Equipment for reducing concentration of nitrogen oxides in flue gas emission of glass kiln

A technology of flue gas emission and nitrogen oxides, which is applied in the direction of gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of environmental protection equipment failing to meet environmental protection requirements, factory and enterprise employee losses, etc., and meet environmental protection emission requirements , easy to operate, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

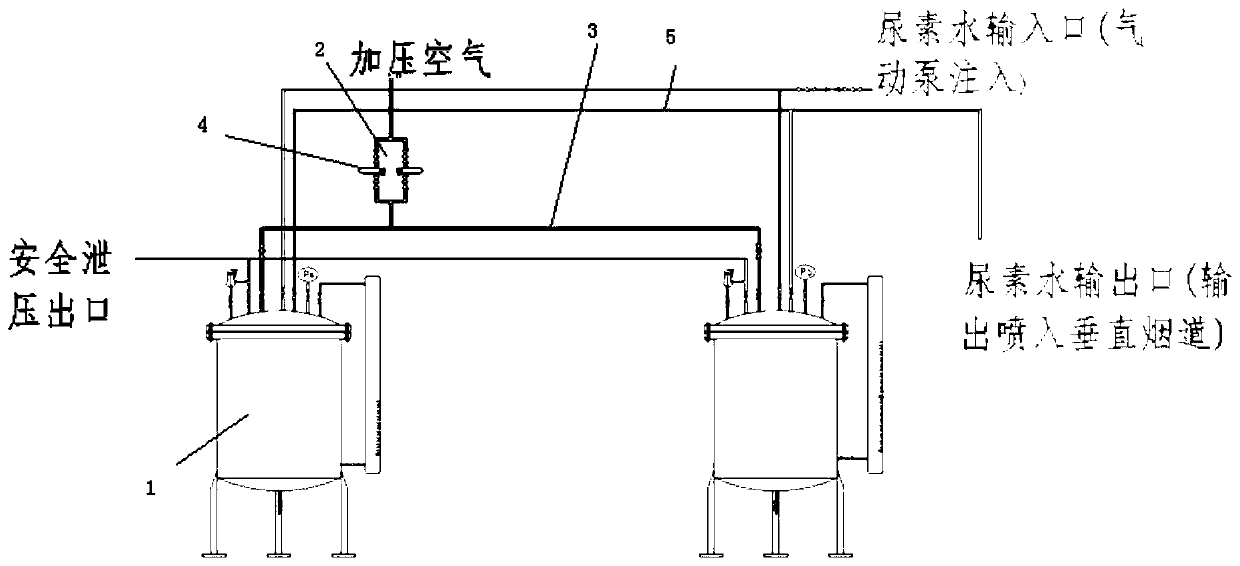

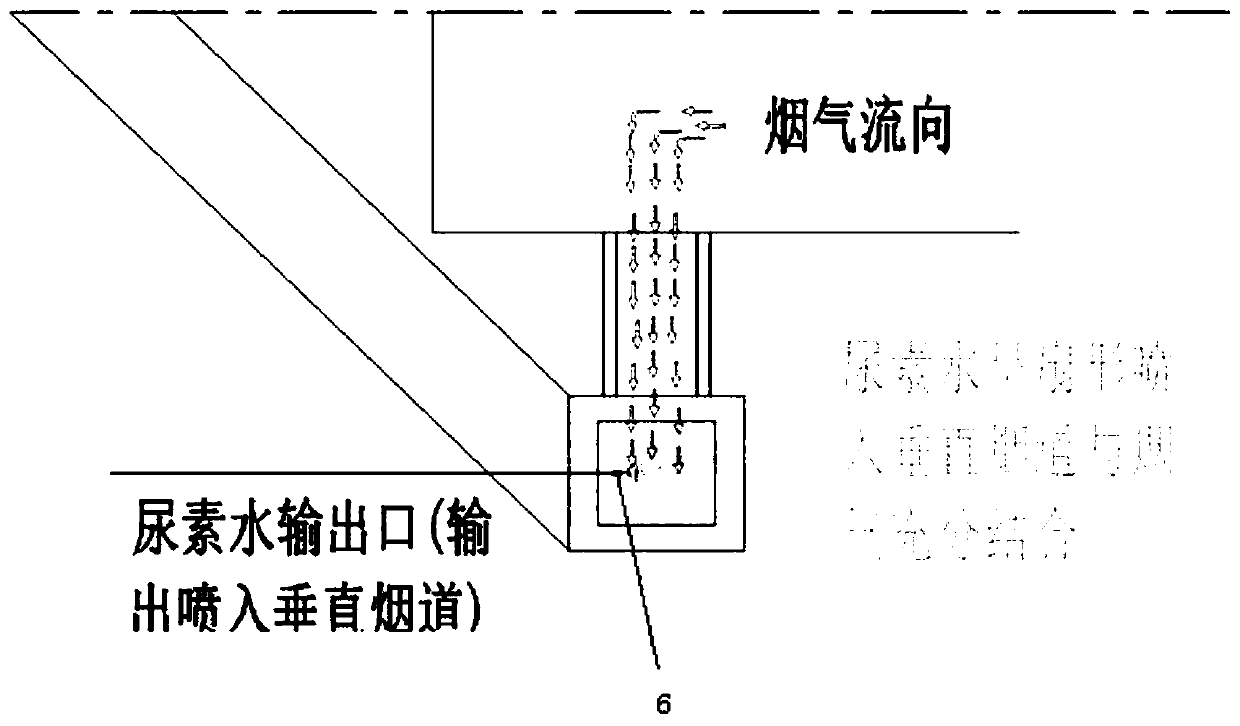

[0018] Such as figure 1 figure 2 Shown: a device for reducing the concentration of nitrogen oxides in flue gas emissions from glass kilns, including a high-pressure tank 1, the input end of the high-pressure tank 1 is connected to the output end of the urea solution, and the output end of the urea solution is passed through a pump For pumping, the top of the high-pressure tank 1 is equipped with an air pressurizing device 2 for air pressurization, the air pressurizing device 2 is connected to the high-pressure tank 1 through the compressed air pipeline 3, and the output end of the high-pressure tank 1 passes through the urea water pipeline 5 Connect the spray gun 6.

[0019] There are respectively 2-3 stainless steel, high-pressure resistant tank bodies; 2 stainless steel fan-shaped spray guns 6; a pressure delivery system; and urea water liquid prepared in proportion to weight.

[0020] There are liquid inlet valve, air inlet valve, exhaust valve, explosion-proof valve, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com