Method of manufacturing a unitary venturi

a technology of venturi and venturi, which is applied in the field of venturi, can solve the problems of minimizing the emission of undesirable gas turbine engine combustion products, reducing the production of undesirable combustion products, and difficult to achieve, and reducing the production of excessive hc and co

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

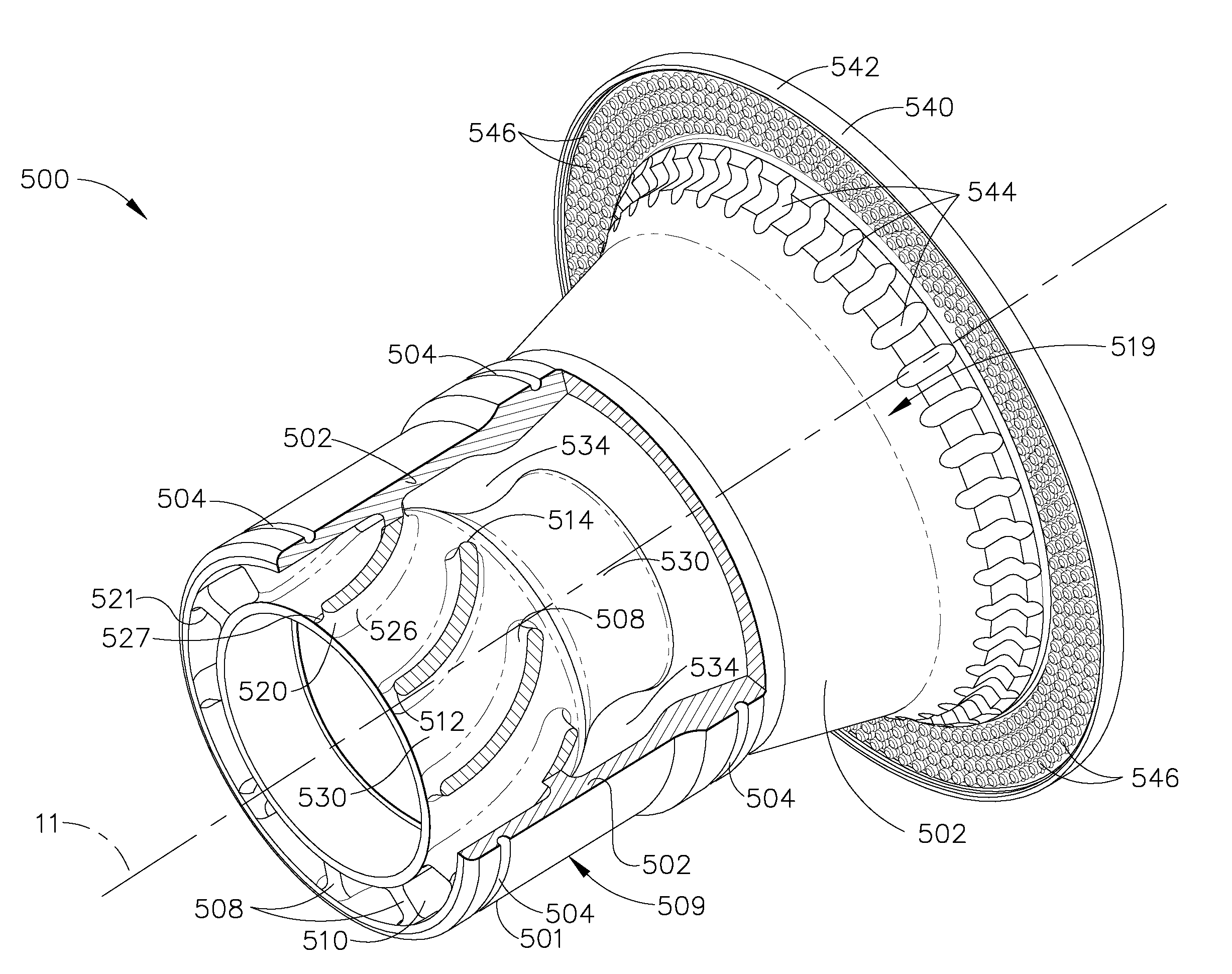

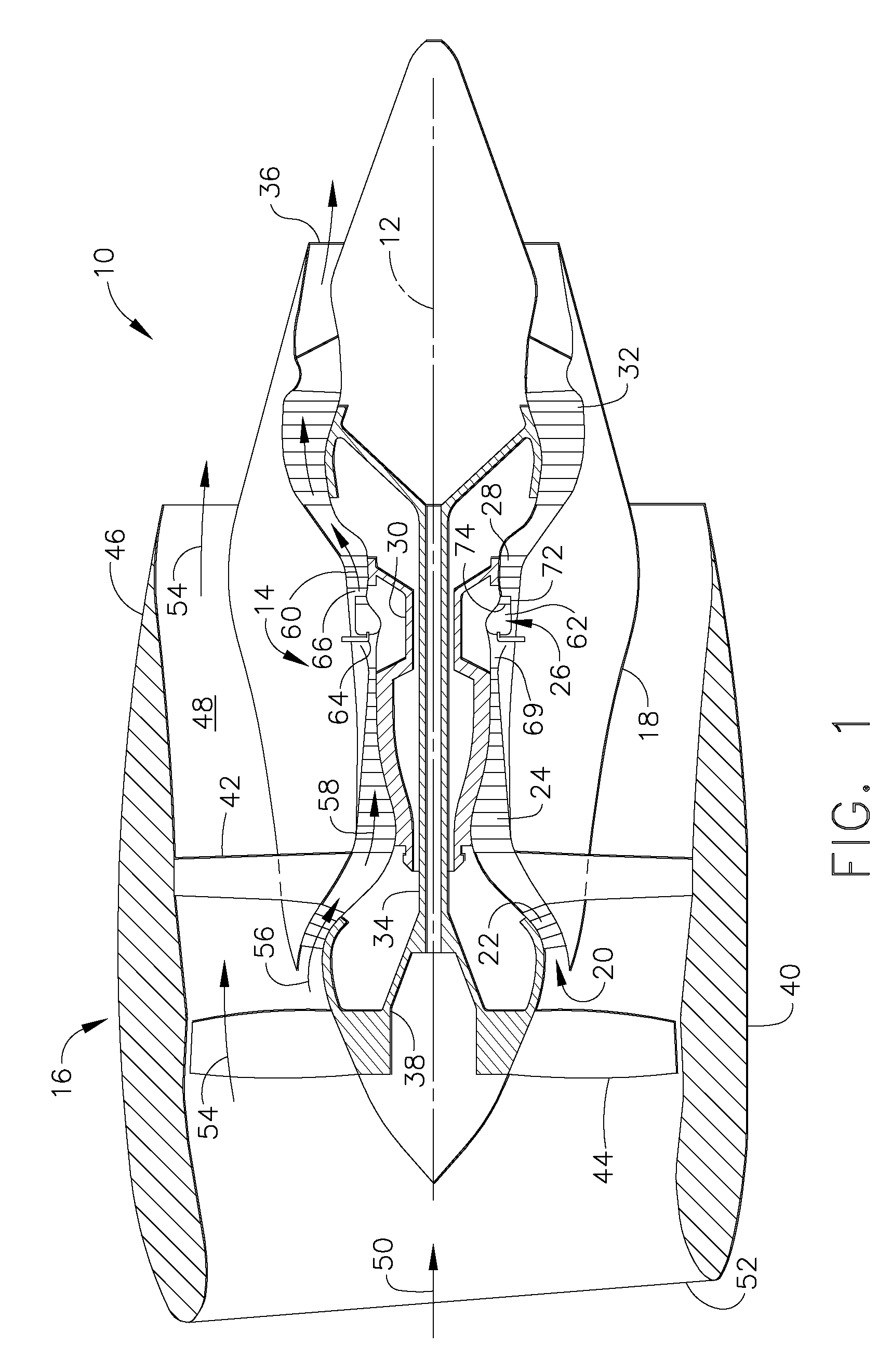

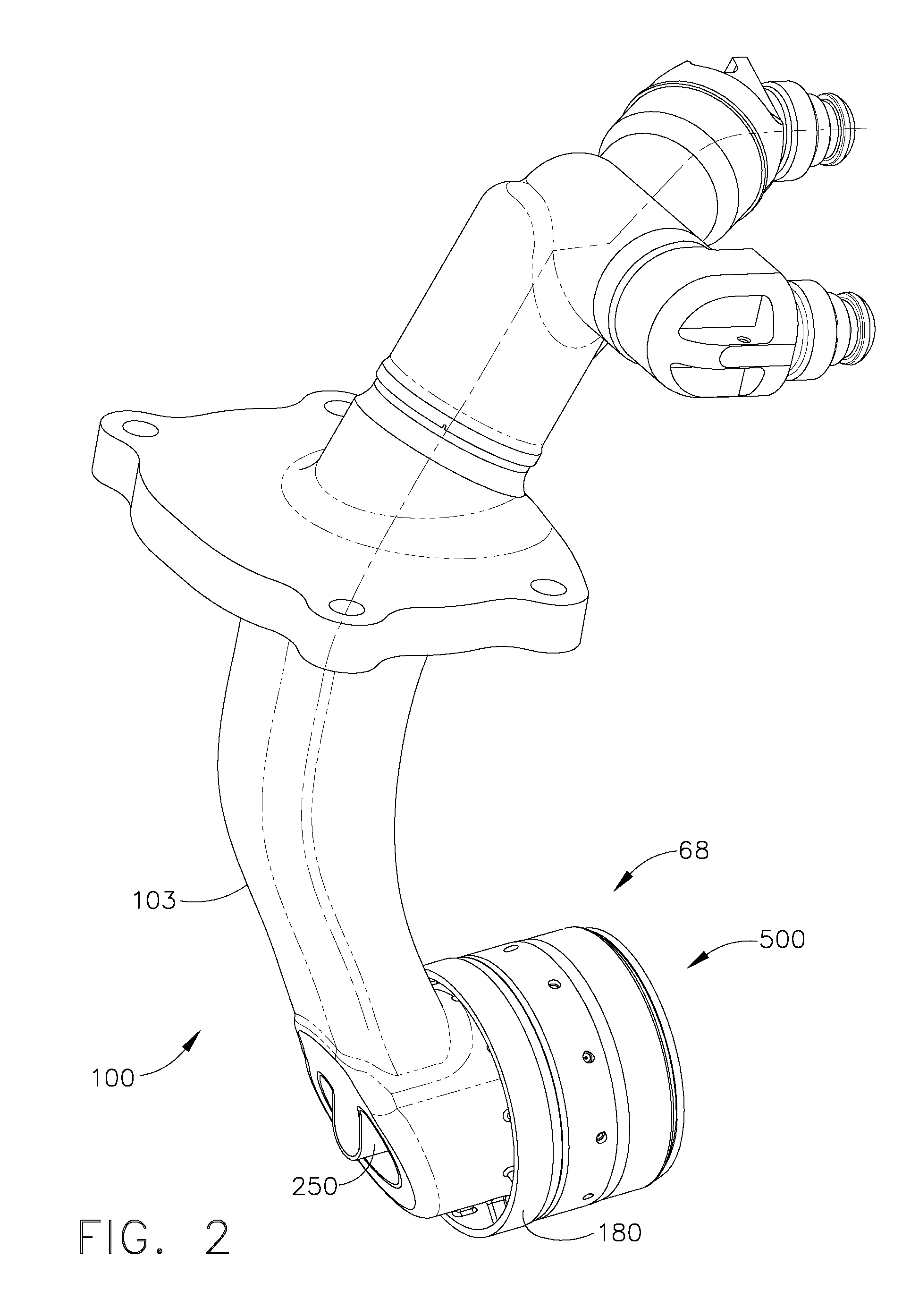

[0022]Referring now to the drawings in detail, wherein identical numerals indicate the same elements throughout the figures, FIG. 1 shows in diagrammatic form an exemplary gas turbine engine 10 (high bypass type) incorporating an exemplary fuel nozzle 100 having an exemplary embodiment of a venturi (such as items 500, shown in the figures and described herein) used for promoting mixing of air with the fuel in the fuel nozzle 100. The exemplary gas turbine engine 10 has an axial centerline axis 12 therethrough for reference purposes. Engine 10 preferably includes a core gas turbine engine generally identified by numeral 14 and a fan section 16 positioned upstream thereof. Core engine 14 typically includes a generally tubular outer casing 18 that defines an annular inlet 20. Outer casing 18 further encloses and supports a booster 22 for raising the pressure of the air that enters core engine 14 to a first pressure level. A high pressure, multi-stage, axial-flow compressor 24 receives ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com