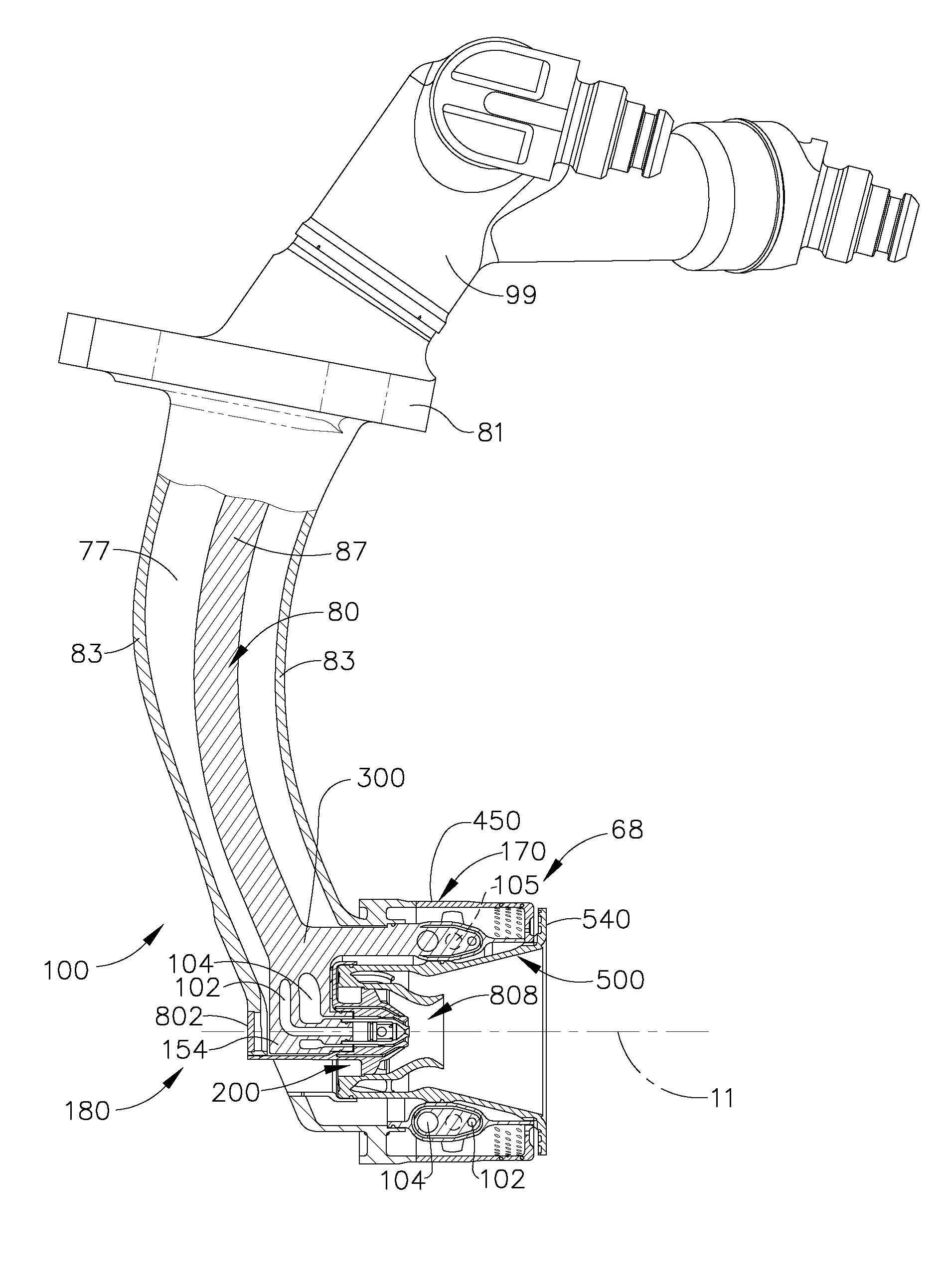

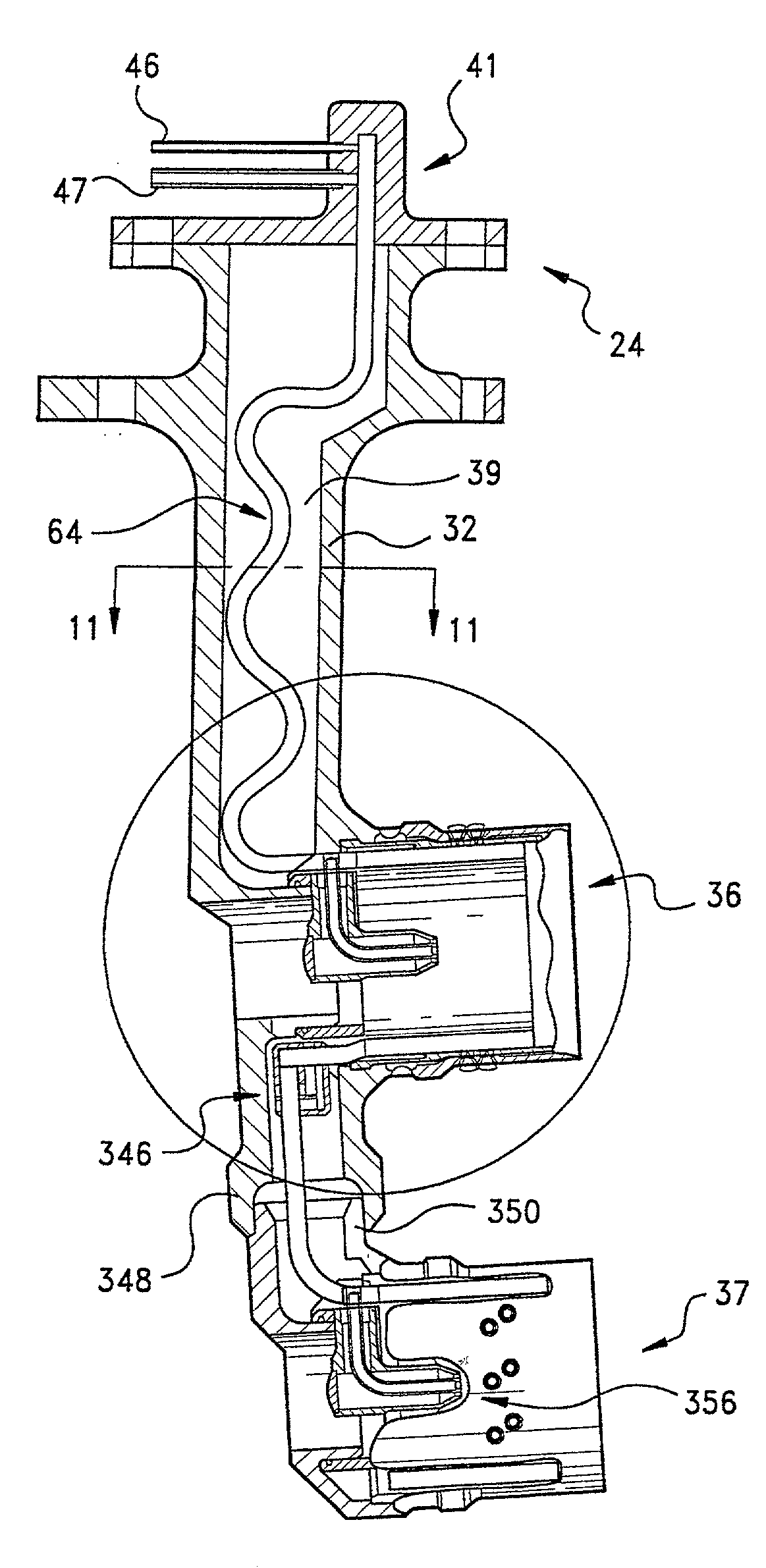

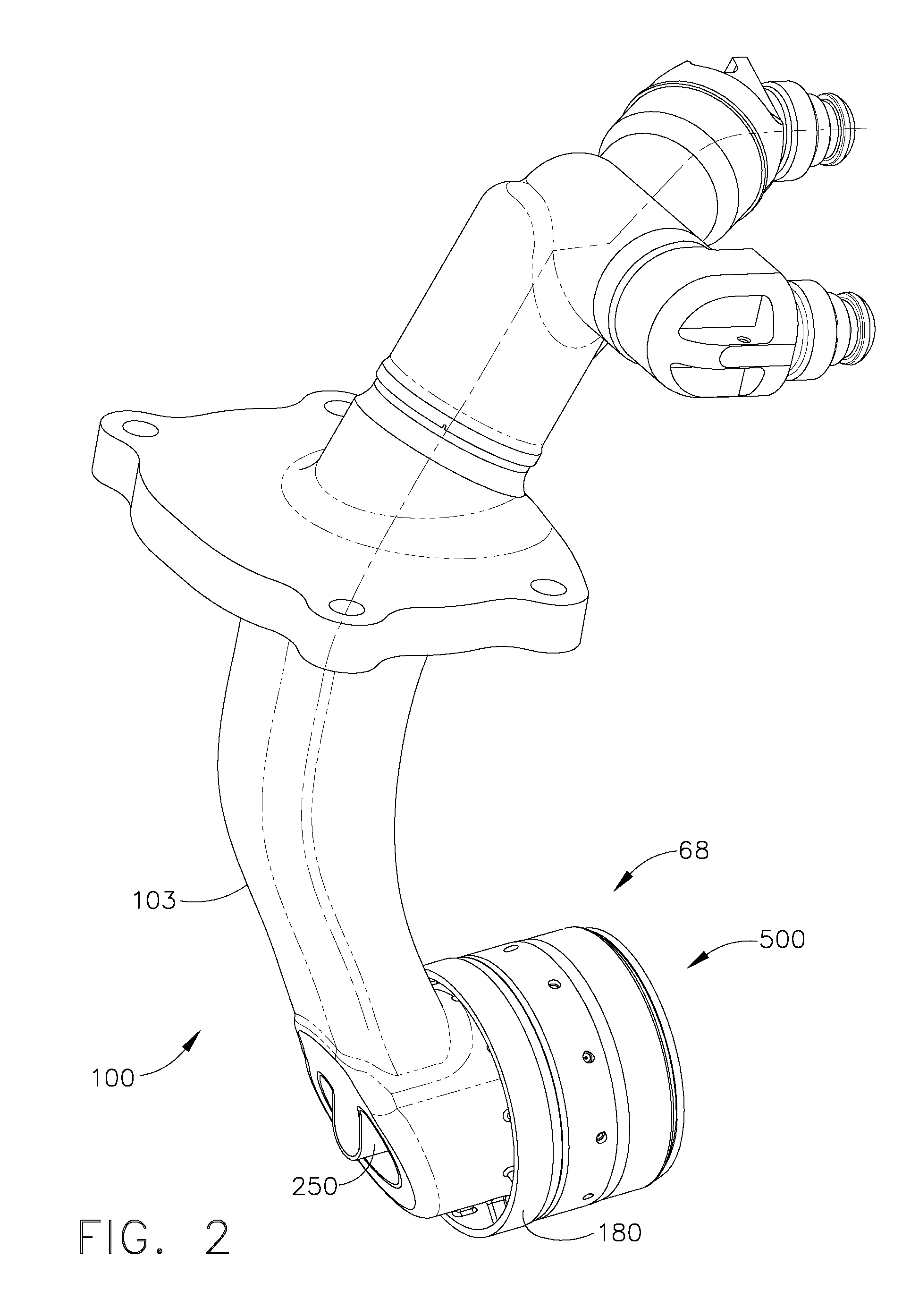

Repairable fuel nozzle

InactiveUS20090256007A1Continuous combustion chamberAdditive manufacturing apparatusDistributorAutomotive engineering

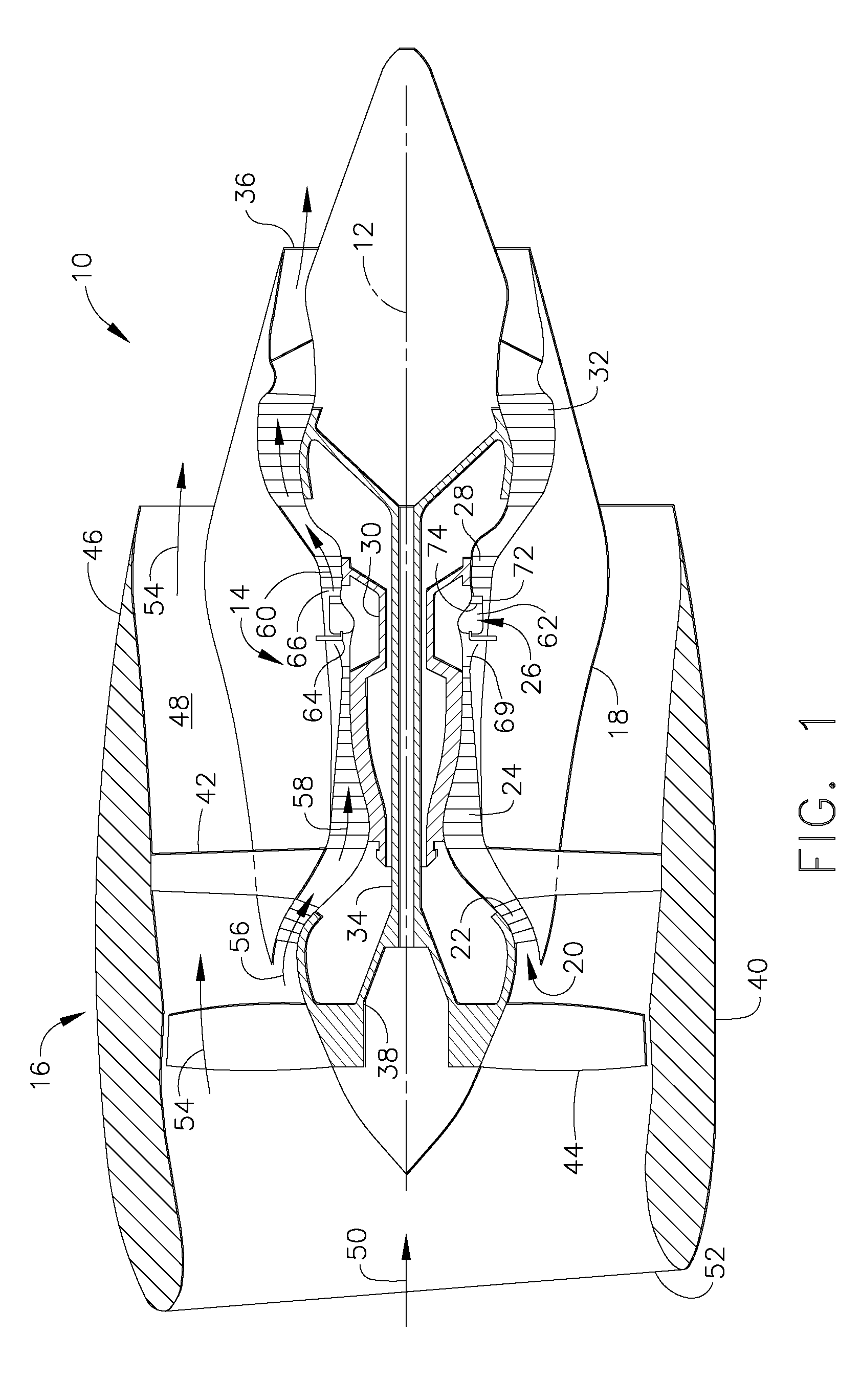

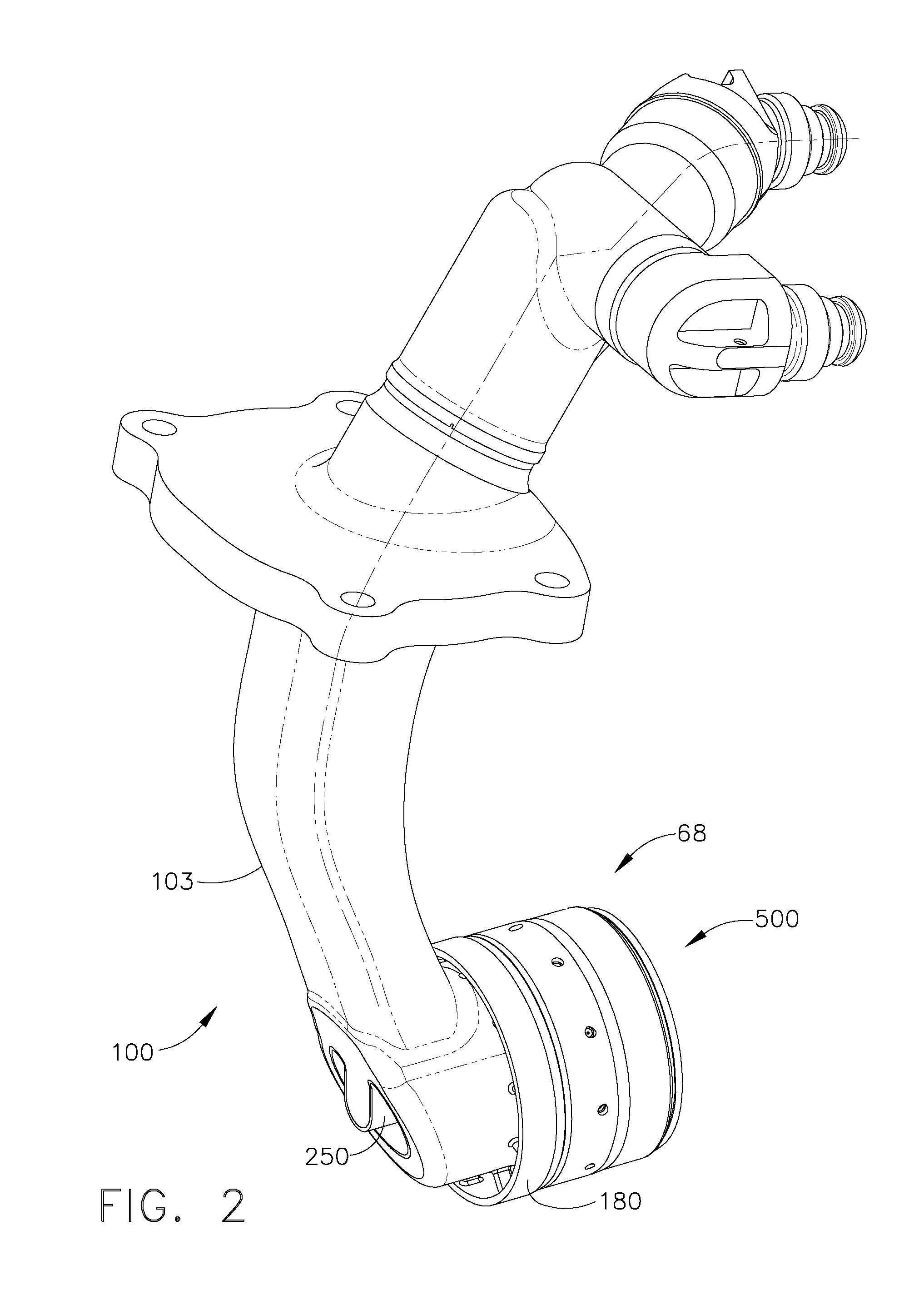

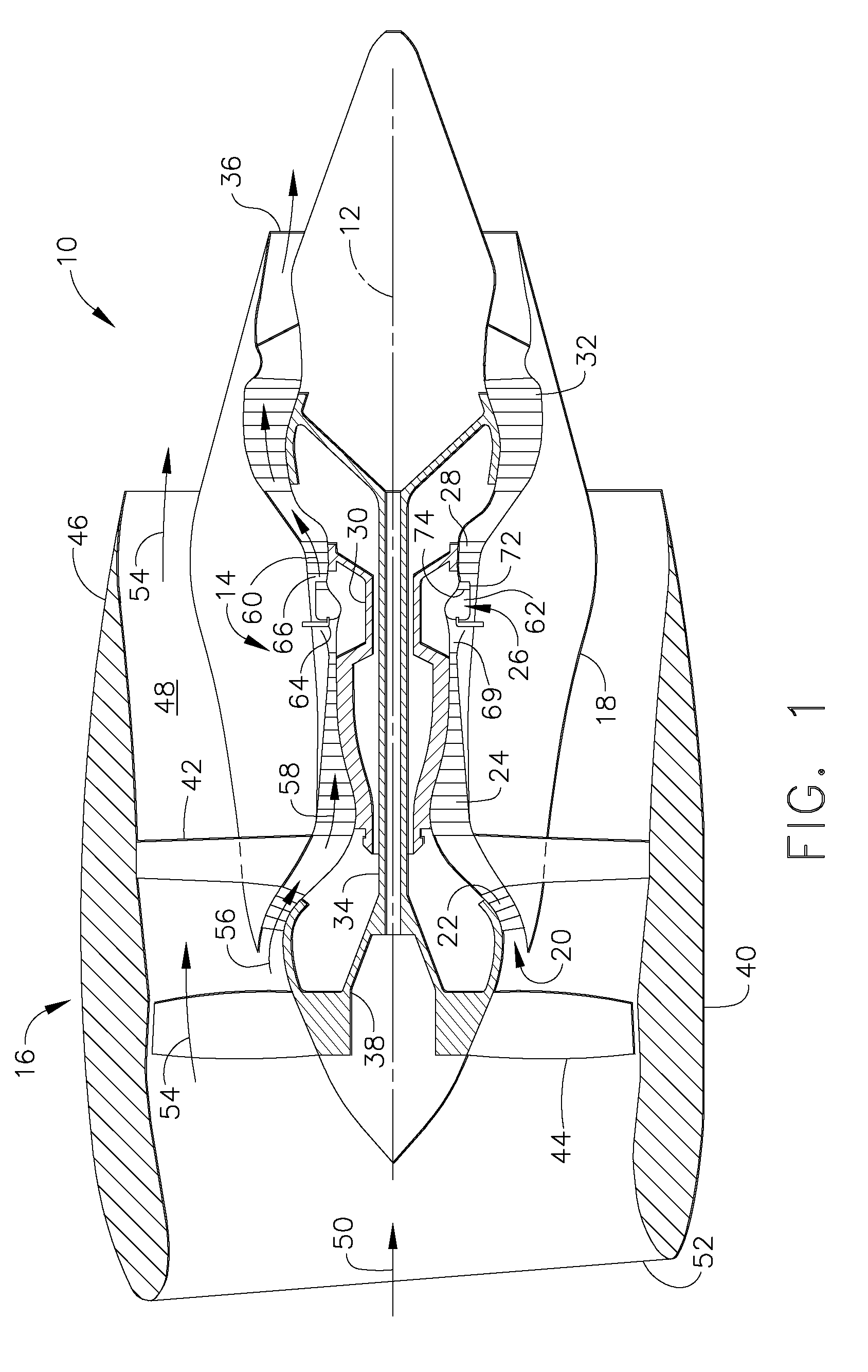

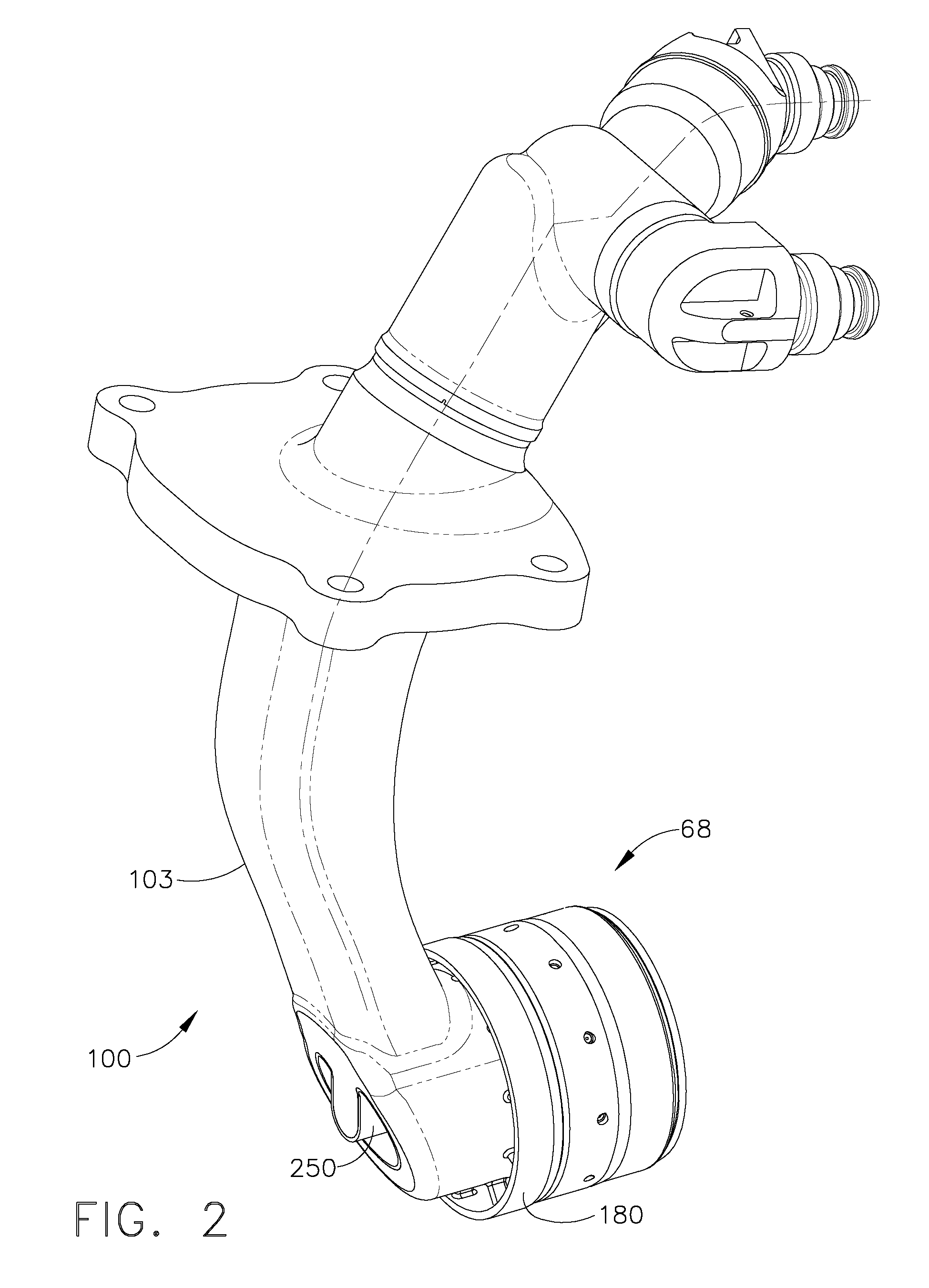

A repairable fuel nozzle is disclosed, comprising an adaptor configured to direct a fuel flow from at least one flow passage in a fuel distributor to a pilot assembly comprising a fuel swirler.

Owner:MCMASTERS MARIE ANN +2

Method of manufacturing combustor components

A method for fabricating a unitary component for a combustor is disclosed, said method comprising the steps of determining three-dimensional information of the unitary component, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary component, and successively forming each layer of the unitary component by fusing a metallic powder using laser energy. A fuel nozzle component is disclosed, comprising a body having a unitary construction wherein the body is made by using a rapid manufacturing process.

Owner:GENERAL ELECTRIC CO

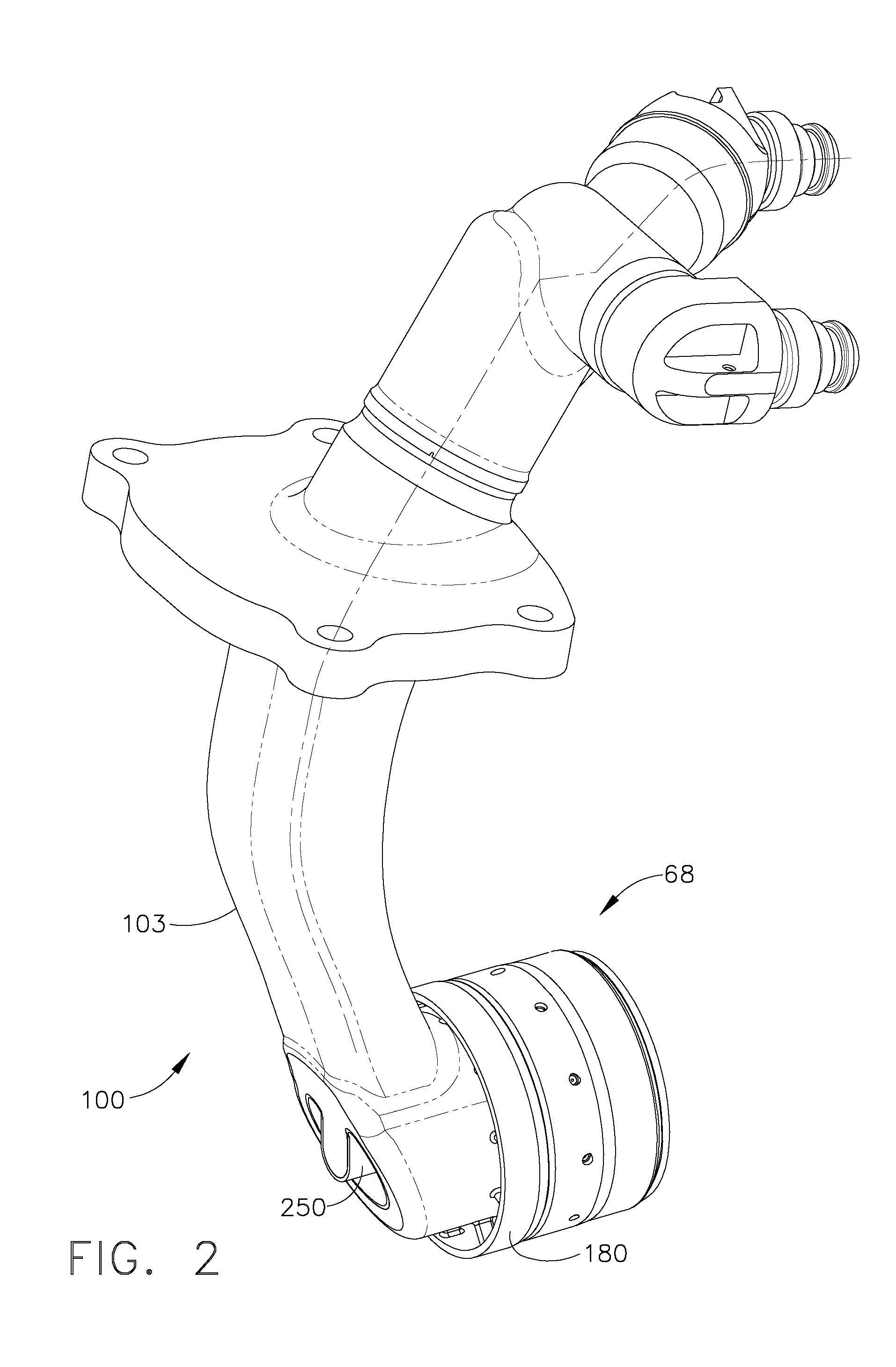

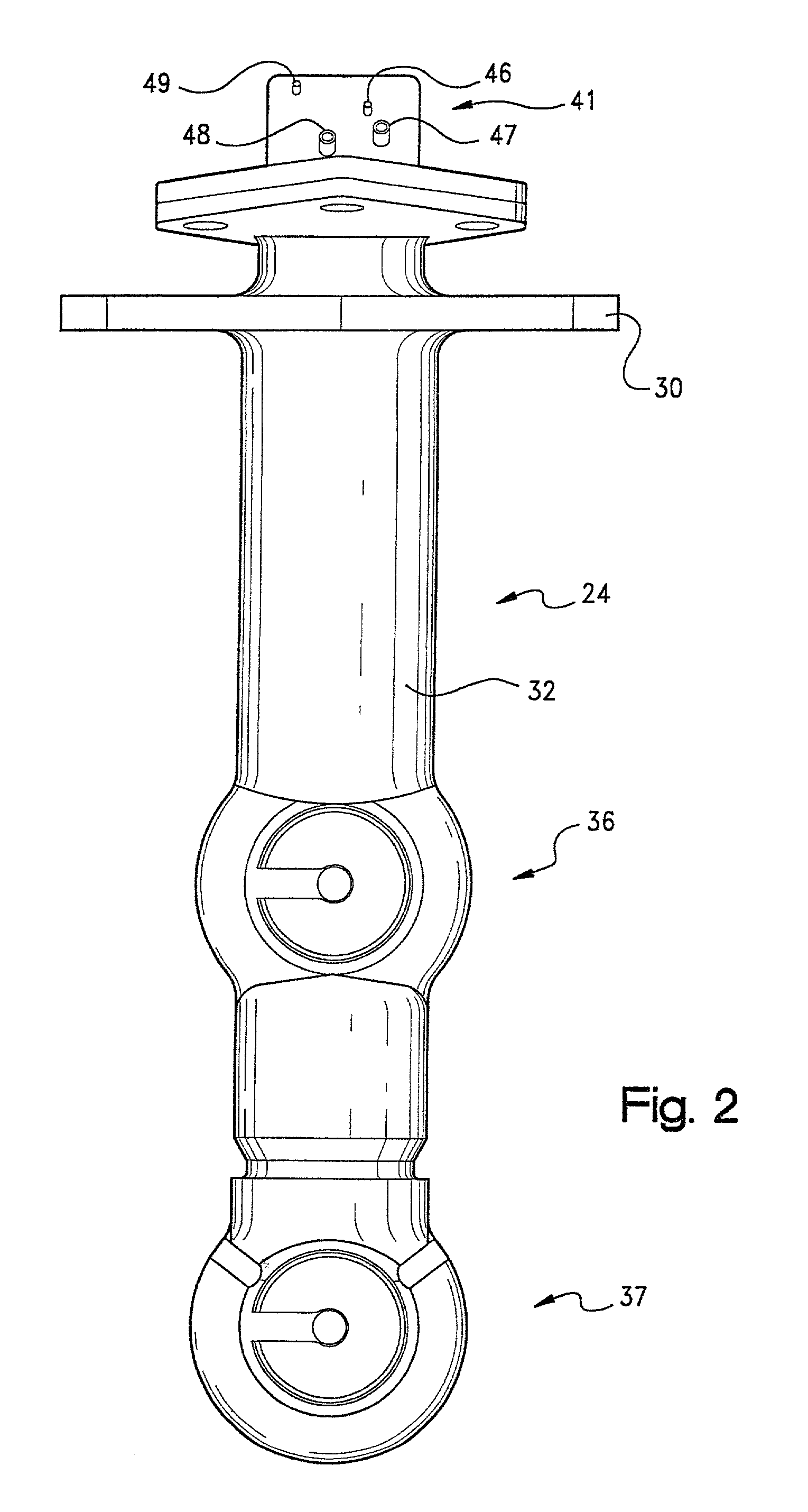

Unitary conduit for transporting fluids

Owner:GENERAL ELECTRIC CO

Method of repairing a fuel nozzle

A method of repairing a fuel nozzle is disclosed comprising the steps of forming a pilot assembly; installing into a repair bore; inserting a primary adaptor into a repair bore such that the primary adaptor is in flow communication with a pilot flow passage and the pilot assembly; and coupling the primary adaptor to a distributor and the new pilot assembly.

Owner:GENERAL ELECTRIC CO

Method of manufacturing a unitary conduit for transporting fluids

A method for fabricating a unitary conduit is disclosed the method comprising the steps of determining three-dimensional information of the unitary conduit having at least one flow passage, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary conduit, and successively forming each layer of the unitary conduit by fusing a metallic powder using laser energy. A unitary conduit is disclosed, comprising a body and a flow passage, wherein the flow passage and the body have a unitary construction, and made by using a rapid manufacturing process.

Owner:GENERAL ELECTRIC CO

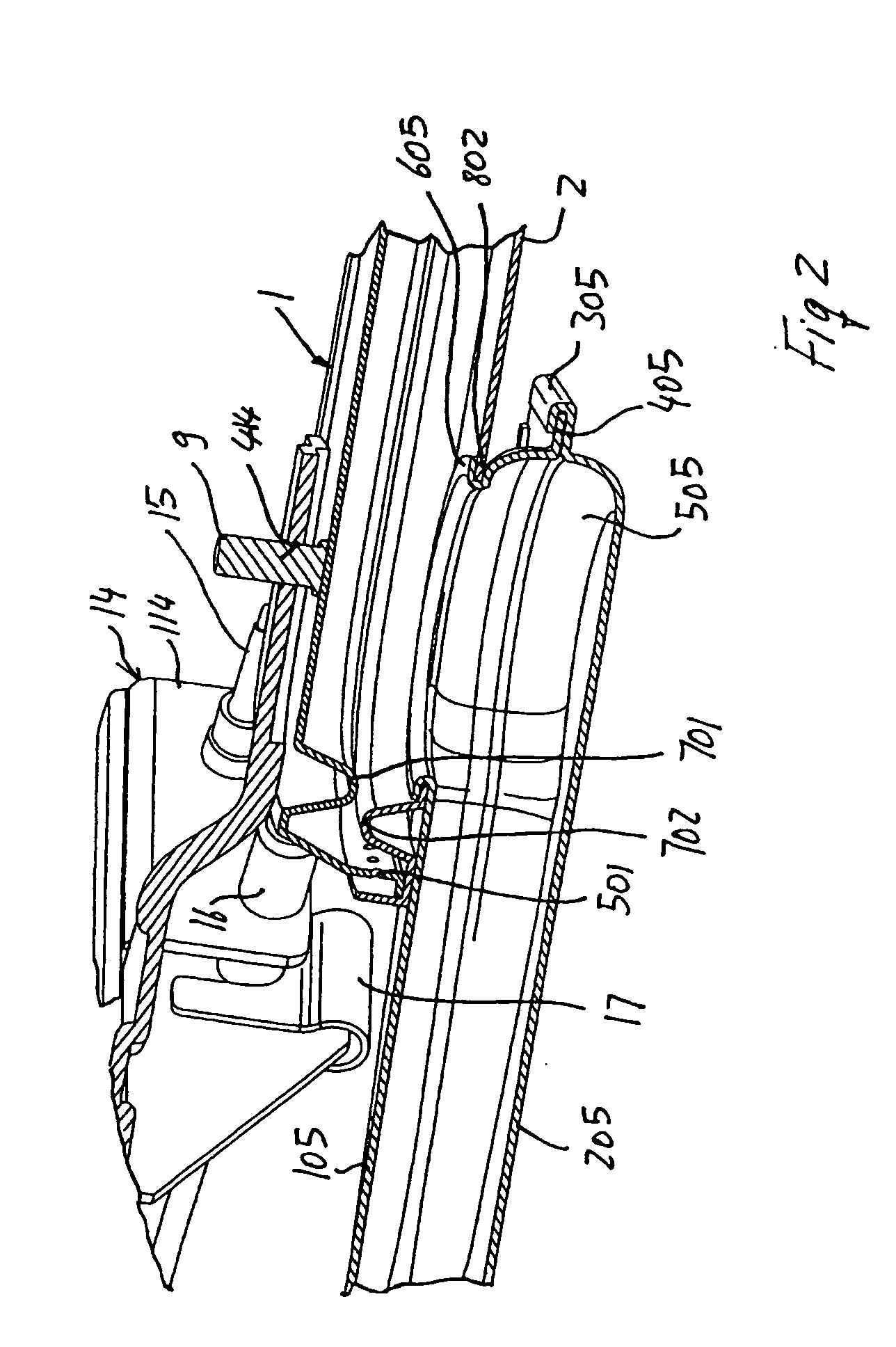

Oven or grill burner, venturi tube, mounting for a thermocouple and/or an igniter, and process for fabricating said burner

ActiveUS20050138789A1Function increaseStrong construction adaptabilityDomestic stoves or rangesBurner manufactureCombustorCoupling

The invention relates to a burner comprising two half shells, one of which is perforated, that are tightly joined together along at least a portion of their edges, so as to form a tubular body communicating with a venturi tube. At least two corresponding ends of the two half shells have a truncated profile, providing the tubular body has at least one truncated end. The invention also relates to a venturi tube for said burner that is composed of two half shells The invention further relates to a mounting for a thermocouple and for an igniter of said burner, the mounting having coupling means that cause mutual contact surfaces to be oriented in at least three non-parallel planes and that prevent mounting rotation, so that the position thereof is accurately defined. The invention also relates to a process for fabricating said burner.

Owner:CAST SPA

Method of manufacturing a fuel distributor

InactiveUS20090256003A1Liquid surface applicatorsTurbine/propulsion fuel flow conduitsDistributorLaser

A method for fabricating a unitary distributor is disclosed, the method comprising the steps of determining three-dimensional information of the unitary distributor having at least one flow passage having an arcuate portion located within a distributor ring body having an axis, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary distributor and successively forming each layer of the unitary distributor by fusing a metallic powder using laser energy. A distributor is disclosed comprising a flow passage with an arcuate portion located in a distributor ring body wherein the distributor is made by using a rapid manufacturing process. A unitary fuel distributor comprising a fuel conduit and a distributor is disclosed wherein the unitary fuel distributor is made by using a rapid manufacturing process.

Owner:GENERAL ELECTRIC CO

Swirlers

Owner:GENERAL ELECTRIC CO

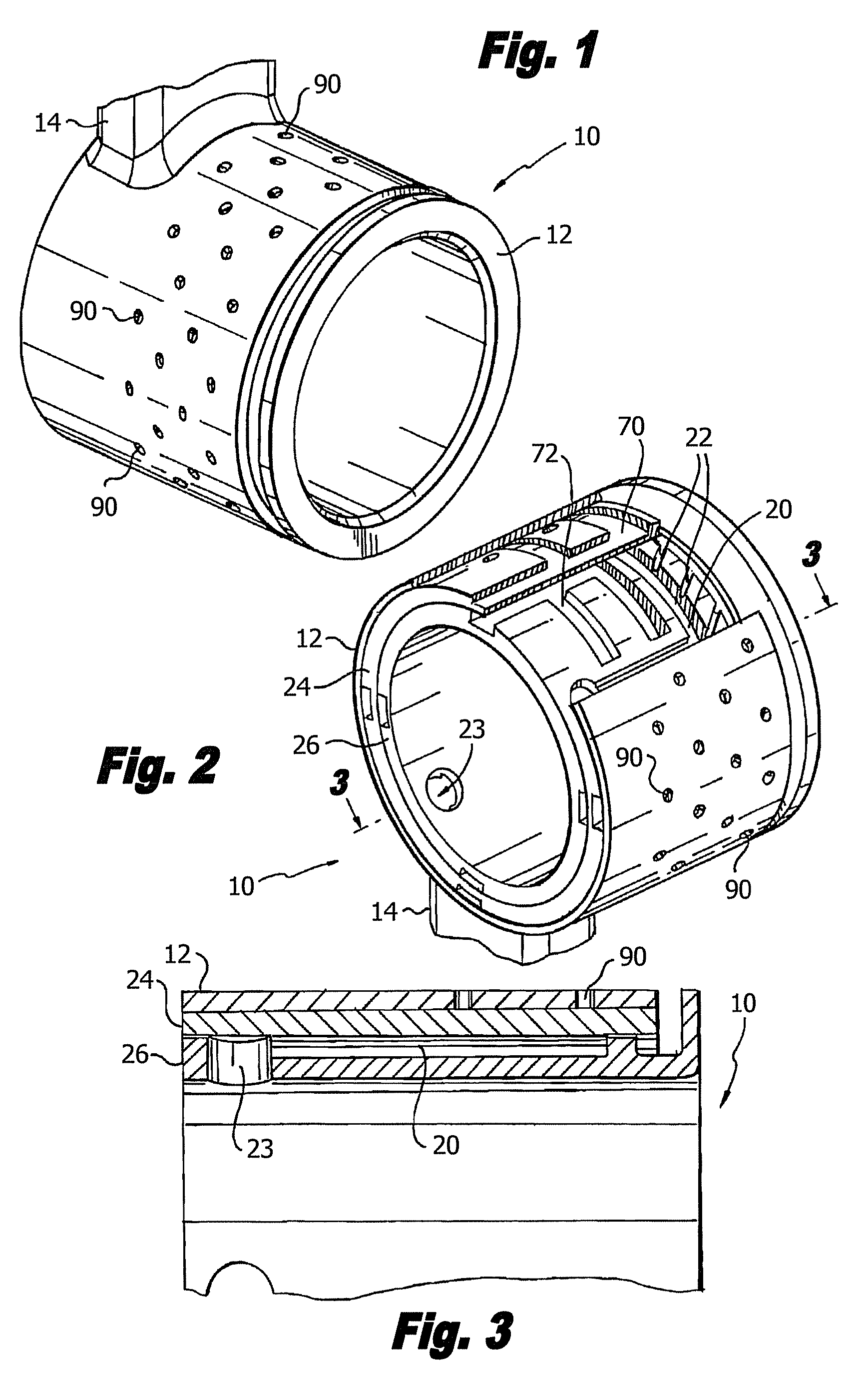

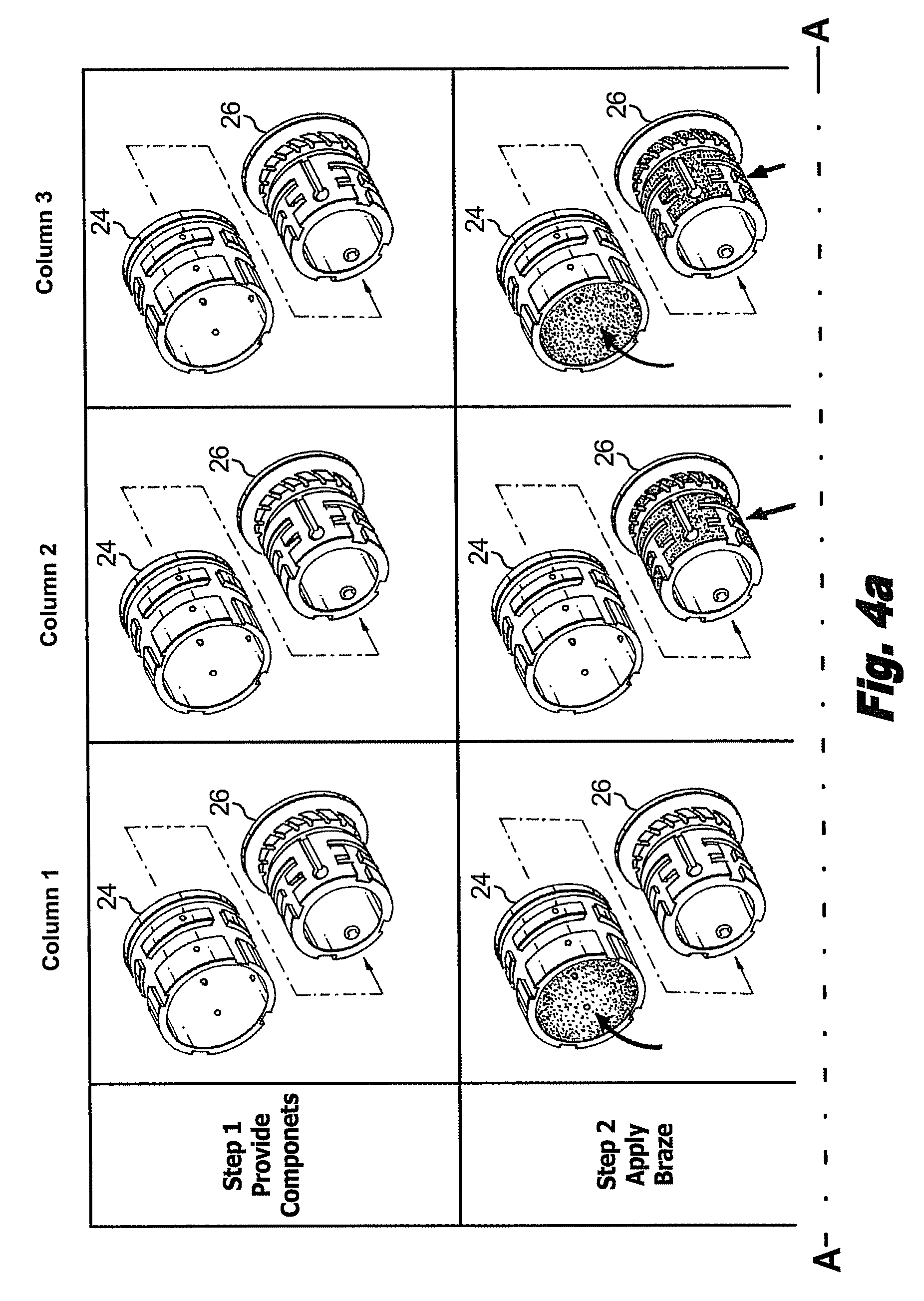

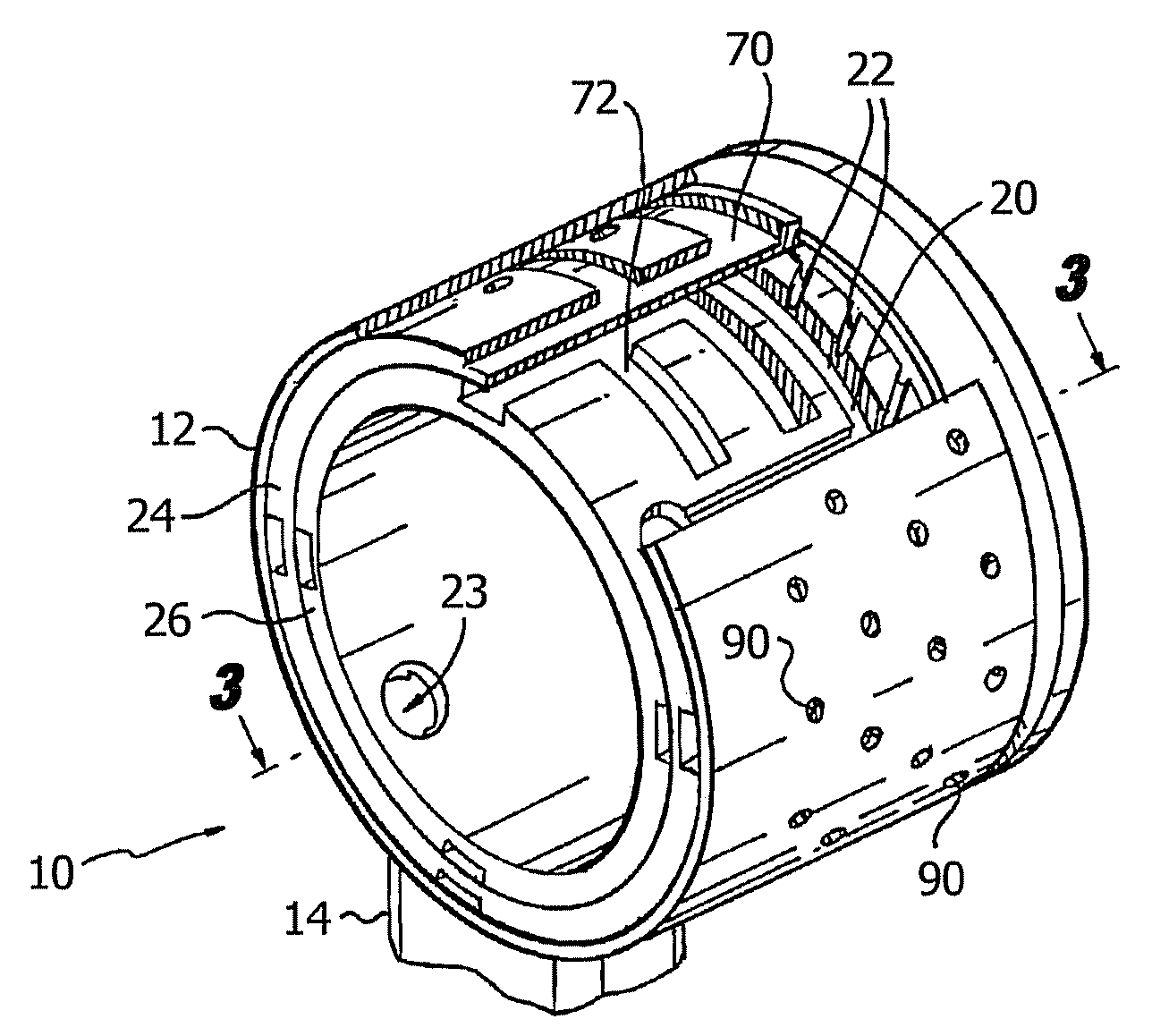

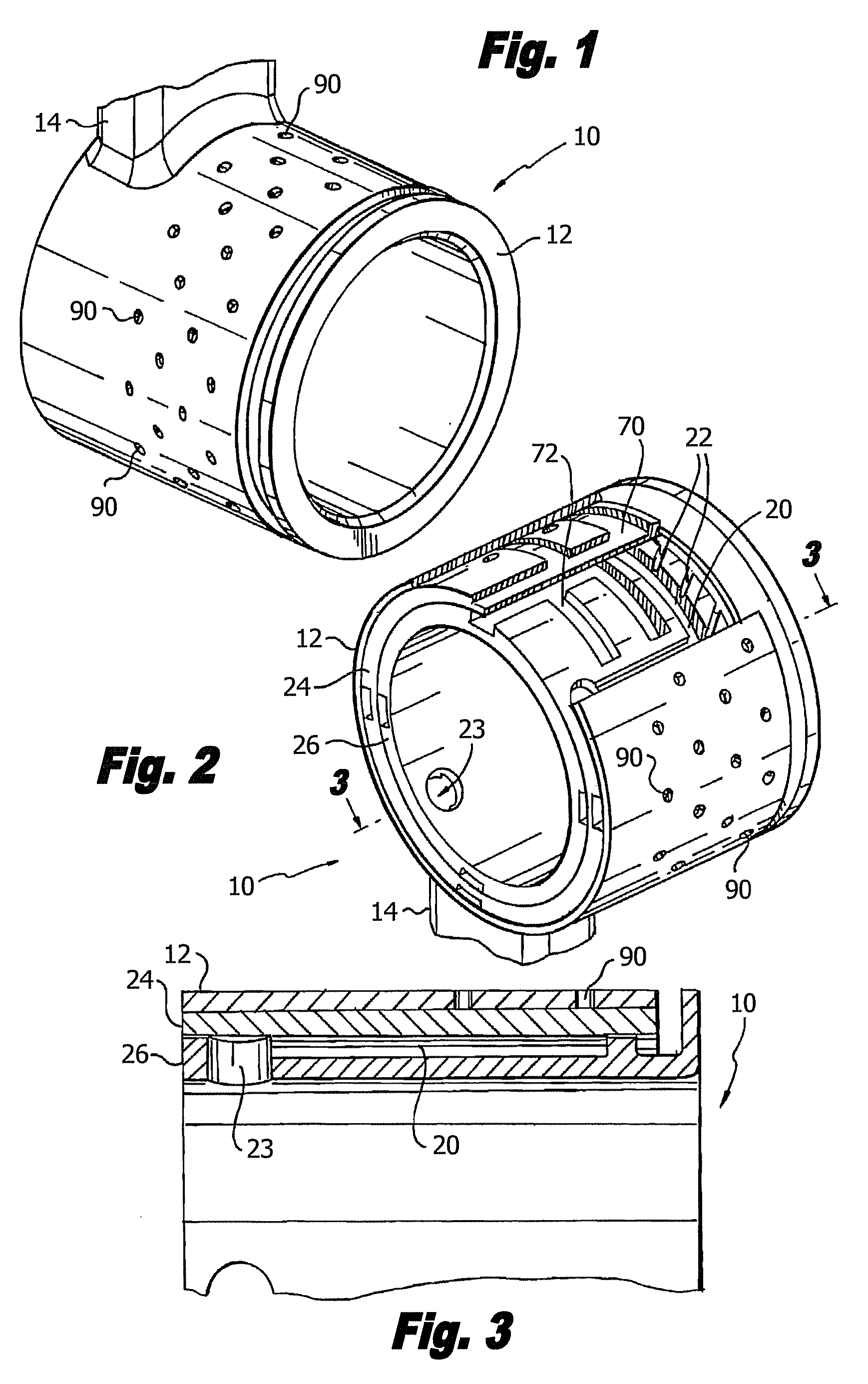

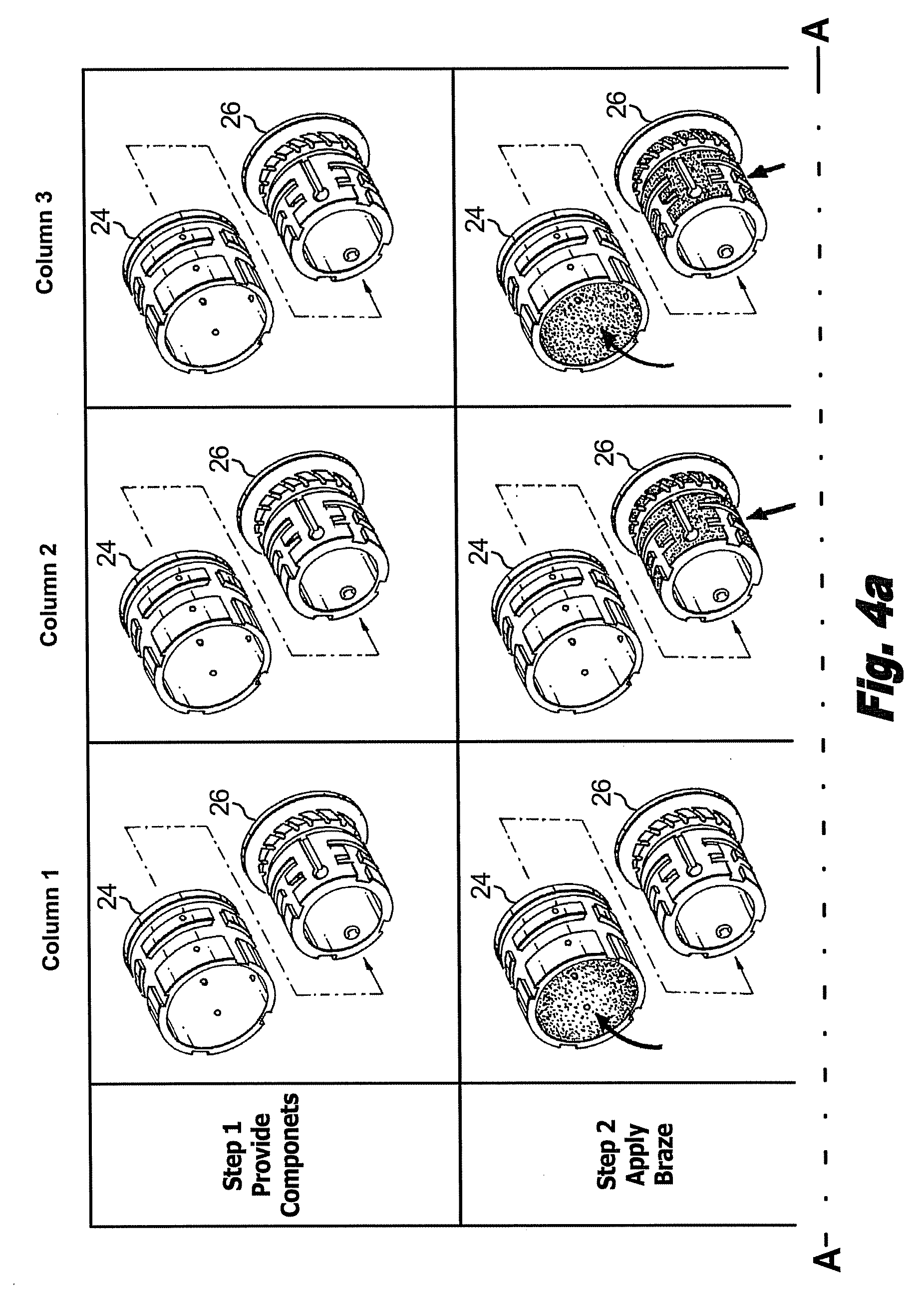

Method of fuel nozzle construction

ActiveUS7926178B2Inhibition formationValve arrangementsLiquid surface applicatorsInterference fitNozzle

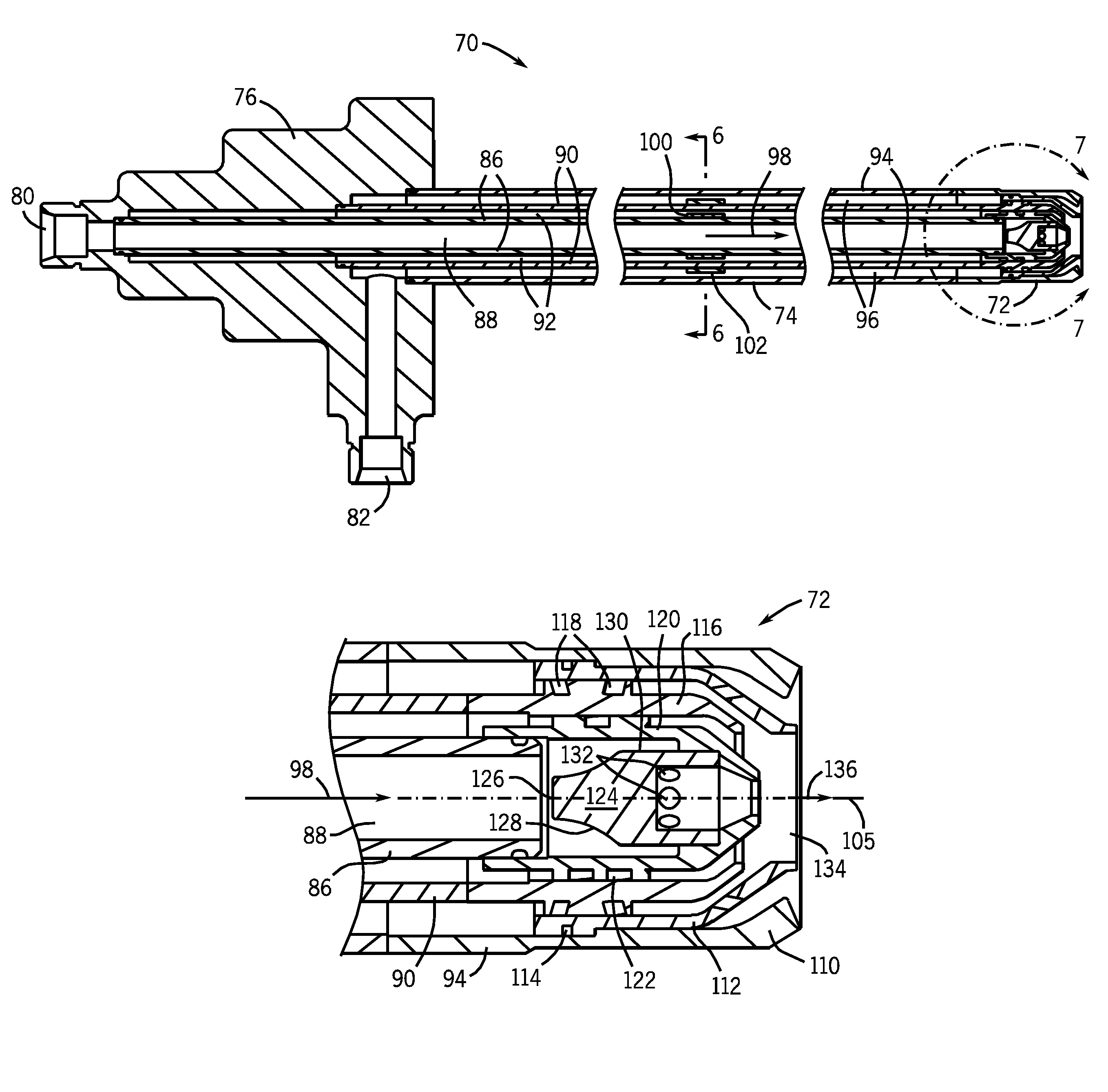

A method of assembling a fuel nozzle includes providing a first nozzle component and a second nozzle component, wherein the first nozzle component is configured and adapted to engage within the second nozzle component. Braze is applied to at least one of the first and second nozzle components. The first nozzle component is assembled into the second nozzle component to provide a diametral interference fit therebetween. The method further includes joining the first and second nozzle components together. A fuel nozzle includes a first cylindrical nozzle component, a second cylindrical nozzle component disposed with an interference fit on an outward surface of the first nozzle component, and a layer of braze joiningly disposed between the first and second nozzle components.

Owner:ROLLS ROYCE PLC

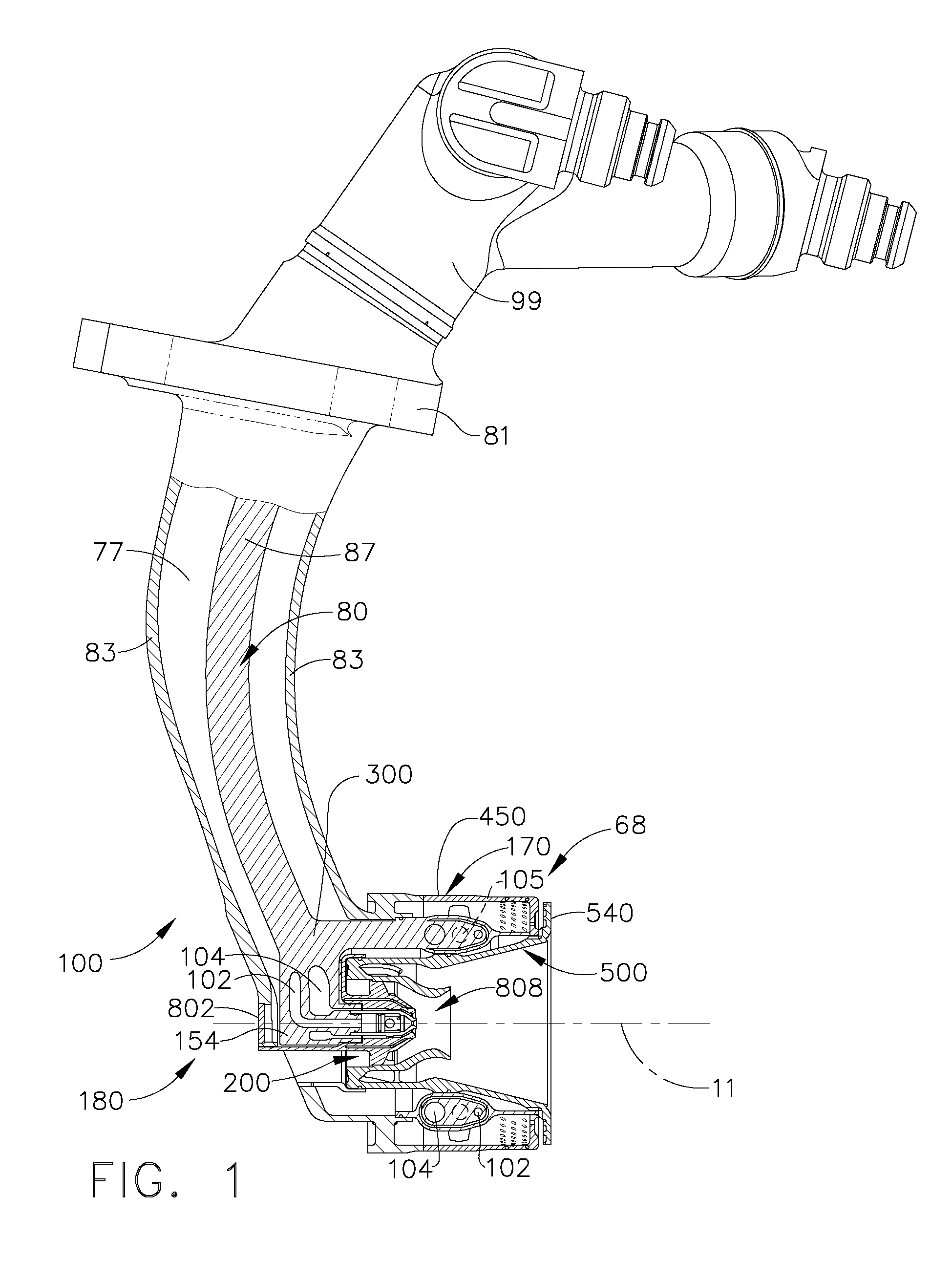

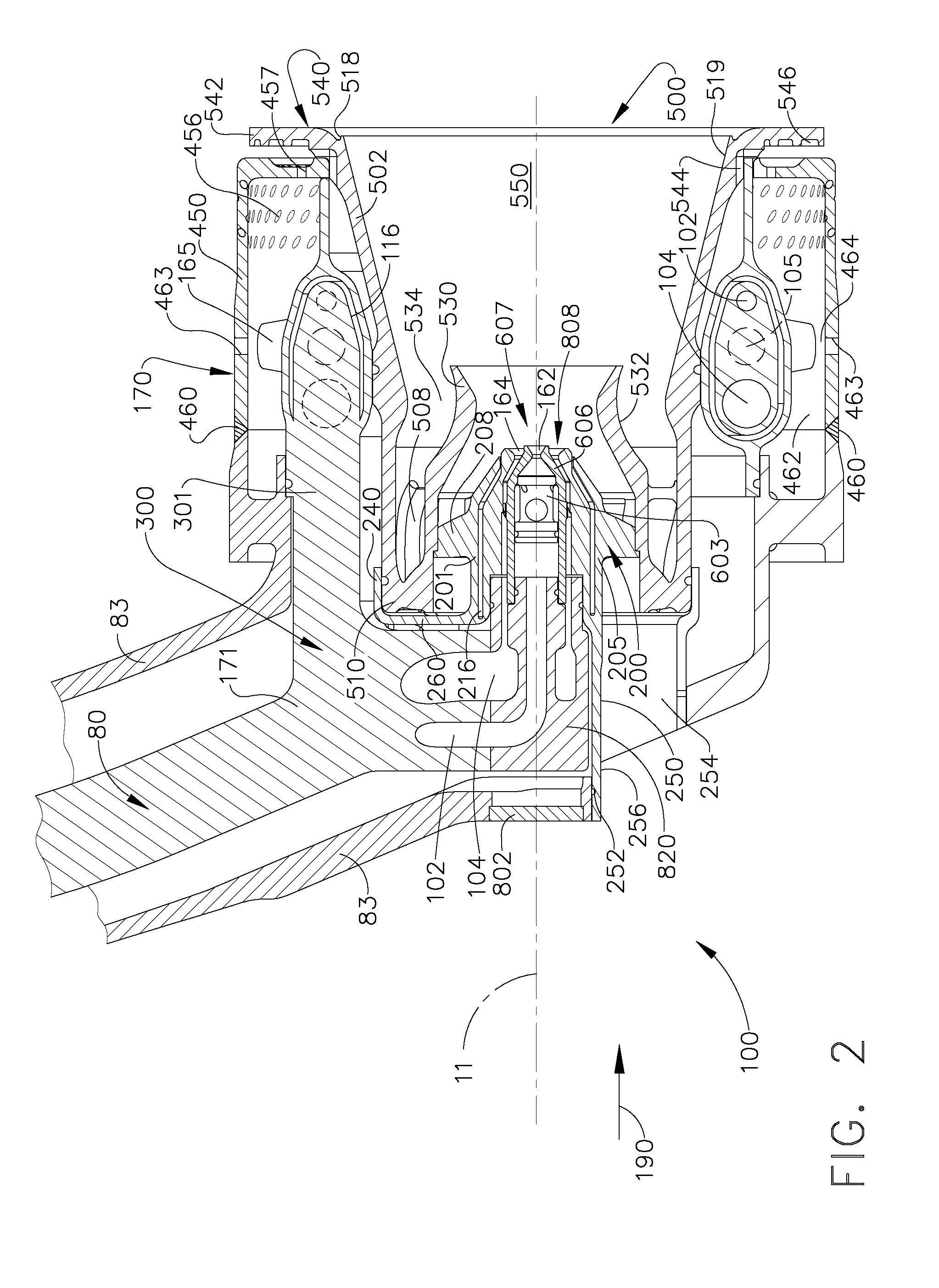

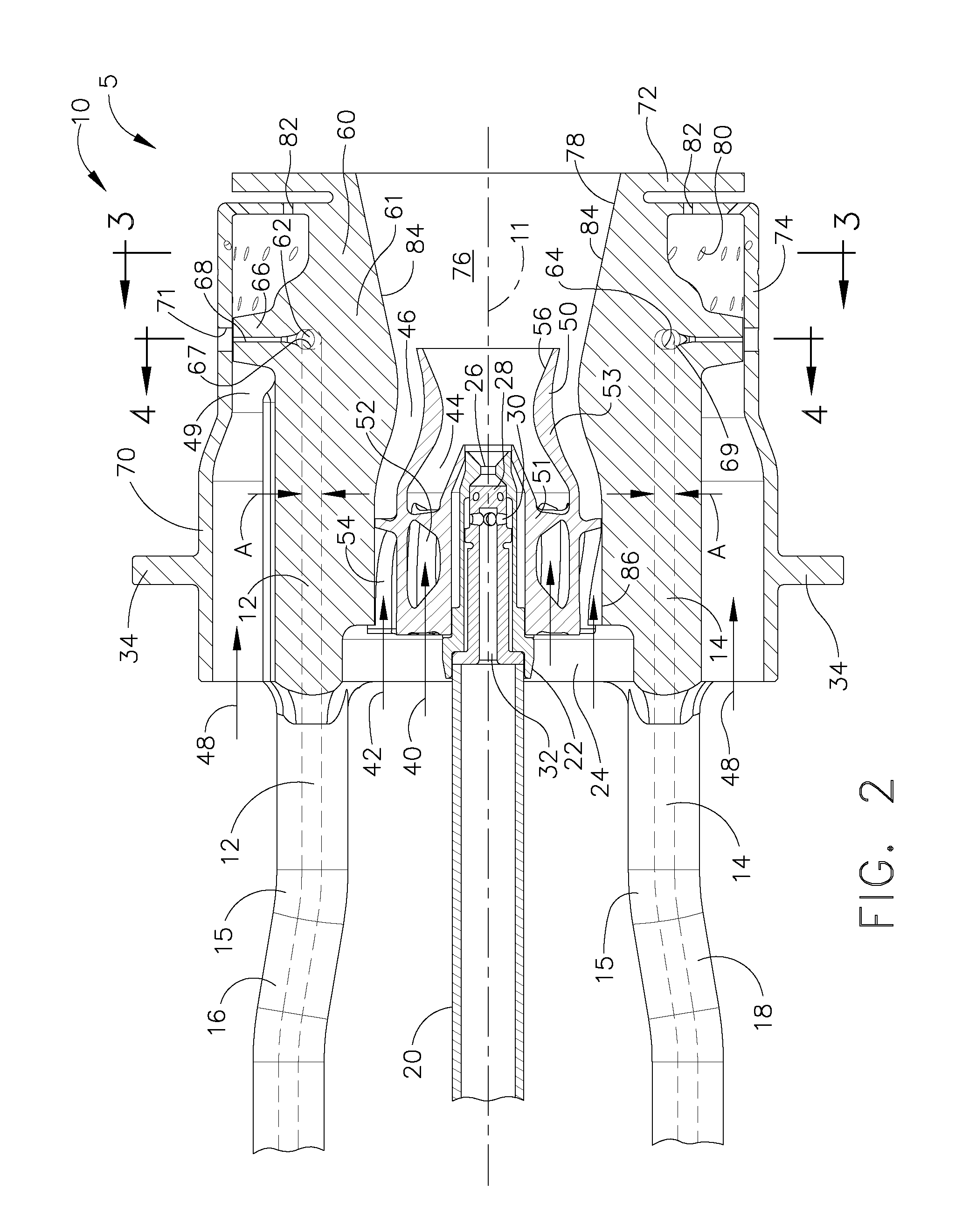

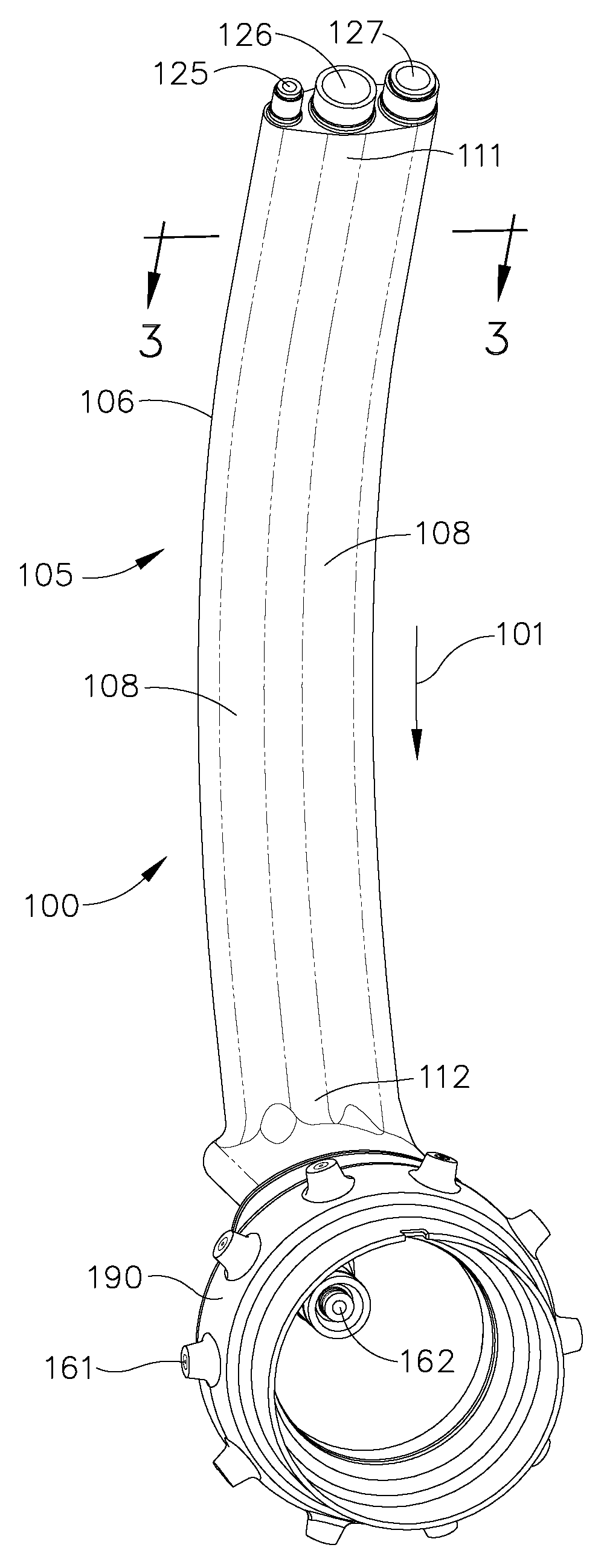

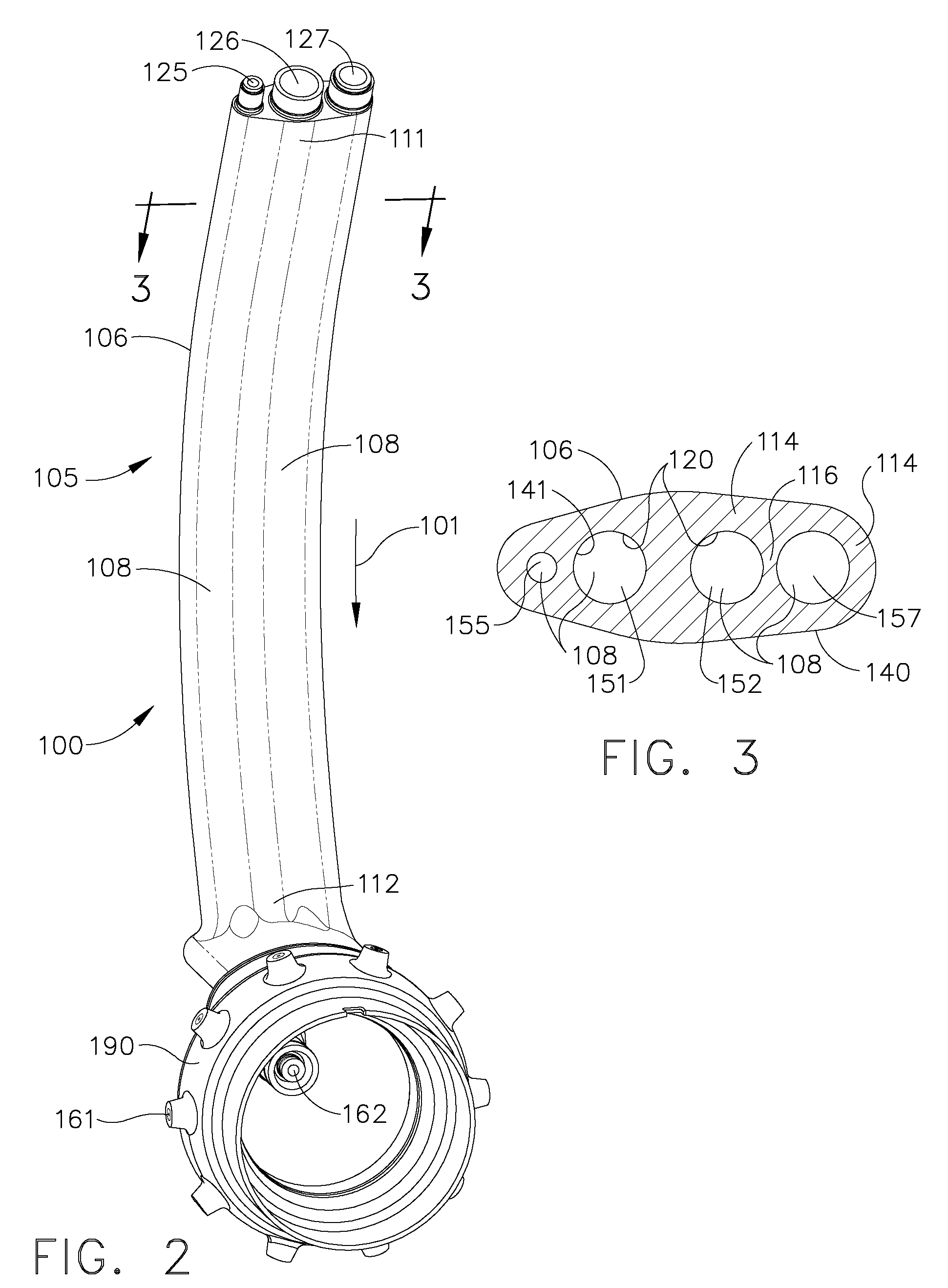

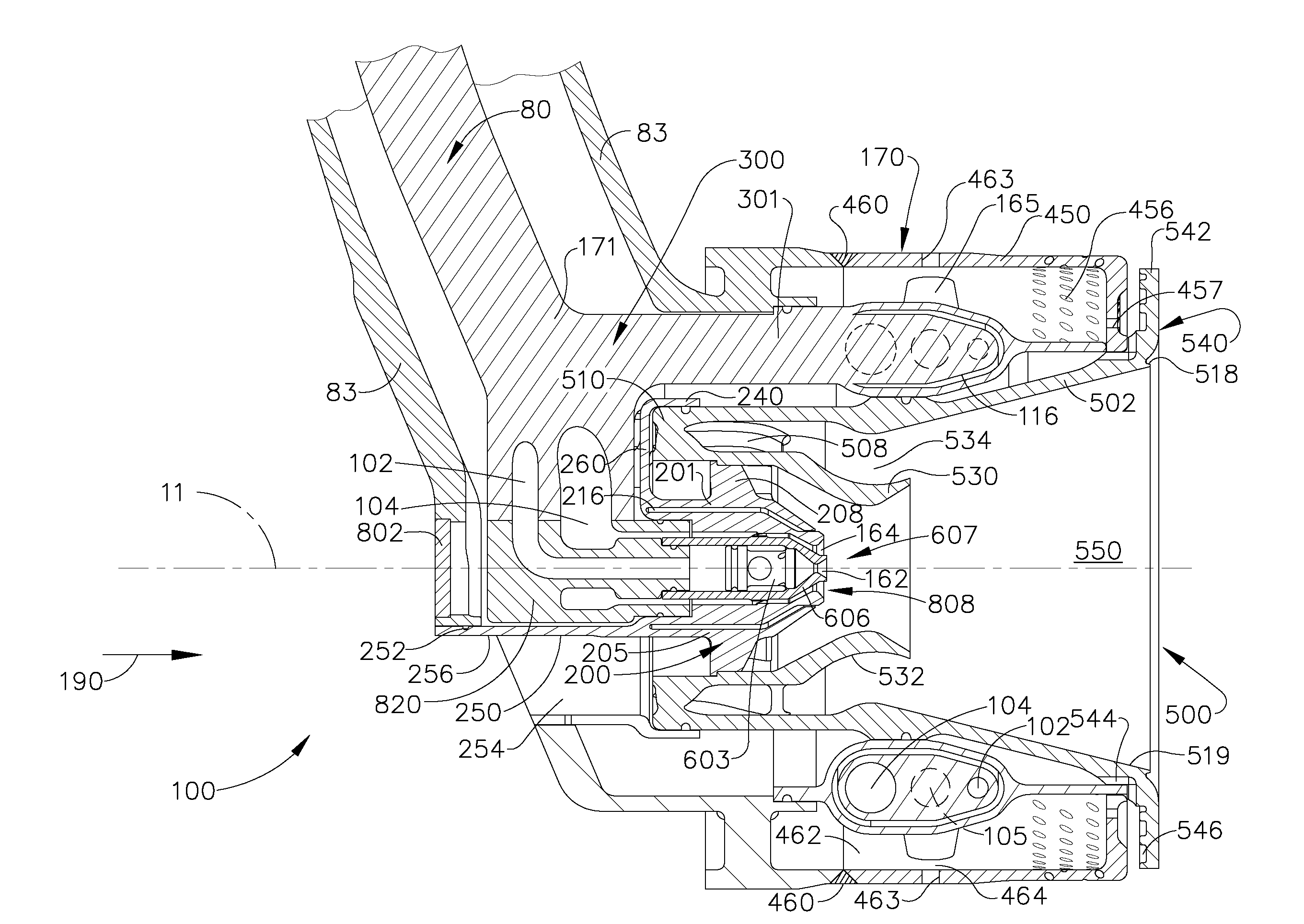

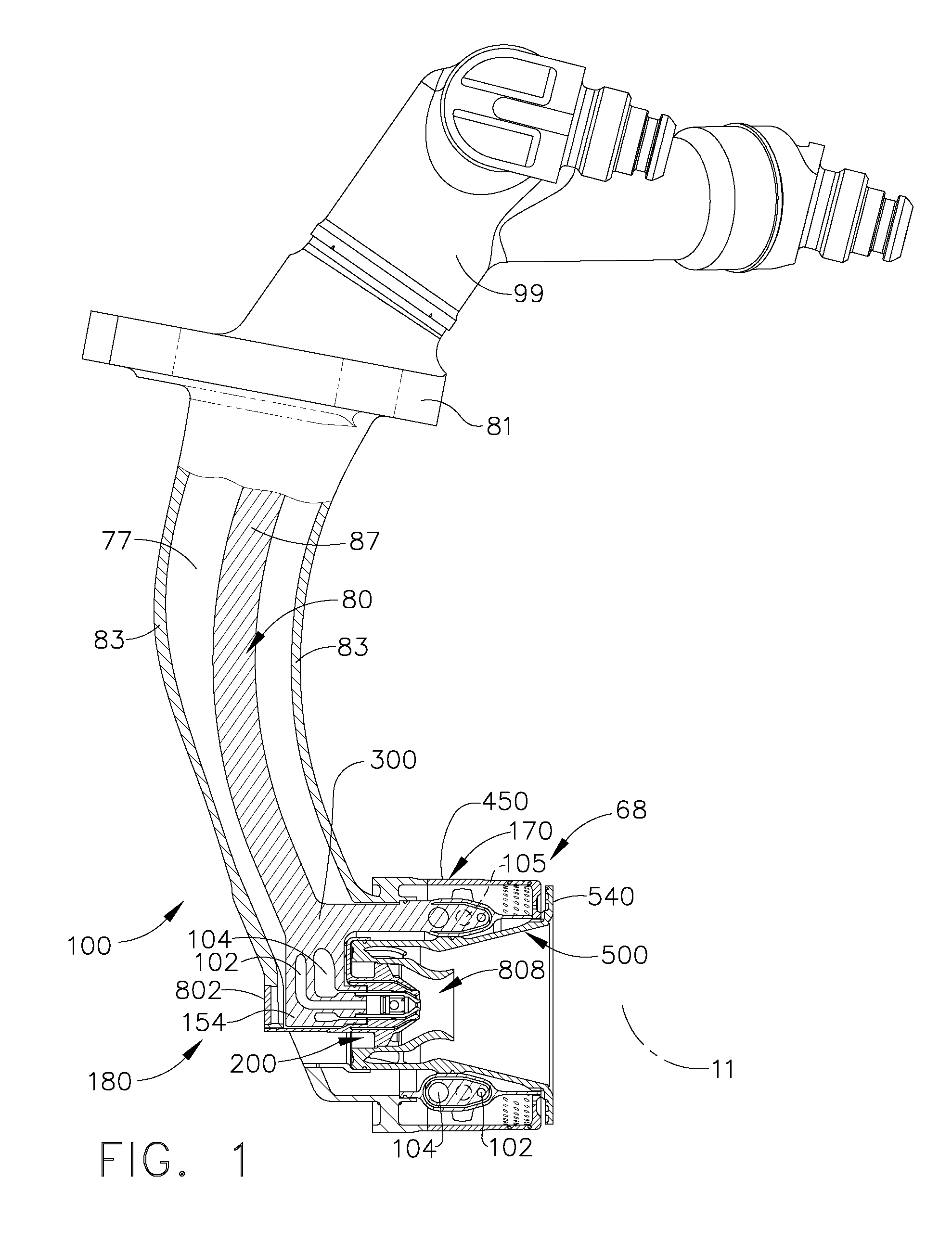

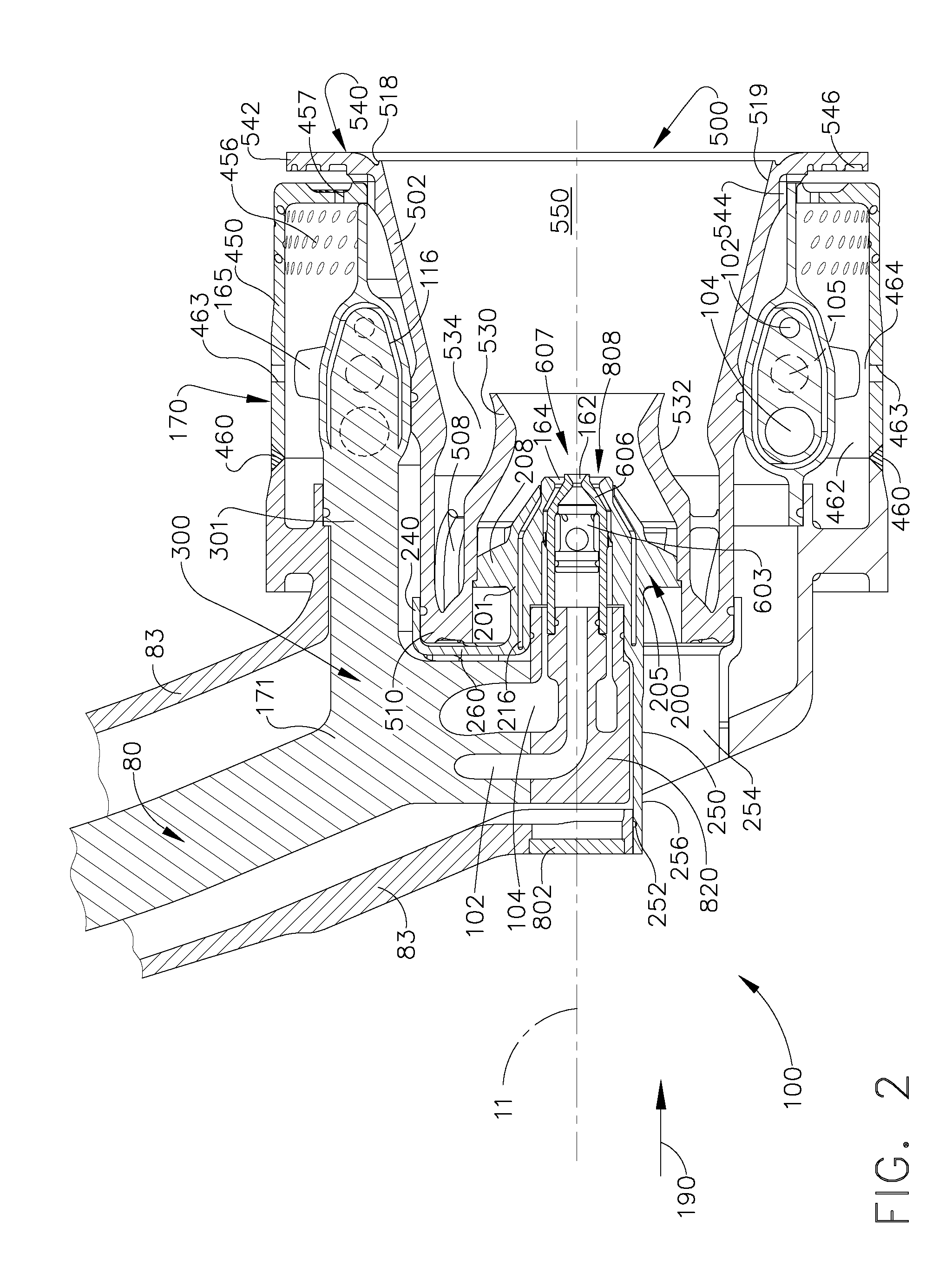

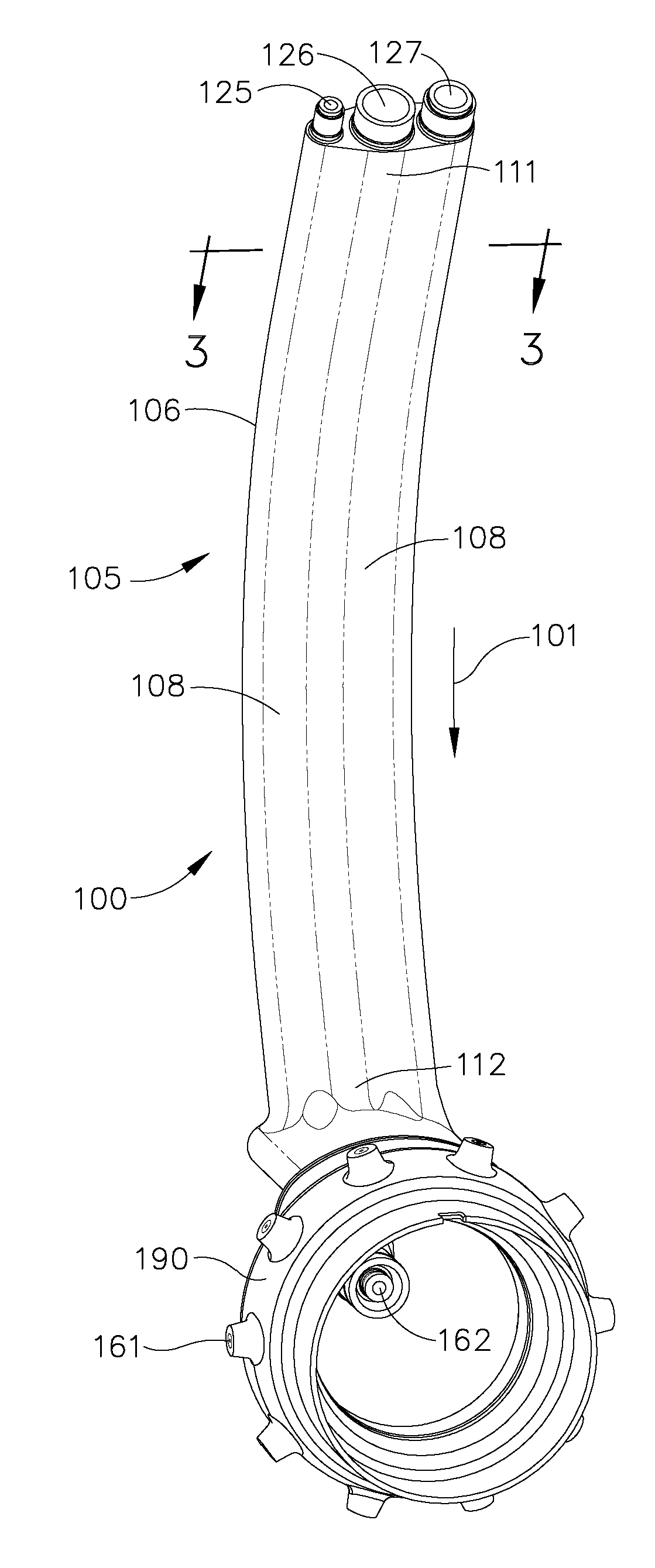

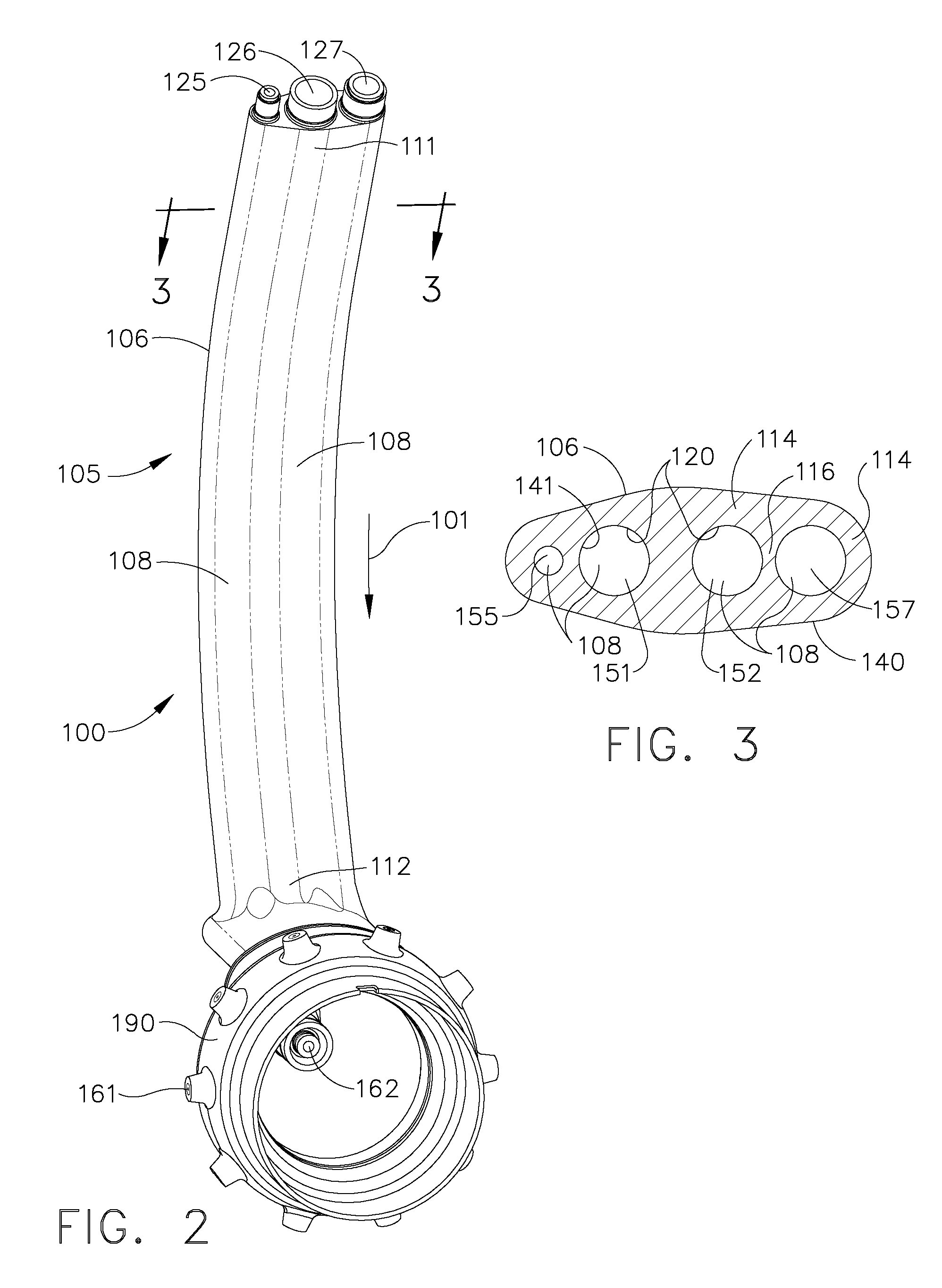

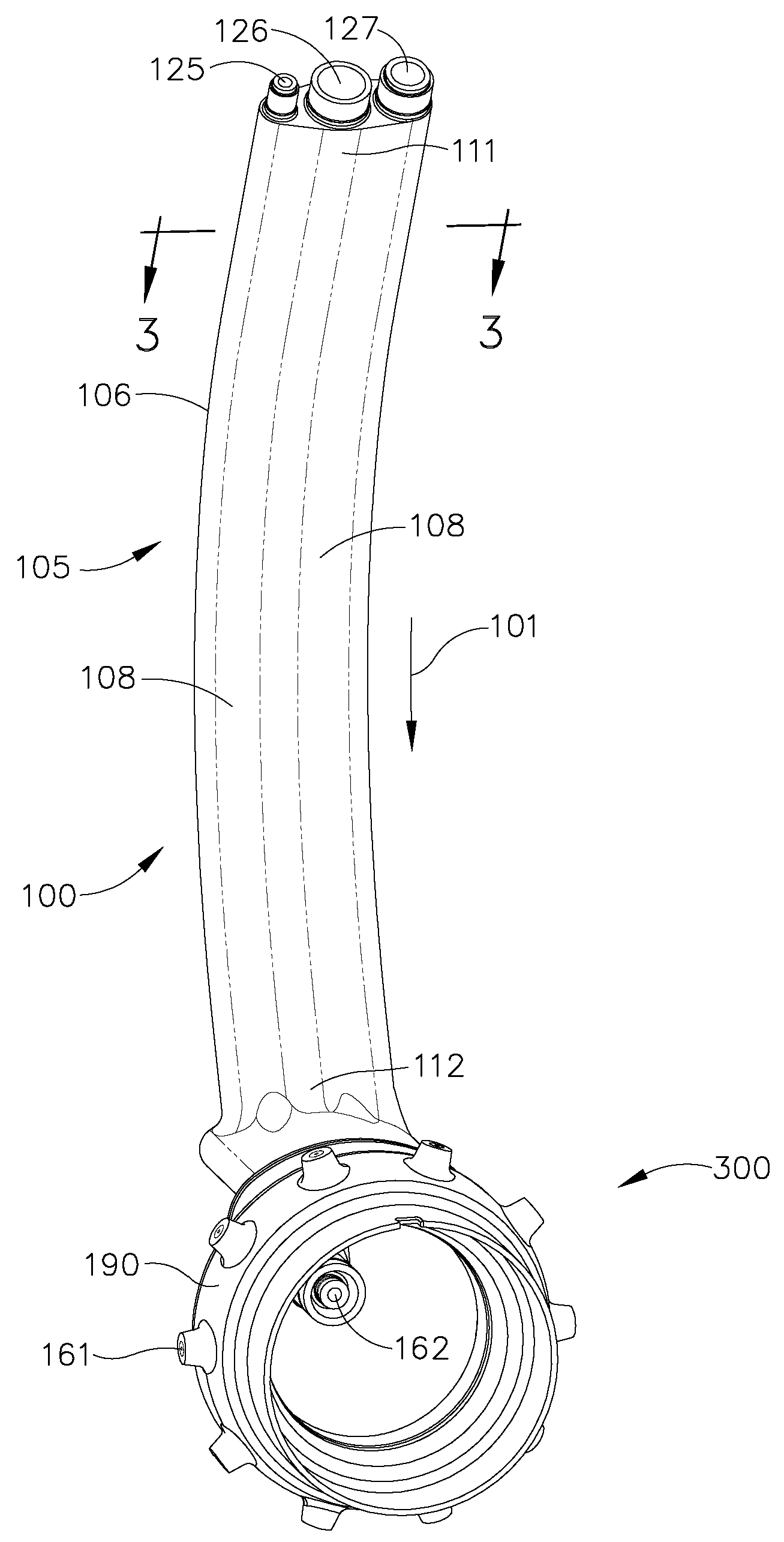

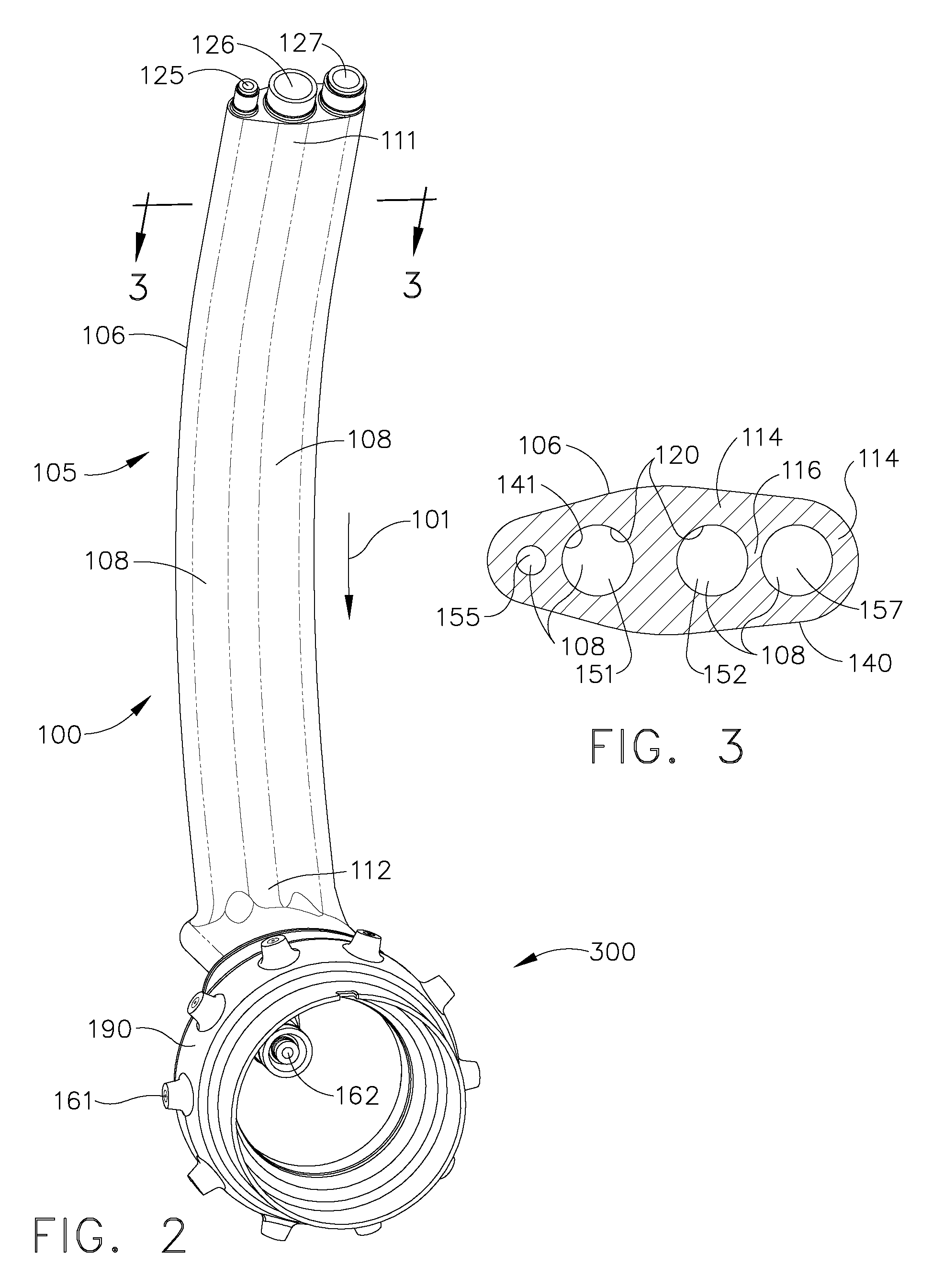

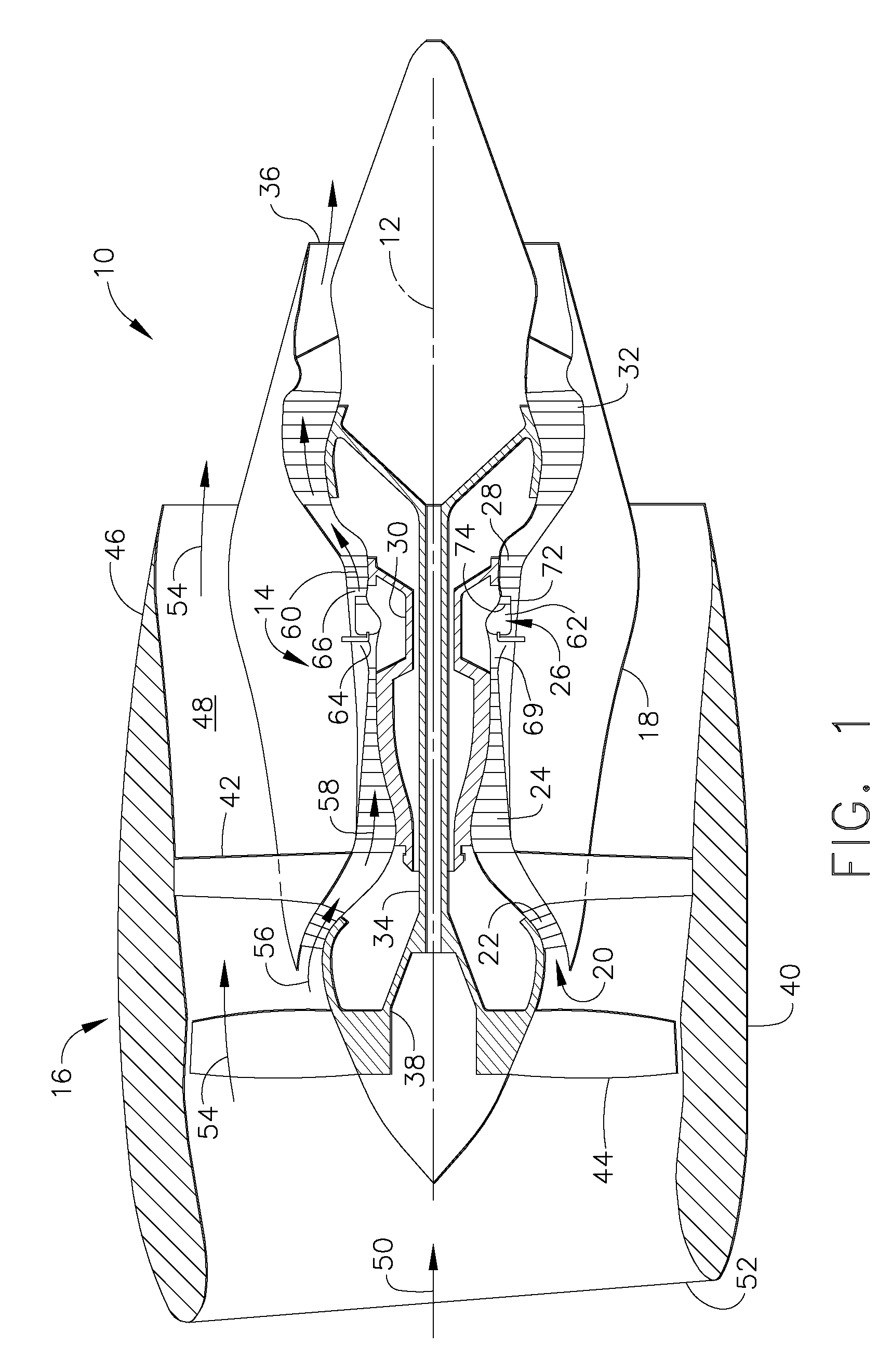

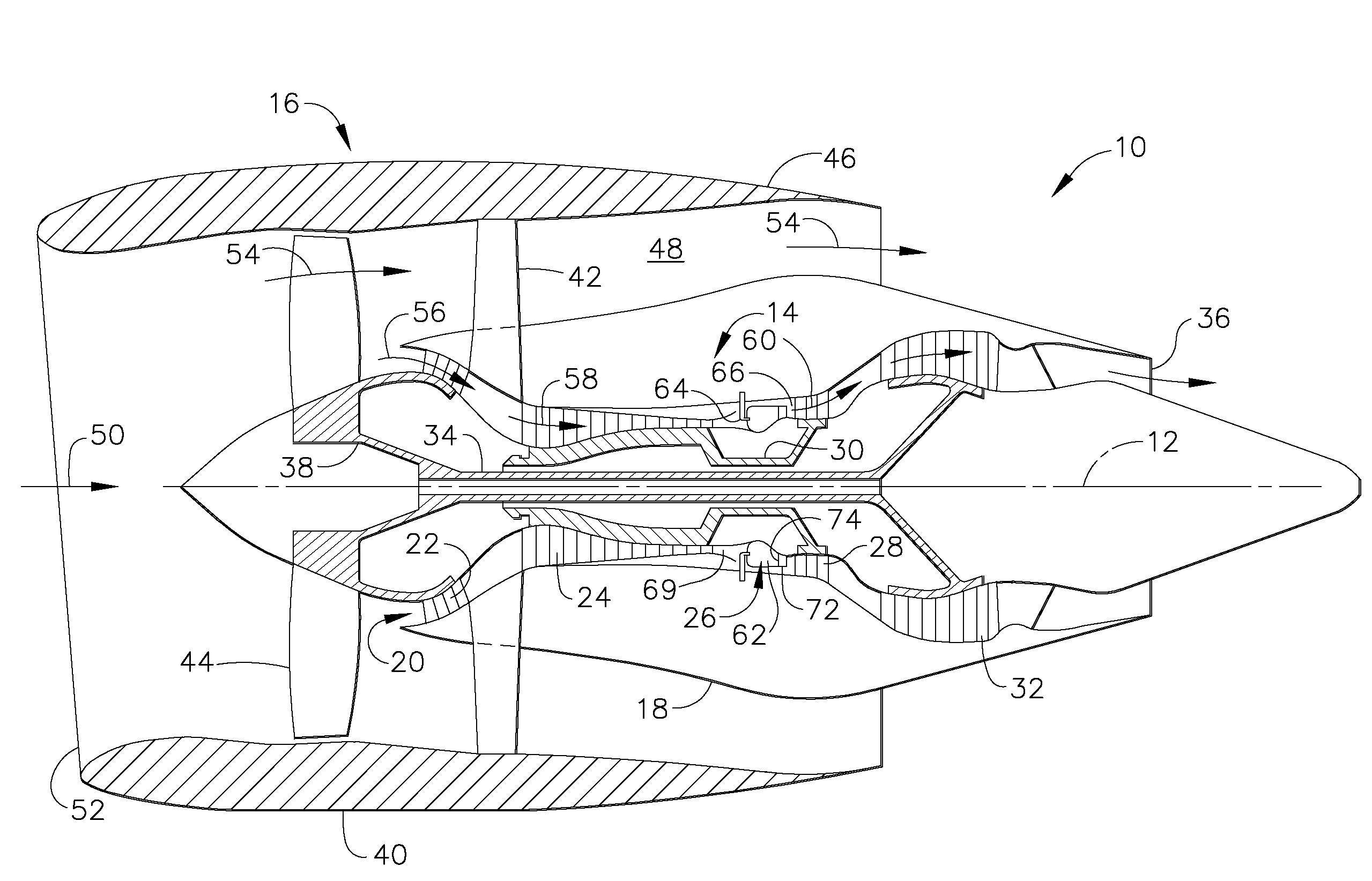

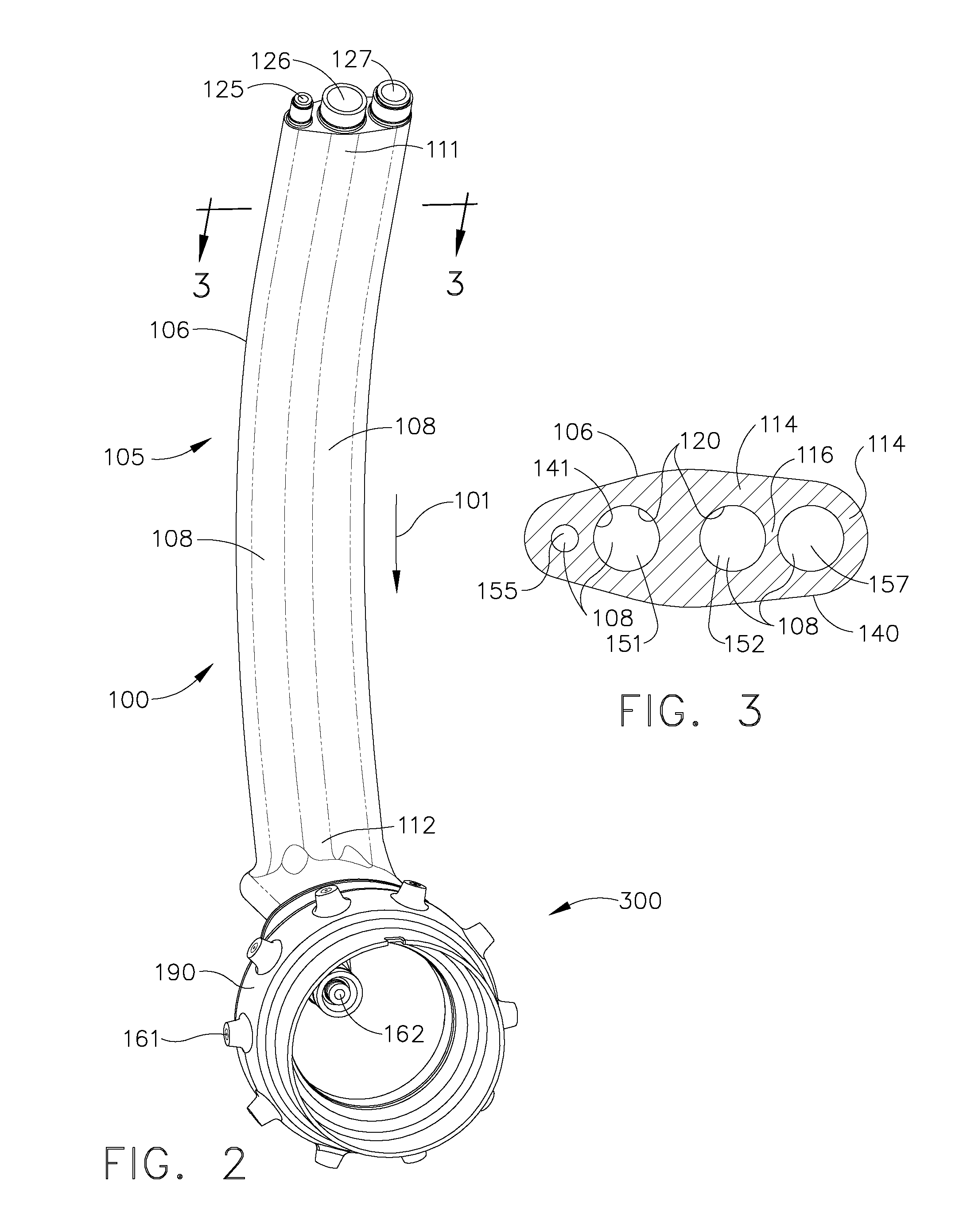

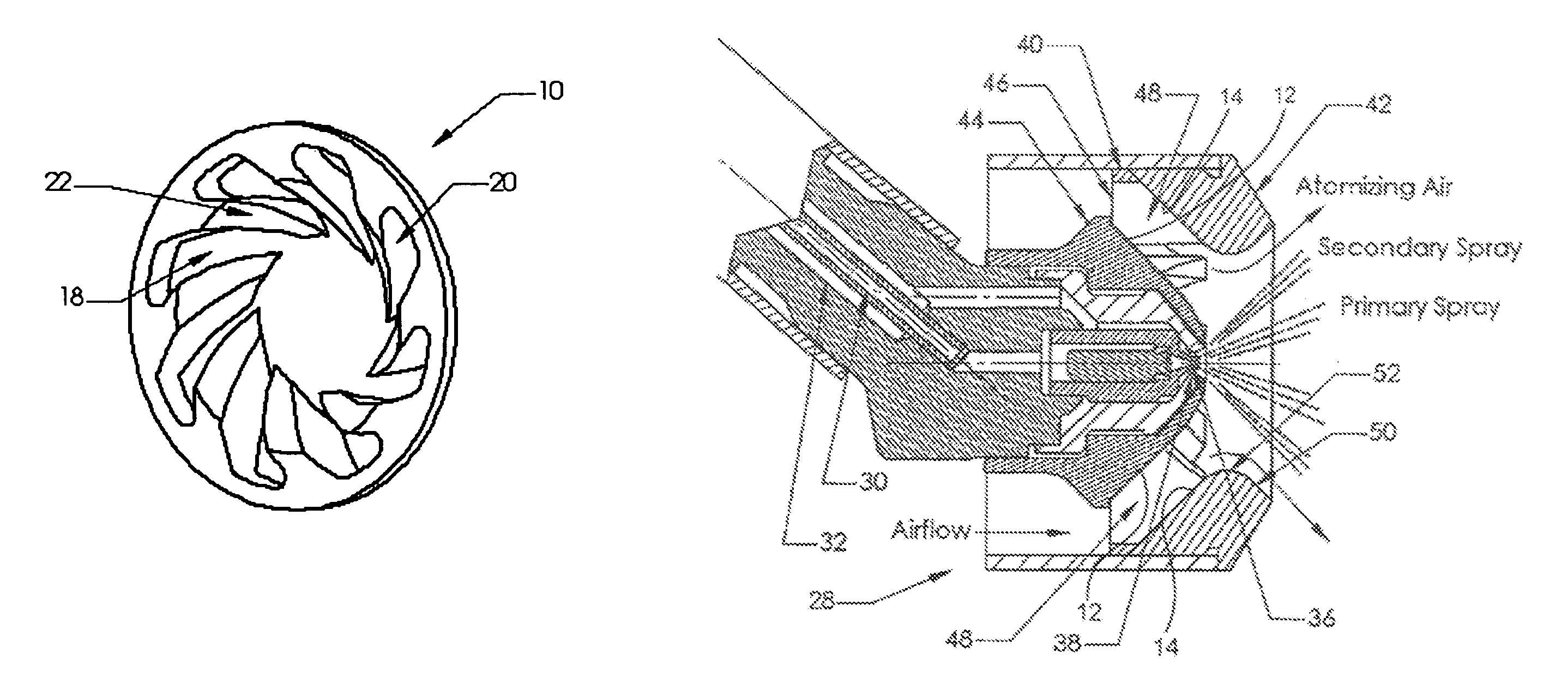

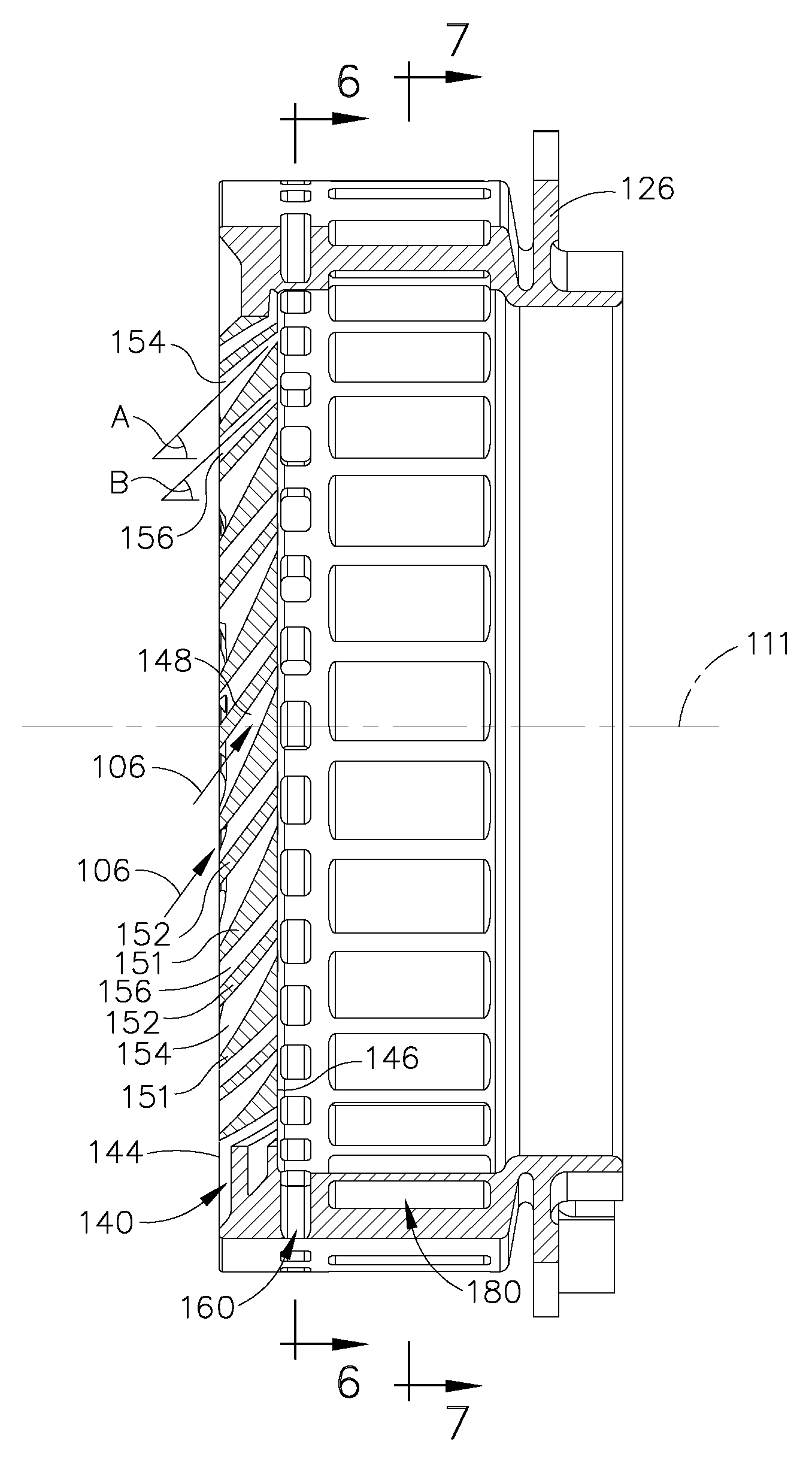

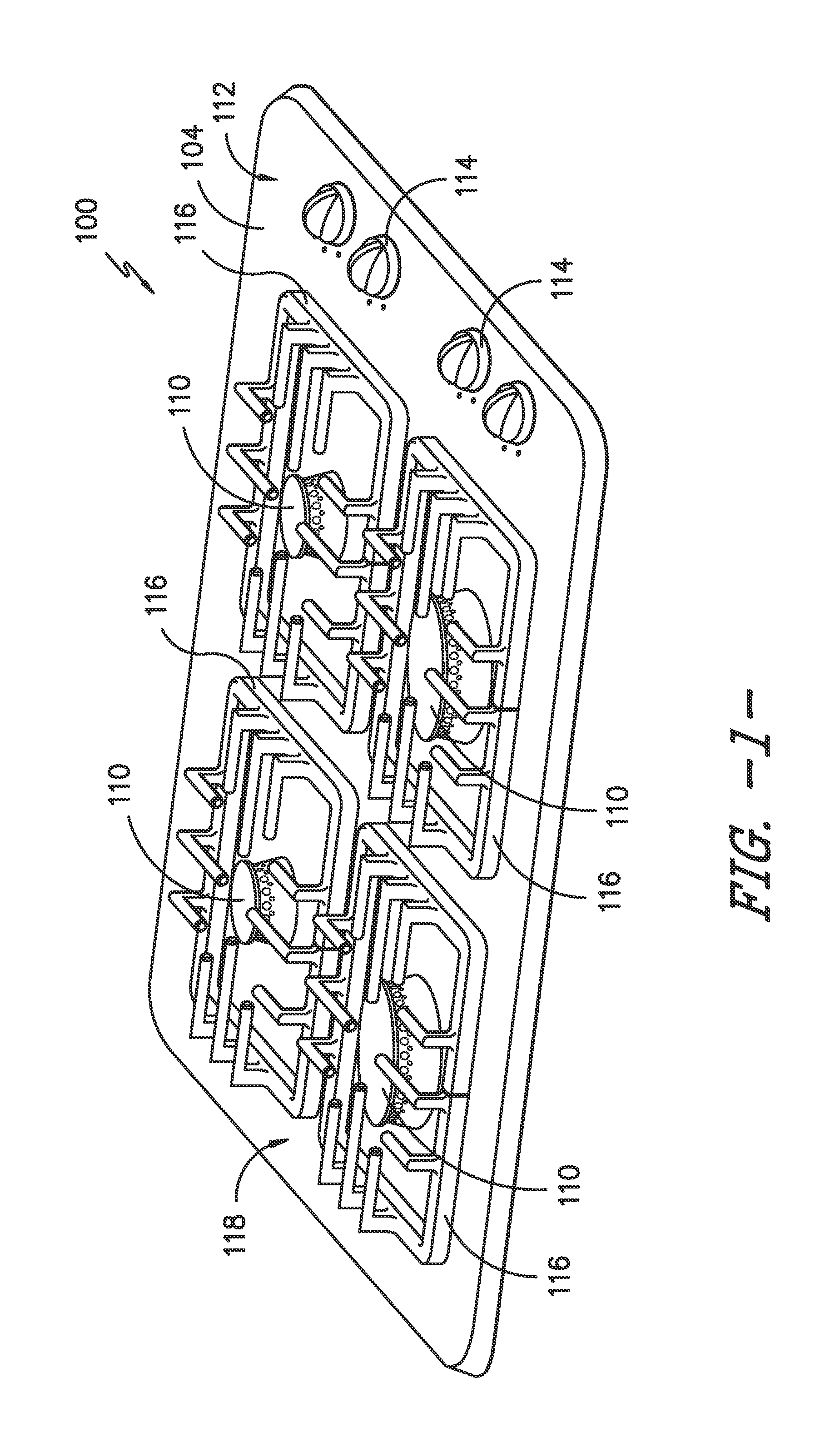

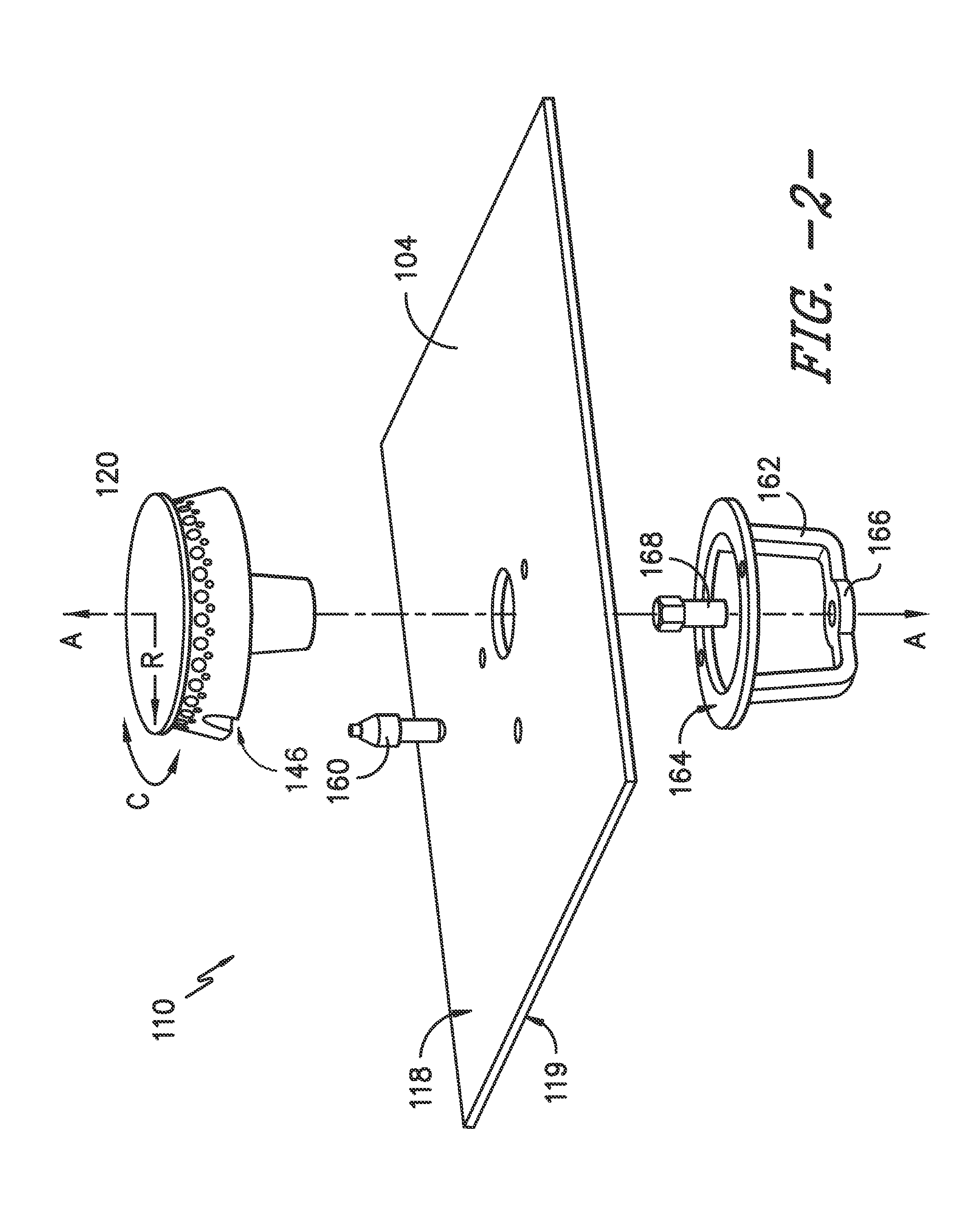

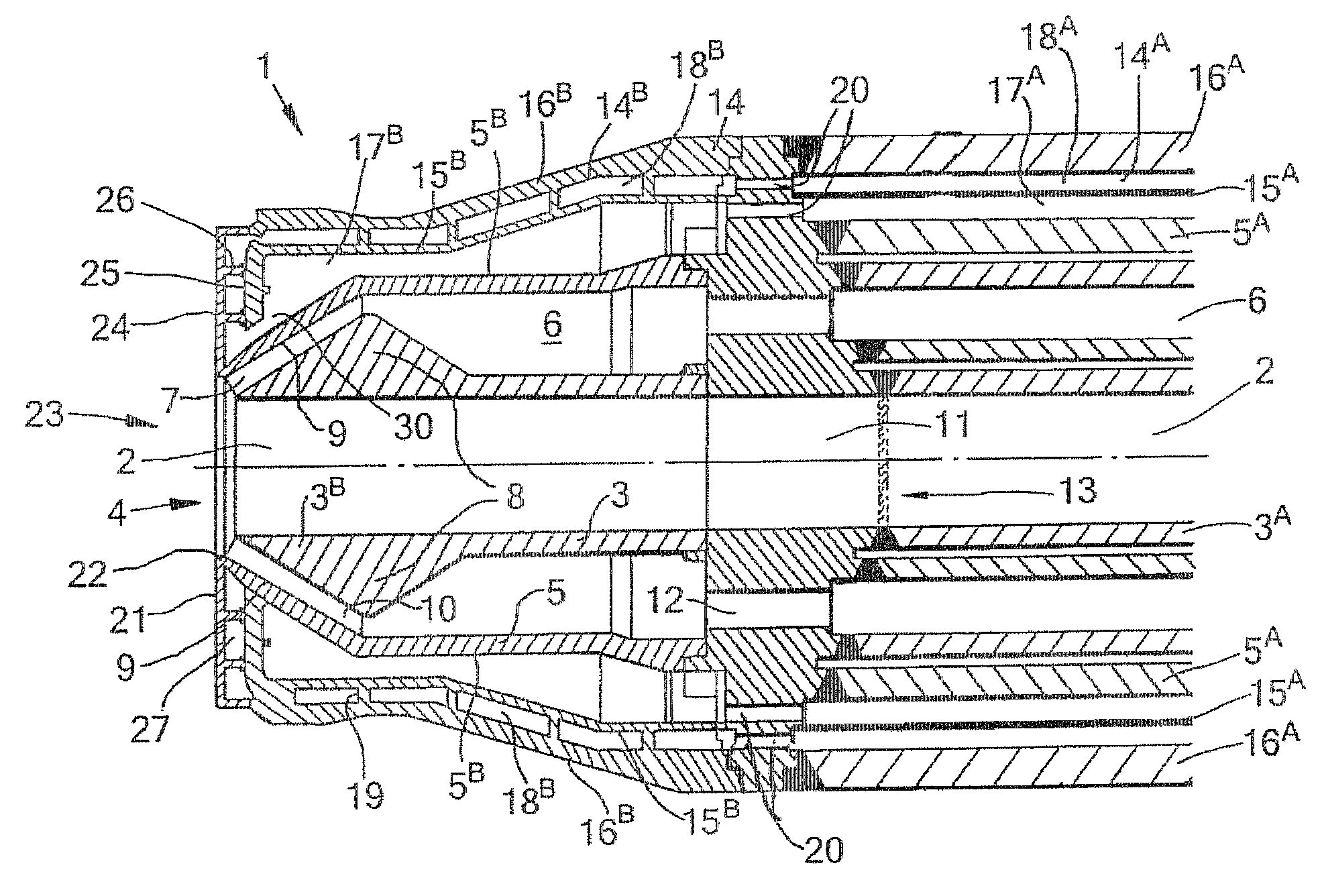

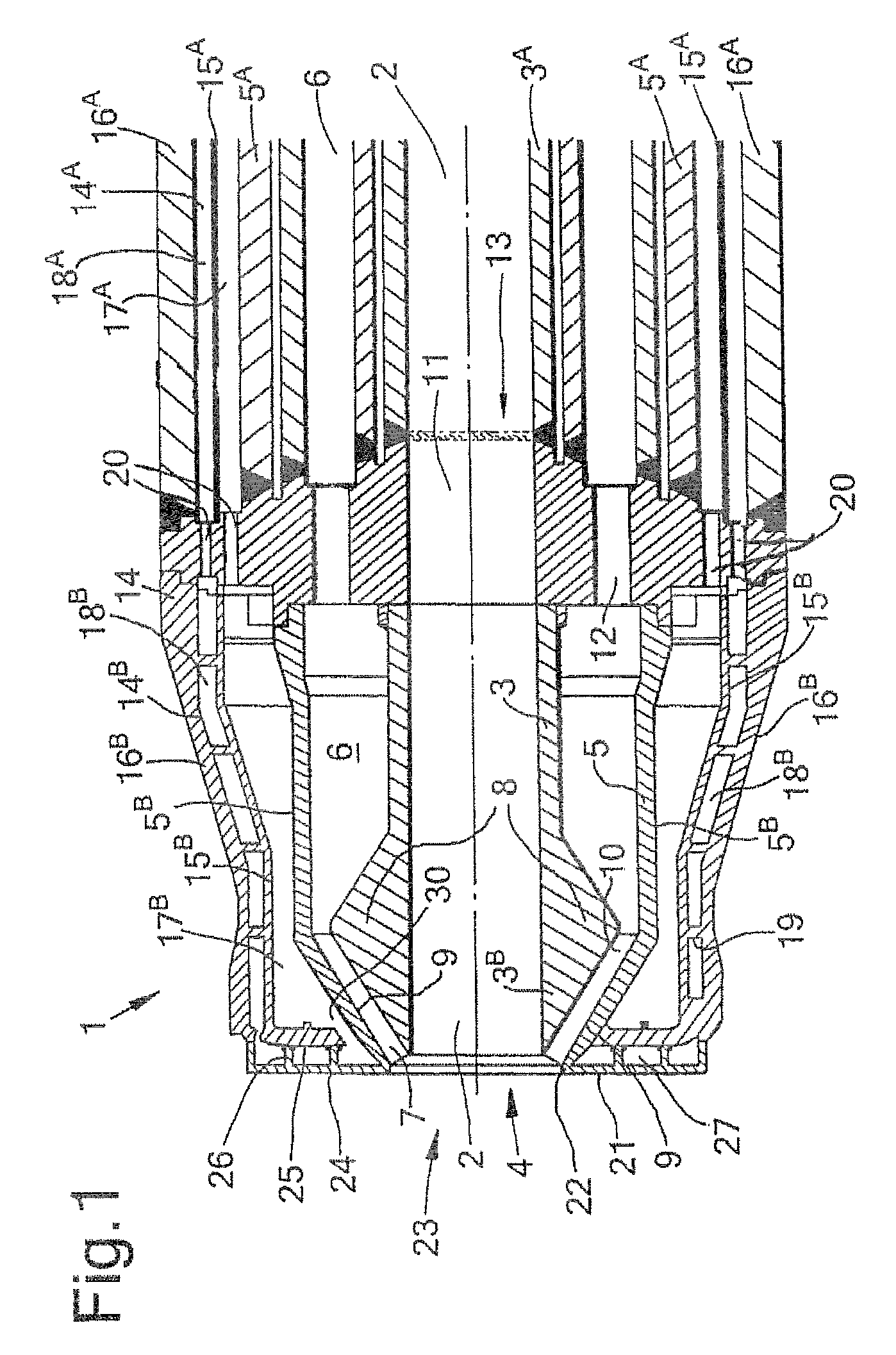

Multi-circuit, multi-injection point atomizer

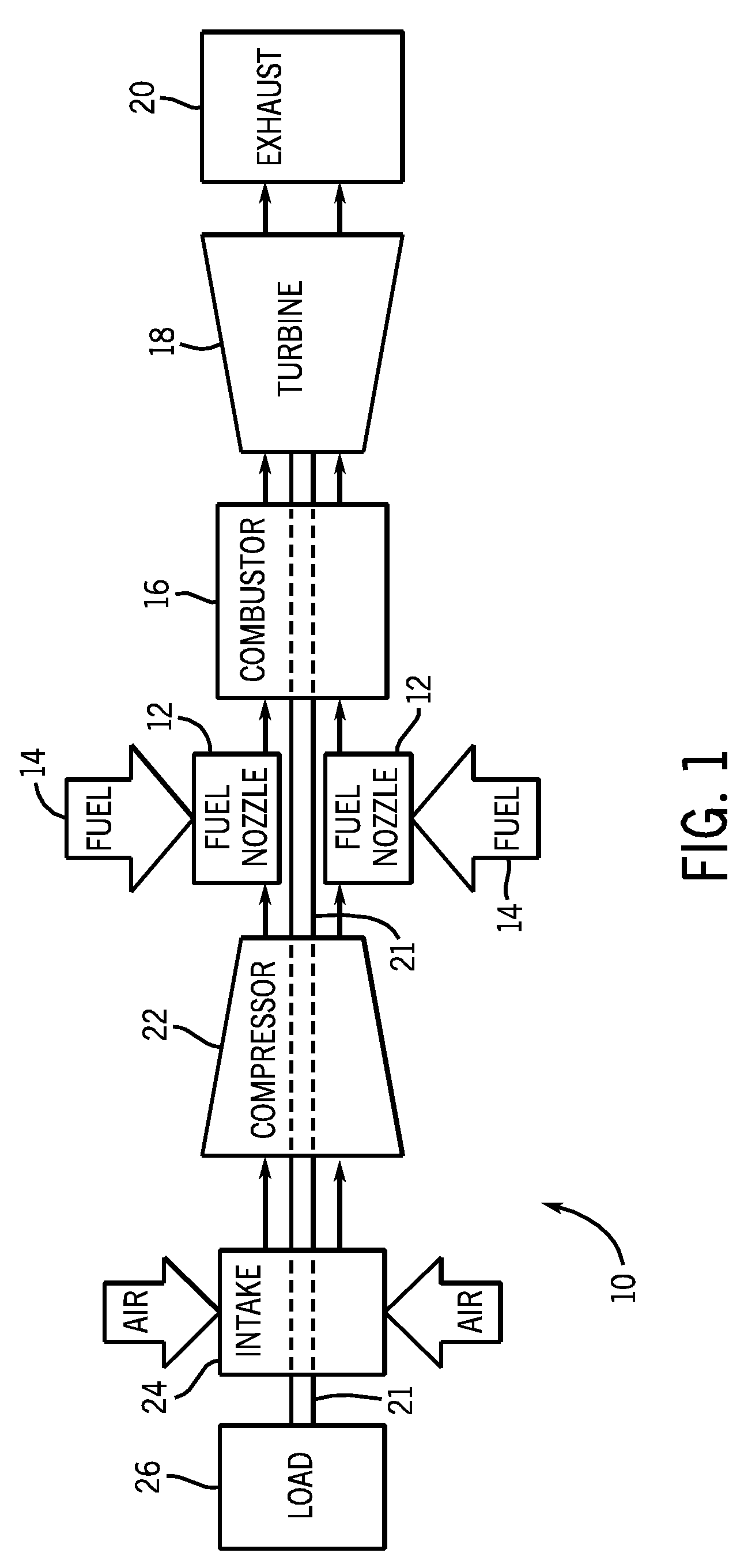

InactiveUS20020129606A1Improve fuel efficiencyCheap manufacturingBurnersTurbine/propulsion fuel supply systemsCombustion chamberMulti injection

A fuel injector nozzle for dispensing fuel in the combustion chamber of a gas turbine engine, includes an elongated, multi-layered, convoluted nozzle feed strip having an internal passage for directing fuel through the length of the strip from the inlet end to an outlet end; and a cylindrical, multi-layered fuel dispensing nozzle unitary with the feed strip and fluidly connected to the outlet end of the feed strip for dispensing the fuel. The multi-layered feed strip and nozzle allows complex porting of fuel circuits through the injector. The internal fluid passages through the feed strip and nozzle are formed by etching.

Owner:PARKER HANNIFIN CORP

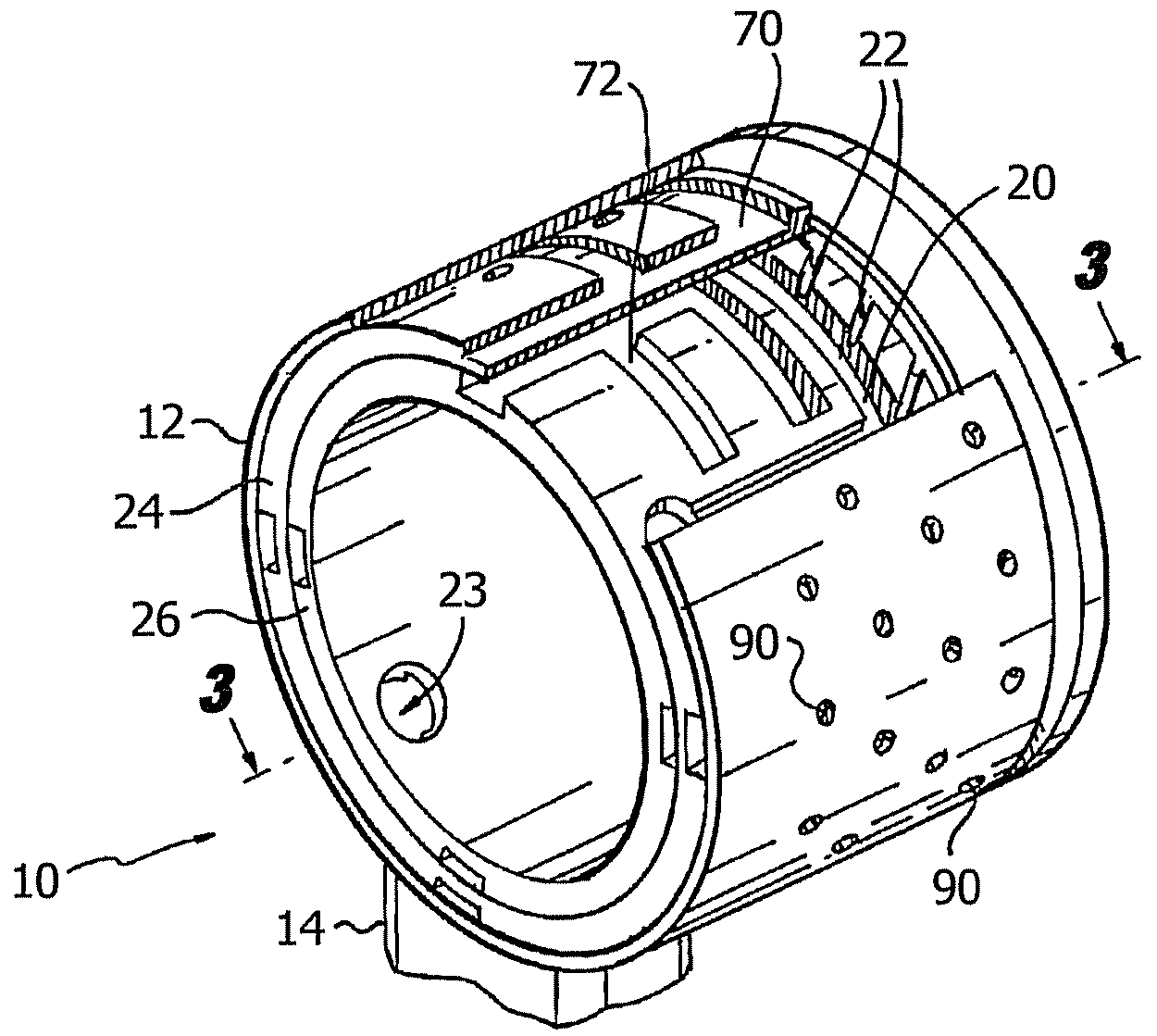

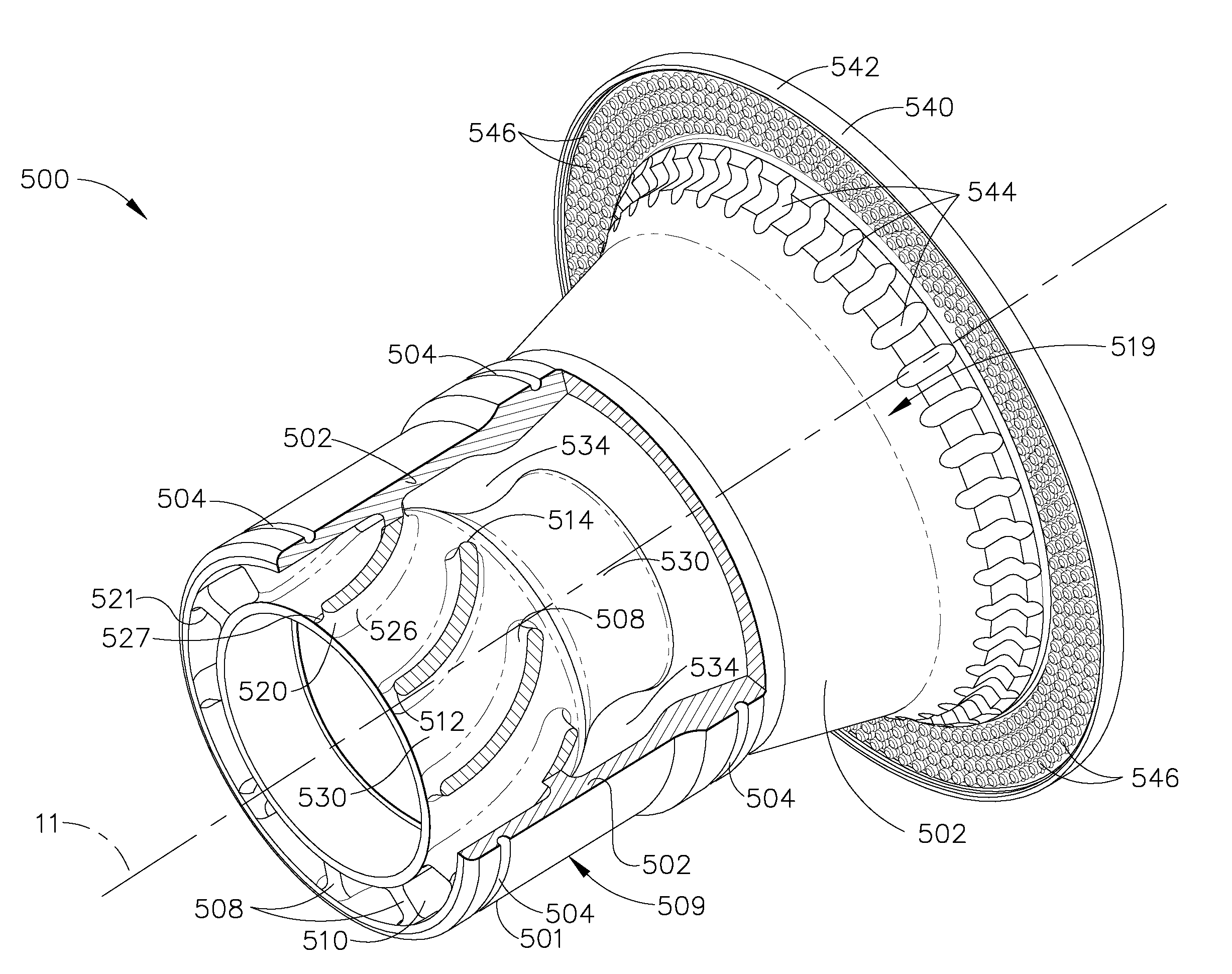

Method of manufacturing a unitary venturi

A method for fabricating a unitary venturi is disclosed, the method comprising the steps of determining three-dimensional information of the unitary venturi having an annular venturi wall and a swirler having a plurality of vanes arranged circumferentially around a swirler axis, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary venturi, and successively forming each layer of the unitary venturi by fusing a metallic powder using laser energy. Exemplary embodiments are disclosed, showing a unitary venturi comprising an annular venturi wall having a swirler axis and a heat shield located at an end wherein unitary venturi is made by using a rapid manufacturing process. In one aspect of the invention, the rapid manufacturing process is a laser sintering process.

Owner:GENERAL ELECTRIC CO

Method of fuel nozzle construction

ActiveUS20090140073A1Inhibition formationValve arrangementsLiquid surface applicatorsInterference fitNozzle

A method of assembling a fuel nozzle includes providing a first nozzle component and a second nozzle component, wherein the first nozzle component is configured and adapted to engage within the second nozzle component. Braze is applied to at least one of the first and second nozzle components. The first nozzle component is assembled into the second nozzle component to provide a diametral interference fit therebetween. The method further includes joining the first and second nozzle components together. A fuel nozzle includes a first cylindrical nozzle component, a second cylindrical nozzle component disposed with an interference fit on an outward surface of the first nozzle component, and a layer of braze joiningly disposed between the first and second nozzle components.

Owner:ROLLS ROYCE PLC

Venturi

A venturi is disclosed, the venturi comprising a mixing cavity surrounded circumferentially by an annular venturi wall, and a swirler having a plurality of vanes arranged circumferentially around a swirler axis, wherein the swirler and the annular venturi wall have a unitary construction. In another exemplary embodiment the venturi comprises an annular venturi wall, a swirler located at an axially forward portion of the venturi, the swirler having a plurality of vanes arranged circumferentially around a swirler axis, and a heat shield located axially aft from the swirler, wherein the annular venturi wall, the swirler and the heat shield have a unitary construction.

Owner:GENERAL ELECTRIC CO

Fuel nozzle liquid cartridge including a fuel insert

In an embodiment, a system includes an end cover and a liquid cartridge. The liquid cartridge is configured to mount in a fuel nozzle of a turbine engine, wherein the liquid cartridge comprises a one piece flange configured to couple to the end cover, wherein the flange comprises a water inlet, an air inlet, and a fuel inlet.

Owner:GENERAL ELECTRIC CO

Fuel distributor

A unitary distributor is disclosed, comprising at least one main flow passage located within a distributor ring body, the main flow passage having an arcuate portion oriented in a circumferential direction around a distributor axis. Exemplary embodiments of a unitary distributor having an annular ring located at the axially forward end of the distributor ring body are disclosed. A fuel distributor is disclosed, comprising a fuel conduit and a distributor wherein the fuel distributor has a unitary construction.

Owner:GENERAL ELECTRIC CO

Method of manufacturing a unitary swirler

A method for fabricating a unitary swirler is disclosed, the method comprising the steps of determining three-dimensional information of the unitary swirler having a plurality of vanes arranged in a circumferential direction on a body around a swirler axis and a wall extending between a rim and a portion of the body, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary swirler, and successively forming each layer of the unitary swirler by fusing a metallic powder using laser energy. Exemplary embodiments are disclosed, showing a unitary swirler comprising a plurality of vanes extending from a hub having a unitary construction wherein unitary swirler is made by using a rapid manufacturing process. In one aspect of the invention, the rapid manufacturing process is a laser sintering process.

Owner:GENERAL ELECTRIC CO

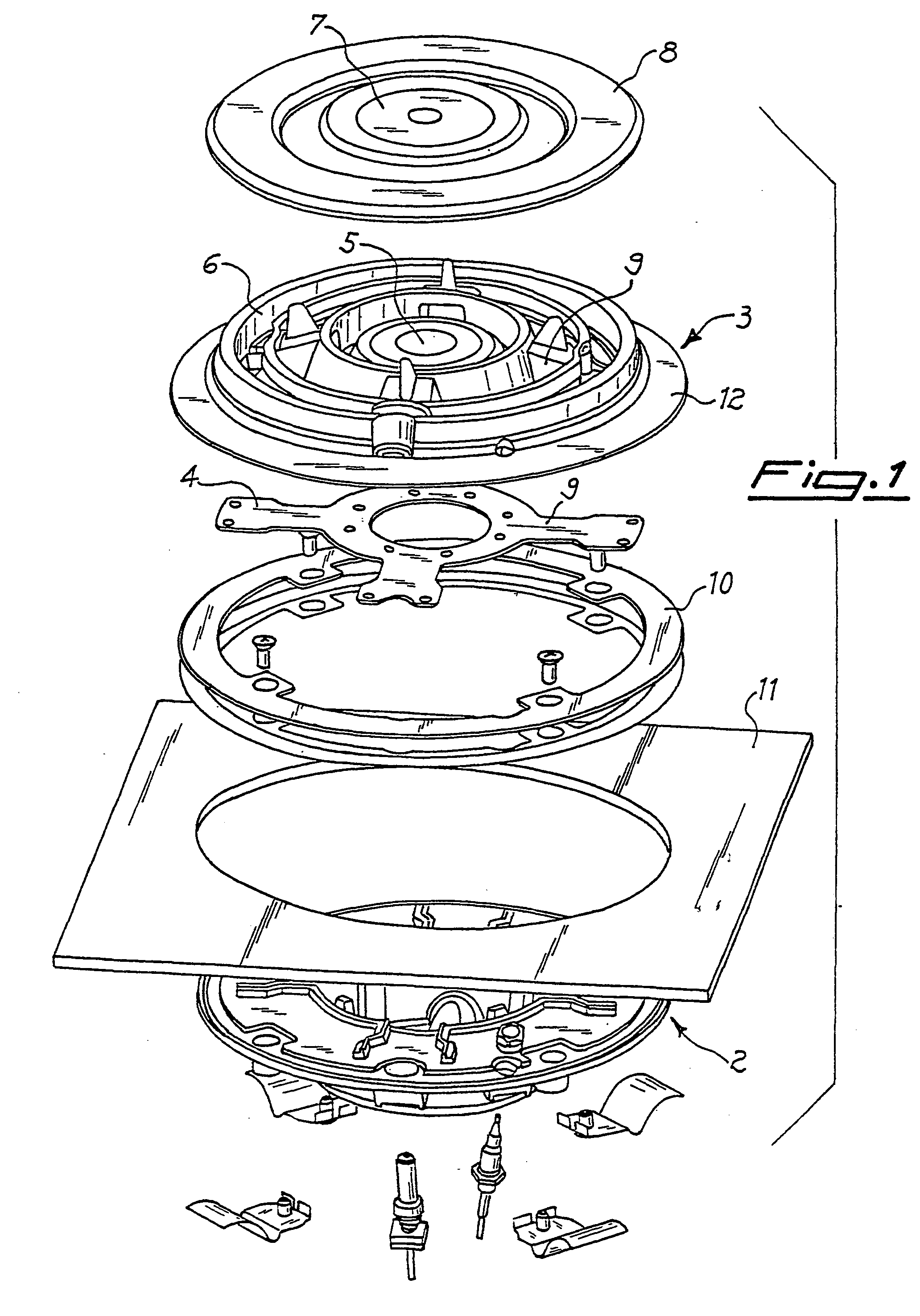

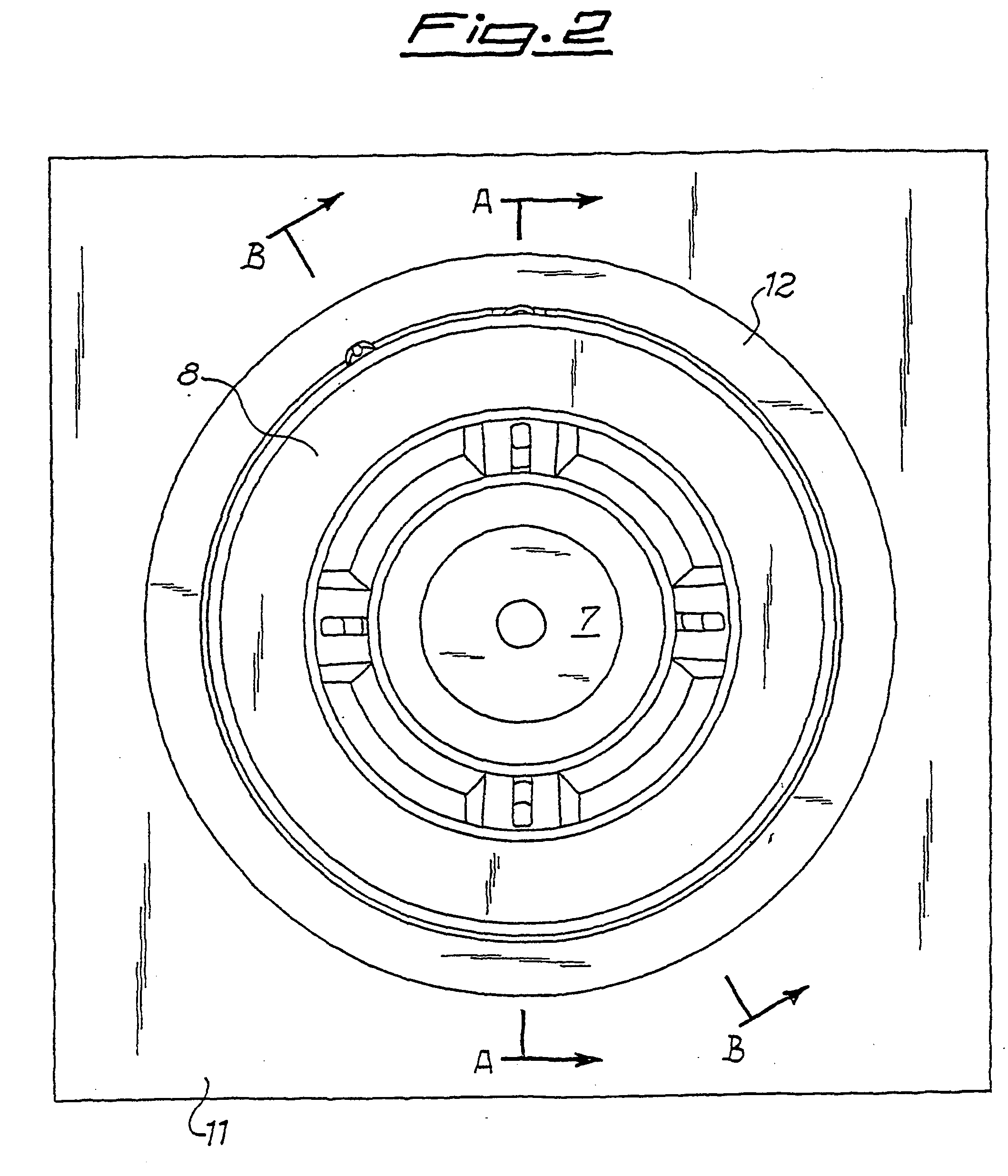

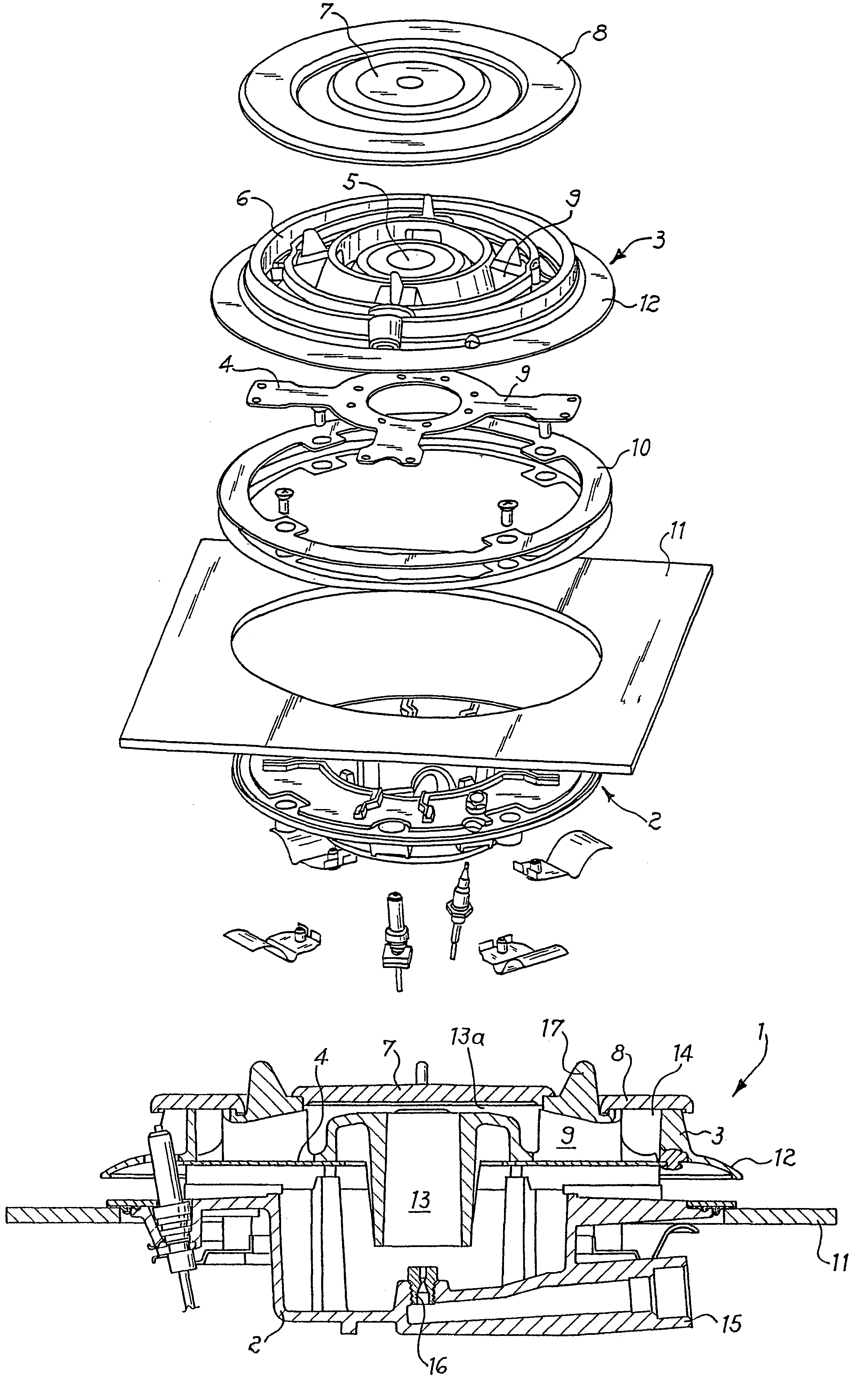

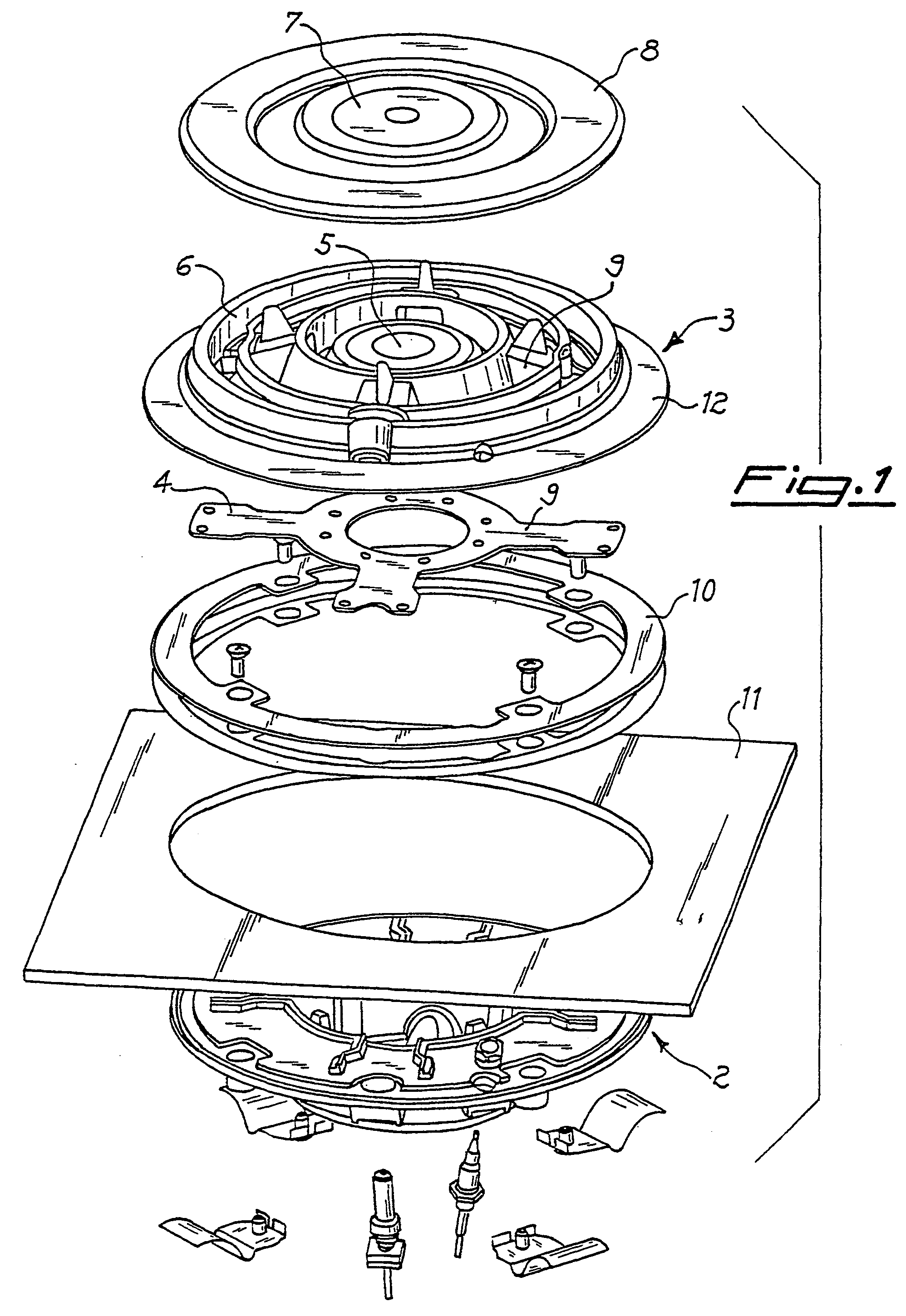

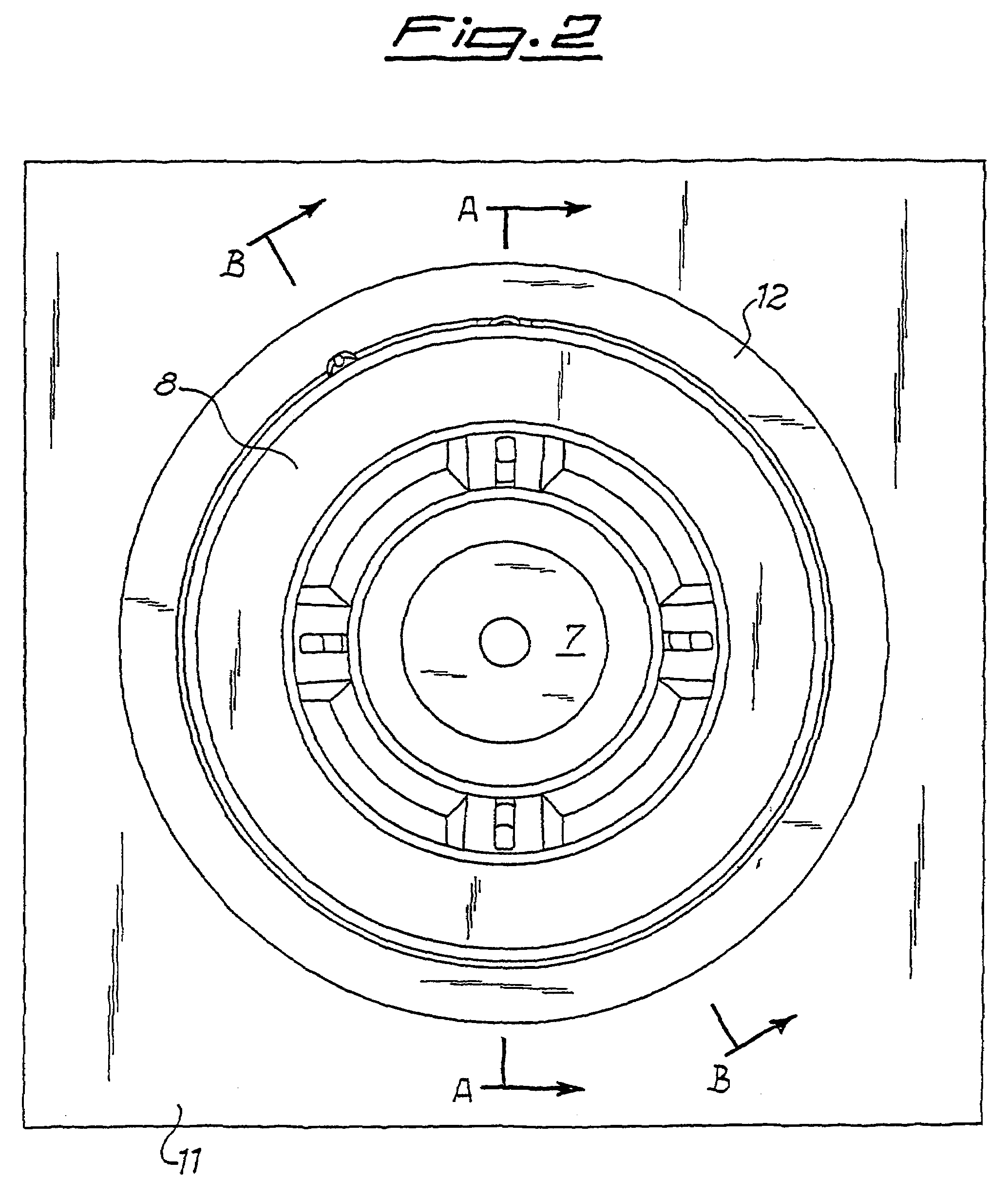

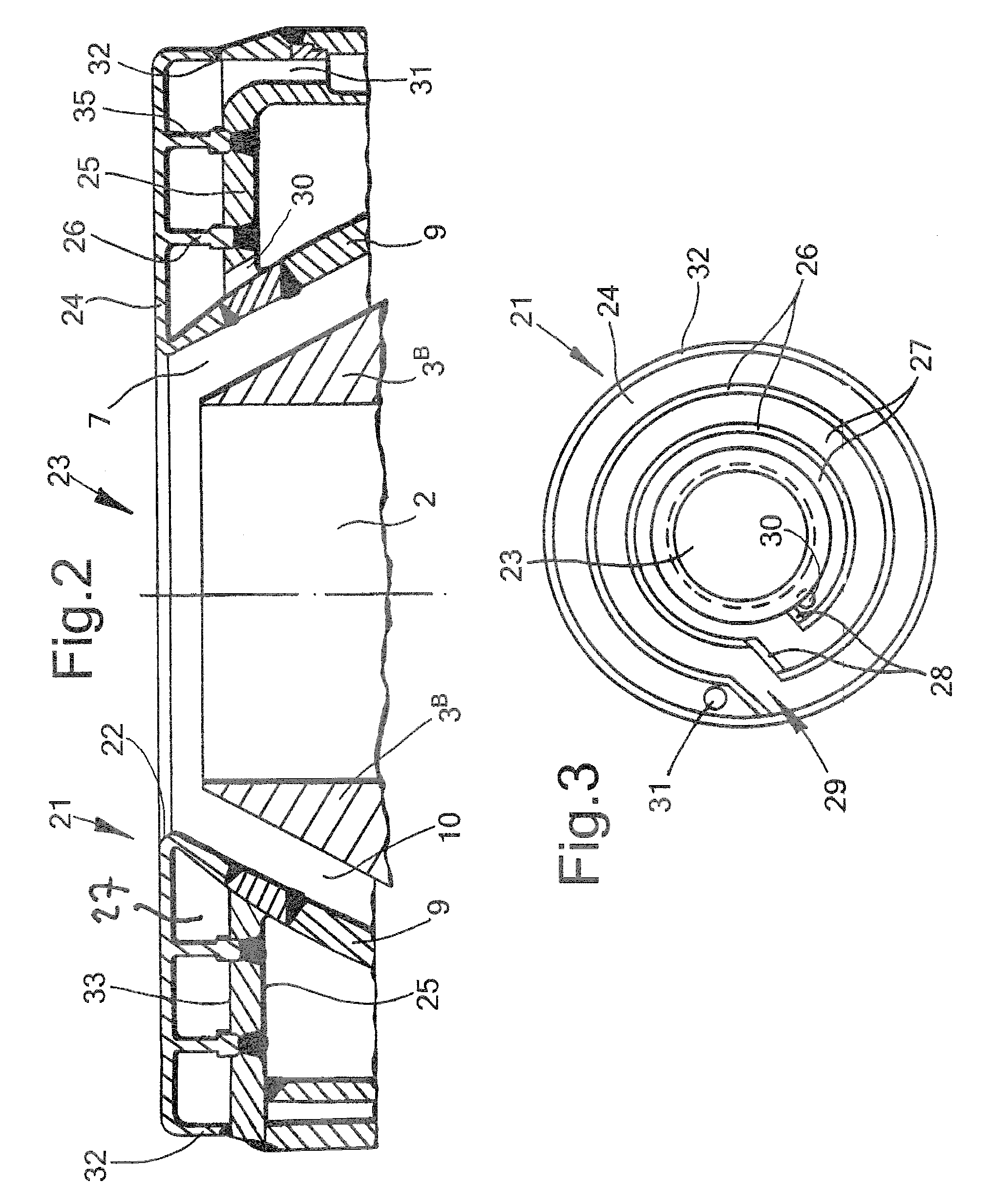

Burner with internal separator

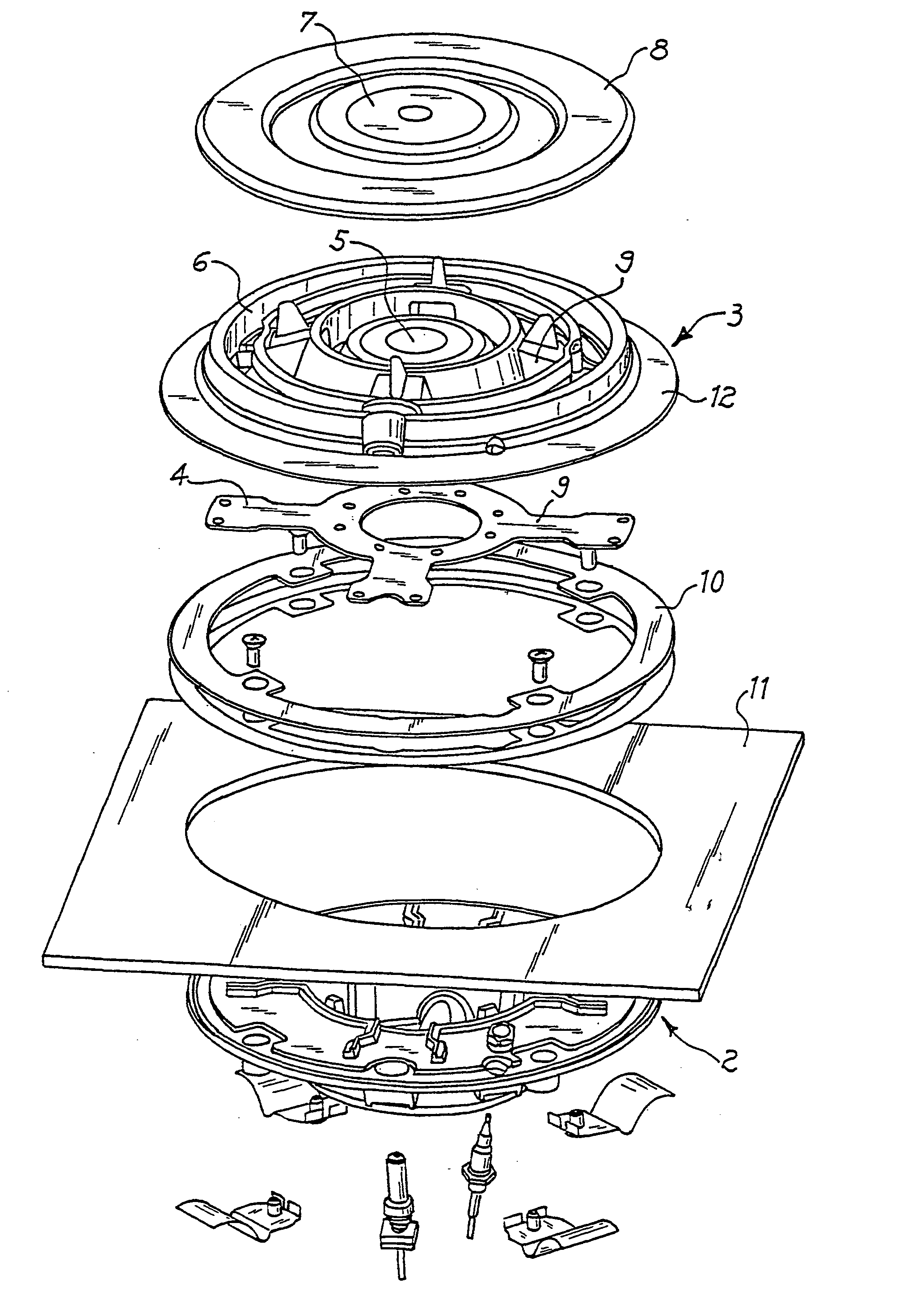

InactiveUS20040029063A1Easy to produceDomestic stoves or rangesBurner material specificationsCombustorEngineering

The invention relates to a burner (1) for cookers, suitable for burning gas, comprising at least two gas crowns, of which one central one and at least one circumferential one, a mixing chamber (13) with Venturi effect, ducts for entry of the primary air and radial ducts (9) for feeding the gas / primary air mixture to the said at least one circumferential crown, comprising a body (3), a head (2) and a separation element (4) that breaks up the internal space into ducts for entry of the primary air and ducts for distribution of the gas / primary air mixture.

Owner:SABAF SPA

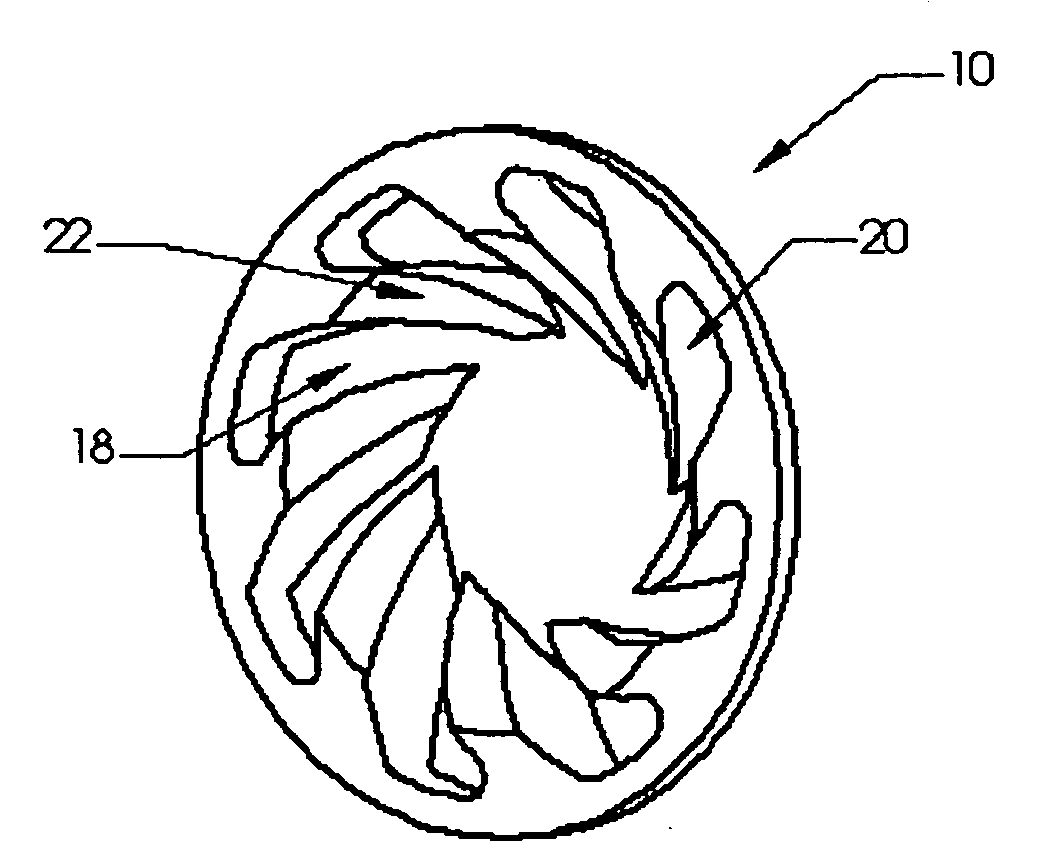

Conical swirler for fuel injectors and combustor domes and methods of manufacturing the same

ActiveUS8348180B2Area minimizationReduce areaContinuous combustion chamberSpray nozzlesCombustorUltimate tensile strength

Owner:COLLINS ENGINE NOZZLES INC

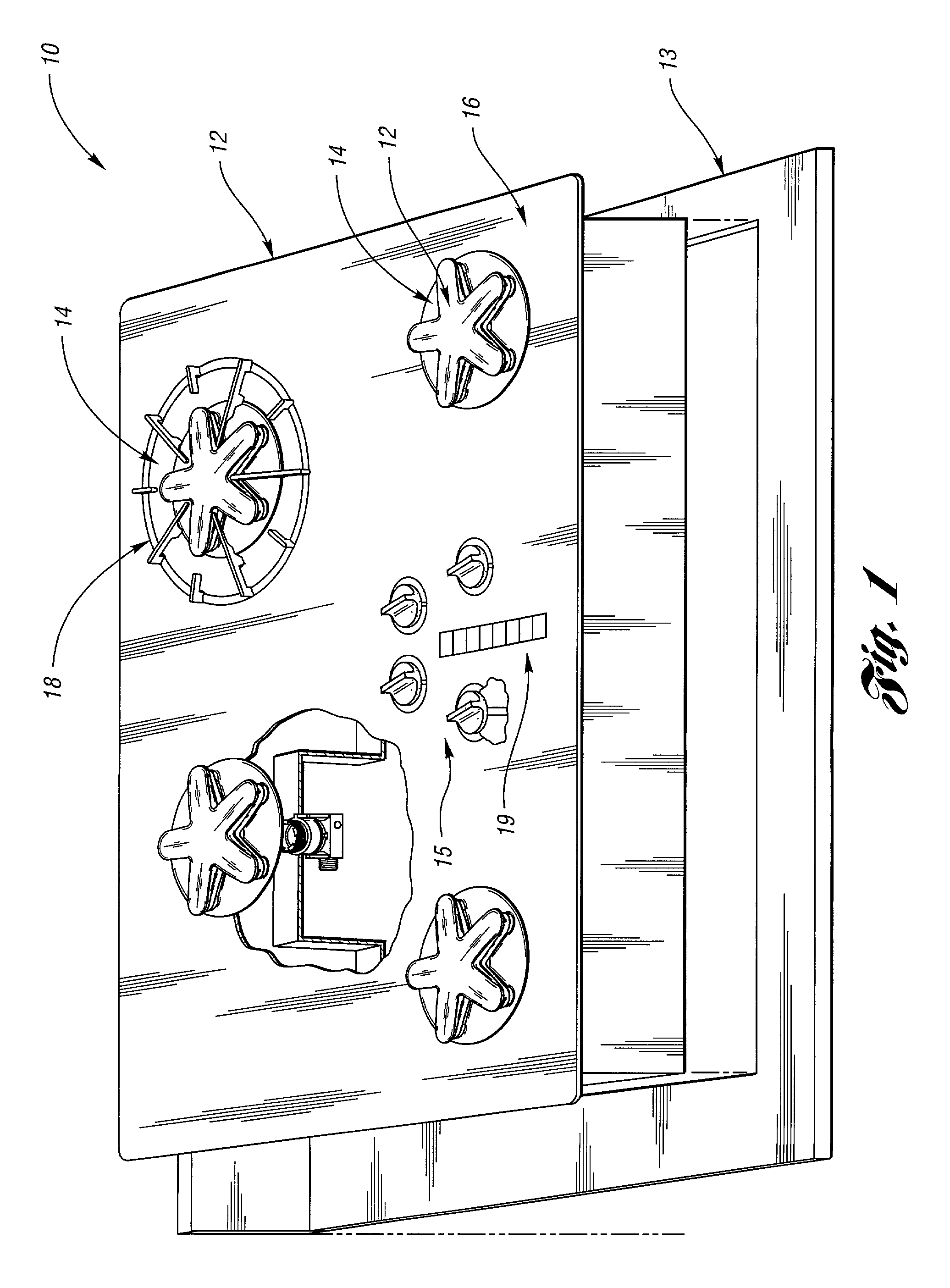

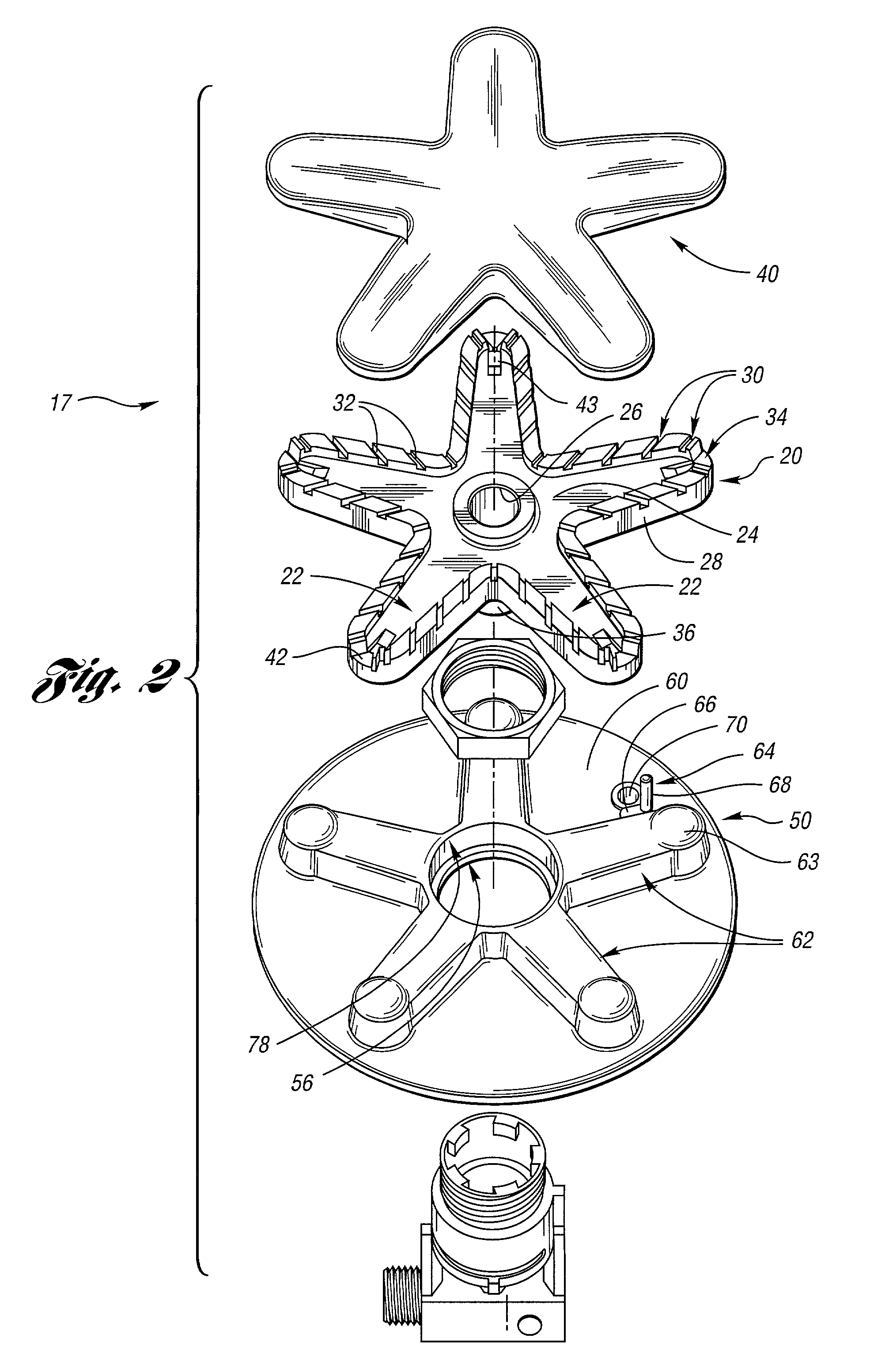

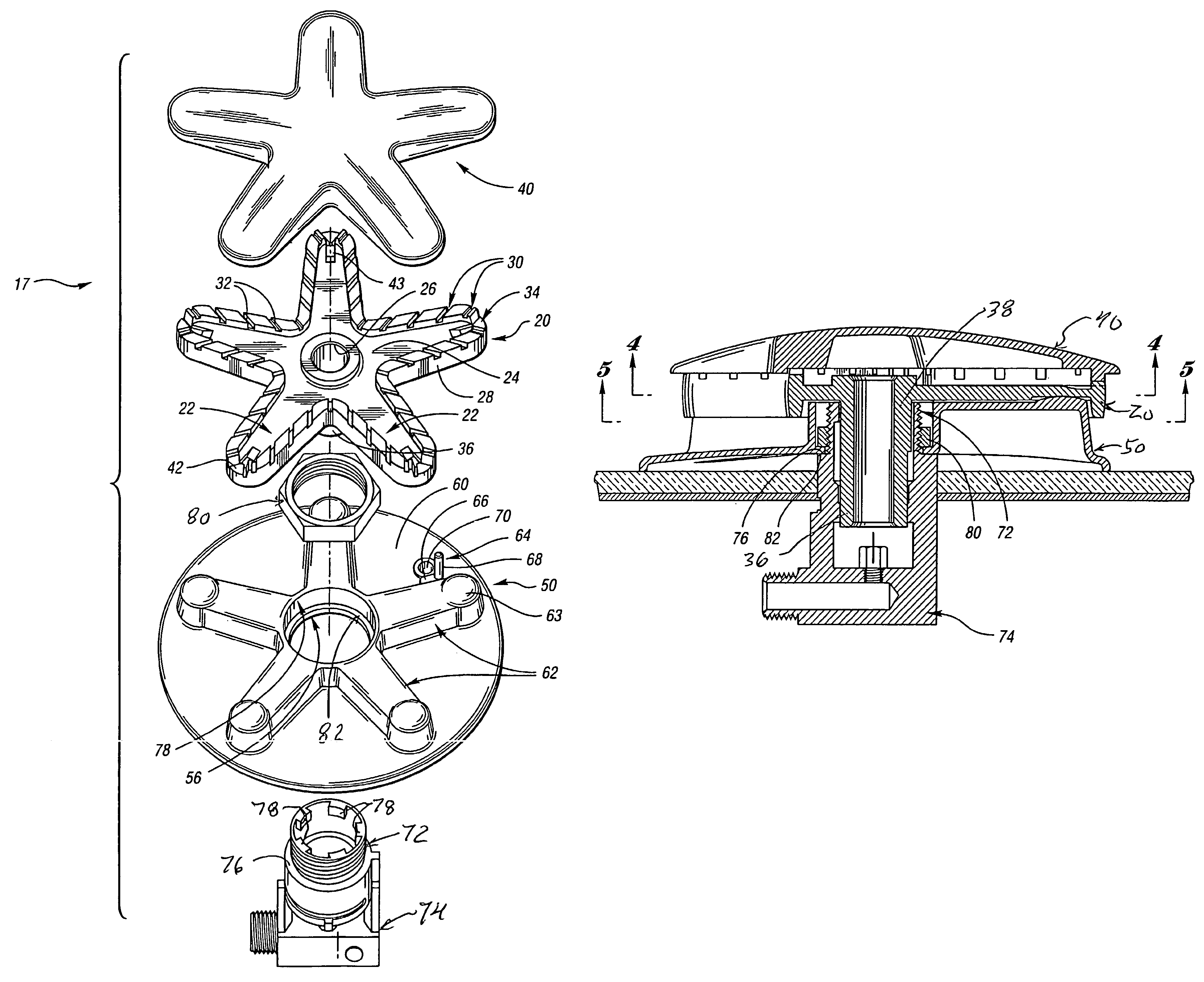

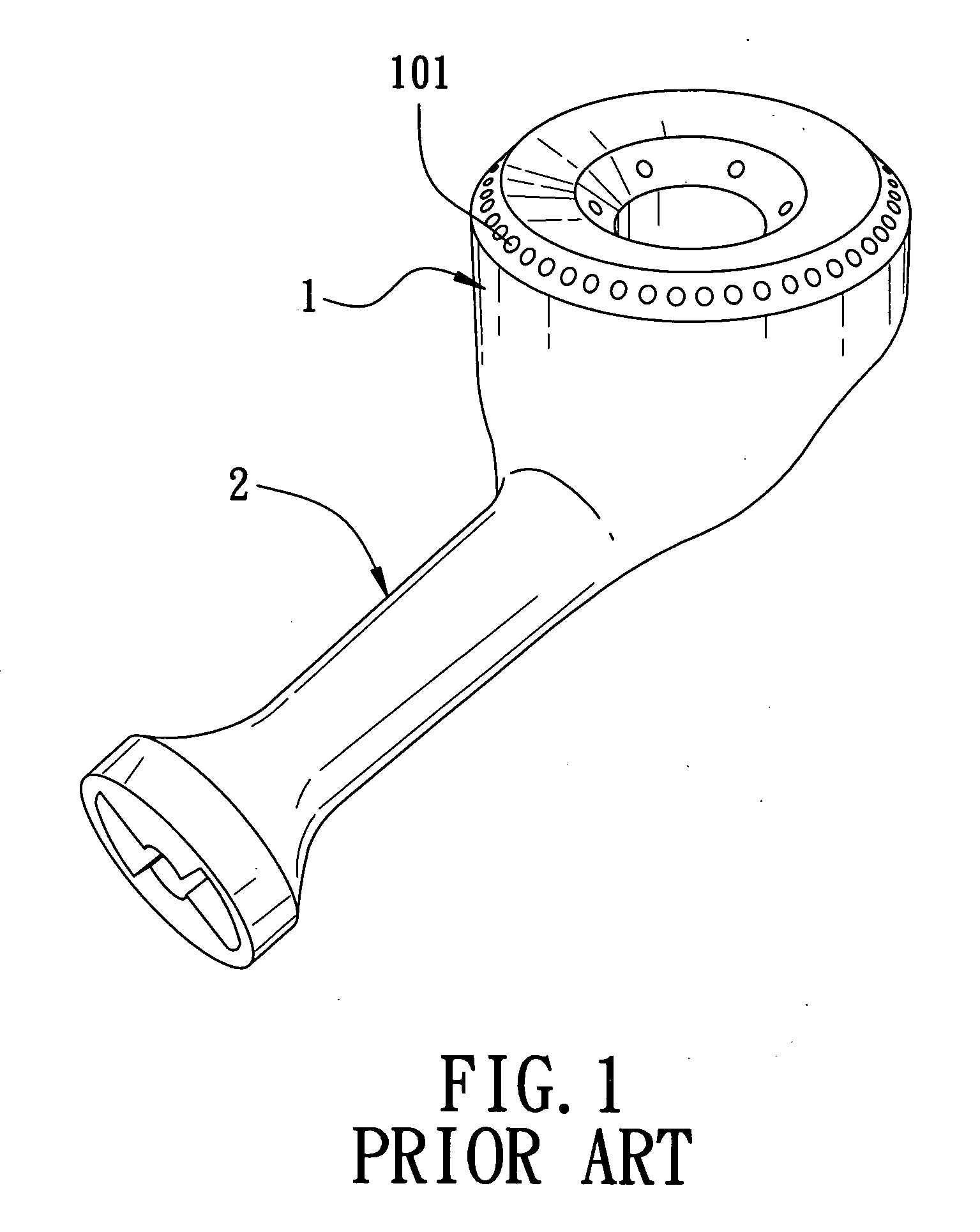

Controlled flame gas burner

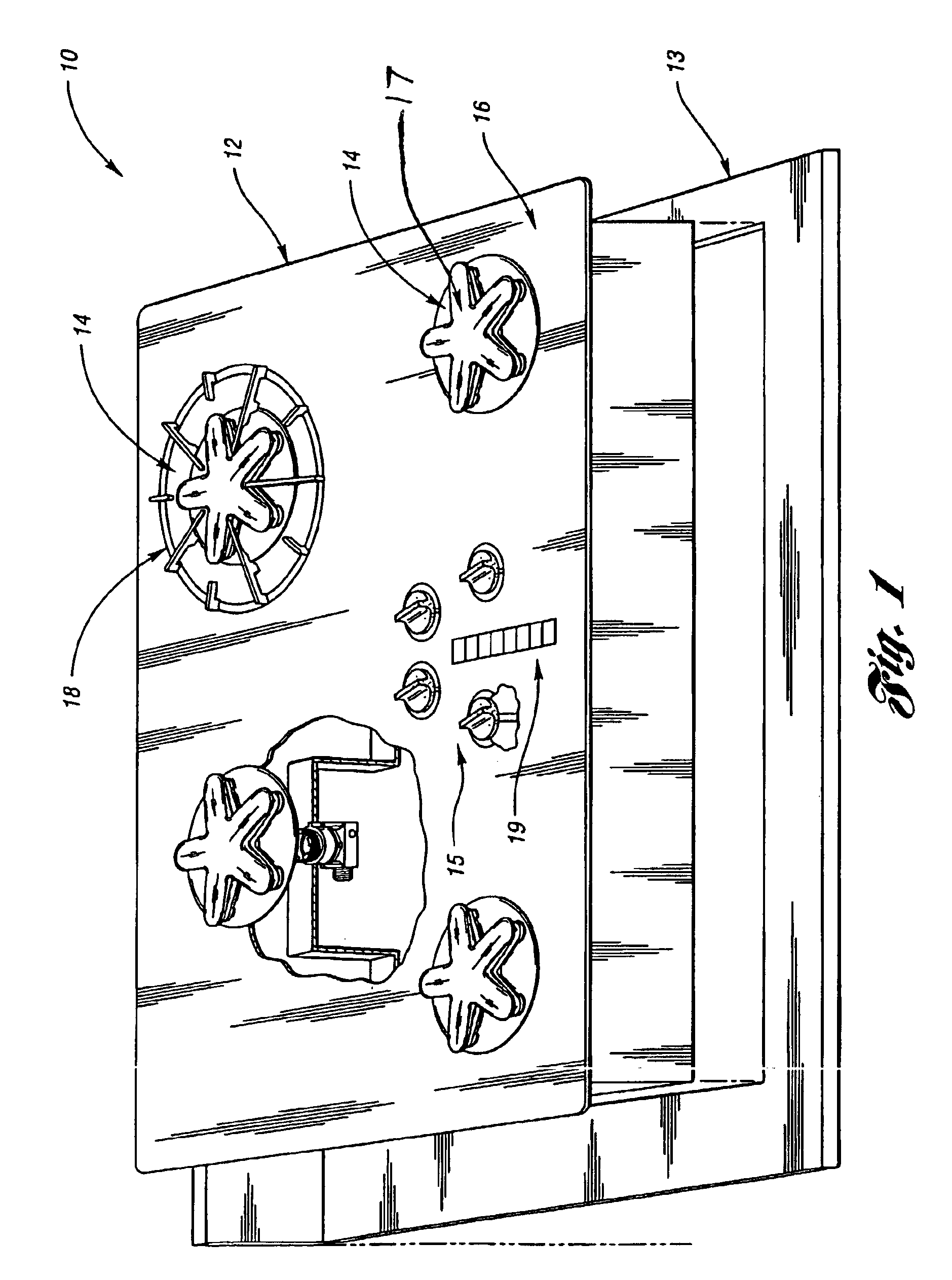

InactiveUS20030087214A1Easy to controlImprove simplicityDomestic stoves or rangesElectric spark ignitersEngineeringFuel gas

A multiple fingered burner includes controls for continuity of gas flow and ignition throughout all of the ports peripherally positioned around the contoured wall of the burner body. A plurality of burner parts are nested together with an indexer limiting insertion to at least one predetermined alignment in order to avoid improper fit or alignment between adjacent burner parts. In addition, the peripherally positioned ports are covered by a laterally extending lip of a cap, and at least one of the parts includes recesses adjacent the laterally extending lip to provide ignitable gas flow passages along the peripheral wall of the burner that maintain continuity of ignition at adjacent burner ports.

Owner:BSH HOME APPLIANCES CORP

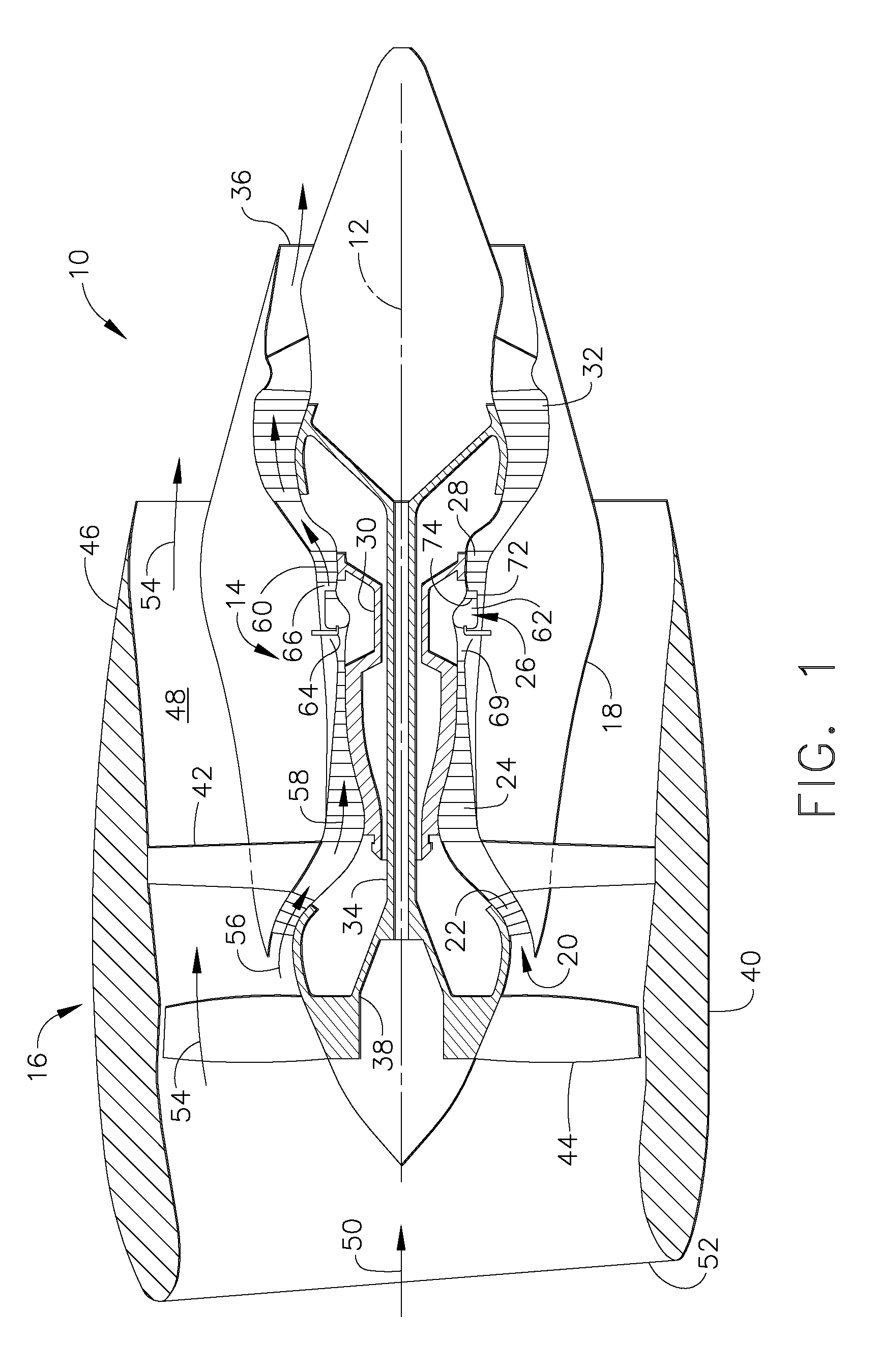

Fuel injectors for gas turbine engines

A fuel injector for a gas turbine engine includes a monolithic nozzle body that defines within its interior one or more fuel circuits. Each fuel circuit includes an inlet, an outlet orifice, a main passage fluidly coupling the inlet with the outlet orifice, and a branch passage connected to the main passage. The branch passage connects to the main passage downstream of the inlet and upstream of the outlet orifice to form an effective metering flow area that is smaller than the flow area of the outlet orifice.

Owner:COLLINS ENGINE NOZZLES INC

Controlled flame gas burner

InactiveUS7322820B2Easy to controlImprove simplicityDomestic stoves or rangesElectric spark ignitersEngineeringGas burner

Owner:BSH HOME APPLIANCES CORP

Method of manufacturing mixers

A method for fabricating a unitary mixer is disclosed, said method comprising the steps of determining three-dimensional information of the unitary mixer having at least one swirler, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary mixer, and successively forming each layer of the unitary mixer by fusing a metallic powder. Exemplary embodiments are disclosed, showing unitary mixer comprising an annular housing and a swirler having a unitary construction wherein unitary mixer is made by using a rapid manufacturing process. In one aspect of the invention, the rapid manufacturing process is a laser sintering process.

Owner:GENERAL ELECTRIC CO

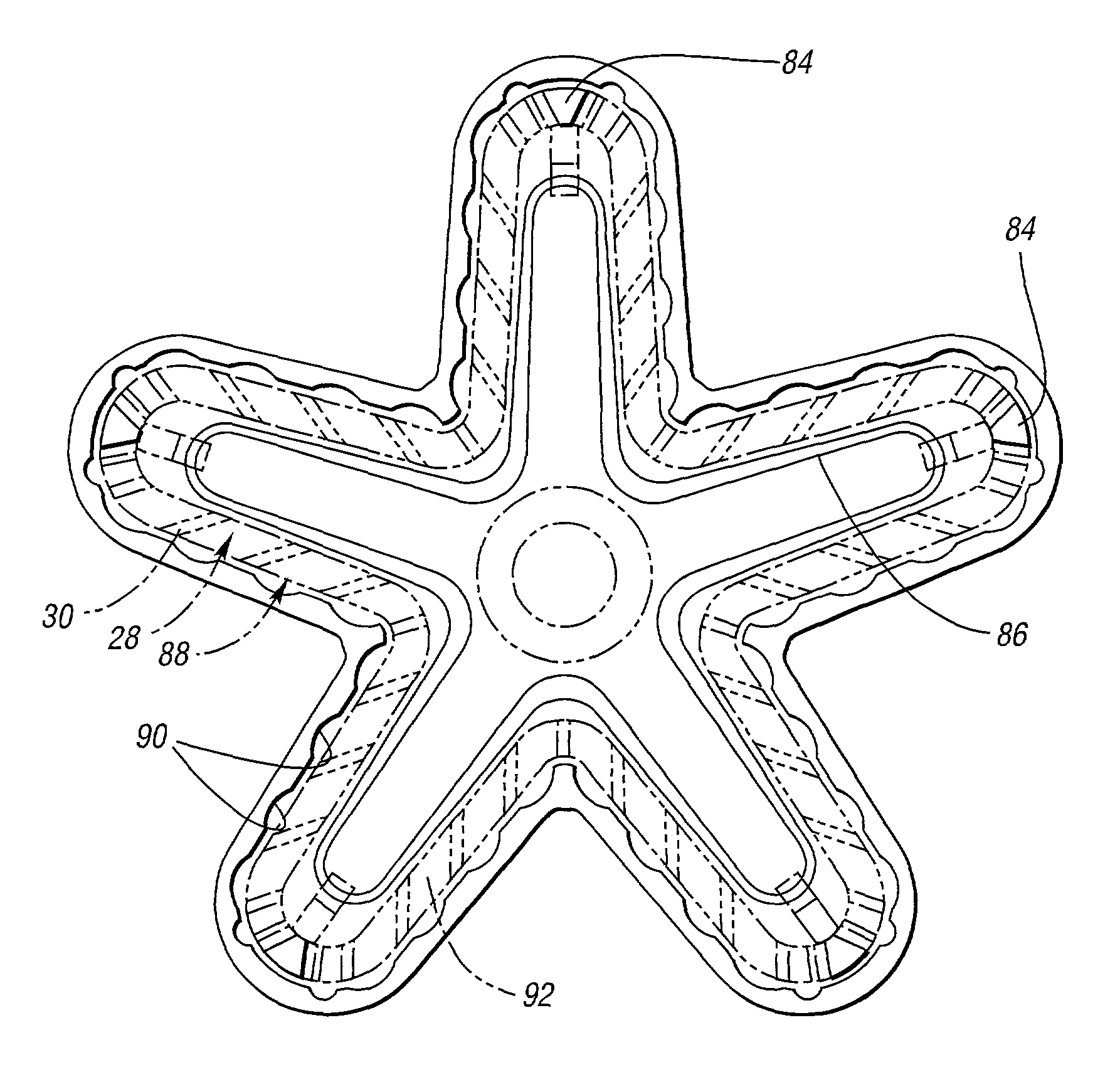

Unitary gas burner

A gas burner and a gas burner assembly for an appliance are provided. The gas burner assembly includes a unitary gas burner comprising a body portion, a cap portion, and a gas conduit portion. A plurality of burner ports is defined in the sidewall of the body portion of the unitary gas burner. A gas burner is also provided. The gas burner comprises a body portion, a cap portion, and a gas conduit portion that are segments of a single piece forming the gas burner.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Gas burner

InactiveUS20070059657A1Low costAvoid it happening againBurner manufactureGaseous fuel burnerBack-fireEngineering

A gas burner includes a looped head seat formed by punching a metal plate, and defining therein a surrounding duct therein which is fluidly communicated with a gas conduit for supplying fuel gas to the surrounding duct, and a looped burner cap engaged with the head seat to define a partition space therebetween. One of inner and outer surrounding regions of an upper wall of the head seat has a plurality of intercommunicating ports, whereas one of corresponding inner and outer surrounding regions of an upper cap wall of the burner cap has a plurality of discharging orifices such that the fuel gas in the surrounding duct is guided to flow through the intercommunicating ports into the partition space and is discharged through the discharging orifices. By means of the arrangement of the ports and the orifices, occurrence of backfires in the surrounding duct can be prevented.

Owner:YEN CHIA HSI

Burner with internal separator

Owner:SABAF SPA

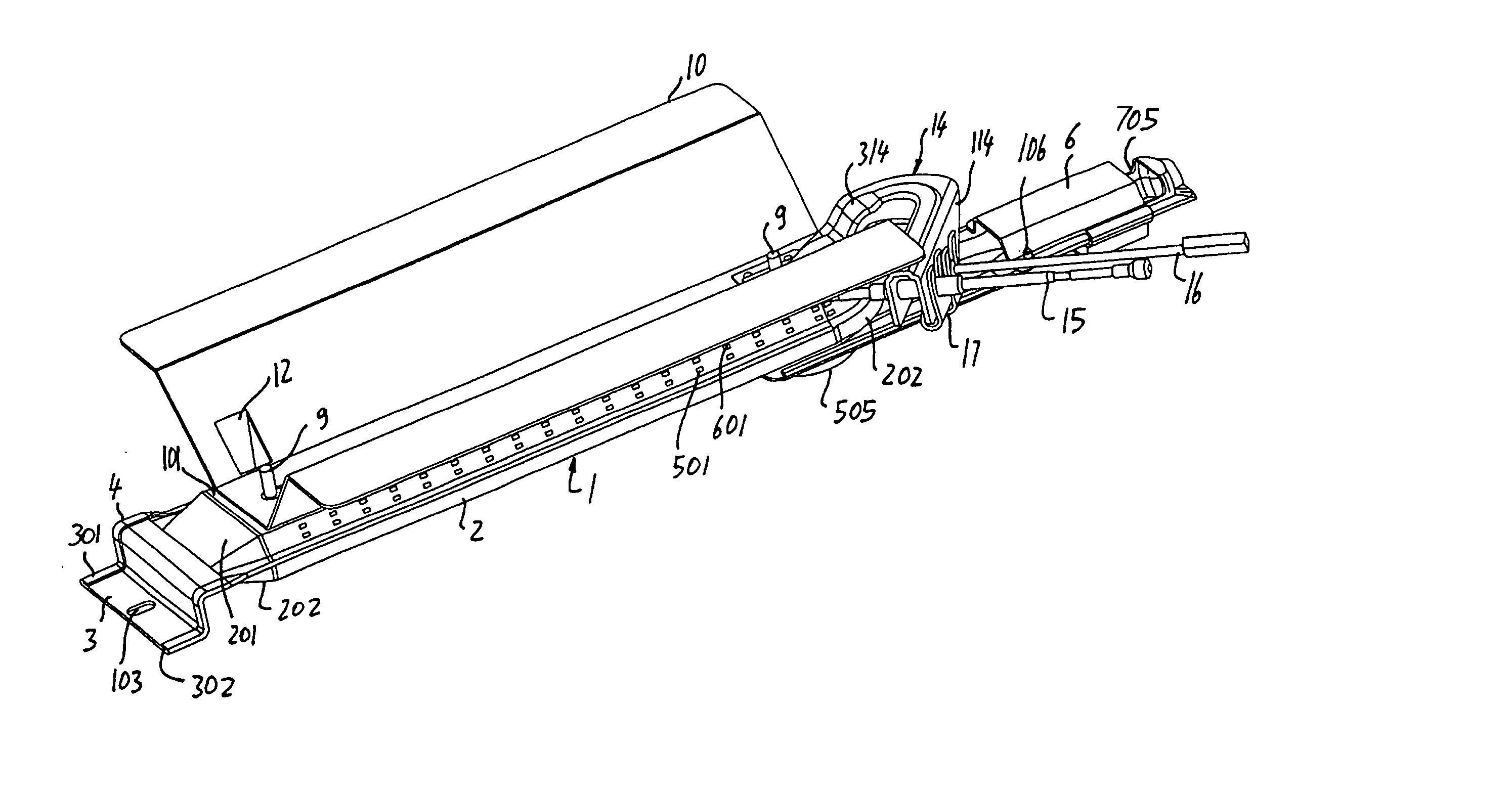

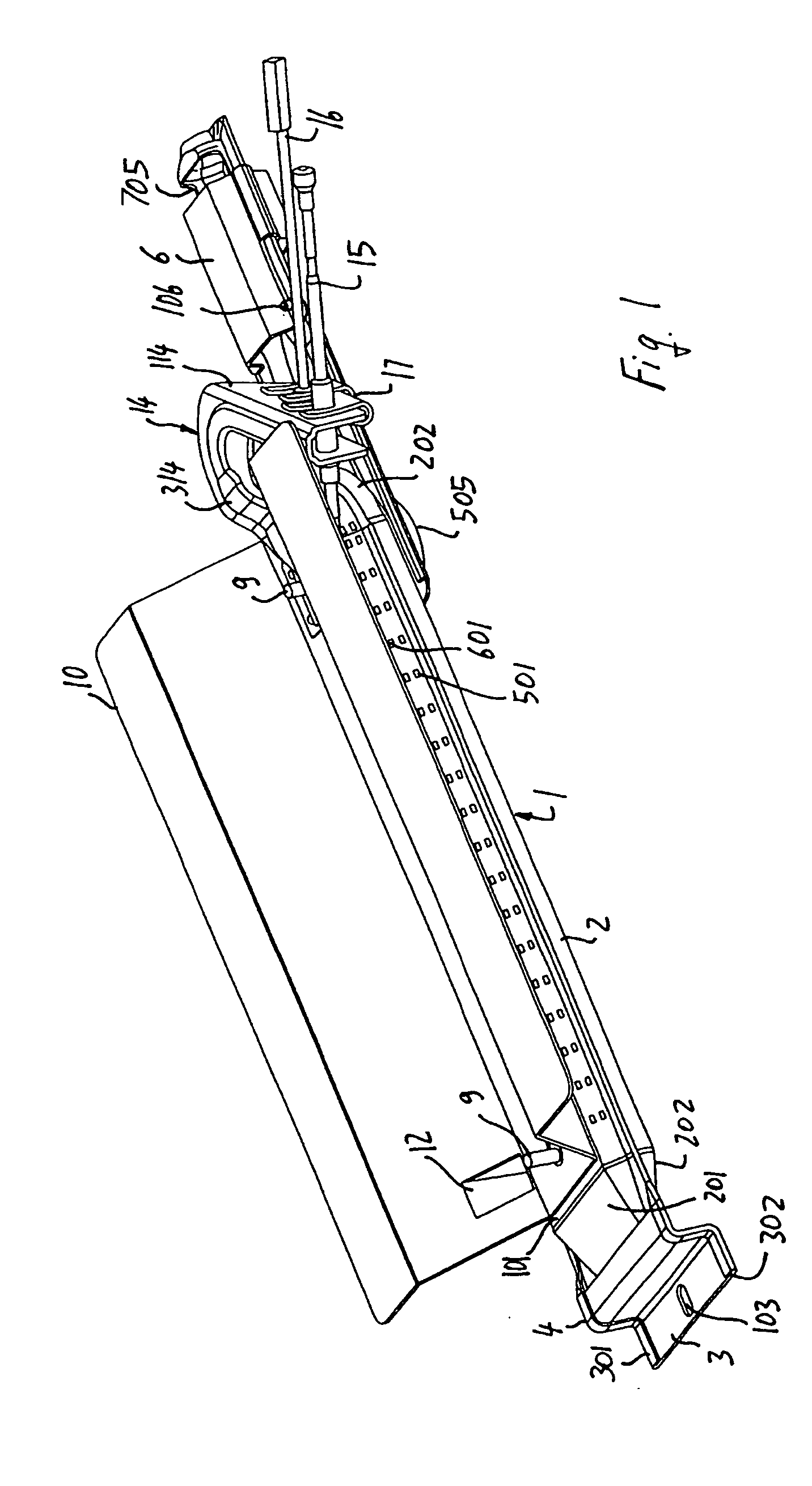

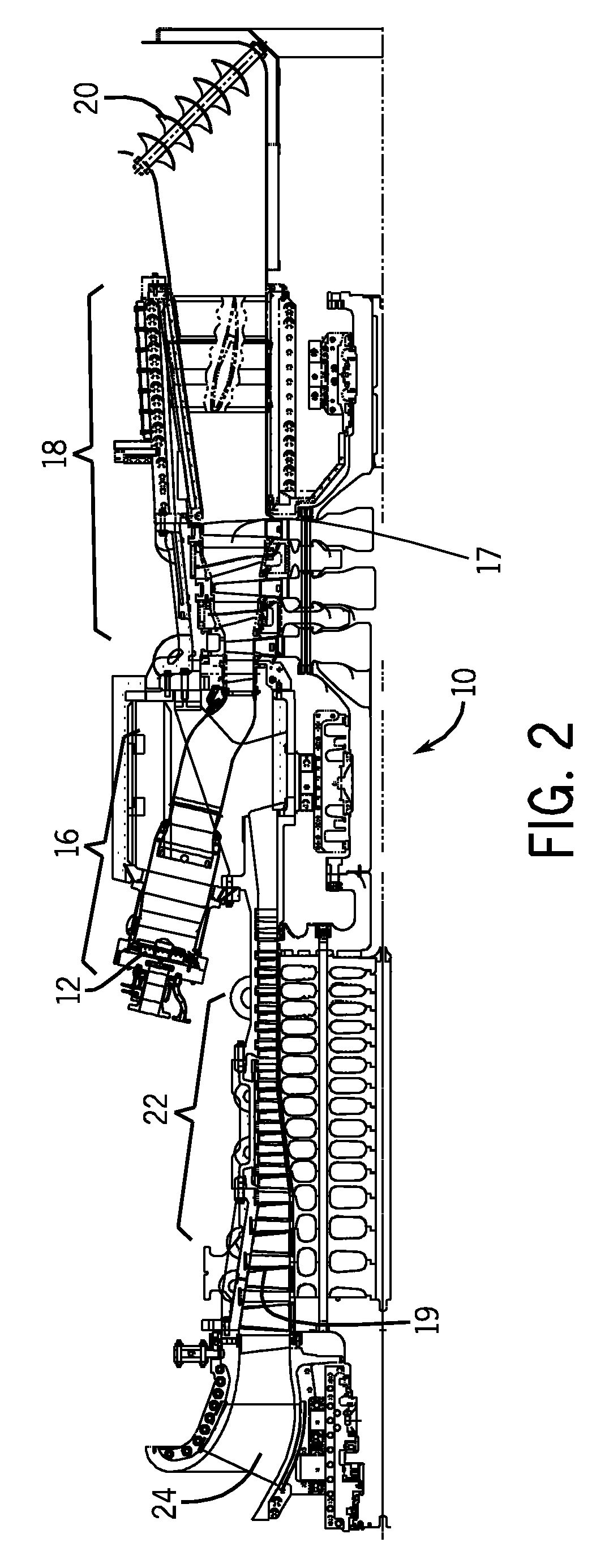

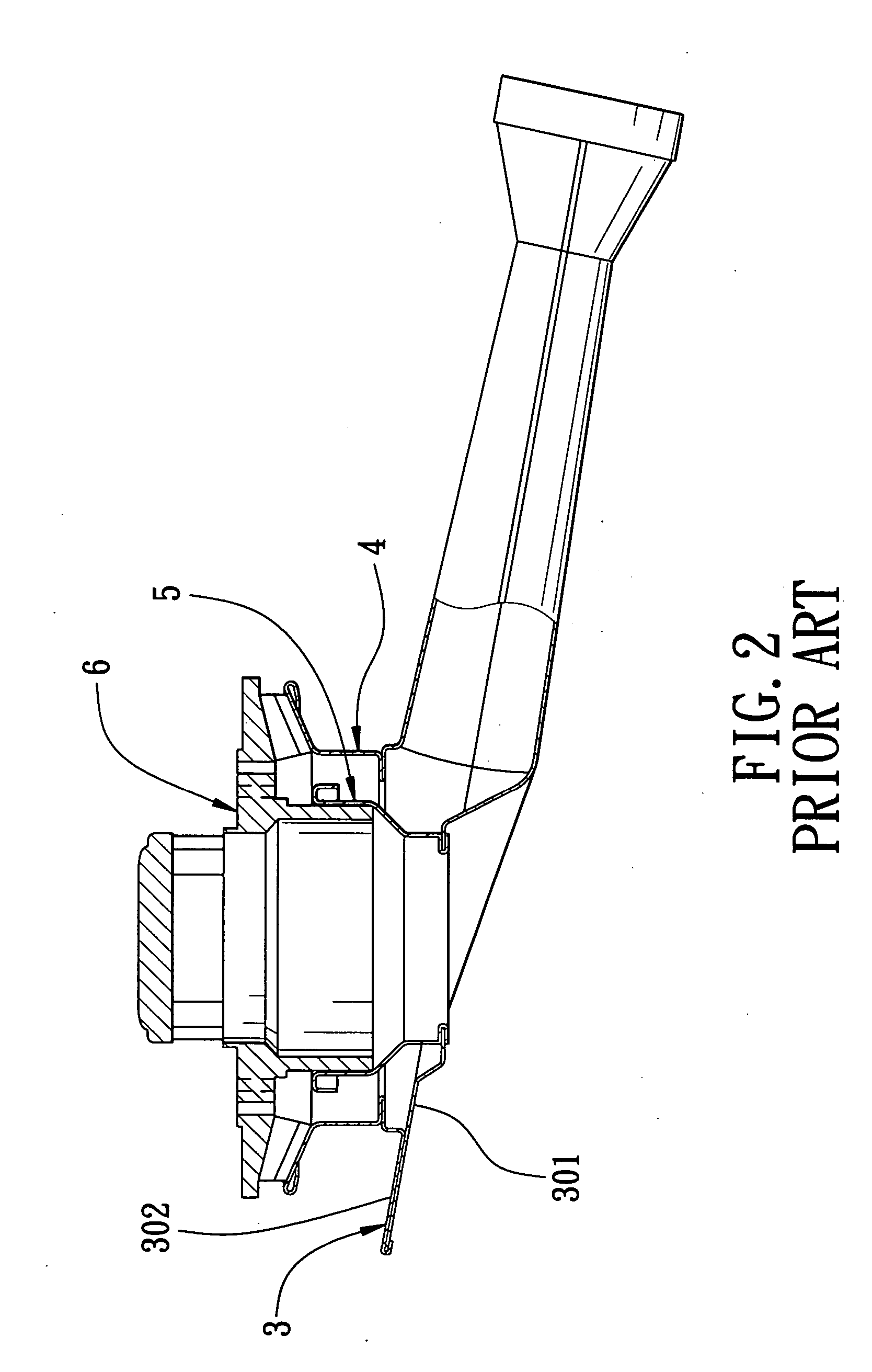

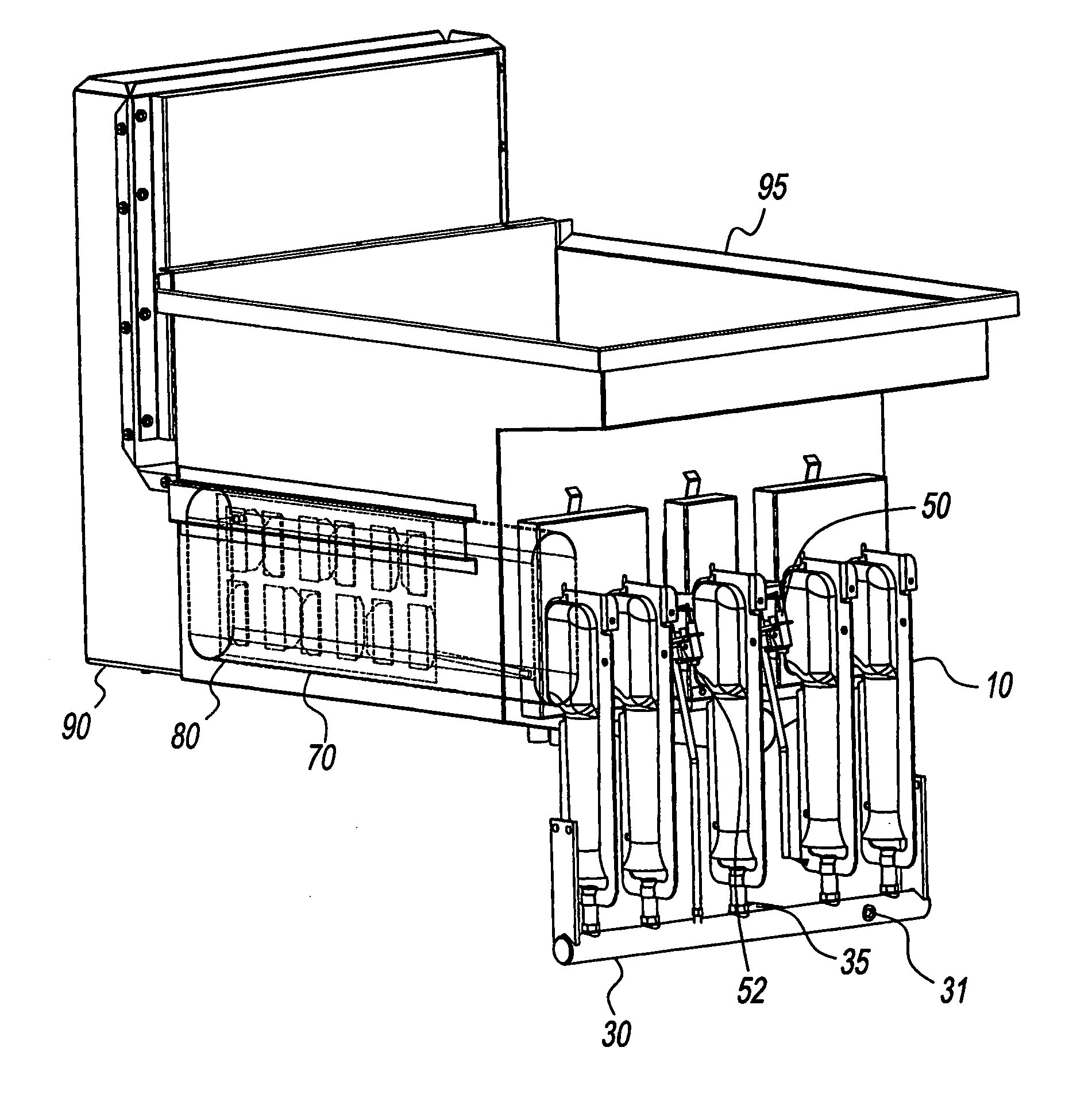

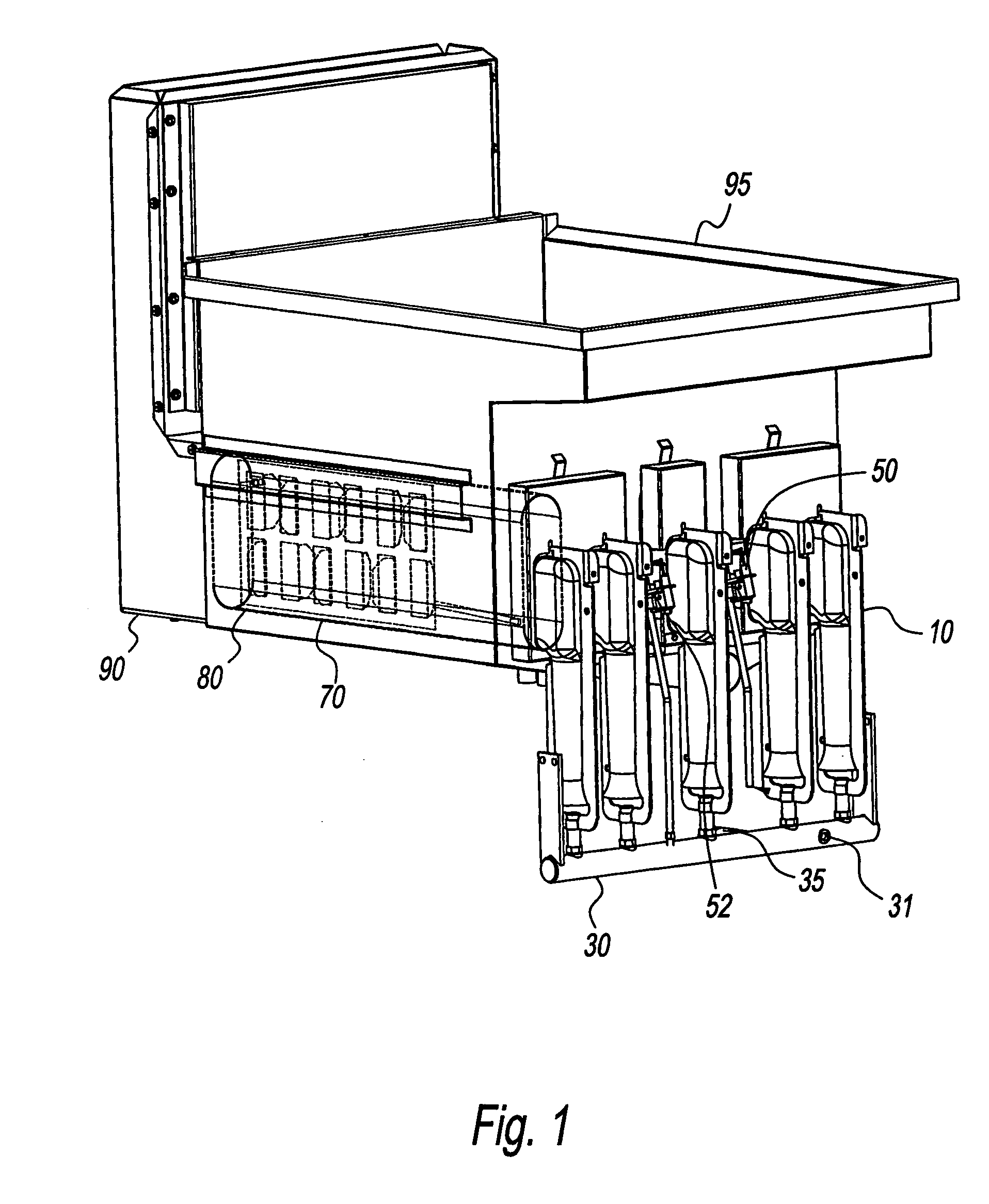

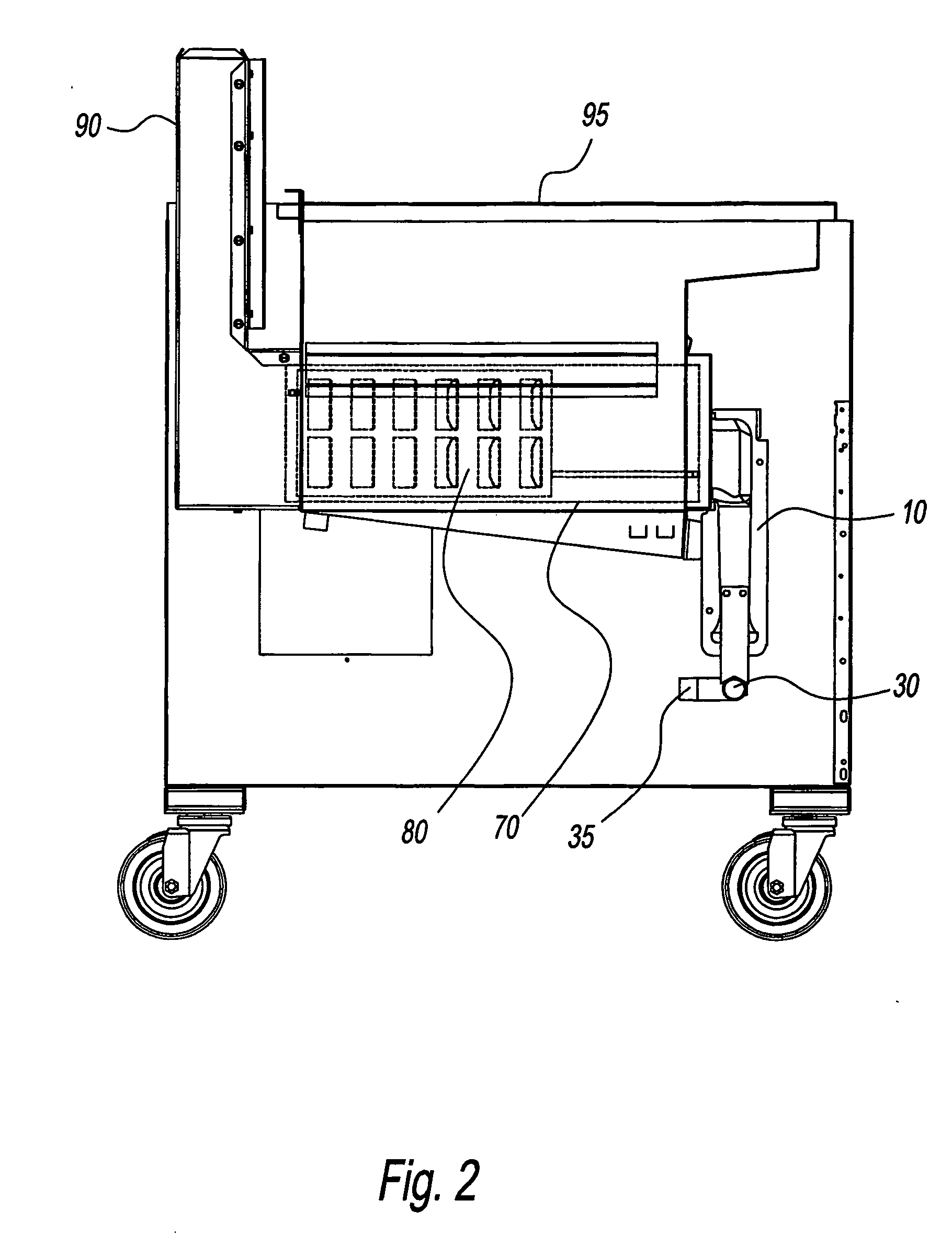

Deep fat tube fryer burner assembly

InactiveUS20070089732A1Increasing burner efficiencyAvoid large movementsBoiling over preventionWater heating stoves/rangesCombustorEngineering

The gas tube fryer comprises substantially 90° in-shot burners, burner mounting boxes, a one-piece burner mounting bracket, and a bracket housing, all of which are used in conjunction with heat exchanger tubes, heat transfer baffles, a frypot, and a flue in a fryer. The burner mounting boxes are keyed specifically to the face of the burner, preventing substantial movement of the burners and introduction of ambient air into the heat exchange tubes. Each burner is also keyed to the mounting bracket, also preventing substantial movement and providing easy installation and repair. The ninety-degree orientation of the burners facilitates mixing of the combustion gases, and the burner comprises a screen on its face that helps to ensure maximum burner efficiency.

Owner:THE FRYMASTER CORP LLC

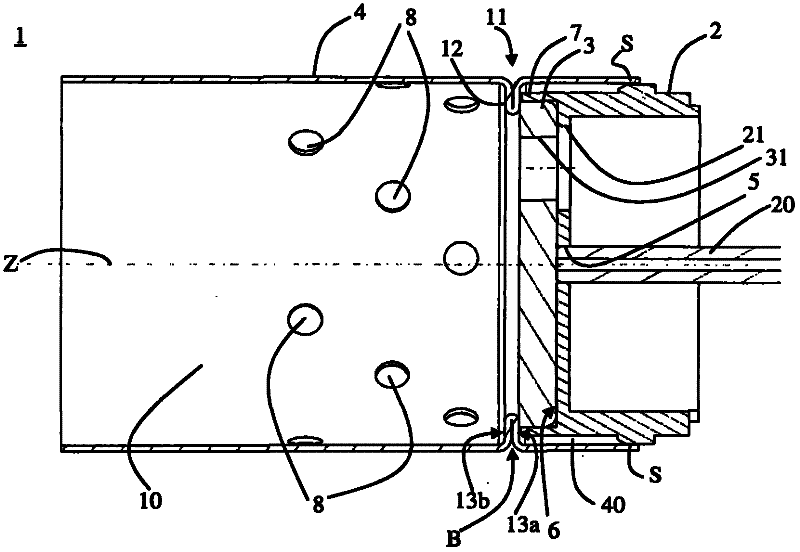

Combustion chamber configuration device for evaporator type combustor

ActiveCN102200279ACost effectiveEasy to manufactureCapillary burnersBurner manufactureCombustion chamberCombustor

The invention provides a combustion chamber configuration device for an evaporator type combustor, especially for a mobile heating device, which includes: an evaporator supporter (2) for holding an evaporator body (3), wherein a fuel supply section opening accesses to the evaporator supporter; an evaporator body (3) made of the absorptive material, wherein the evaporator body (3) is abutted against the evaporator supporter (2) and a circumferential combustion chamber wall (4) which is fixed to the evaporator supporter (2) for forming a combustion chamber (10) which converts the fuel by using the combustion air. The combustion chamber wall (4) includes an inward-extended projection (12) which is formed by deformation of the material of the combustion chamber wall (4) and the evaporator body (3) is retained in a manner that the inward-extended projection (12) abuts against the evaporator supporter (2).

Owner:WEBASTO AG

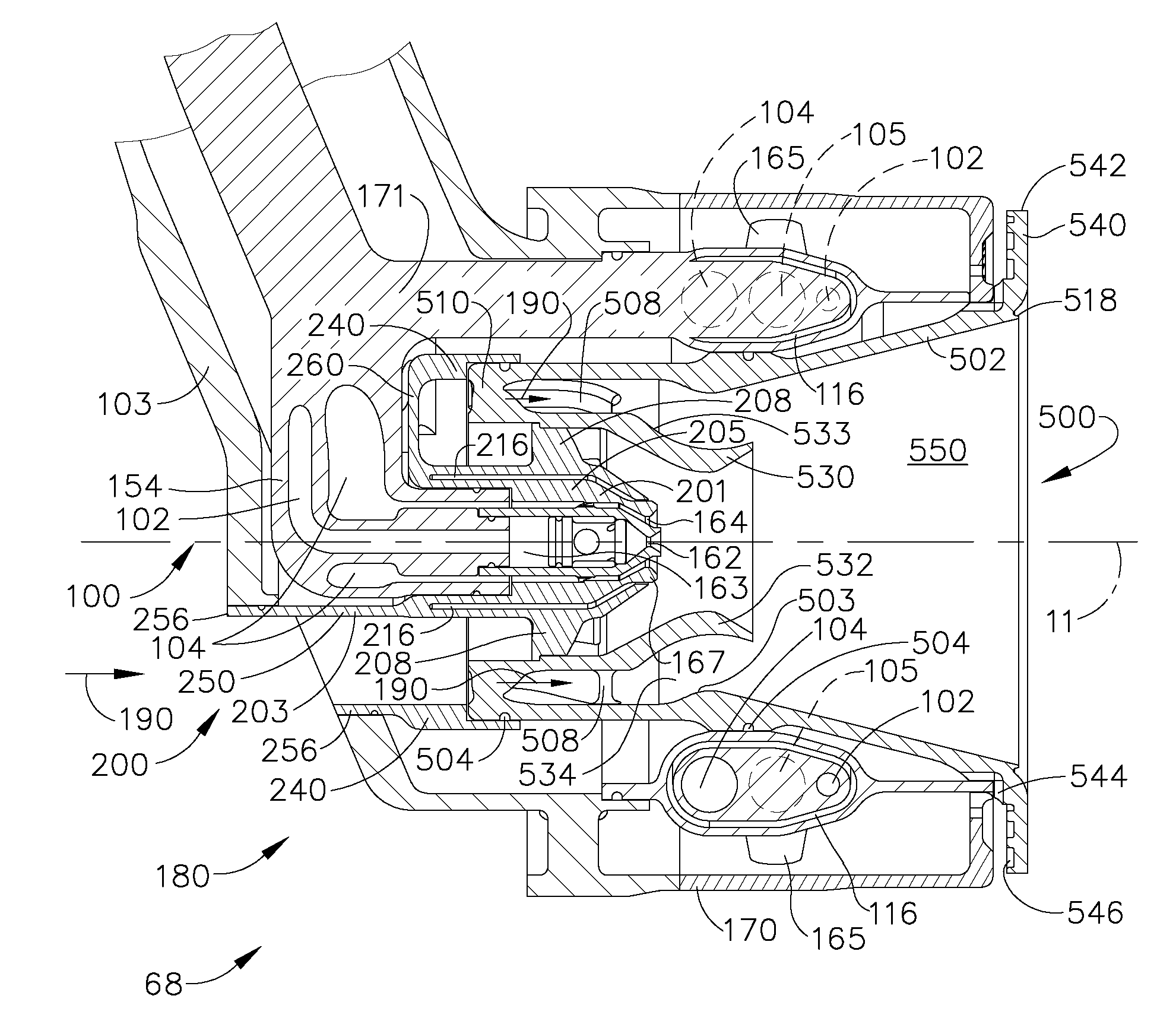

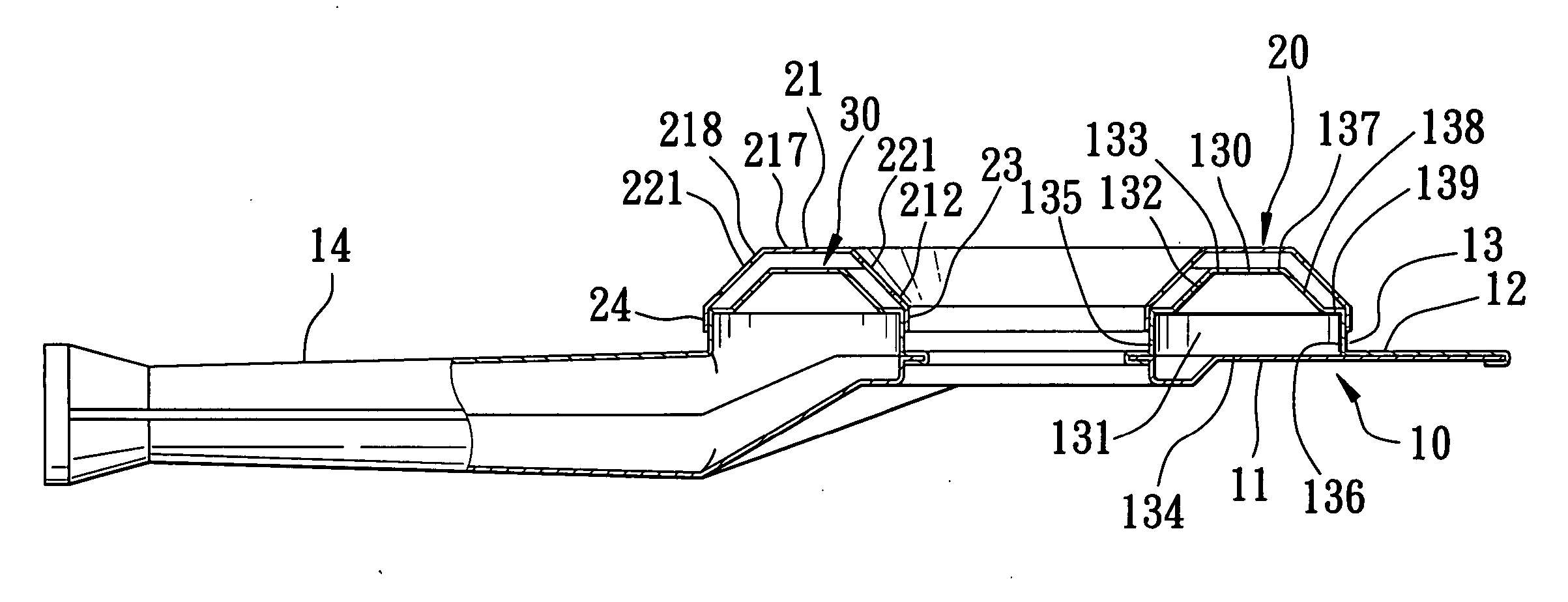

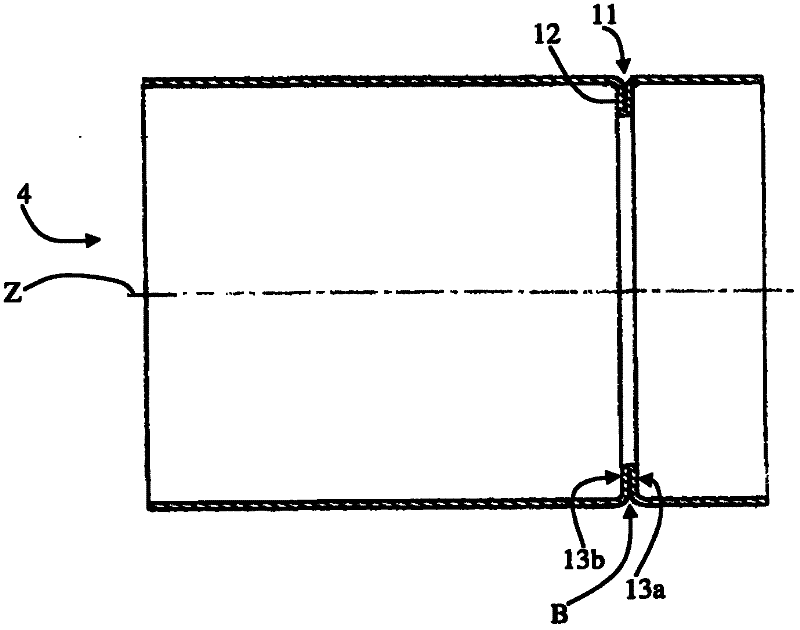

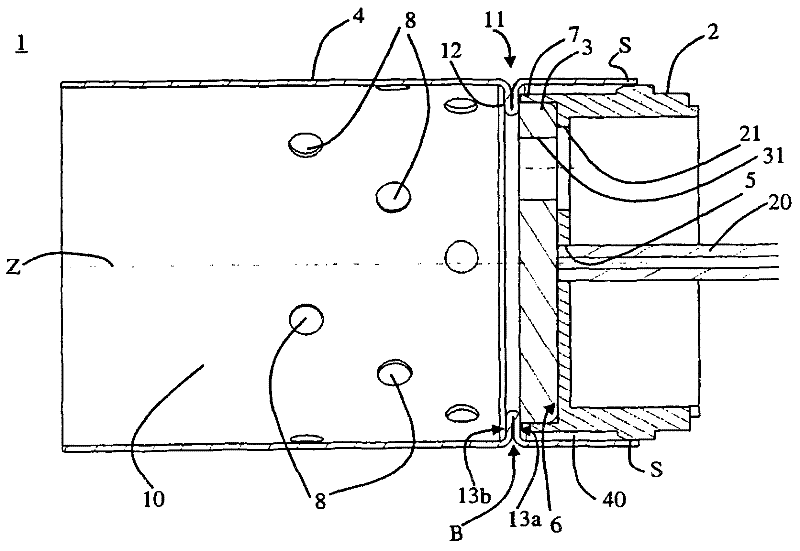

Method of manufacturing a burner front face

ActiveUS9032623B2Improve cooling effectHigh mechanical strengthHydrogenGasifier mechanical detailsCombustorCoolant flow

The invention relates to a method of manufacturing a front face (21) for a burner (1), particularly for the gasification of solid carbonaceous materials by partial combustion. The front face (21) comprises a central aperture (23) corresponding to the discharge end of the burner, a front side wall (24) and a backside wall (25) spaced by one or more baffles (26) defining a coolant flow path with a coolant inlet (30) and a coolant outlet (31). The front side wall (24) and the one or more baffles (26) are made of a single piece of metal and the backside wall (25) is welded on the free top ends of the one or more baffles. The front face can for example be made of a steel according to UNS N07718.

Owner:AIR PROD & CHEM INC

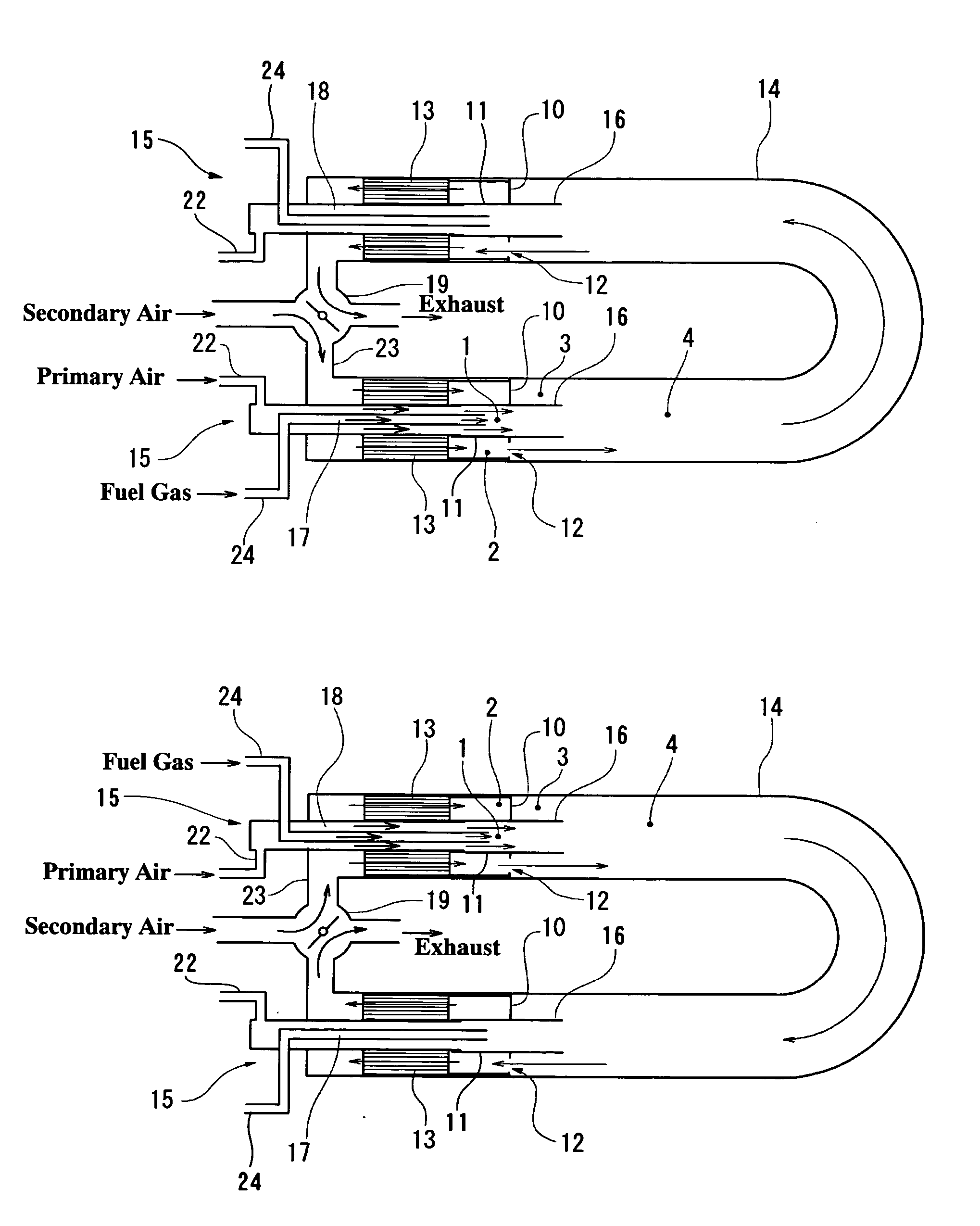

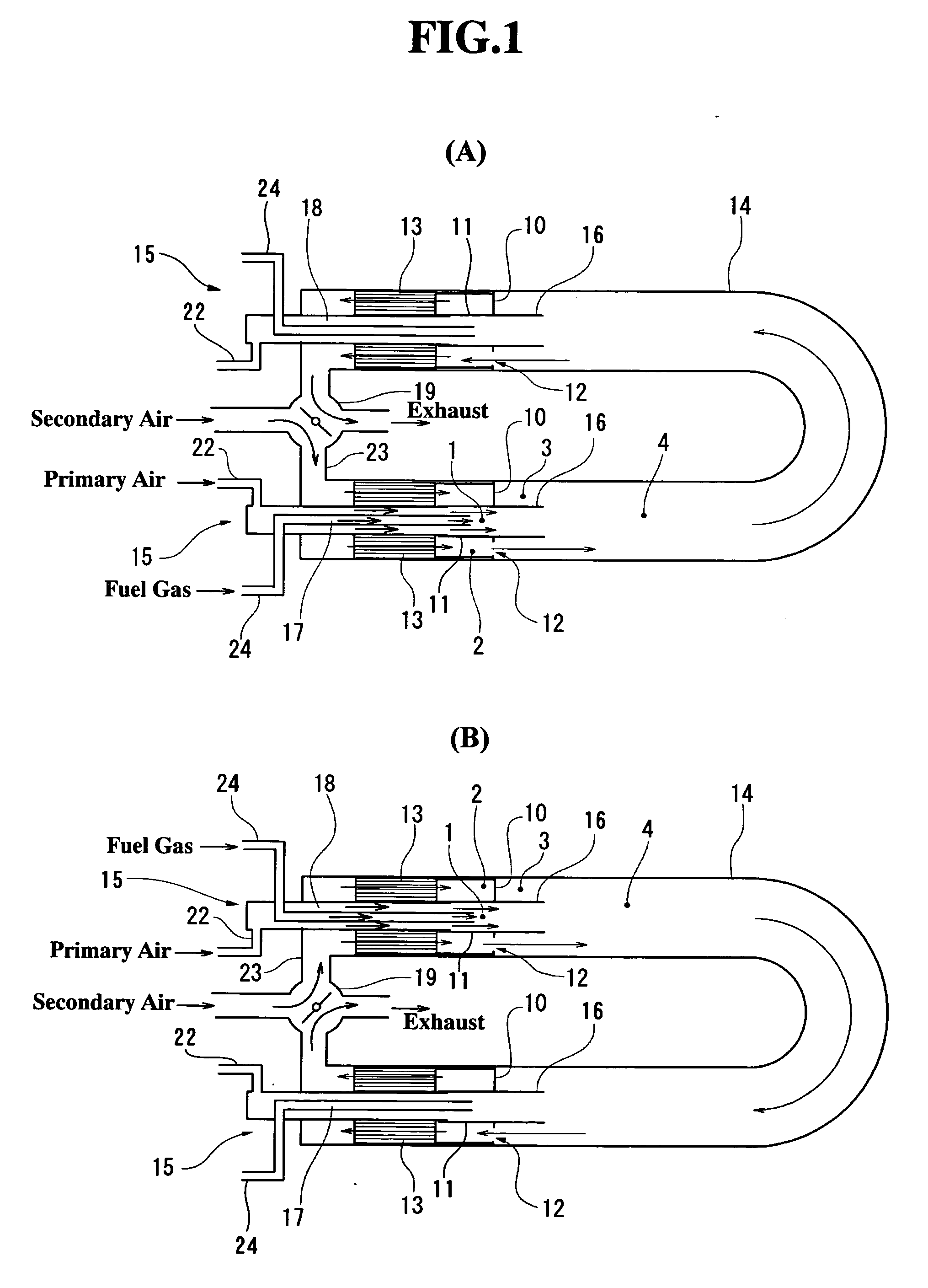

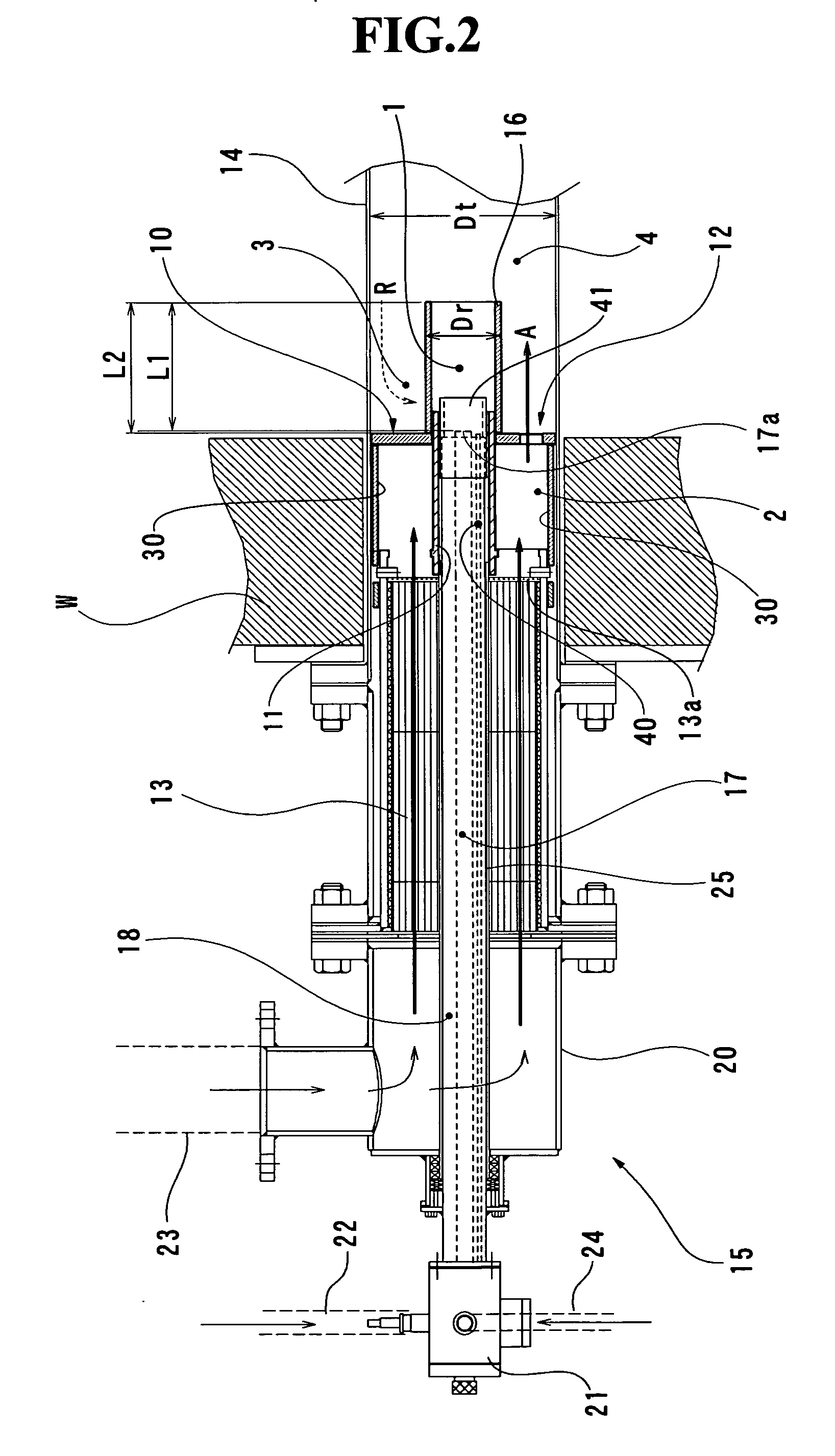

Alternate combustion type regenerative radiant tube burner apparatus

InactiveUS20070054227A1Reduce the concentration of nitrogen oxidesIncrease concentrationCombustion using gaseous and pulverulent fuelPulsating combustionNitrogen oxidesCombustion chamber

The present invention relates to an alternate combustion type regenerative radiant tube burner apparatus which comprises a circular plate positioned between a burner unit and a main combustion chamber, so that preheated secondary combustion air is fed through an opening of the circular plate to the main combustion chamber. The burner apparatus has the circular plate (10), an annular air throat (2), a cylindrical peripheral cover (30) and a heat-transfer tube (11,16). A front end portion of the peripheral cover is integrally connected with a peripheral edge portion of the circular plate so as to prevent the secondary combustion air of the air throat from leaking on a periphery of the circular plate to the air diluting chamber (3). According to the present invention, the concentration of nitrogen oxides in the combustion exhaust gas can be definitely prevented from increasing, without being affected by the installation condition or thermal deformation of the radiant tube burner apparatus.

Owner:NIPPON FURNACE KOGYO KAISHA LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com