Dust reduction apparatus depending on supply of falling coal in coal drying apparatus using reheat steam

A technology of reheating steam and drying equipment, which is applied in the direction of drying, drying machine, heating to dry solid materials, etc., and can solve the problems of spraying and drying efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

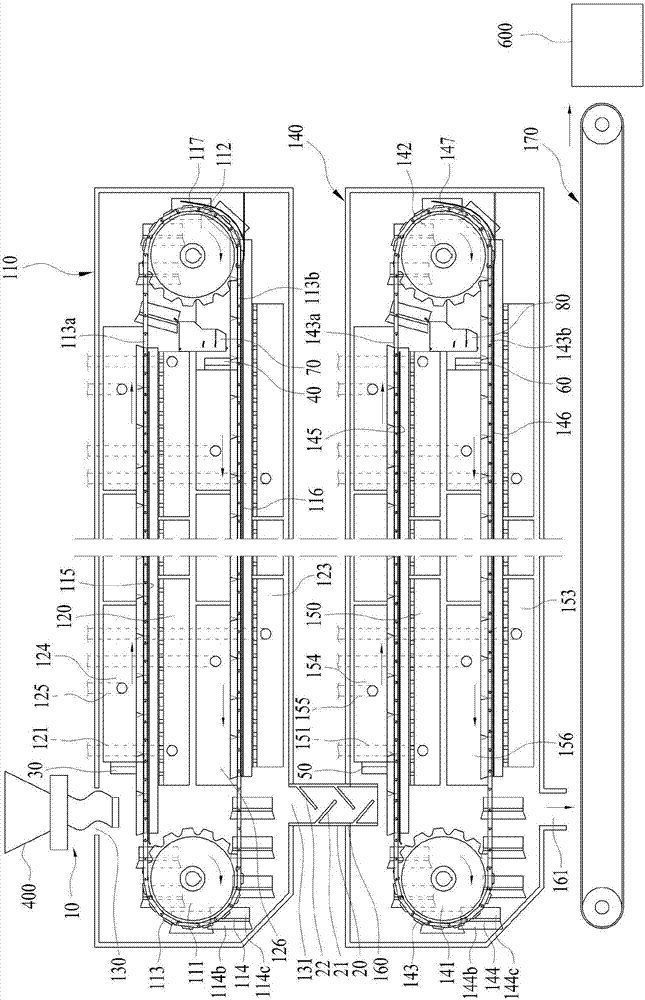

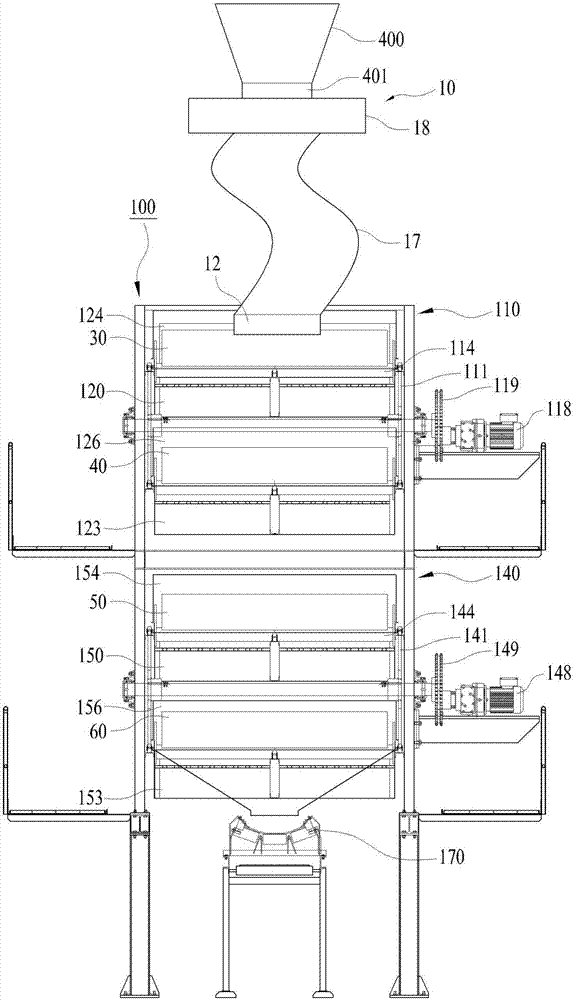

[0057] Hereinafter, the dust reduction device caused by the supply of falling coal in the coal drying device using reheated steam according to the present invention will be described in detail with reference to the accompanying drawings.

[0058] In the present invention, when coal is transferred and dried by a transfer device such as a conveyor or a transfer plate, it suppresses, shields and reduces dust generated in the transfer device by coal dropped and put in during transfer. In particular, the dust reducing device is installed in a coal drying device that reduces the generation of dust when the coal is lowered to the coal dryer on the lower floor and put into the coal dryer while the dried coal is being transferred to the transfer plate. minimize.

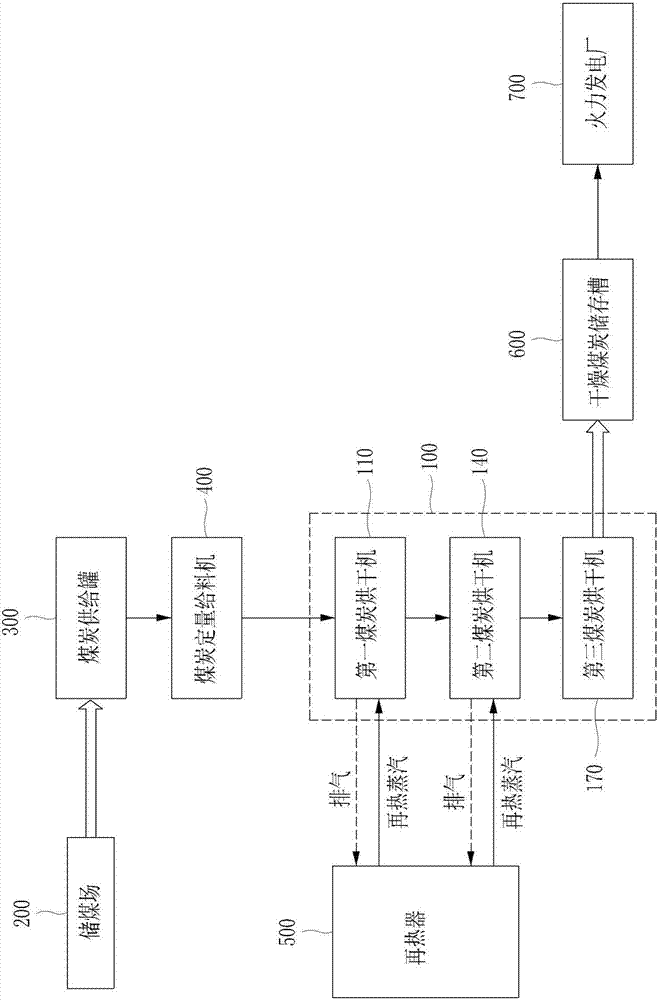

[0059] exist figure 1 Among them, the coal storage yard 200 is a place for storing and storing coal used as fuel for boilers of thermal power plants. Coal contains surface moisture and internal moisture. In particular, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com