Biomass charcoal gas co-production coupled biomass power generation system and biomass power generation method

A biomass power generation and biomass charcoal technology, which is applied in the direction of combustion methods, biofuels, gaseous fuel supply/distribution, etc., can solve the problems of low temperature corrosion, dust accumulation in the air preheater of biomass direct-fired boilers, etc., and achieve the purpose of slowing down the accumulation Ash and low-temperature corrosion, increase air temperature, slow down the effect of boiler ash and low-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

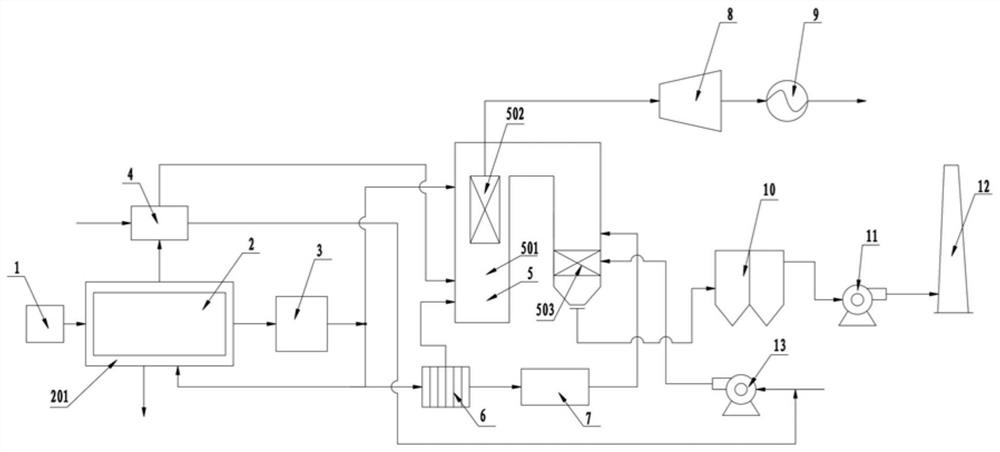

[0036] Such as figure 1 As shown, the biomass charcoal-gas cogeneration coupling biomass power generation system provided by the embodiment of the present invention includes: feeding equipment 1, charcoal-gas cogeneration equipment 2, gas purification equipment 3, heat exchanger 4, biomass direct-fired boiler 5. Gas purification equipment 6, pulse soot blowing equipment 7 and boiler blower 13;

[0037] The feeding device 1 is in communication with the charcoal-gas cogeneration device 2, the flue gas outlet of the charcoal-gas cogeneration device 2 is in fluid communication with the heat exchanger 4, and the gas outlet of the charcoal-gas cogeneration device 2 is in fluid communication with the gas purification device 3;

[0038] The flue gas outlet of the heat exchanger 4 is in fluid communication with the combustion chamber 501 of the biomass direct-fired boiler 5;

[0039] The air inlet of the boiler blower 13 is in fluid communication with the air outlet of the heat exchan...

Embodiment 2

[0056] Such as figure 1 As shown, the biomass power generation method provided in the embodiment of the present invention adopts the biomass charcoal gas cogeneration coupled biomass power generation system provided in Embodiment 1, and includes the following steps:

[0057] The biomass is sent to the charcoal-gas cogeneration equipment 2, and the biomass undergoes pyrolysis and carbonization reaction and is transformed into biochar and combustible gas, and the combustible gas is passed into the gas purification device 3 for purification;

[0058] The purified clean gas is passed into the heating chamber 201 of the charcoal-gas cogeneration equipment 2, the combustion chamber 501 of the biomass direct-fired boiler 5, and the gas purification equipment 6 respectively. The gas burns and releases heat in the heating chamber 201 of the charcoal-gas cogeneration equipment 2 and the combustion chamber 501 of the biomass direct-fired boiler 5; the gas is purified in the gas purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com