Alternate combustion type regenerative radiant tube burner apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

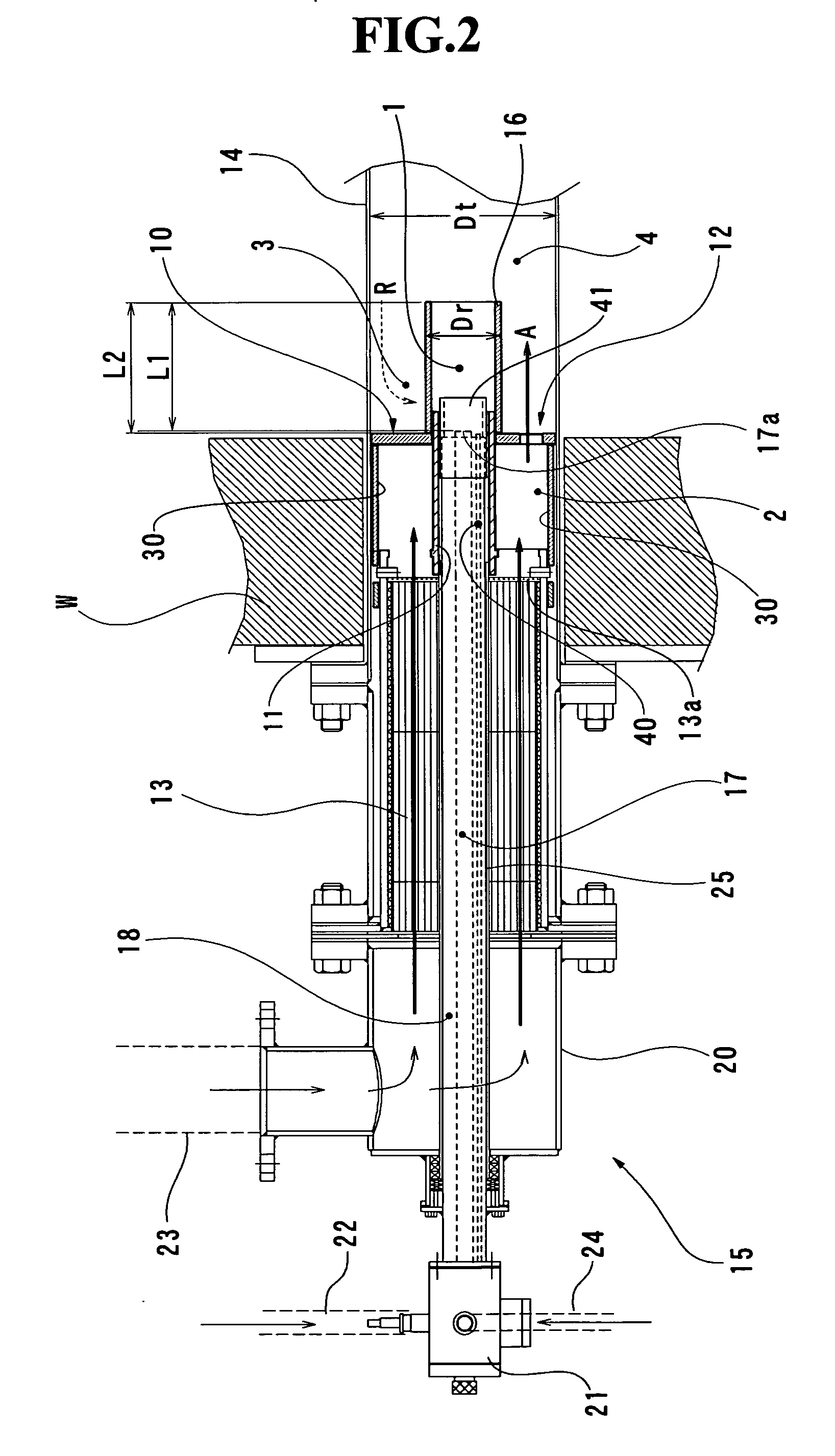

[0044] With reference to the attached drawings, a preferred embodiment of the present invention is described hereinafter.

Structure of Burner Apparatus

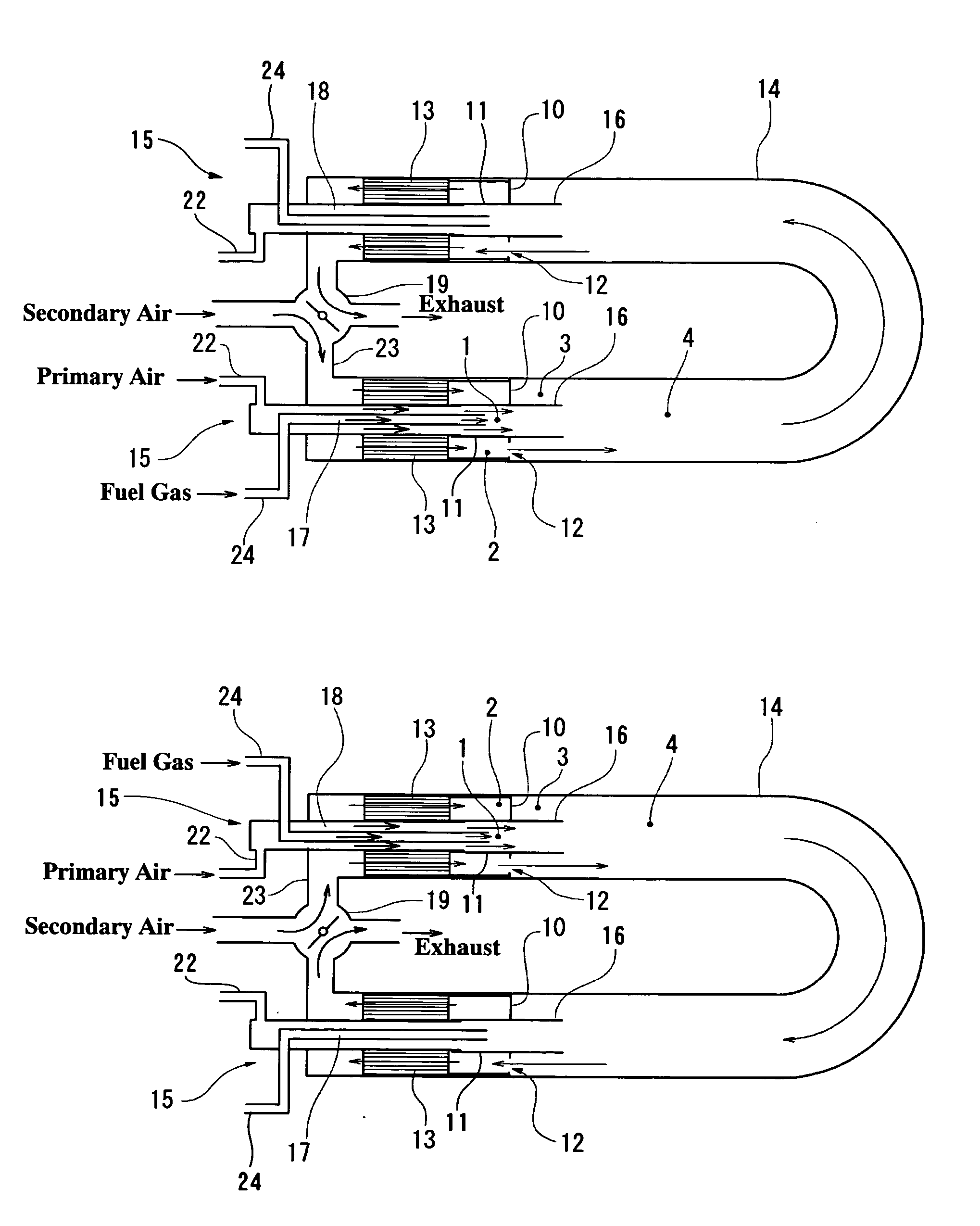

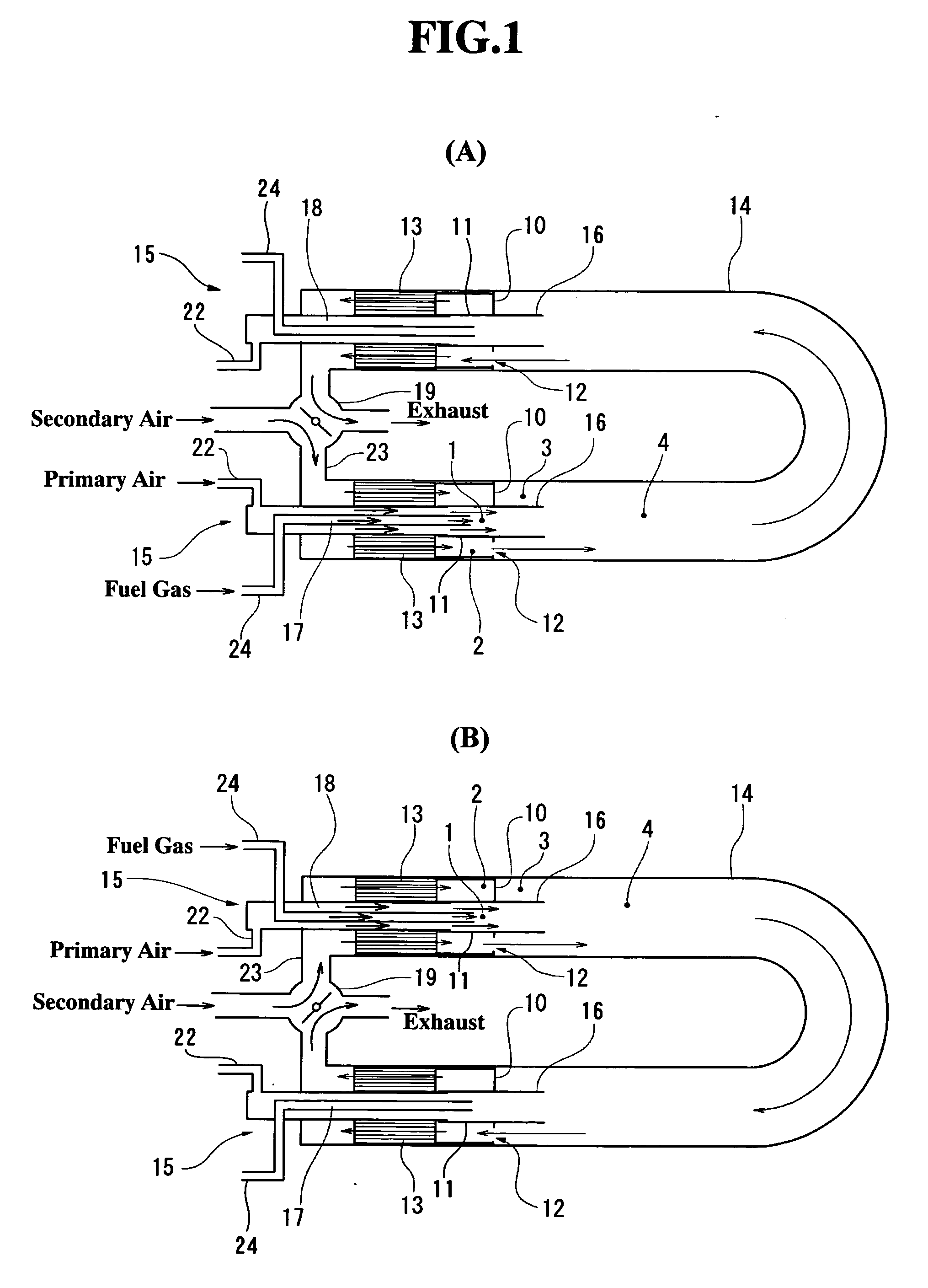

[0045] As shown in FIG. 1, an alternate combustion type regenerative radiant tube burner apparatus (referred to as “burner apparatus” hereinafter) has a radiant tube 14 forming a main combustion chamber 4. Burner units 15 are provided on both end portions of the tube 4. A four-way valve 19 is connected with the respective burner units 15 so that each of the burner units 15 is selectively connected to either an air supply system or an exhaust system. Each of the burner units 15 is provided with a ceramic regenerator 13 having a honey-comb structure. A fuel feed passage 17 and a primary air passage 18 of the burner unit 15 extend through the regenerator 13. The burner units 15 in a pair are alternately changed over to either an operation mode as shown in FIG. 1(A) or an operation mode as shown in FIG. 1(B) at predetermined time interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com