Patents

Literature

154results about How to "Reduce imports" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength easy-formation atmospheric corrosion resisting steel

The invention relates to high strength easily forming atmospheric corrosion resistant steel. The invention provides the high strength easily forming atmospheric corrosion resistant steel aiming at the problems in existing steel that the weatherability is bad and the service life is lowered under the condition that the thickness is thinned. The high strength easily forming atmospheric corrosion resistant steel is composed of components of following weight percent: C: 0.04-0.09%, Si: 0.10-0.50%, Mn: 1.20-1.70%, P: <=0.020%, S: < =0.010%, Cu: 0.20-0.60%, Cr: 0.40-0.80%, Ni: 0.20-0.50% and Nb: 0.03-0.07%, and also comprises one or a plurality of Mo: <=0.20%, Ti: <=0.03% and Als: <=0.035%, and allowance is Fe and unavoidable impurity. The yield strength of the steel of the invention is more than or equal to 550MPa, the tensile strength is more than or equal to 650MPa, the percentage elongation is more than or equal to 18%, the corrosion resistance is equivalent to SPA-H steel which is used for previous containers, and the steel has excellent welding performance, cold roll forming performance and low temperature impact toughness, which is beneficial for extending and applying.

Owner:武钢集团有限公司

A method for making semi-processed cold rolled silicon steel in thin slab continuous casting and continuous rolling process

ActiveCN1864879ALess investment in equipmentReduce process linksMelt-holding vesselsRoll mill control devicesThin slabAluminium

The invention relates to a method for using sheet blank continuous casting continuous rolling to produce silicon steel. In the BOF smelt process, it uses bottom argon blow technique in the whole processes; adds composite deoxidant and aluminum into steel pack when outputting steel to remove oxygen; adds manganese, silicon steel and ferro-phosphorus to alloy; blows argon to the melt steel in all process; uses LF furnace to refine the melt steel; using CSP continuous casting machine to cast the melt steel into casting blank; heats the casting blank via TF furnace to be rolled by continuous rolling machine to be hot rolling sheet coil; acid washes hot rolling plate to be cold rolled via rough roller cold rolling machine to be cold rolled sheet coil; anneals via the anneal furnace; flattens the annealed sheet coil via flatten machine group while the extending rate is 2-18%; corrects the sheet shape via correct machine; packs and stores the coil into the storehouse. The inventive method can reduce the cost of producing device and improve the additive value of sheet blank continuous casting continuous rolling product.

Owner:湖南华菱涟钢特种新材料有限公司 +1

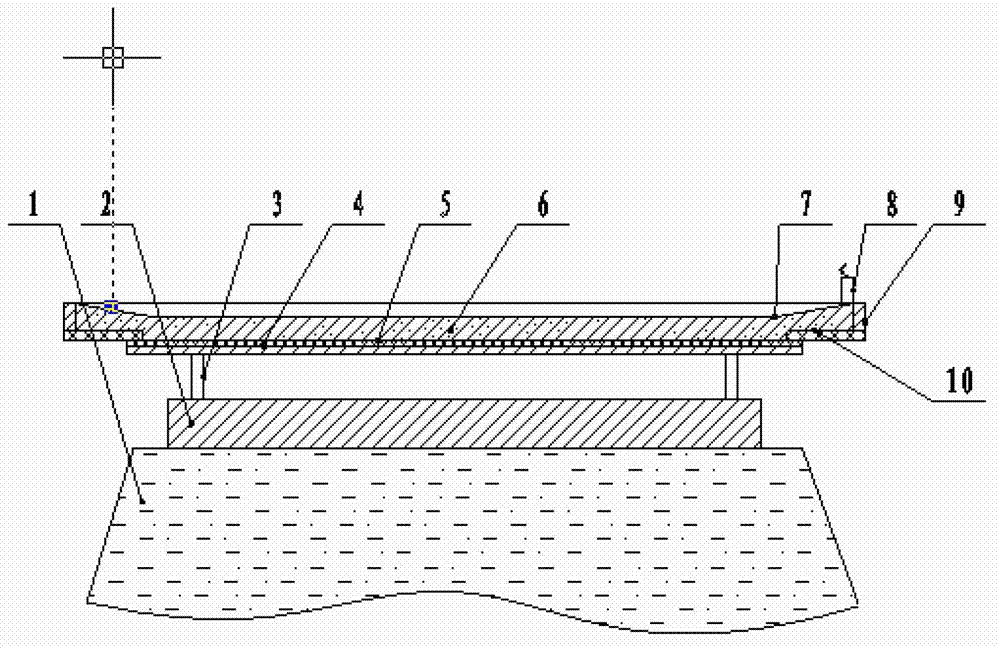

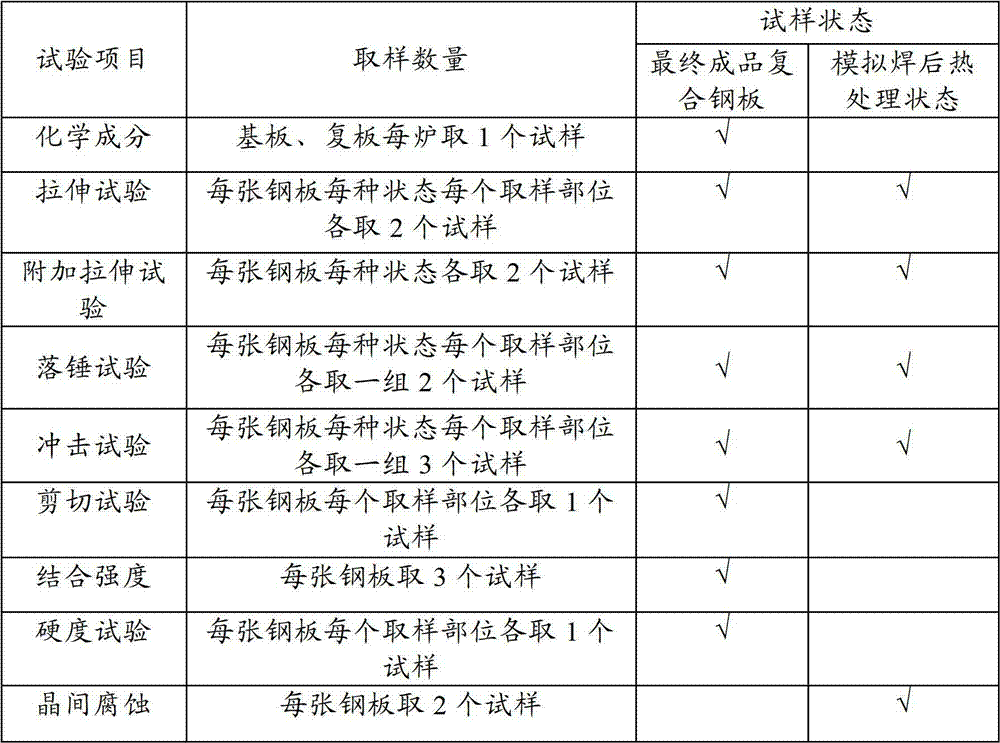

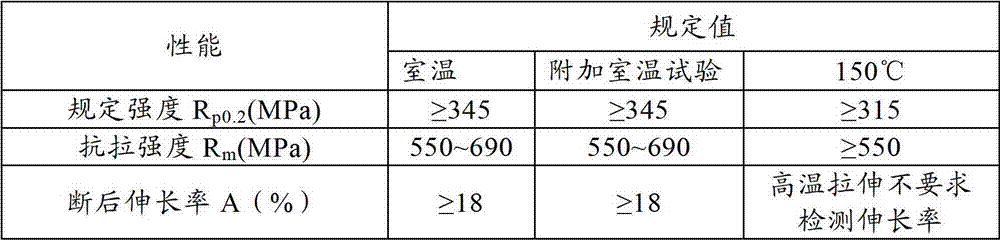

Clad steel plate for nuclear power engineering and manufacturing method of clad steel plate

ActiveCN102825858AUniform corrosion resistance on the surfaceImprove mechanical propertiesMetal layered productsNon-electric welding apparatusTemperingNuclear power

The invention relates to a clad steel plate for nuclear power engineering. The clad steel plate comprises a base plate and a cladding plate, wherein the base plate is a killed steel plate, the cladding plate is a nickel-chromium austenitic stainless steel plate, and the base plate and the cladding plate are combined to form the clad steel plate; the base plate comprises the following components: not larger than 0.25% of C, 1.00-1.80% of Mn, not larger than 0.015% of P, not larger than 0.015% of S, 0.10-0.50% of Si, 0.35-0.70% of Mo, 0.30-0.80% of Ni, not larger than 0.125% of Cu, not larger than 0.25% of Cr, not larger than 0.06% of V, not larger than 0.02% of Nb, not larger than 0.03% of Ti, not larger than 0.25% of Co, not less than 0.02% of Al, and the balance of iron and unavoidable impurities; and the cladding plate comprises the following components: not larger than 0.035% of C, not larger than 2.00% of Mn, not larger than 0.015% of P, not larger than 0.015% of S, not larger than 0.80% of Si, 7.00-12.5% of Ni, not larger than 0.12% of Cu, 17.50-20.50% of Cr, not larger than 0.06% of V, not larger than 0.05% of Co, not larger than 0.11% of N and the balance of iron and unavoidable impurities. The invention further discloses a method for manufacturing of the clad steel plate. The method comprises the following step of (1) surface treatment; (2) explosion welding; and (3) thermal treatment: keeping 920-940 DEG C after the clad steel plate is subjected to the explosion welding in the step of (2), ventilating nitrogen after heating the clad steel plate to be 750-770 DEG C, cooling and carrying out high-temperature tempering to obtain the clad steel plate.

Owner:太原钢铁(集团)有限公司

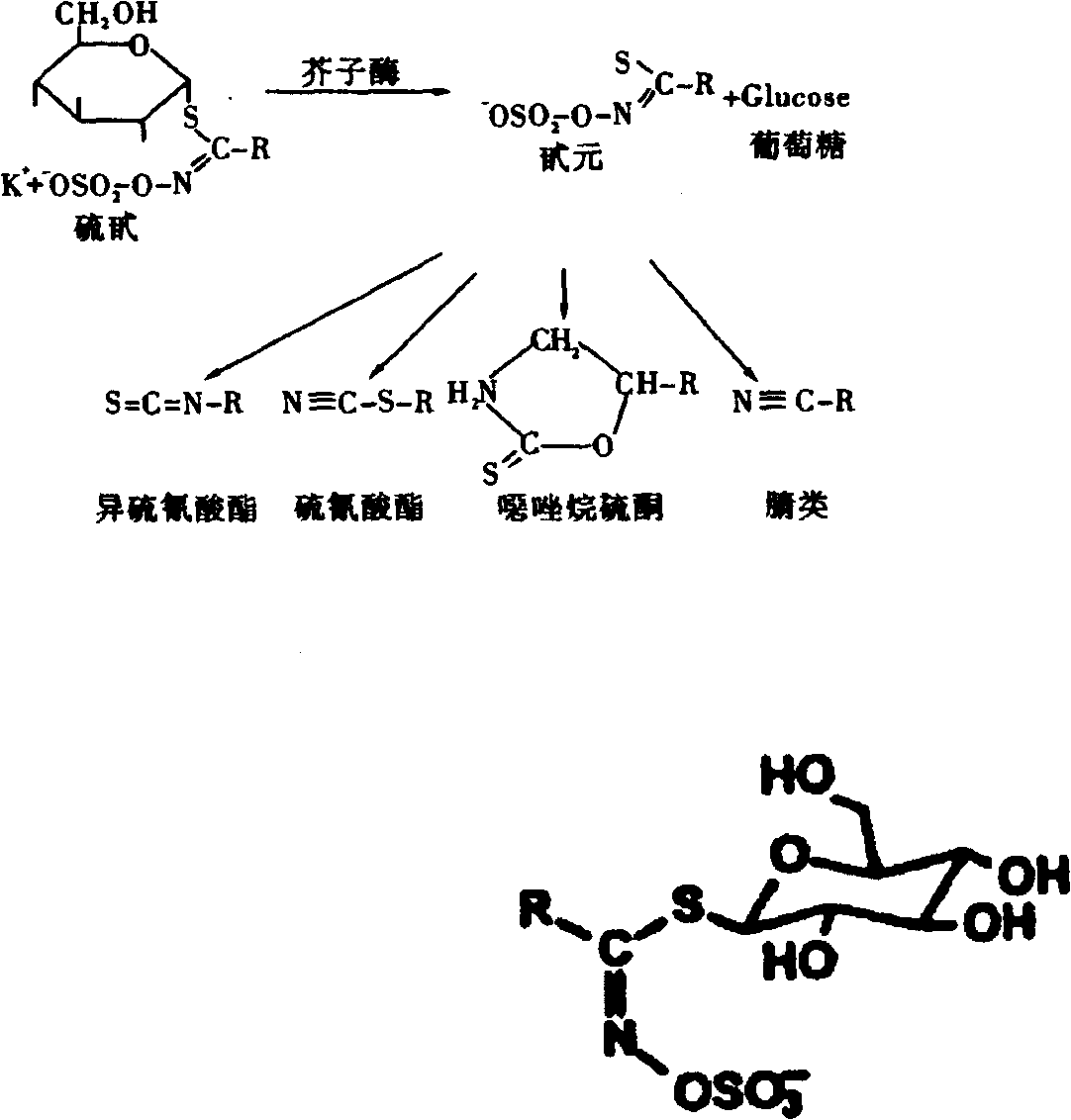

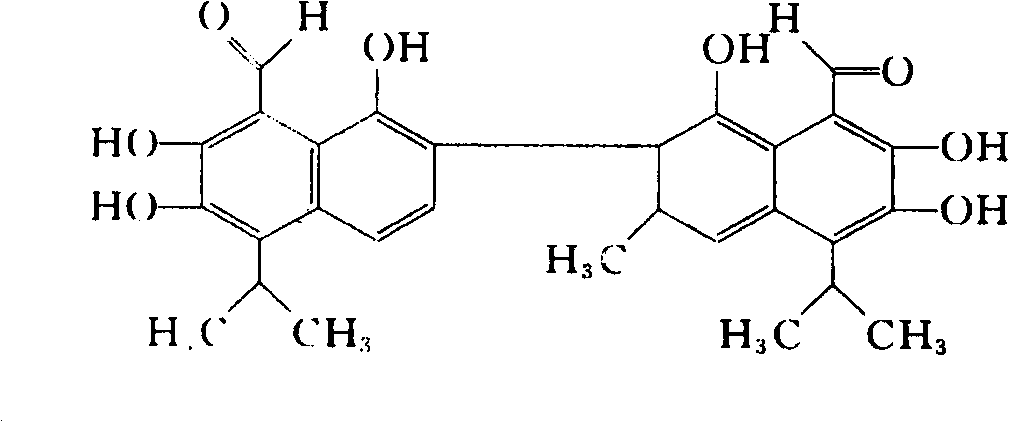

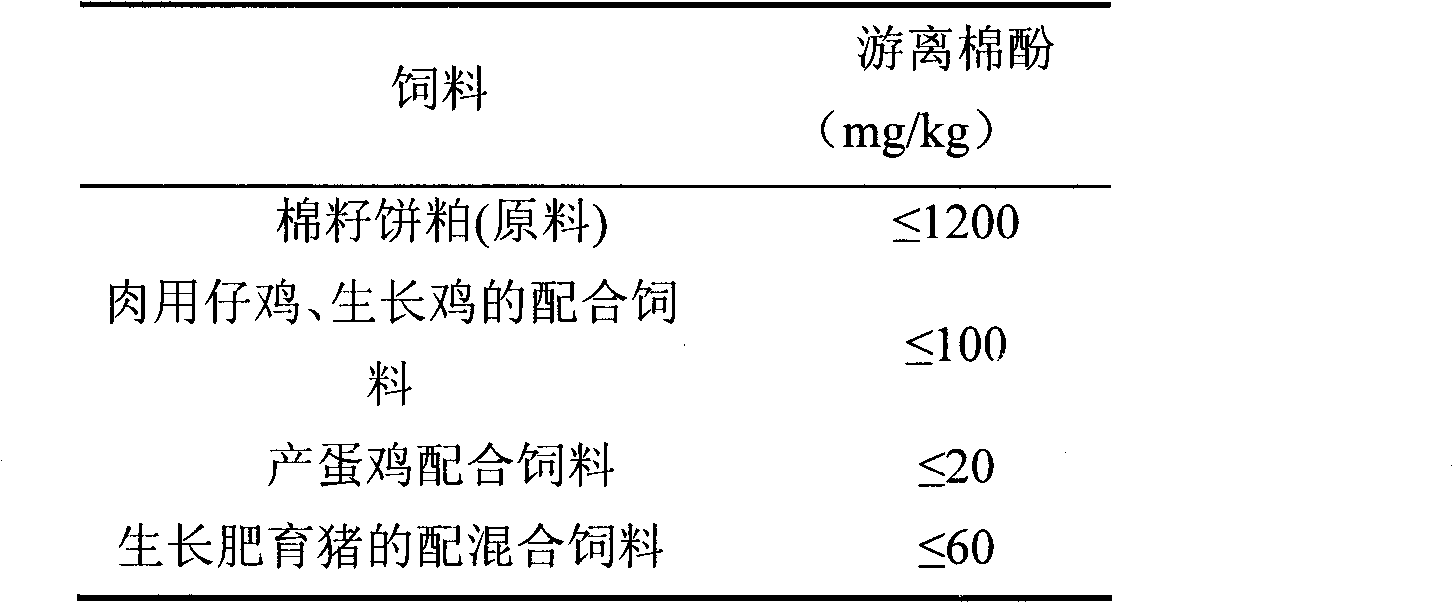

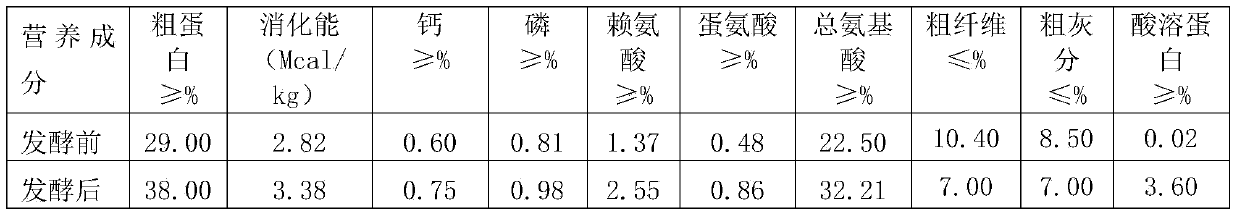

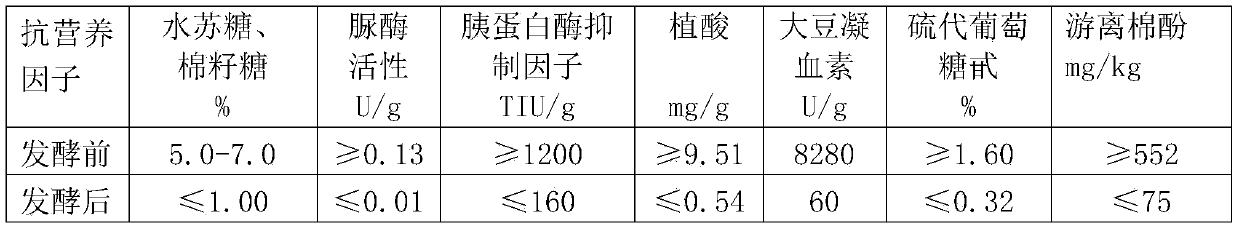

Method for removing cotton rapeseed meal toxicant by fermentation method and enhancing nutrient value thereof, feeding fermented cotton rapeseed meal protein feedstock and applications thereof

The invention discloses a method for removing cotton rapeseed meal toxicant by fermentation method and enhancing nutrient value thereof, a feeding fermented cotton rapeseed meal protein feedstock and applications thereof. The method comprises the steps that: cottonseed meal and rapeseed meal are mixed, the mixture is first added with feedstock water and complex enzyme preparation, and then inoculated with microorganism strain capable of producing protease bacteria or / and lactic acid bacteria as well as decomposing glucosinolate or / and gossypol, then fermentation is performed to obtain treated cotton rapeseed meal so as to obtain nontoxic, highly-nutrient feeding fermented cotton rapeseed meal protein feedstock, and the feeding fermented cotton rapeseed meal protein feedstock is used as protein feedstock component to form cotton rapeseed meal animal feed according to 15% of the addition proportion. Using modern biological technology, the method solves the problems of low utilization rate of cotton rapeseed meal, small amount of addition in the feed, the presence of toxicant and the like, and eases the strain on feed protein in our country.

Owner:北京金泰得生物科技股份有限公司

Methanol gasoline modified alcohol additive

InactiveCN101024788ASolve the problem of easy water absorptionDoes not reduce the use effectLiquid carbonaceous fuelsBenzoic acidZinc peroxide

The invention relates to a methanol gas oil modification alcohol additive that uses acetone, toluol, isobutyl alcohol, benzoic acid, ferrocene and zinc peroxide as raw material, and whisking equal in the volume under room temperature and normal pressure to gain the product. It adds 1-3% additive into methanol to gain modified mellow after whisking, and adding the mellow into naphtha or 90# diesel oil to gain the 90#, 93#, 97# and 98# methanol gas oil. The gas oil condensation point would be decreased by adjusting the methanol gas oil and the pollution would be sharply decreased. It has great social benefits and economic benefits.

Owner:北京福众金源环保科技有限公司

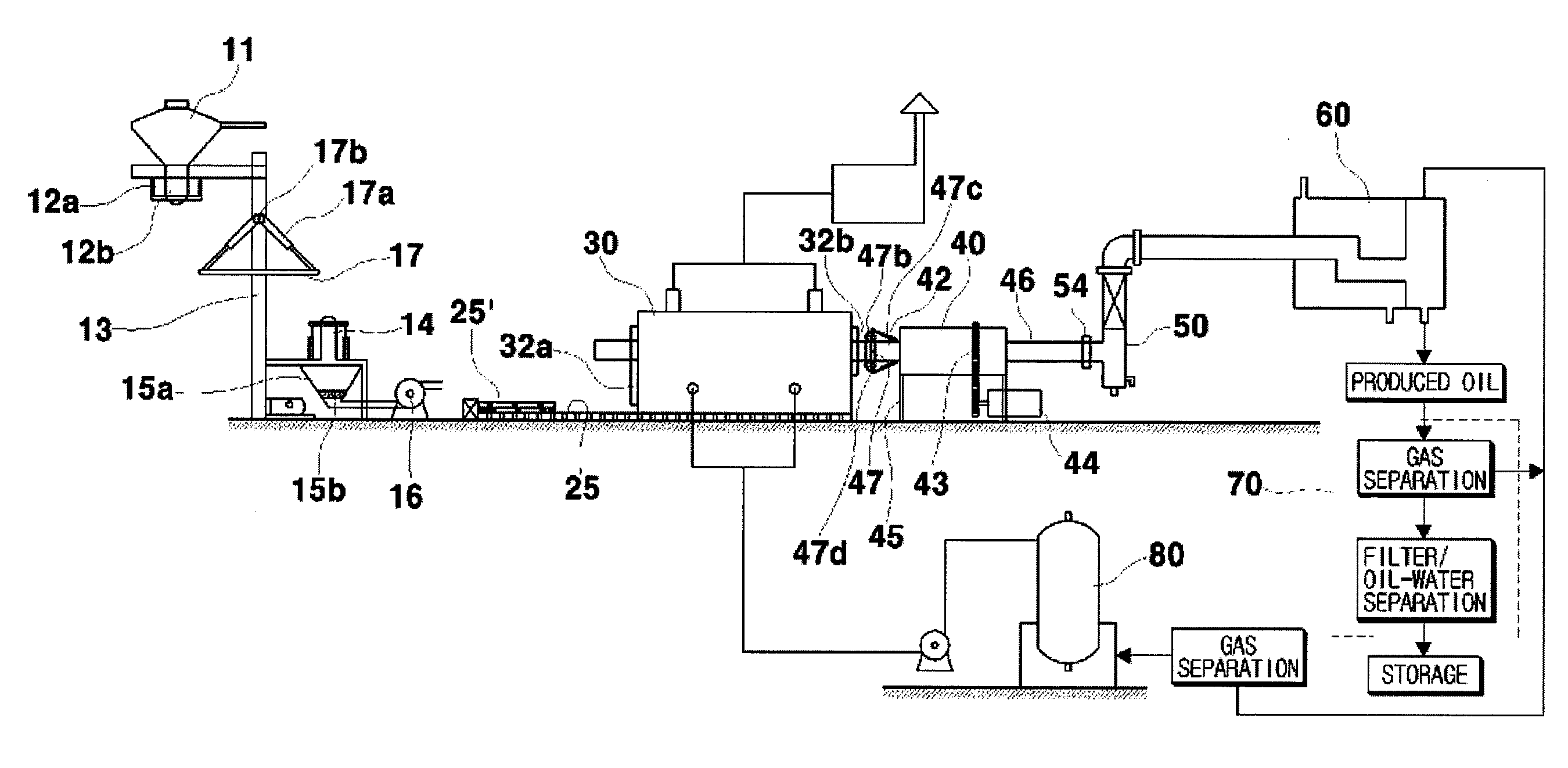

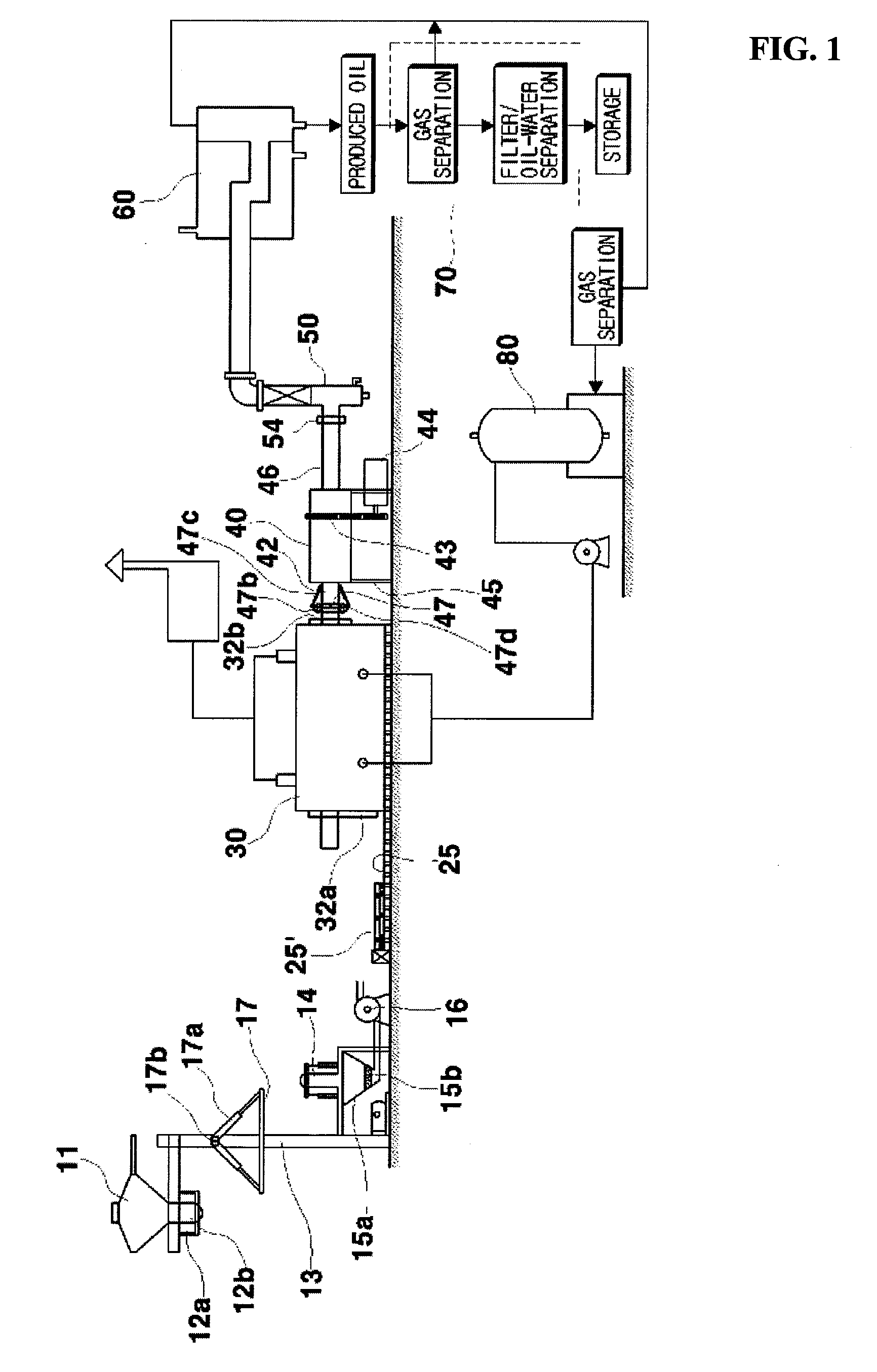

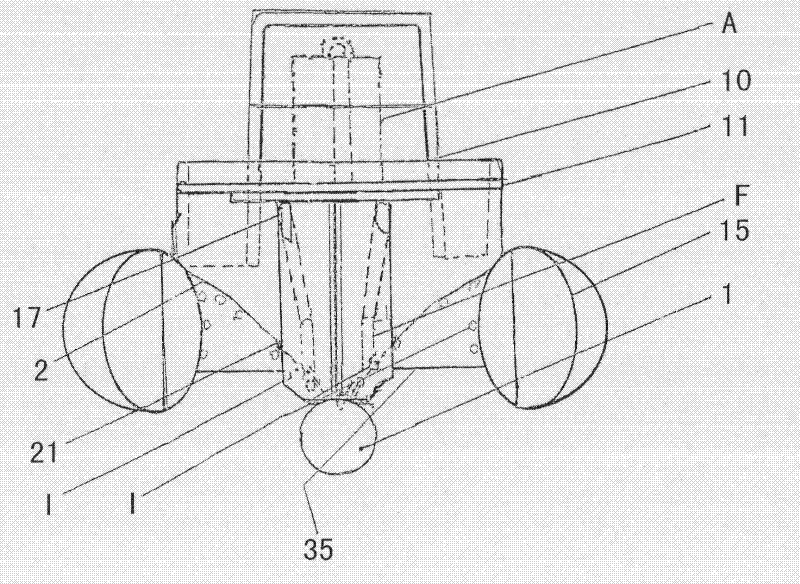

Oil extraction device for pyrolysis of plastics waste material and extraction method thereof

InactiveUS20090314622A1Economical efficiencyEfficiently collecting the pyrolyzed gasDispersed particle filtrationTransportation and packagingCombustion chamberCombustor

An oil extraction system and method for pyrolyzing waste plastic materials are disclosed. The oil extraction system includes: a waste feeding device for supplying waste plastic materials contained in a hopper to a primary pyrolysis chamber through a feed inlet, wherein the primary pyrolysis chamber pyrolyzes the supplied waste plastic materials; a double jacket furnace having a burner and for heating the primary pyrolysis chamber loaded into a burning room of the furnace; a rotation device for rotating the primary pyrolysis chamber loaded into the burning room of the furnace; a secondary pyrolysis chamber for re-pyrolyzing gas produced in the primary pyrolysis chamber, and for separating carbides and residue; a condenser for liquefying the gas separated from the secondary plyrolysis chamber by compression and forming oil; and an oil-water separator for separating oil and water condensed in the condenser.

Owner:PULSE ENERGY

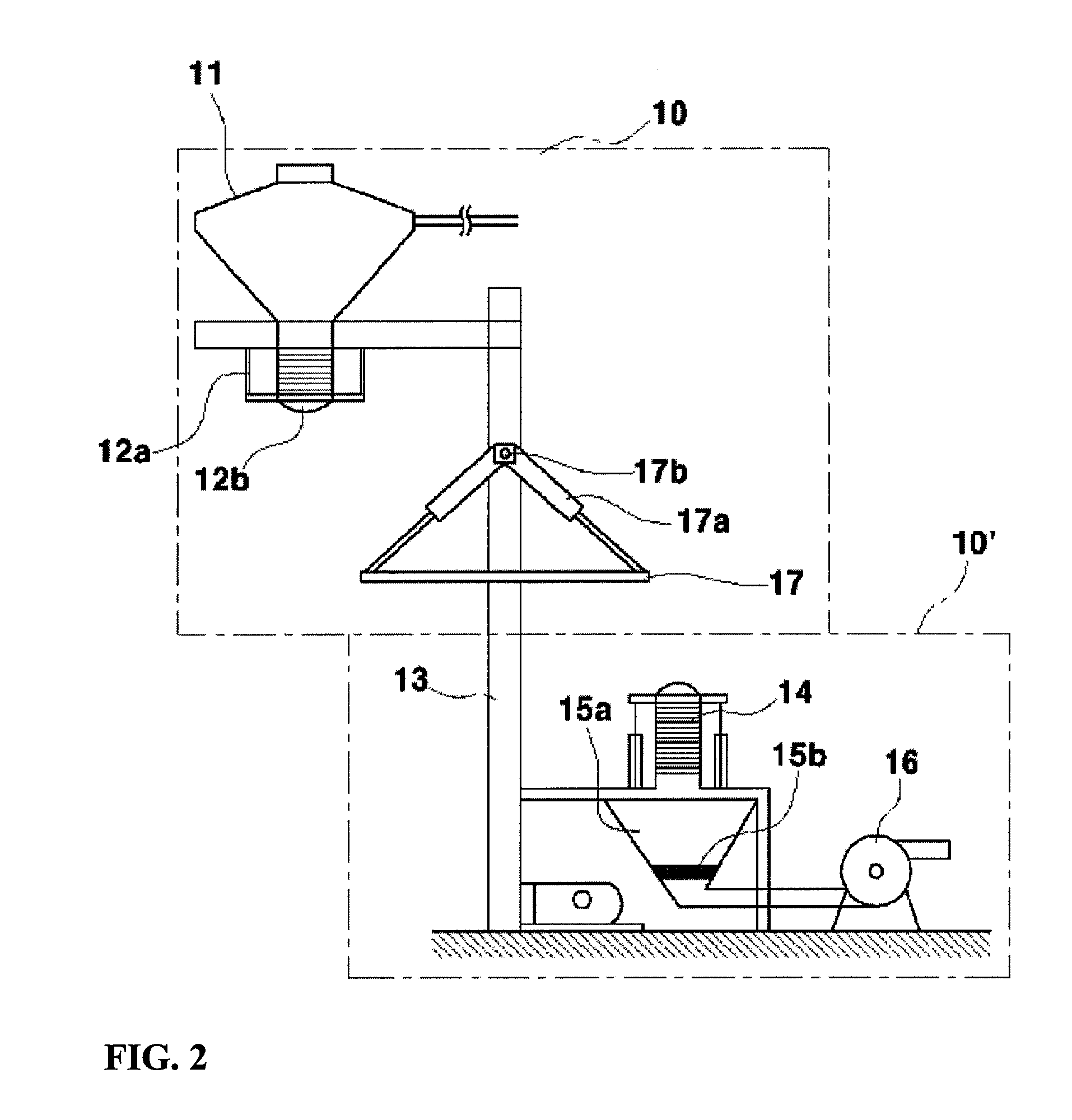

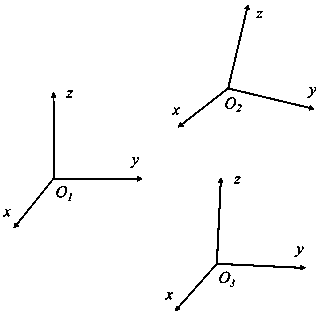

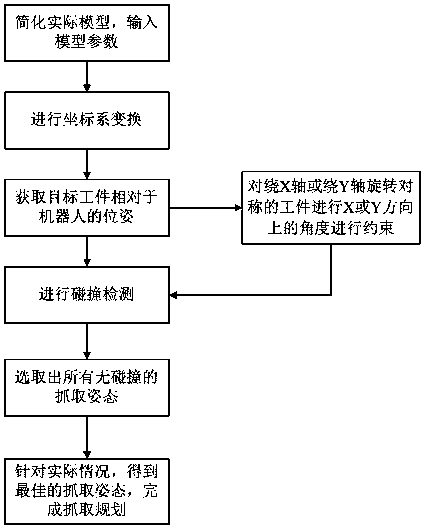

Robot material frame grabbing planning and collision detection method

ActiveCN111558940AReduce productionReduce importsProgramme-controlled manipulatorReduced modelComputer graphics (images)

The invention provides a robot material frame grabbing planning and collision detection method. The method includes the following steps that S1, an actual model is simplified, and model parameters areinput to establish a simplified model; S2, a coordinate system is established based on the simplified model, and coordinate system transformation is performed; S3, the pose of a target workpiece relative to a robot is obtained; S4, the pose is transformed to obtain a grabbing pose, and the grabbing pose is put into the coordinate system for collision detection; and S5, grabbing planning is performed based on the collision detection. According to the robot material frame grabbing planning and collision detection method, by abstracting and simplifying the complex environment, the simplified model is established, collision detection and grabbing planning are carried out through coordinate system transformation, cumbersome model making and import is reduced, and the grabbing results can be quickly given.

Owner:FOSHAN LONGSHEN ROBOT

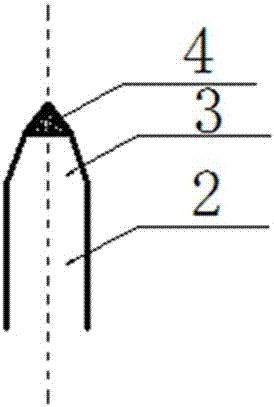

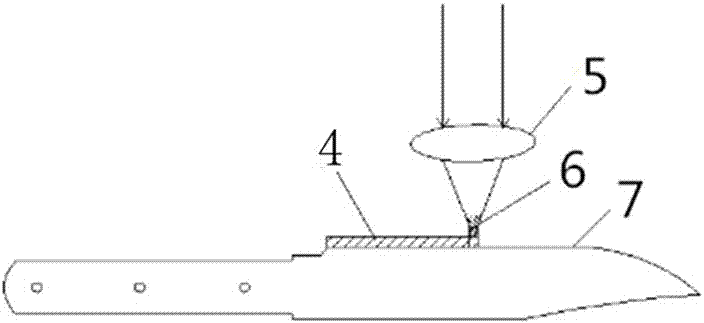

High-hardness additive manufacturing tool

PendingCN107022759AImprove wear resistanceExtended service lifeMetallic material coating processesMetal working apparatusManganeseHardness

The invention discloses a high-hardness additive manufacturing tool which comprises a tool handle, a tool body, a blade and an additive manufacturing strengthening layer. The additive manufacturing strengthening layer is prepared by adopting lasers at the cutting edge line position of the blade in a coaxial powder feed manner. Iron-based self-fluxing alloyed powder serves as a preparation material of the additive manufacturing strengthening layer and comprises, by mass percent, 0.6%-1.5% of carbon, 23%-35% of chromium, 1%-2.5% of silicon, 1%-2% of boron, 6.5%-12% of nickel, 1%-2% of manganese, 0.2%-0.3% of molybdenum and 44.7%-66.7% of iron, and the size range of the powder ranges from 125 micrometers to 275 micrometers. The high-hardness additive manufacturing tool has the beneficial effects that a reasonable additive manufacturing material ratio is adopted, after grinding and edging, the cutting edge hardness of the blade can reach HRC60 or above, the wear resistance of the tool can be obviously improved, the service life of the tool can be obviously prolonged, the import volume of high-end steel can be reduced, and the manufacturing cost of the tool can be reduced.

Owner:YANGJIANG KNIFESCISSOR HARDWARE RES INSTITUTION OF IND TECH +1

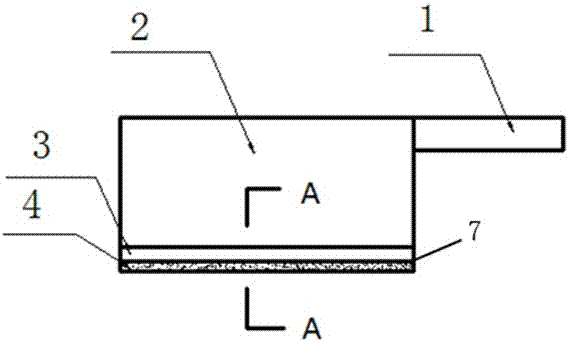

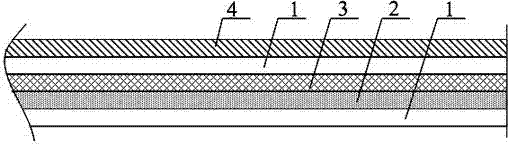

Plate applied to cabinet body and cabinet door of power distribution cabinet and power distribution cabinet

InactiveCN104734028AImprove securityReduce importsSynthetic resin layered productsSubstation/switching arrangement casingsFire - disastersPower equipment

The invention discloses a plate applied to a cabinet body and a cabinet door of a power distribution cabinet, and belongs to the field of power equipment. The plate comprises an interlayer, wherein the interlayer is provided with a shielding layer and a heat preservation layer from outside to inside, and a fireproof layer is arranged on the inner layer of the interlayer. The shielding layer is arranged in a traditional interlayer to avoid influences of electromagnetism on precise electric equipment in the power distribution cabinet in a strong electromagnetic environment and guarantee normal operation of the precise electric equipment. The heat preservation layer is arranged on the inner layer of the shielding layer, can slow down conduction of high temperature outside the cabinet body to the cabinet body by the plate and keeps the temperature of the cabinet body normal and stable; the fireproof layer arranged on the inner side of the interlayer can prevent spreading of a fire disaster happening in the cabinet body. The invention further discloses the power distribution cabinet adopting the plate.

Owner:江苏诚纳电气有限公司

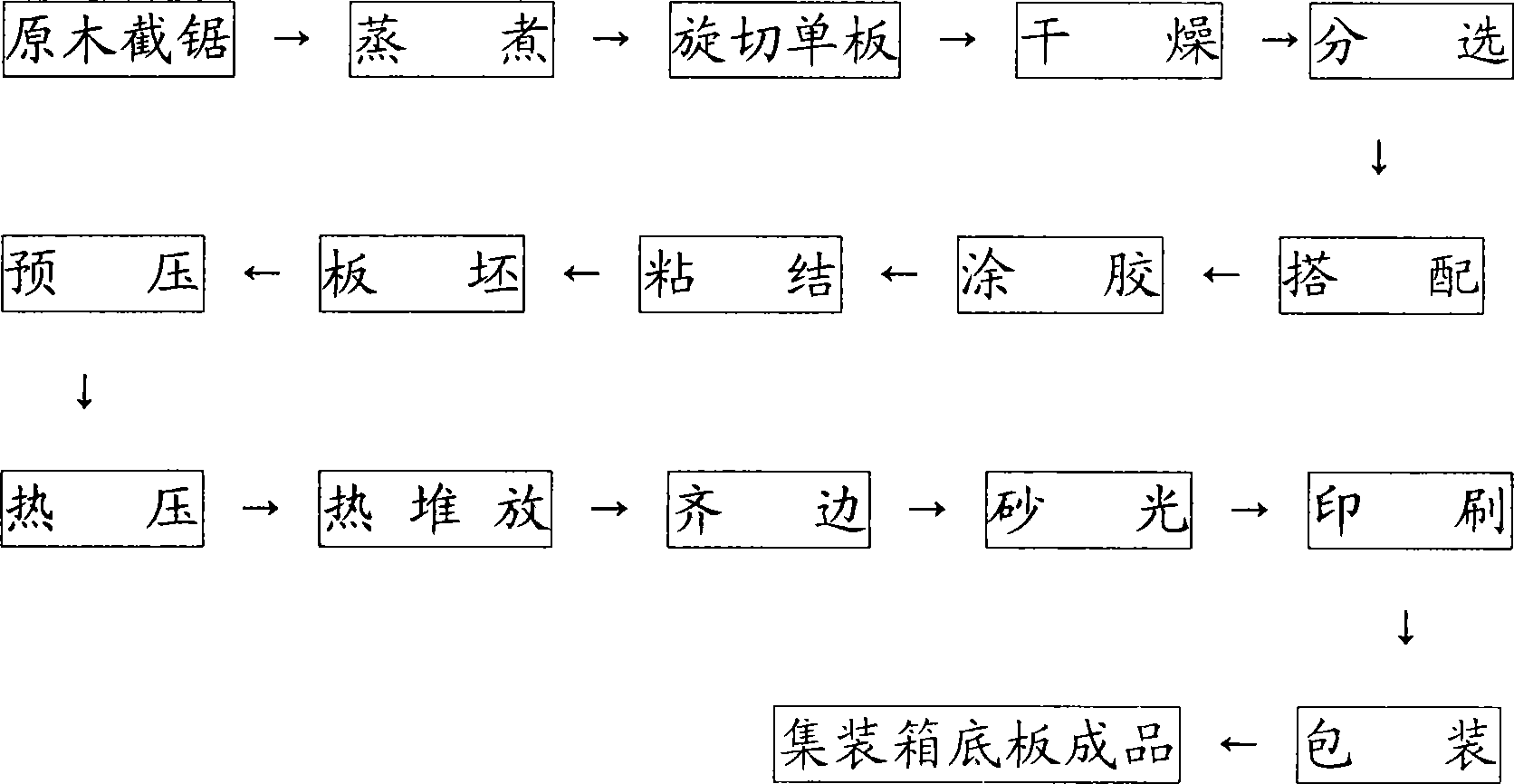

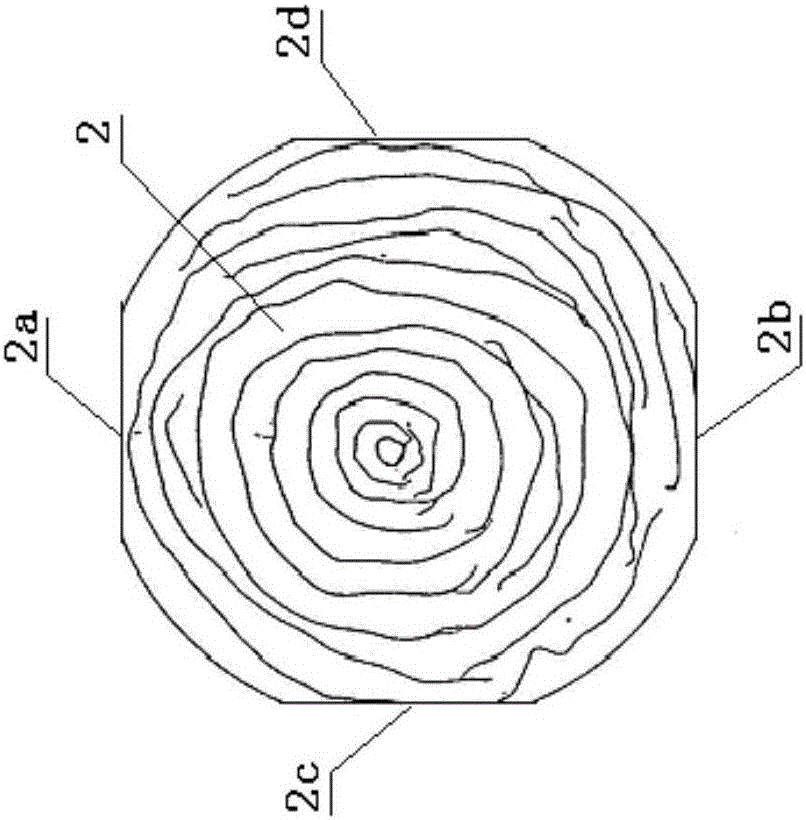

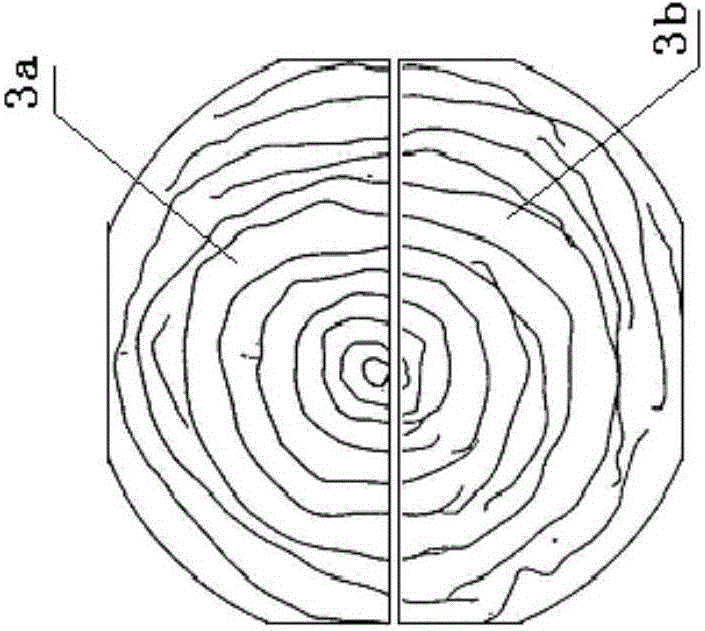

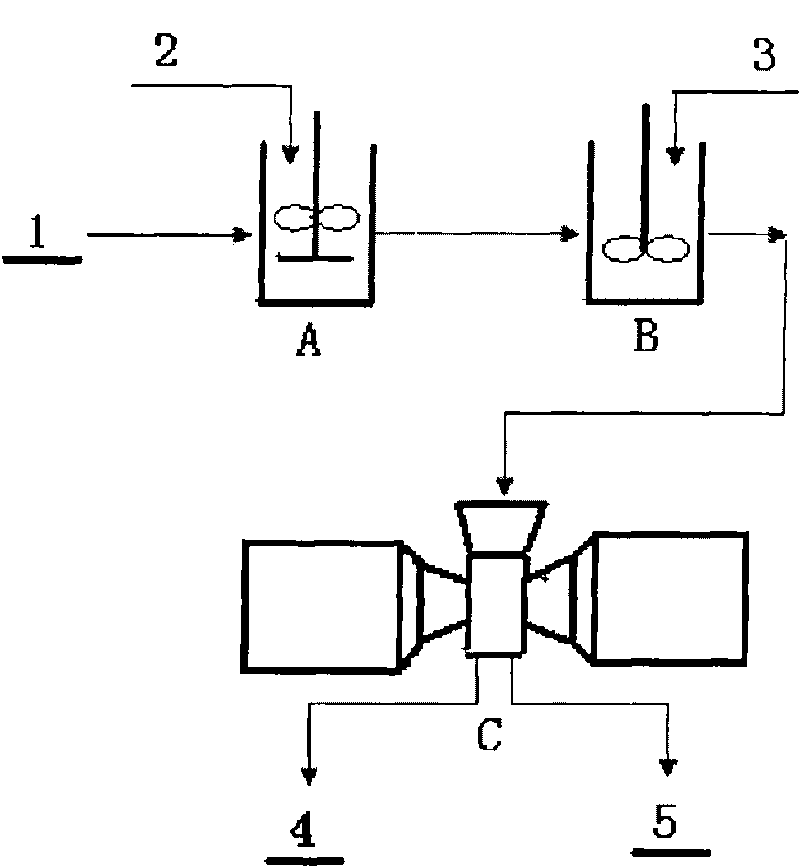

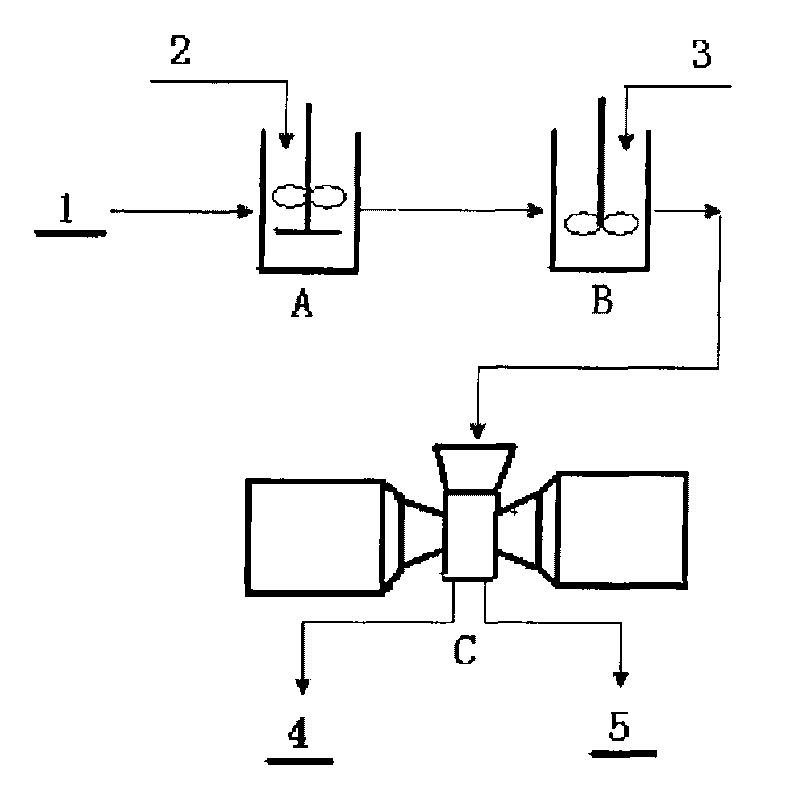

Production method of plywood for container bottom board

ActiveCN101508125AReduce importsReasonable structureNon-fibrous pulp additionPaper/cardboardSingle plateEngineering

The invention provides a method for manufacturing a plywood used for a bottom board of a container, which relates to the technical field of plates. The invention provides the method for manufacturing the plywood used for the bottom board of the container and a novel composite plywood by key technology of 'scientific material selection and matching-based scientific structure'. The method comprises the following steps of log pruning, boiling, veneer rotary cutting, drying, sorting, matching, gluing, bonding, plate blanking, prepressing, hot press, thermal stacking, trimming, graveling, printing and packaging so as to manufacture a finished product of the bottom board of the container. The bottom board is applied to containers, doors and windows, furniture, automobile, ships and other aspects. The method is simple, and the product has the advantages of reasonable structure, good quality, high strength, good elasticity, no deformation, no foaming, strong pressure resisting capability, low cost, long service life and wide range of application, and can be printed with the required patterns on the surface and has beautiful appearance.

Owner:肇庆市正森木业有限公司

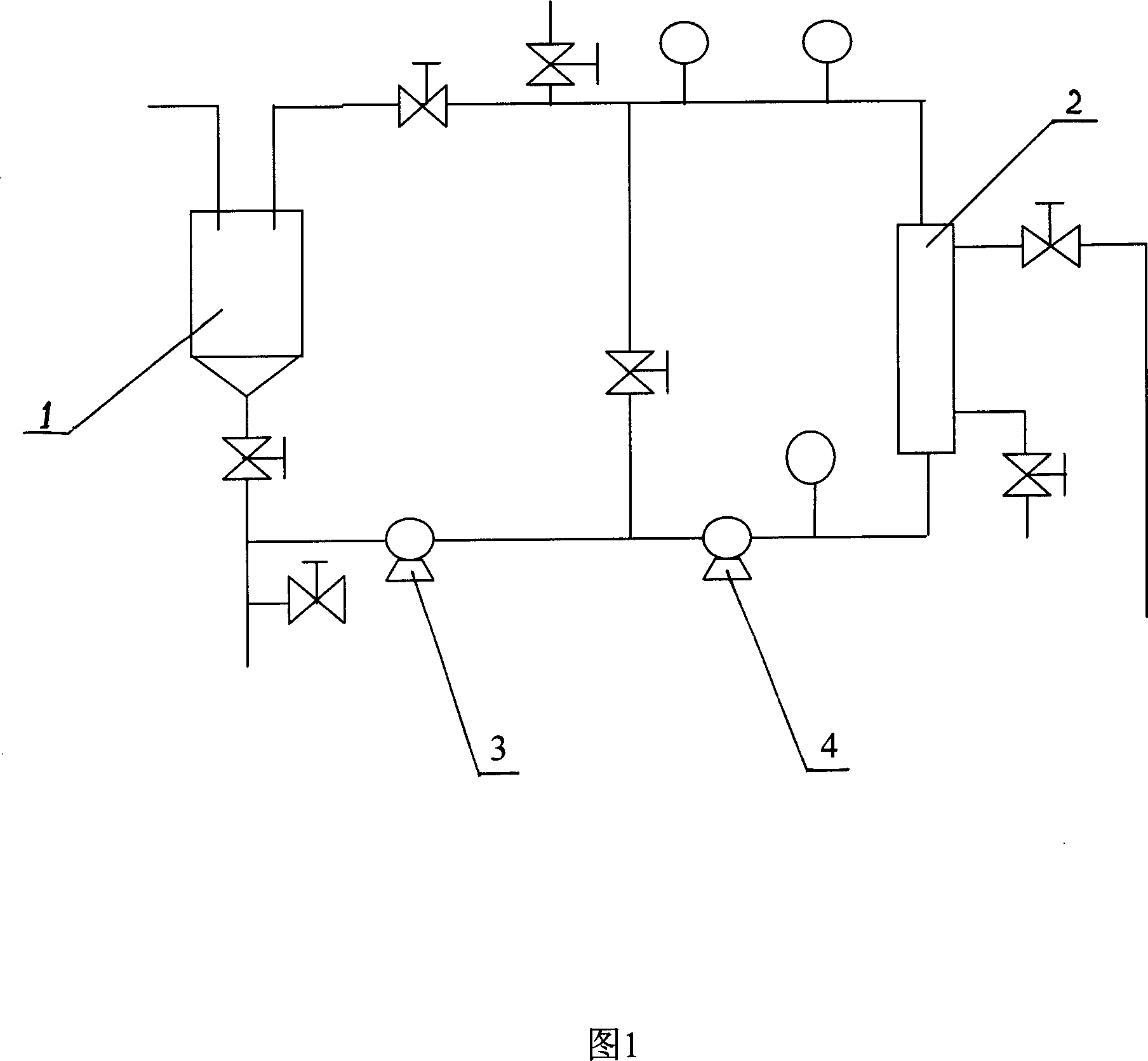

Extraction technology of avermectin

The invention discloses an extracting technology of avermectin, which comprises the following steps: blending dried mycelium of avermectin and carbinol or alcohol with weight rate at 1: 5-1: 10 in the immersing tank; stirring under 20-25 deg.c for 3-6h; filtering the filtrate under 0.1-0.6Mpa through filter membrane system with aperture at 10um-2nm; transmitting filtrate to semiproduct manufacturing system; returning partial residual liquid to immersing tank; entering the other half filtrate in the filter membrane circulating system through circulating pump; draining the slag in the immersing tank after filtering.

Owner:河北美邦工程科技股份有限公司

Environmental protection methanol diesel oil

InactiveCN101033419AEasy to stratifySolve the problem of cold start at low temperatureLiquid carbonaceous fuelsPetroleumMethanol

This invention relates to an environment protection methyl alcohol gasoline taking diesel oil, methyl alcohol, isobutanol, toluol and n-butyl alcohol as the raw materials to mix them in a container fully and uniformly under normal temperature and pressure to get a liquid product, which can be used in stead of diesel oil and reduces solidifying point of diesel oil .

Owner:北京福众金源环保科技有限公司

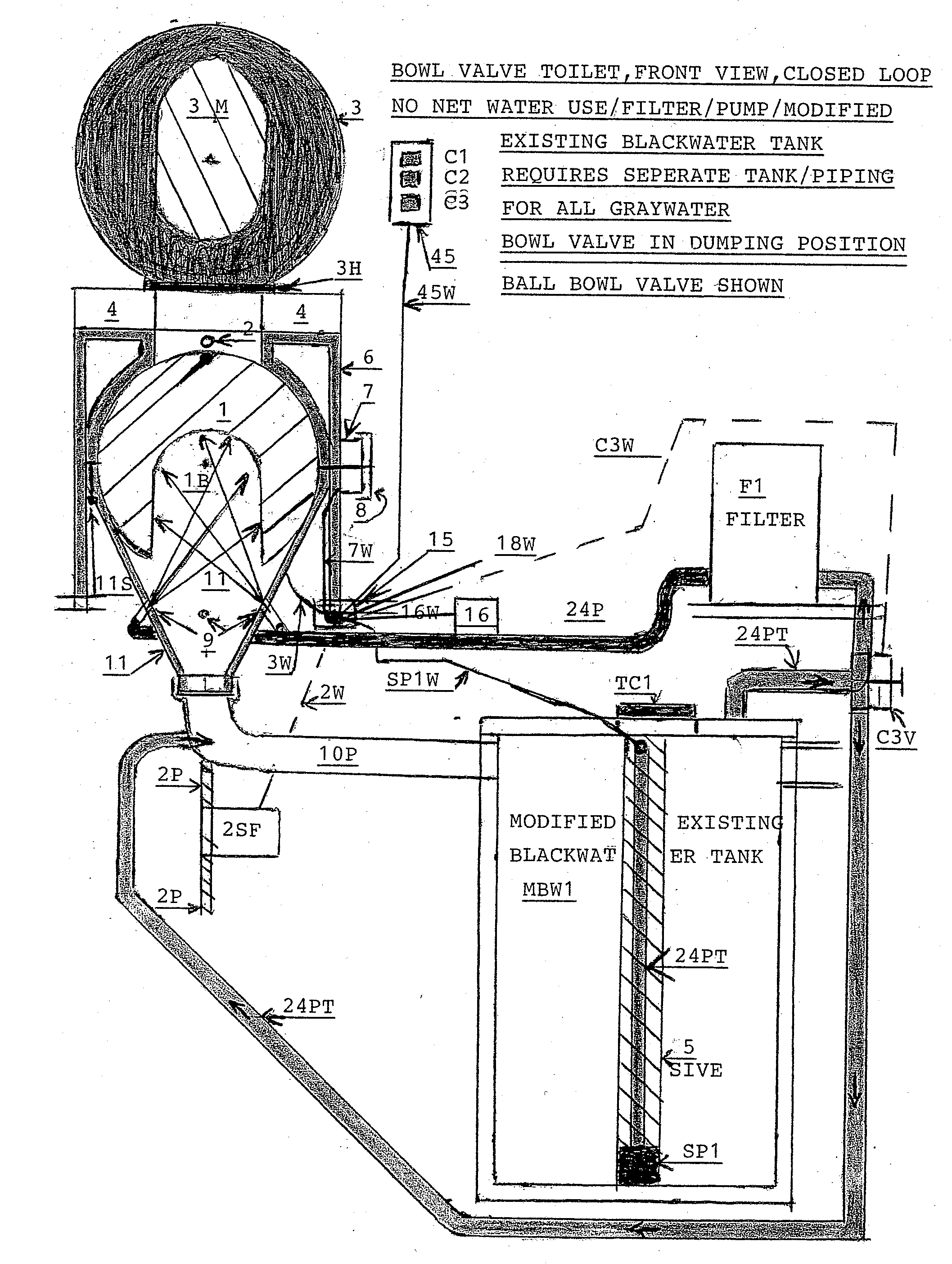

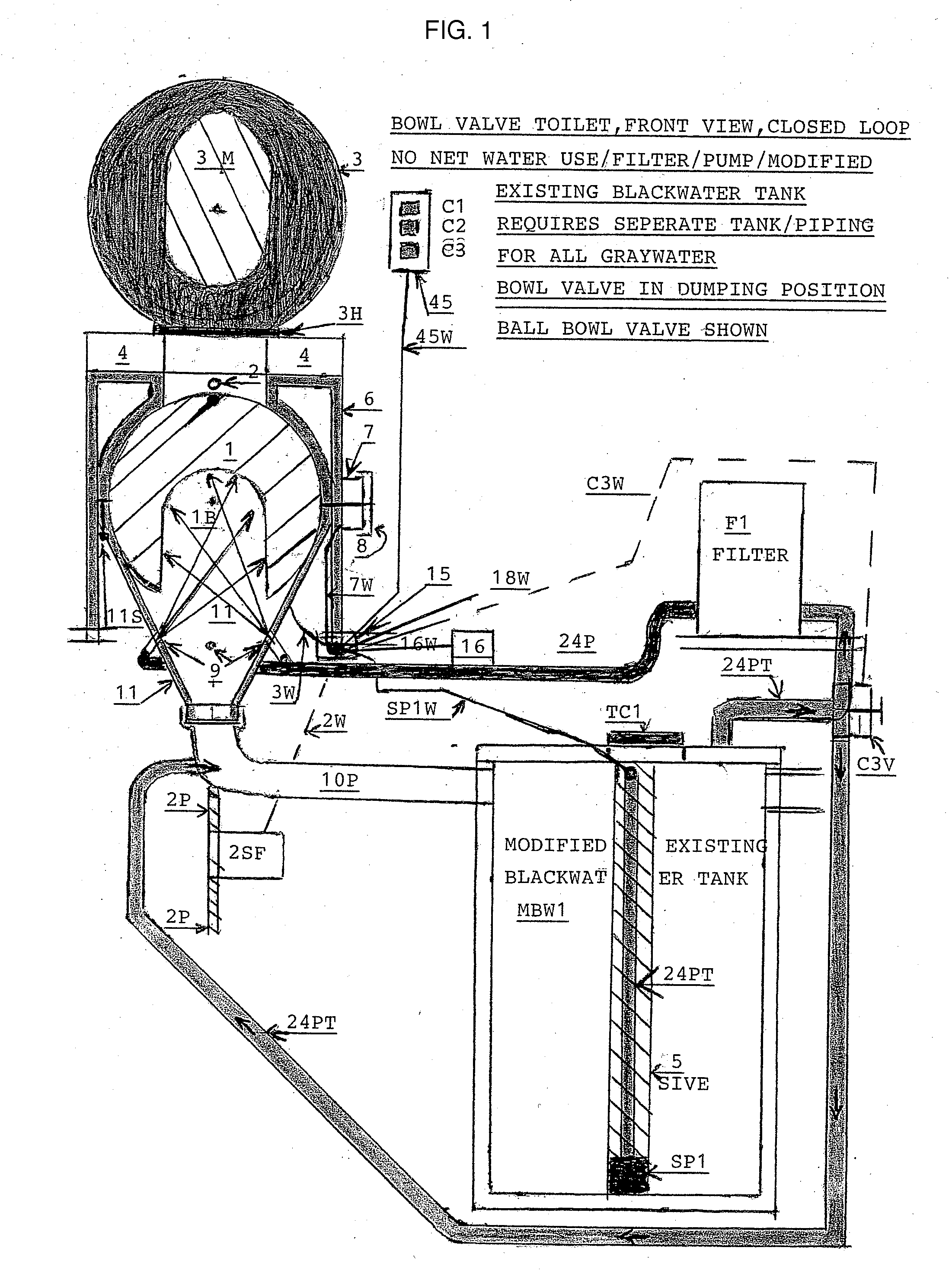

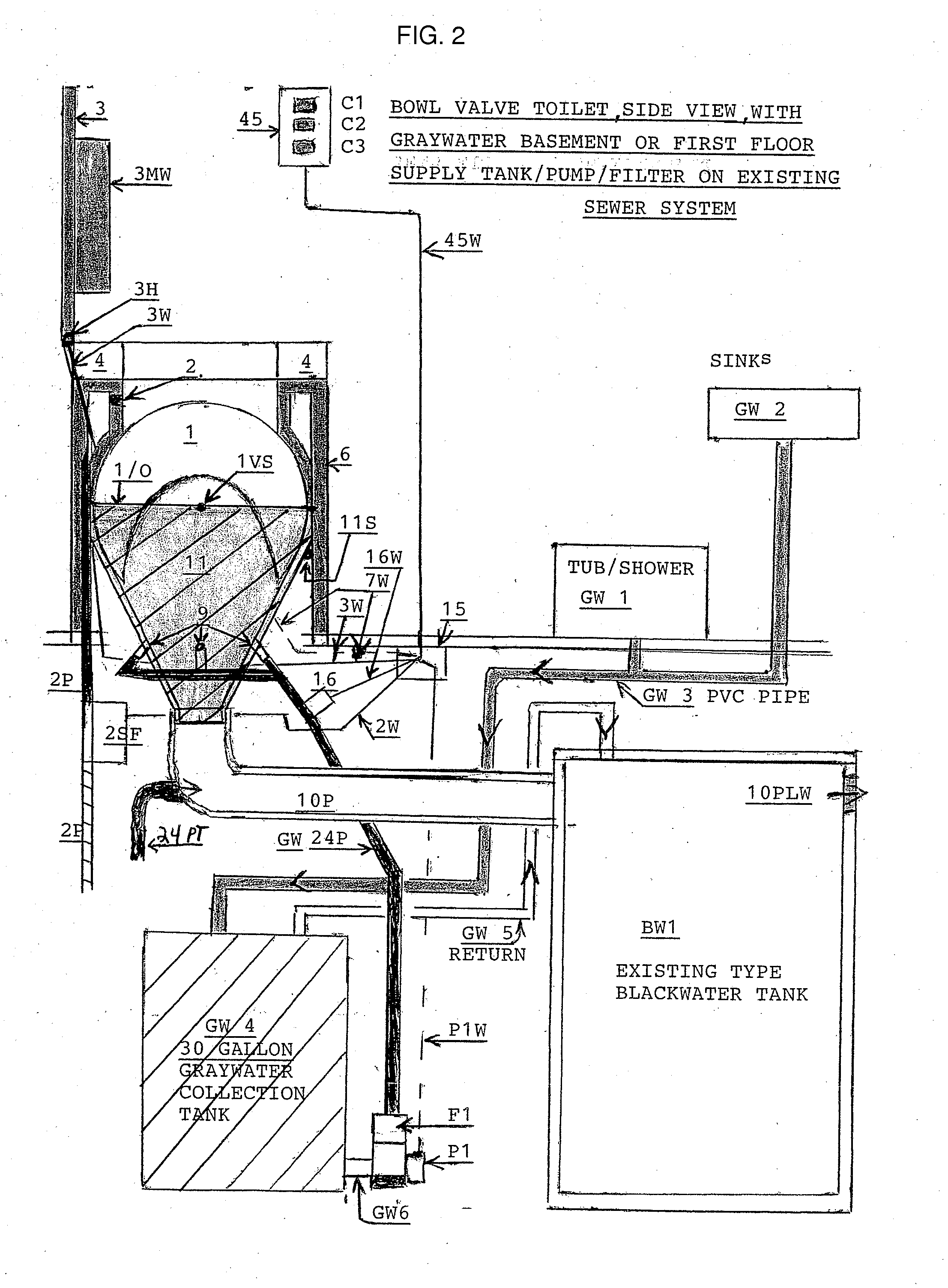

No water/graywater/selfsanitizing, valve toilet, waste recycling system

The international schedule of classes of goods and services appears to be (11) apparatus for sanitary purposes, including water supply, heating, steam generating, cooking, ventilating; and (7) a form of machine. What is new in the art of toilets and waste recycling systems as pertains to this invention is;Replacement of the function of the water, the toilet bowl, and p-trap with the bowl valve (in bowl valve toilet) and the in sewer line valves, below cone type toilet or in sewer line valve and ptrap or pressure seal toilet cover and p trap in line (drawings 1-2, 8-11)In toilet air suction of smell outside via toilet (2)Automatic water / steam pressure spray nozzles / toilet flush / cleaning / sanitizing with water saving time cycle selection / valve activation (9, 24N, 9ST, C1, C2, C3, 45, 1, 7, 25, 3M)Reuse of blackwater for flushing in closed loop or graywater in open loopHeat treatment of waste and system sanitizing with it to safety use waste as fertilizer in field, garden, lawn, via the microwave toilet cover 3M heating prior to dumping valves, via microwave steam generation (D.11) threw spray nozzles and holding in sewer trap to cook threw (25STP) or heating tank when full (D.3) with solar, gas, ect. Hot water coil.

Owner:KURTZ JAMES D LAMMERS

Method for producing low cost oriented silicon steel using continuous casting and rolling technique of sheet bar

InactiveCN101433911AReduce precipitationHigh continuous casting slab surface temperatureTemperature control deviceMetal rolling arrangementsThin slabAcid washing

The invention relates to a method for producing low-cost oriented silicon steel by the thin slab continuous casting and tandem rolling technique, which belongs to a manufacturing technique for steel materials with high added value. The method is as follows: continuous casting billets with a thickness of between 50 and 120 millimeters are formed by a thin slab continuous casting and tandem rolling device, and enter a soaking furnace for heat preservation at casting speed of between 3.1 and 6 meters per minute when the surface temperature of the casting billets is guaranteed to be not less than 800 DEG C; the continuous casting billets are heated by the soaking furnace and subjected to hot-rolling to form hot-rolling plates with a thickness between 1.5 and 3.5 millimeters; and after the hot-rolling plates are subjected to acid washing, cold rolling, intermediate annealing, cold rolling and secondary recrystallization and annealing, and the structure and the texture required by the oriented silicon steel are obtained, and the magnetism of the products can reach the performance index of the trademark of the oriented silicon steel of the national standard requirement. The method has the characteristic of production of the low-cost oriented silicon steel with the national standard trademark by the thin slab continuous casting and tandem rolling technique used in actual industrial production, has the advantages of short flow, low cost and high production efficiency, and can save the process of normalized annealing by controlling the finishing temperature, so as to further save the cost and improve the production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

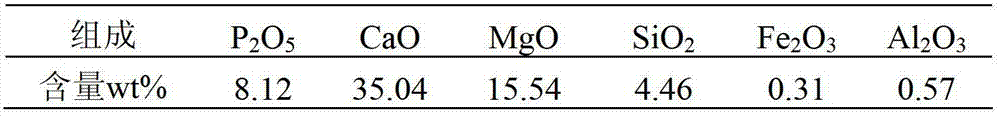

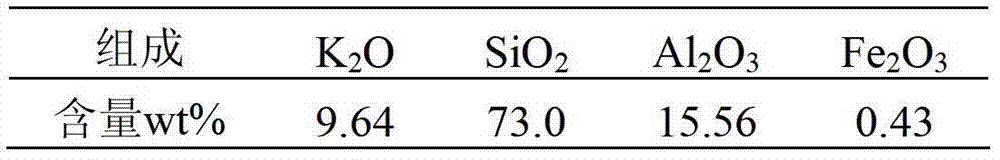

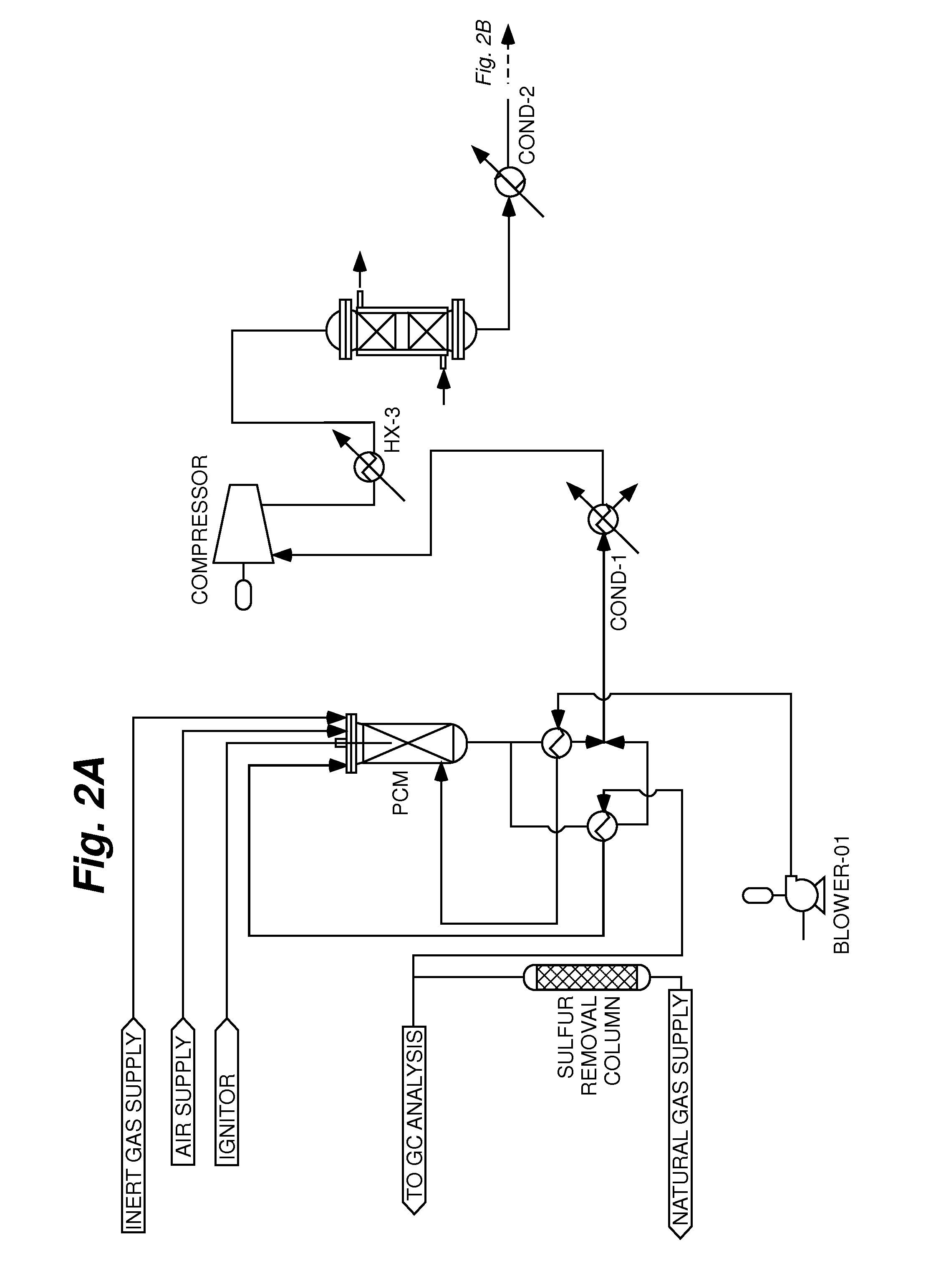

Method for producing alkaline fertilizer from insoluble potassium-containing rock by kiln process

ActiveCN103086778AIncreased alkalinityReduce the temperatureFertilizer mixturesPotassiumPhosphogypsum

The invention discloses a method for producing an alkaline fertilizer from insoluble potassium-containing rock by a kiln process, belonging to the technical field of chemical production. The method comprises the following steps: mixing phosphate rock tailings or low-grade phosphate rock with the insoluble potassium-containing rock according to the weight ratio of 1:(0.4-0.9), further adding anthracite accounting for 3-8% of the total mixed weight, drying, grinding and further preparing a material block; and then placing into a kiln, roasting at the temperature of 1000-1200 DEG C for 30-150 minutes to prepare sintered clinker, finally performing water quenching, reducing the temperature of the sintered clinker to 400-700 DEG C, and draining, drying, crushing and grinding the sintered clinker after water quenching to prepare the alkaline fertilizer. According to the method disclosed by the invention, the roasting temperature is only 1000-1200 DEG C, the energy consumption is low, and the process is simple; and phosphogypsum is not used, SO2 gas causing serious pollution of air is not contained in tail gas, and the special treatment of the tail gas is not required.

Owner:KINGENTA NORSTERRA CHEM CO LTD

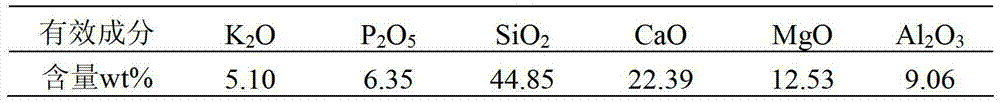

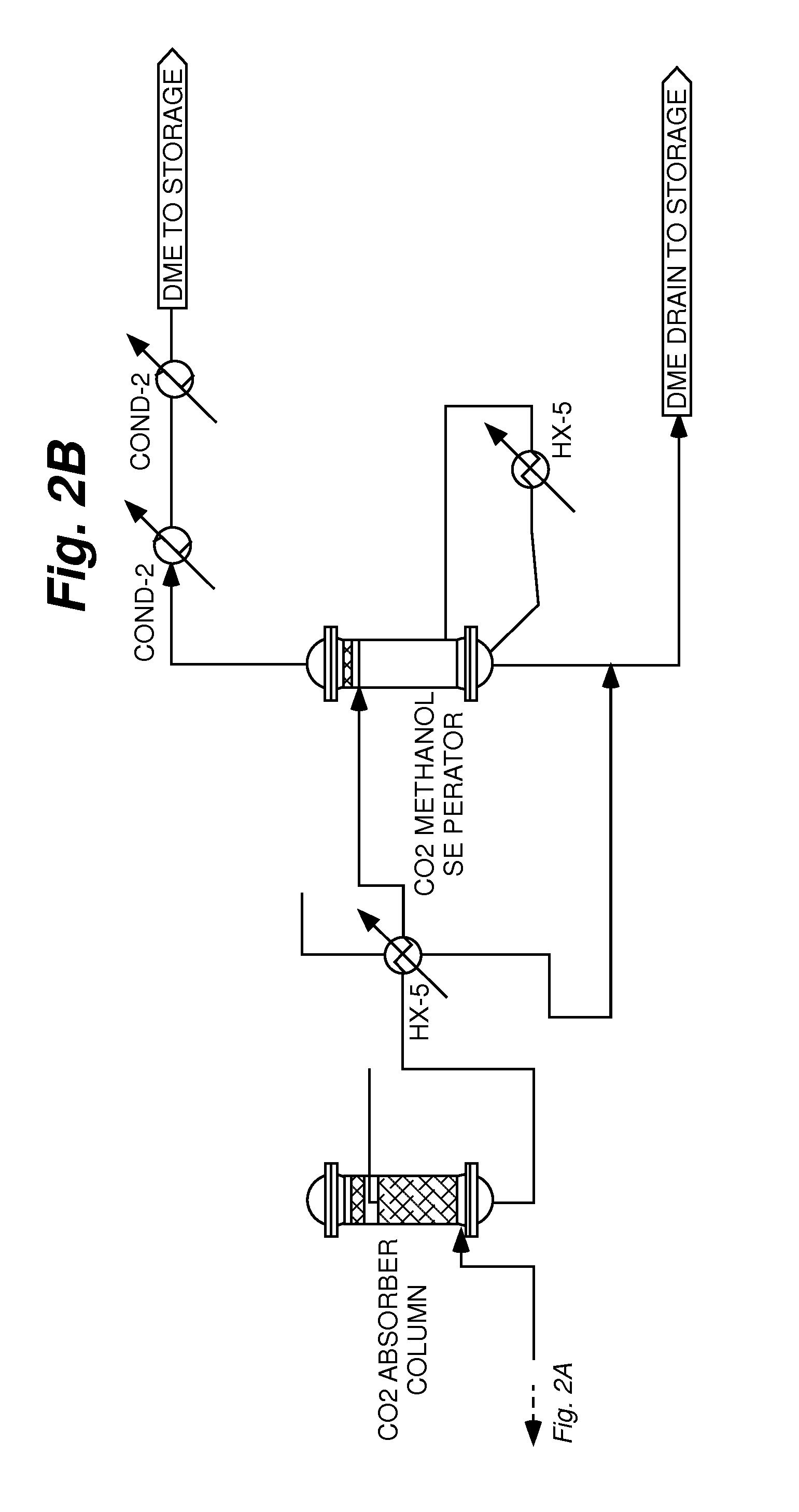

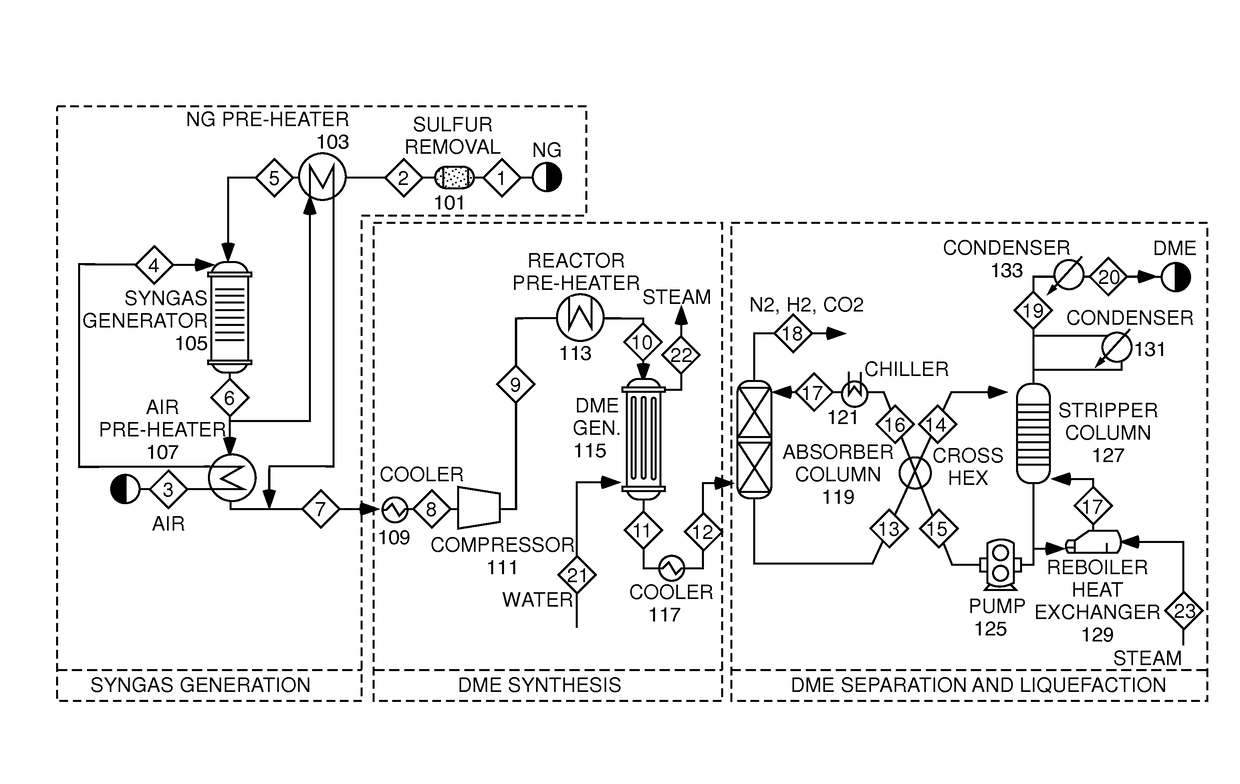

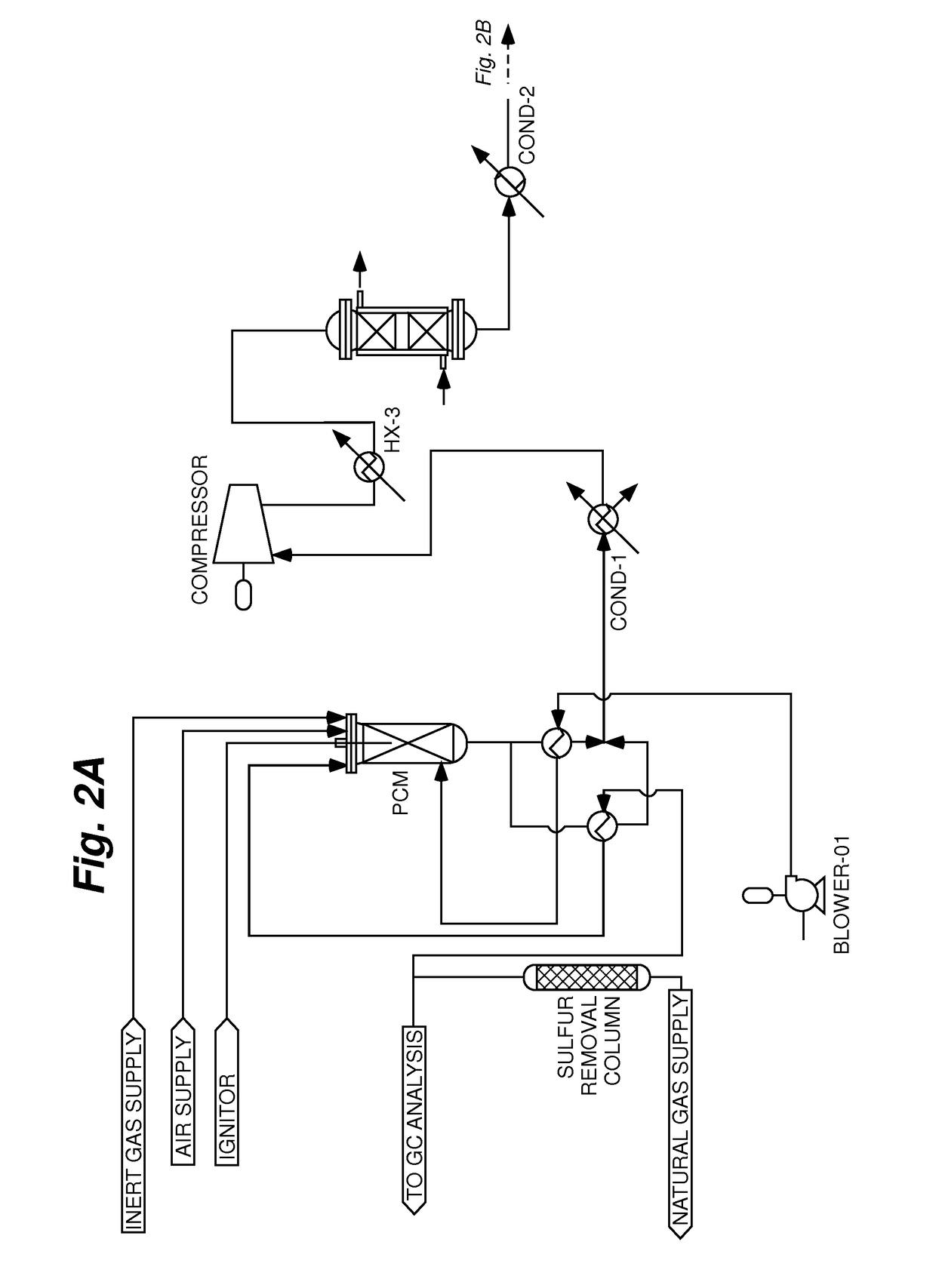

Systems and methods for manufacture of dimethyl ether (DME) from natural gas and flare gas feedstock

ActiveUS20160152537A1Enhance economic and energy securityEconomic benefitHydrogenEther separation/purificationNitrogen gasPetroleum

A unique design for a mobile system that reforms flare gas or natural gas, using air without steam, to directly produce dimethyl ether (DME), a diesel substitute, is disclosed. The system first reforms the air-methane mixture at ambient atmospheric pressures, and then compresses the resulting CO-hydrogen-nitrogen gas mixture to up to 600 psi, and feeds it through a combined reactor which reacts the gas mixture directly into dimethyl ether. The nitrogen is returned by the system back to the atmosphere. DME is an excellent diesel fuel, and can be used to displace significantly costlier and dirtier petroleum-based diesel fuel, while solving a critical problem with flaring. For example, the over 120 billion cubic feet per year that is currently flared in North Dakota could be converted into over 3 million tons of DME.

Owner:PIONEER ENERGY

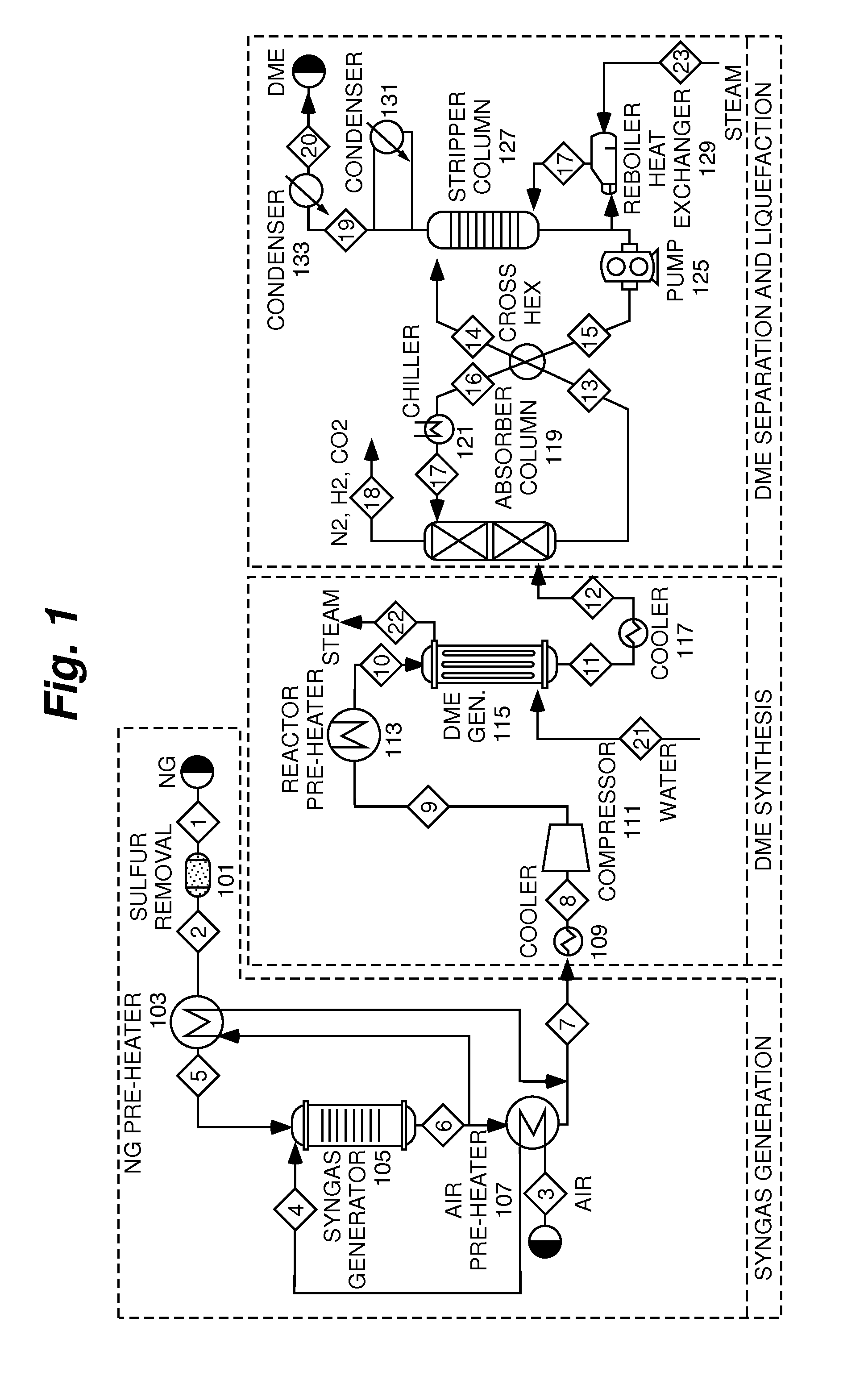

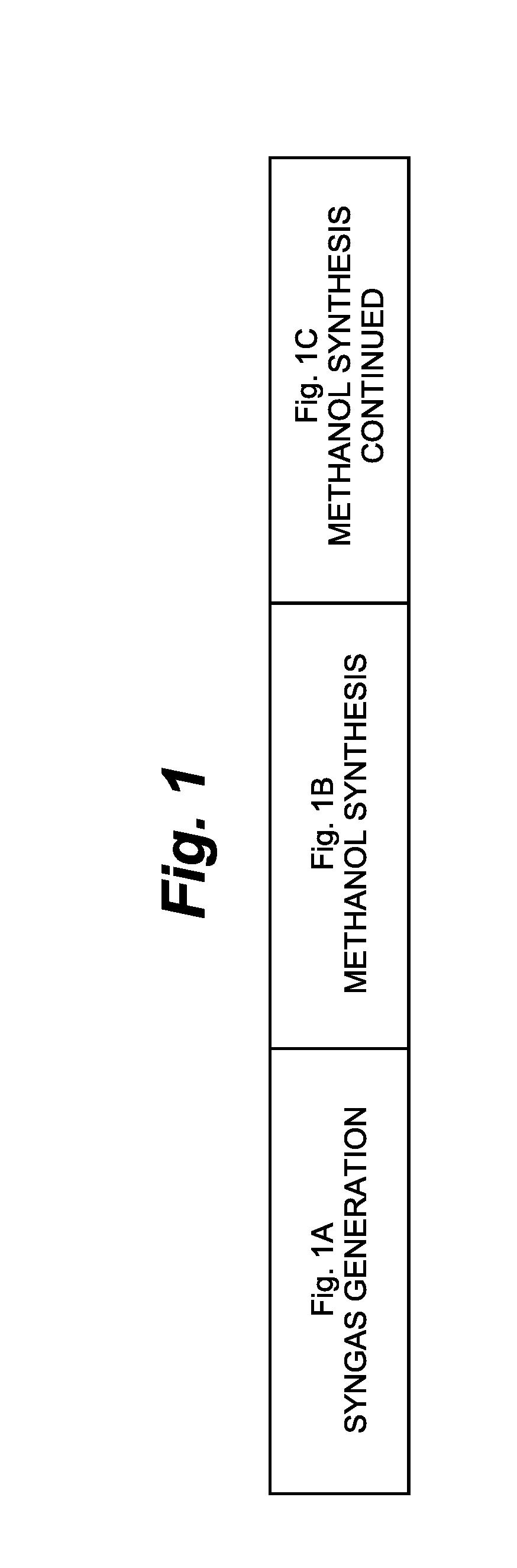

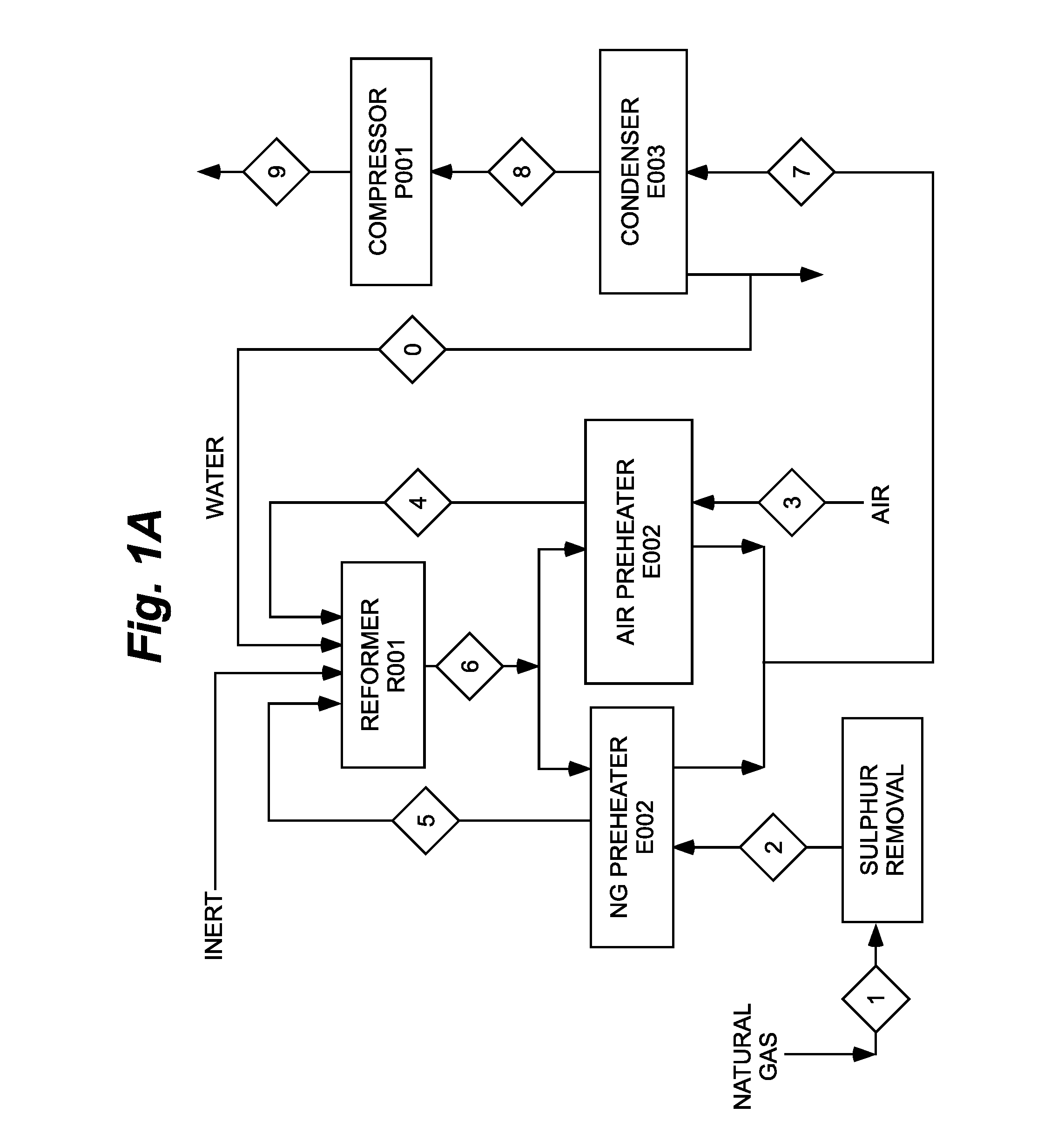

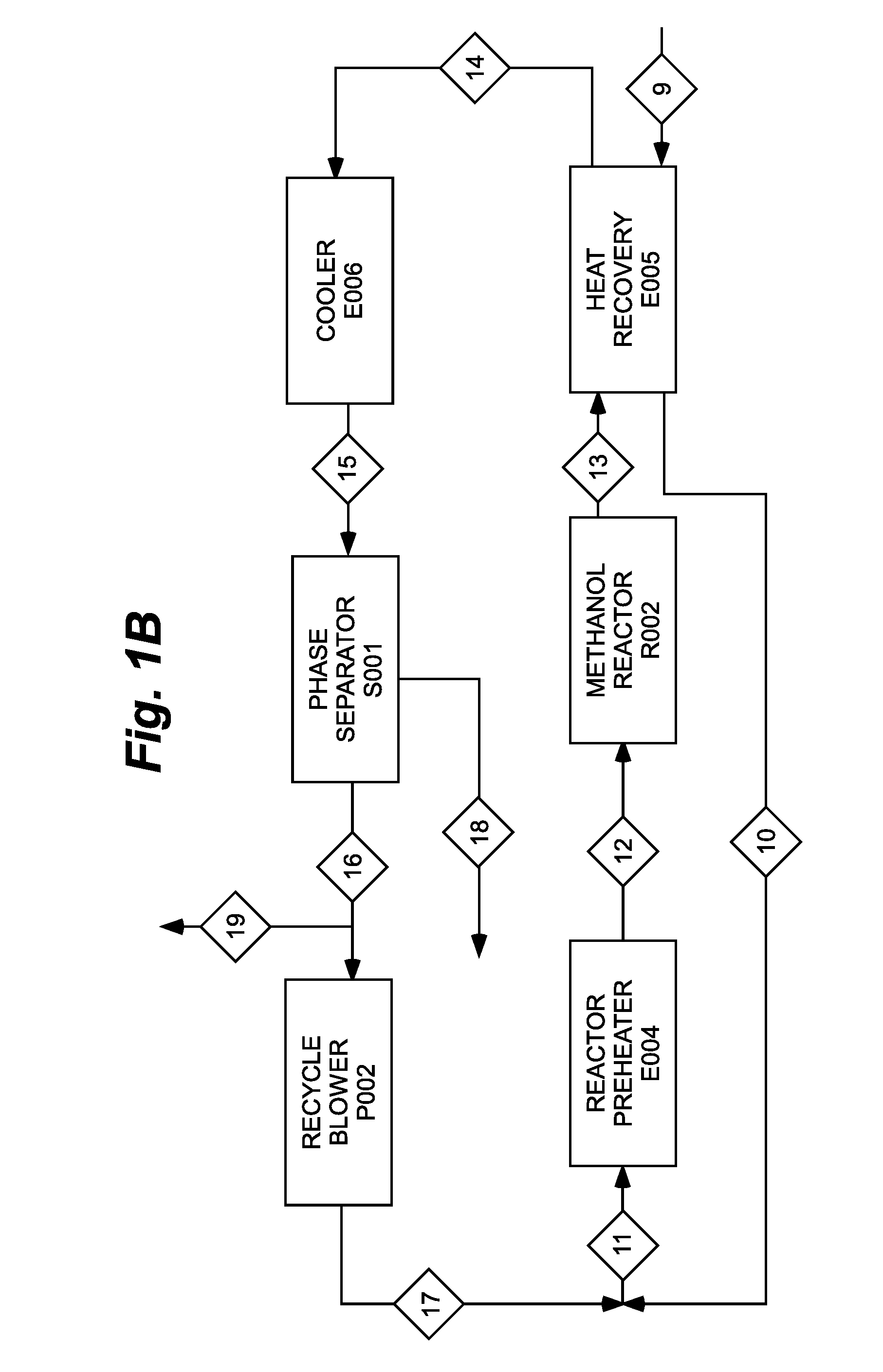

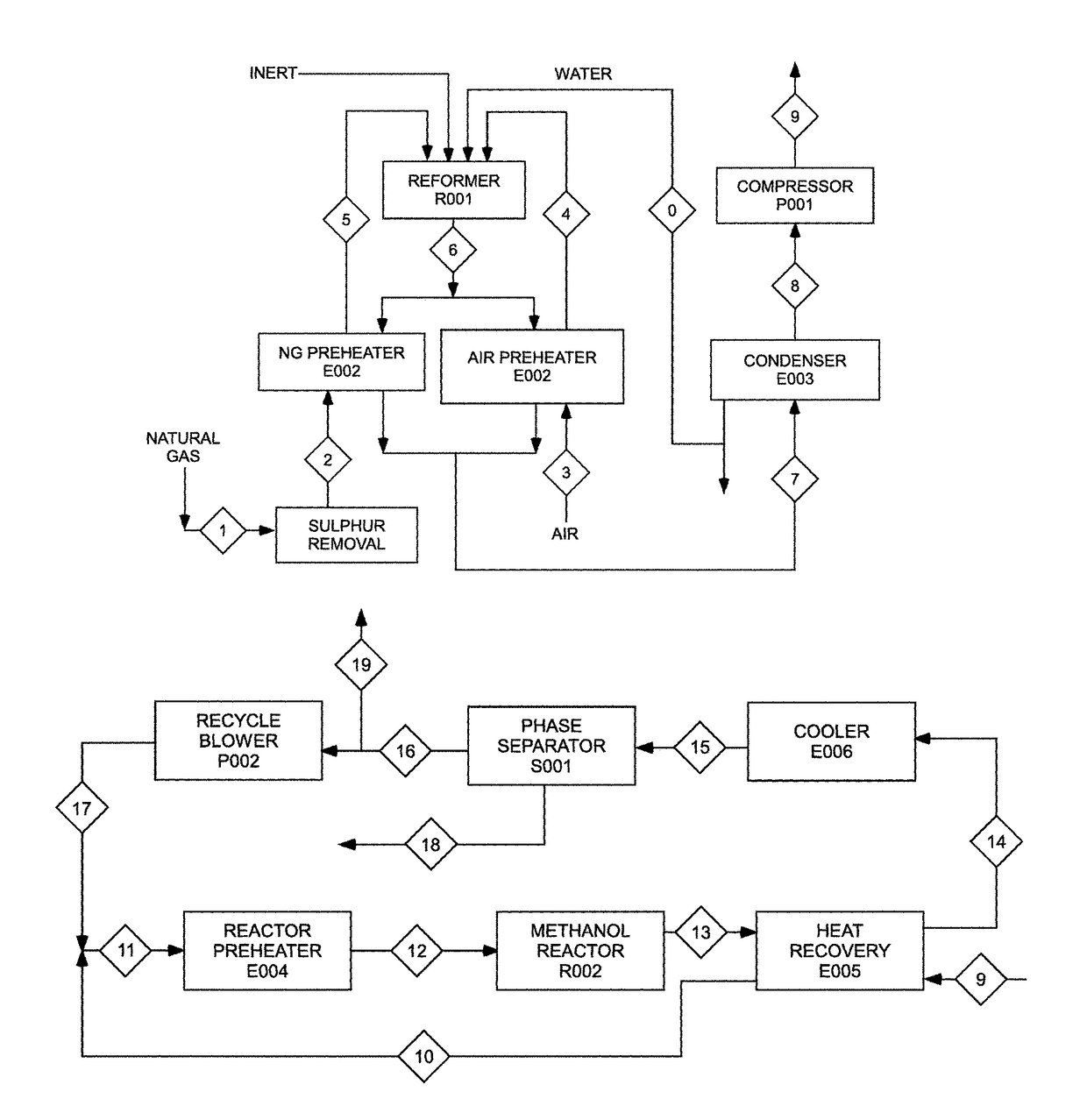

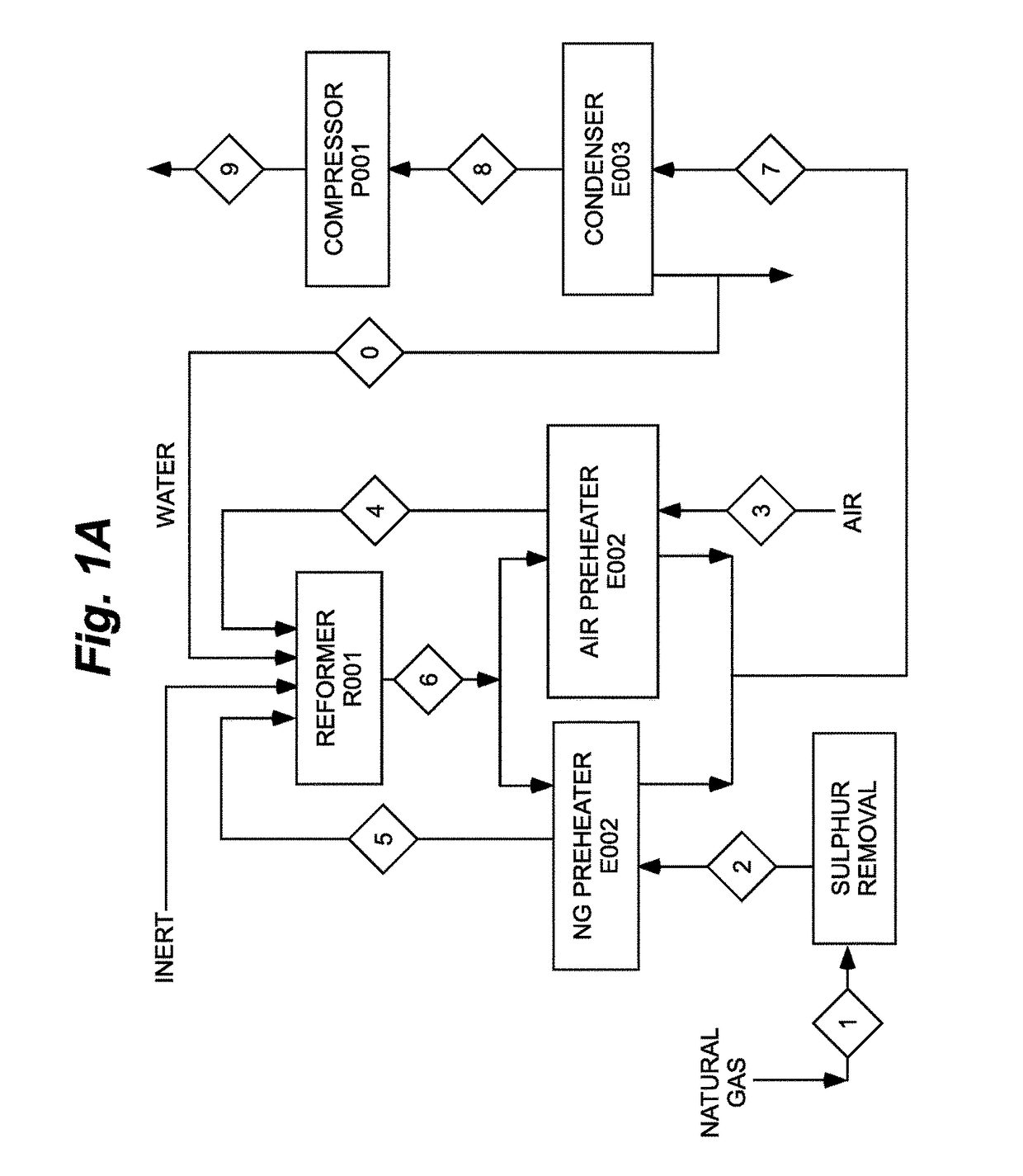

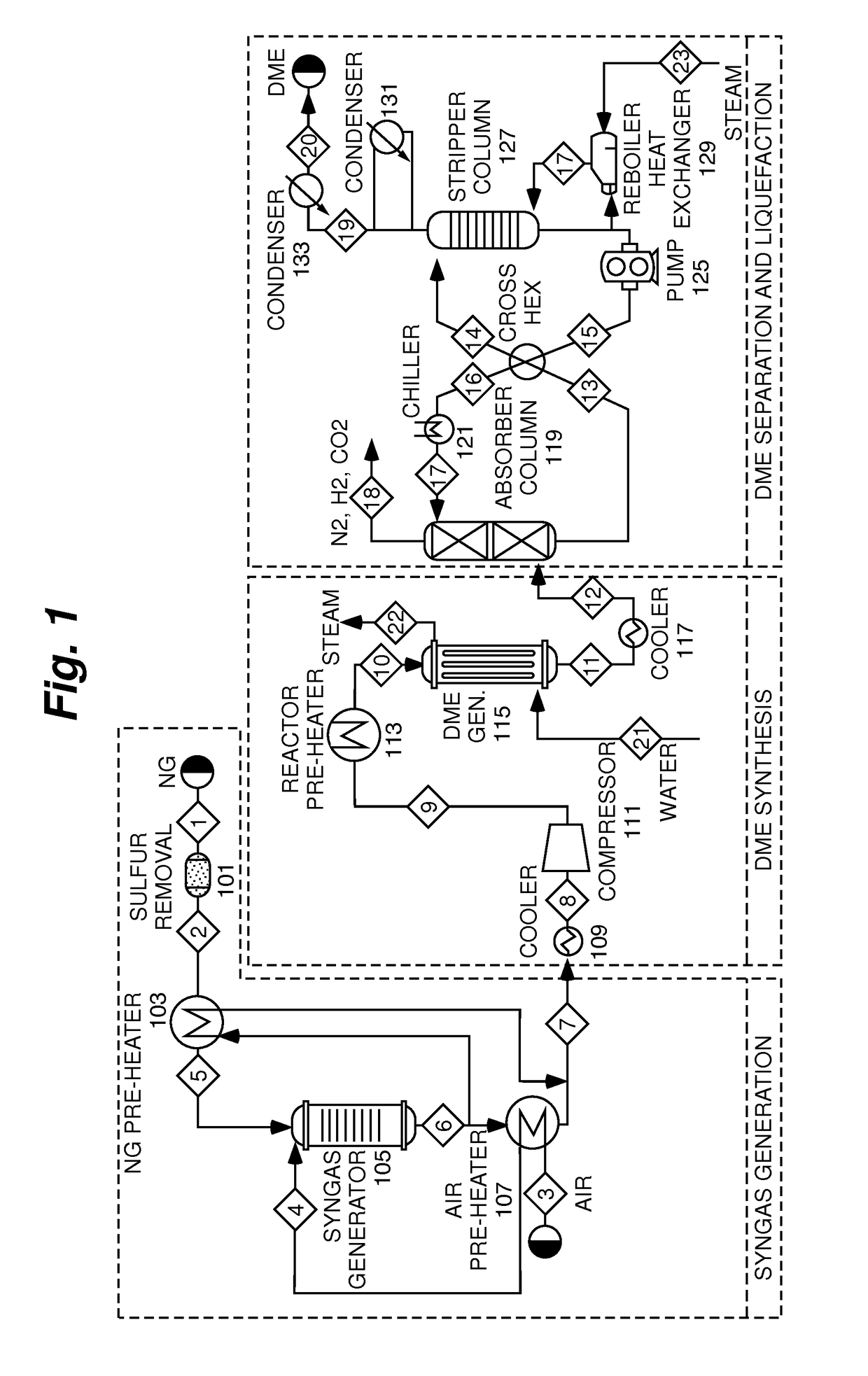

Systems and methods for manufacture of methanol from natural gas and flare gas feedstock

ActiveUS20160159714A1Carbon monoxide conversion is enhancedSpeed up the conversion processHydrogenInternal combustion piston enginesNitrogen gasFlare

A mobile system and method that reform flare gas, methane, or natural gas, using air without steam, to directly produce methanol, a clean burning gasoline blend, component, and / or substitute are disclosed. The system first reforms the air-methane mixture at ambient atmospheric pressure, then compresses the resulting CO-hydrogen-nitrogen gas mixture to 600 psi, and feeds it through a methanol reactor which reacts the gas mixture directly into methanol. The nitrogen is returned by the system back to the atmosphere. Methanol is a clean burning gasoline substitute, and can be used to displace significantly costlier and dirtier petroleum-based fuel, while solving a critical problem with flaring. For example, the over 120 billion cubic feet per year that was flared in North Dakota in 2014 could be converted into over 6 million tons of methanol.

Owner:PIONEER ENERGY

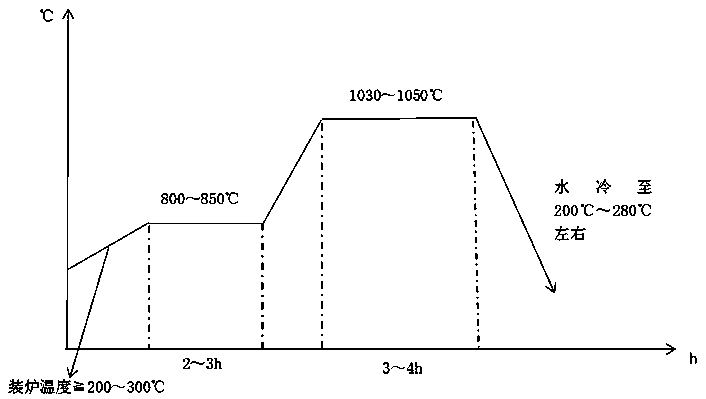

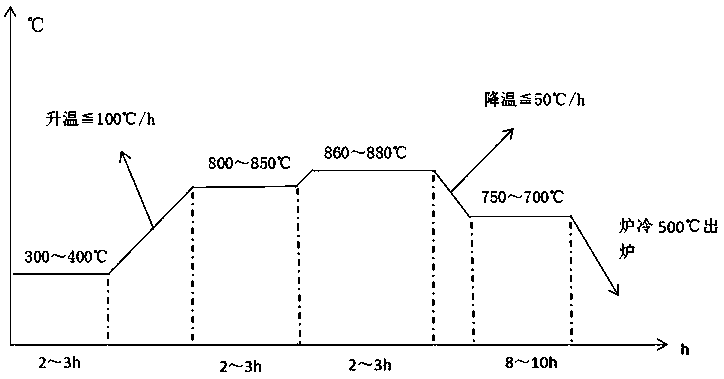

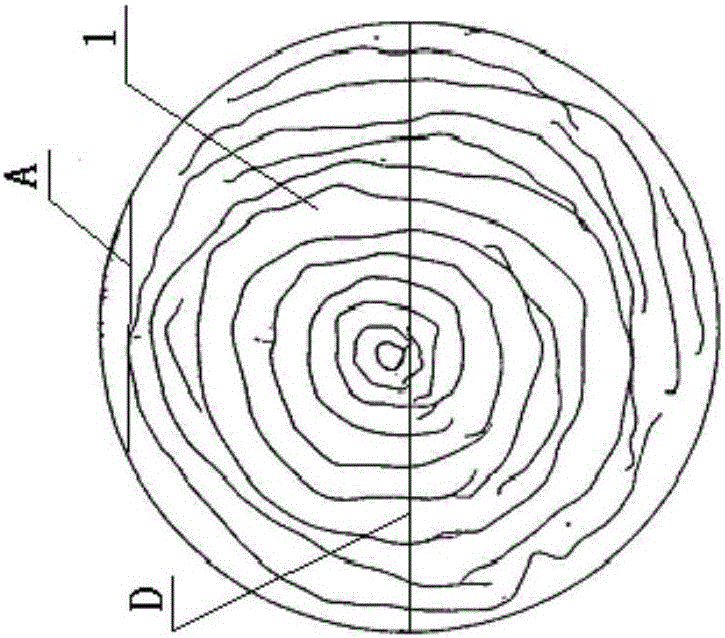

High-temperature-resistant artificial crystal forming die steel material and preparation method thereof

ActiveCN109371329AGuaranteed performanceLow in harmful elementsProcess efficiency improvementSmelting processUltra fine

The invention discloses a high-temperature-resistant artificial crystal forming die steel material and a preparation method thereof. The die steel material comprises the following components in percentages by weight: 0.38-0.45% of C, 0.50-0.70% of Si, 0.40-0.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 5.20-5.50% of Cr, 0.80-1.20% of Ni, 1.40-1.80% of Mo, 0.50-0.80% of V, 1.40-1.80% of W, 0.10-0.20% of Nb, 0.001-0.003% of Y, 0.001-0.005% of B, less than or equal to 80 ppm of [N], less than or equal to 2 ppm of [H], less than or equal to 15 ppm of [O] and thebalance of Fe; and during preparation, a smelting process of EBT smelting, LF refining, VD vacuum degassing and ESR electroslag secondary dissolving and a steel treatment process of steel ingot annealing, forging, steel annealing and ultra-fine heat treatment are adopted, the special die steel material for forming a high-temperature-resistant artificial crystal craft is obtained, the steel of theinvention has the hardness being HRC60, and the durability of properties such as high temperature fatigue strength and cold and hot fatigue strength is superior to the durability of properties such as high temperature fatigue strength and cold and hot fatigue strength of like products in China.

Owner:黄石华中模具材料研究所 +1

Fermented feedstuff preparation for piglets as well as preparation method and application thereof

InactiveCN105360644AMeet physiological nutritional requirementsEasy to useAnimal feeding stuffChemistryPeanut meal

The invention discloses a fermented feedstuff preparation for piglets as well as a preparation method and application thereof, and aims at providing a fermented feedstuff preparation with carbohydrates, crude proteins, amino acids, crude fibers, digestible energy, phosphorus, calcium, trace elements and the like meeting the physiological and nutritional requirements of the piglets. The technical scheme is as follows: the fermented feedstuff preparation for the piglets comprises the following raw materials in parts by weight: 90-95 parts of corn, 62-68 parts of soybean meal, 55-60 parts of cottonseed meal, 55-60 parts of rapeseed meal, 45-50 parts of bran, 40-45 parts of peanut meal, 40-45 parts of cassava residue, 30-35 parts of pine needle meal, 20-25 parts of myrtle leaves, 15-20 parts of kelp powder, 15-20 parts of medical stones and 2-5 parts of molasses. The invention belongs to the technical field of feeds.

Owner:广州市天伟生物科技有限公司

Plate material, solid wood composite floor base material and column material made from branch materials and round rod materials, and manufacturing method

The invention provides a plate material, a solid wood composite floor base material and a column material made from branch materials and round rod materials, and a manufacturing method. A core material is formed by splicing half-square round battens; each half-square round batten is a square round batten material obtained by cutting the front, back, left and right surfaces of the a round bar material into bastard faces and forming a circular arc between the two adjacent bastard faces; the square round batten material is sawed into two symmetrical halves by through a center axial line and a bastard face center line to become two half-square round battens with the same cross sections; a part of a plurality of square round batten materials and / or half-square round battens and / or half-square round battens is combined according to requirements; the adjacent bastard faces are bonded to form the required column material, plate material or solid wood composite floor base material. Through the ingenious design and the simple process, the branch materials and the rod materials are made into various materials, so that the wood utilization rate is greatly improved; the precious wood resources are saved; the importing rare hardwood is reduced; the plate material cost is reduced. The purpose is wide; the solid-wood composite floor base material and various plate materials can be manufactured; partition walls, furniture, floor slabs, upright posts and cross beams can be made.

Owner:WUHAN WANGRENZHONG NOVEL SHEET MATERIAL INVESTMENT MANAGEMENT CO LTD

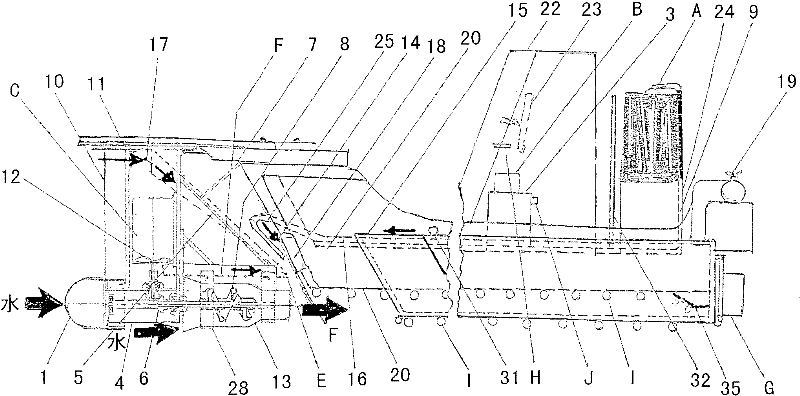

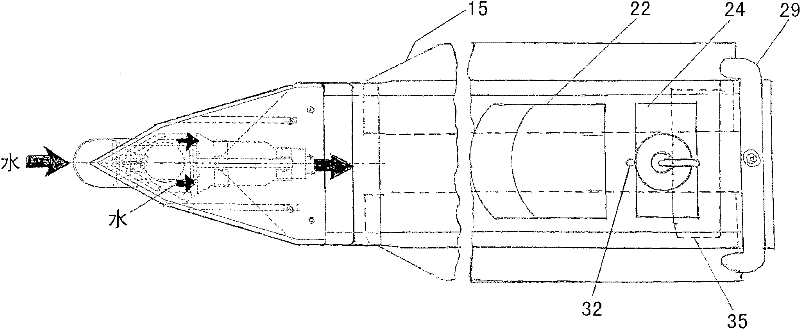

Energy-saving pneumatic/electric boat capable of making hydrogen and removing carbon dioxide bubbles

InactiveCN102241272AHuge economic effectEnsure safetyPropulsion based emission reductionFinal product manufactureFishingStern

The invention provides an energy-saving pneumatic / electric boat capable of making hydrogen and removing carbon dioxide bubbles. According to the technical scheme of the invention, firstly, a gasoline engine on a fishing boat is dismantled the fishing boat is transformed into an electric boat or a pneumatic boat, such as a jet aircraft, a propeller is changed to a position near a bow, the water resistance at the bottom of the boat is reduced by more than 30% through the bubble increment scheme; secondly, a screw rod at a buttock is still remained, the electric motor transformation is arranged in the position where the gasoline engine is removed, transformation is implemented on the existing boat as soon as possible and the corresponding effects can be obtained as early as possible. Furthermore, the boat above the medium size can use surplus offshore electricity to make hydrogen, a small part of electricity is used for fresh-keeping of aquatic products and the like, and a large part of electricity is stored in a container with two copper safety valves and can be sold after the boat is harbored; furthermore, the carbon dioxide removing boat which can generate electricity for sale when the boat is harbored is a ultra-safe and stable boat which comprises a lightning protection rod and an anti-transverse wave gas container.

Owner:炭崎 公政 +1

Precise investment casting powder and investment casting and moulding process thereof

InactiveCN101804442AHigh strengthImprove liquidityFoundry mouldsFoundry coresInvestment castingQuartz

The invention discloses precise investment casting powder and an investment casting and moulding process using the same. The precise investment casting powder comprises the following raw materials in percentage by weight: 25 to 35 percent of alpha semi-hydrated gypsum powder and 65 to 75 percent of quartz powder. After the two raw materials are mixed, based on the weight of the mixture, 0.2 to 0.6 part of superplastieizer, 0.1 to 0.3 part of water reducing agent and 0.2 to 0.5 part of antifoaming agent are added into 100 parts of the mixture. The materials are uniformly mixed to form the finished product, namely the precise investment casting powder. The investment casting and moulding process comprises the following steps: according to the precise investment casting powder prepared from the raw materials, adding 38 to 40 percent of water into 100 percent of the precise investment casting powder, stirring the mixture to form paste, pumping air out of the paste, pouring the paste into a mould to perform vacuum treatment moulding, solidification and baking at a high temperature, and casting the molten metal to cast a cast product or store the molten metal for later use.

Owner:贾传新

Systems and methods for manufacture of methanol from natural gas and flare gas feedstock

ActiveUS9637433B2Enhance economic and energy securityEconomic benefitInternal combustion piston enginesOrganic compound preparationFlareNitrogen gas

Owner:PIONEER ENERGY

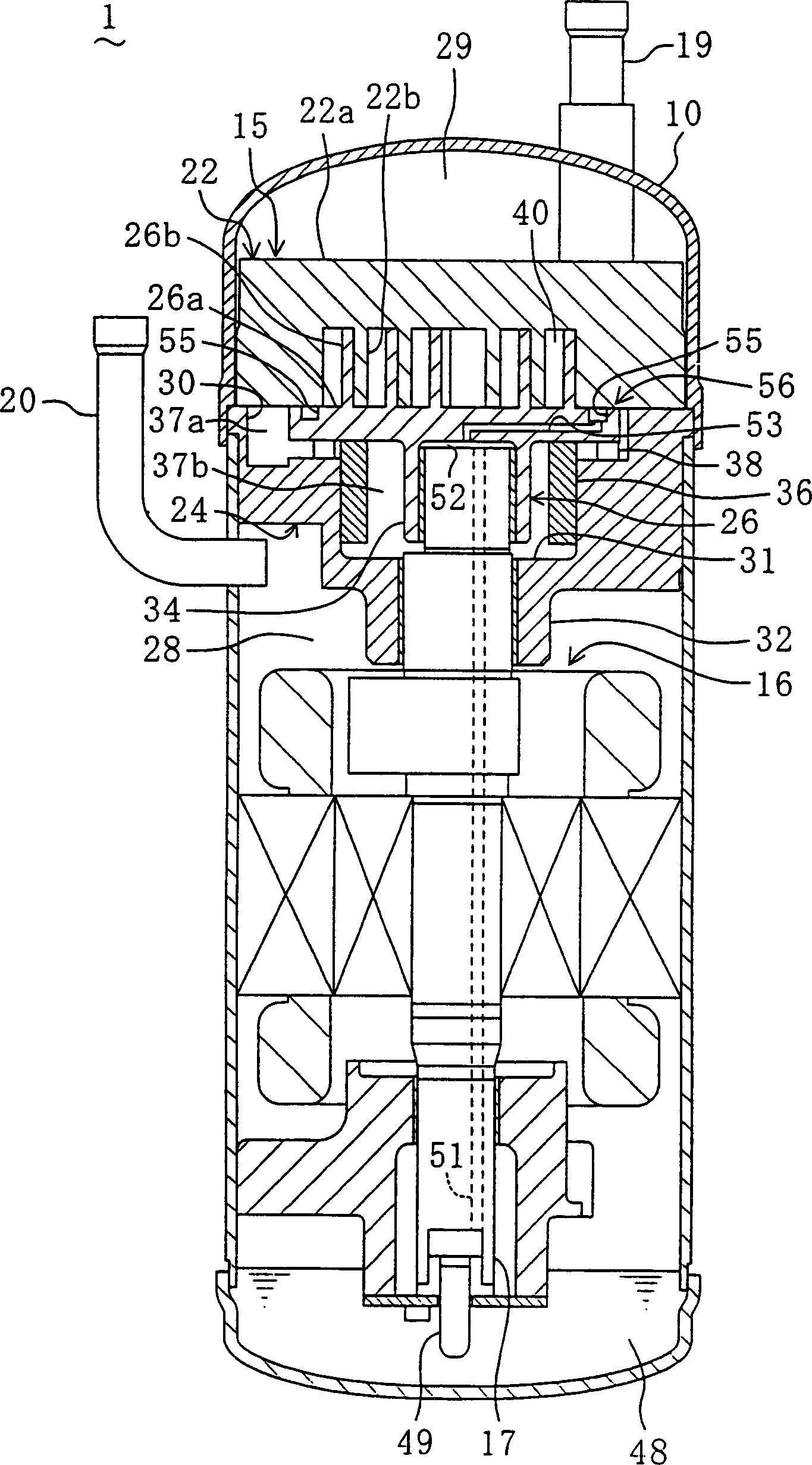

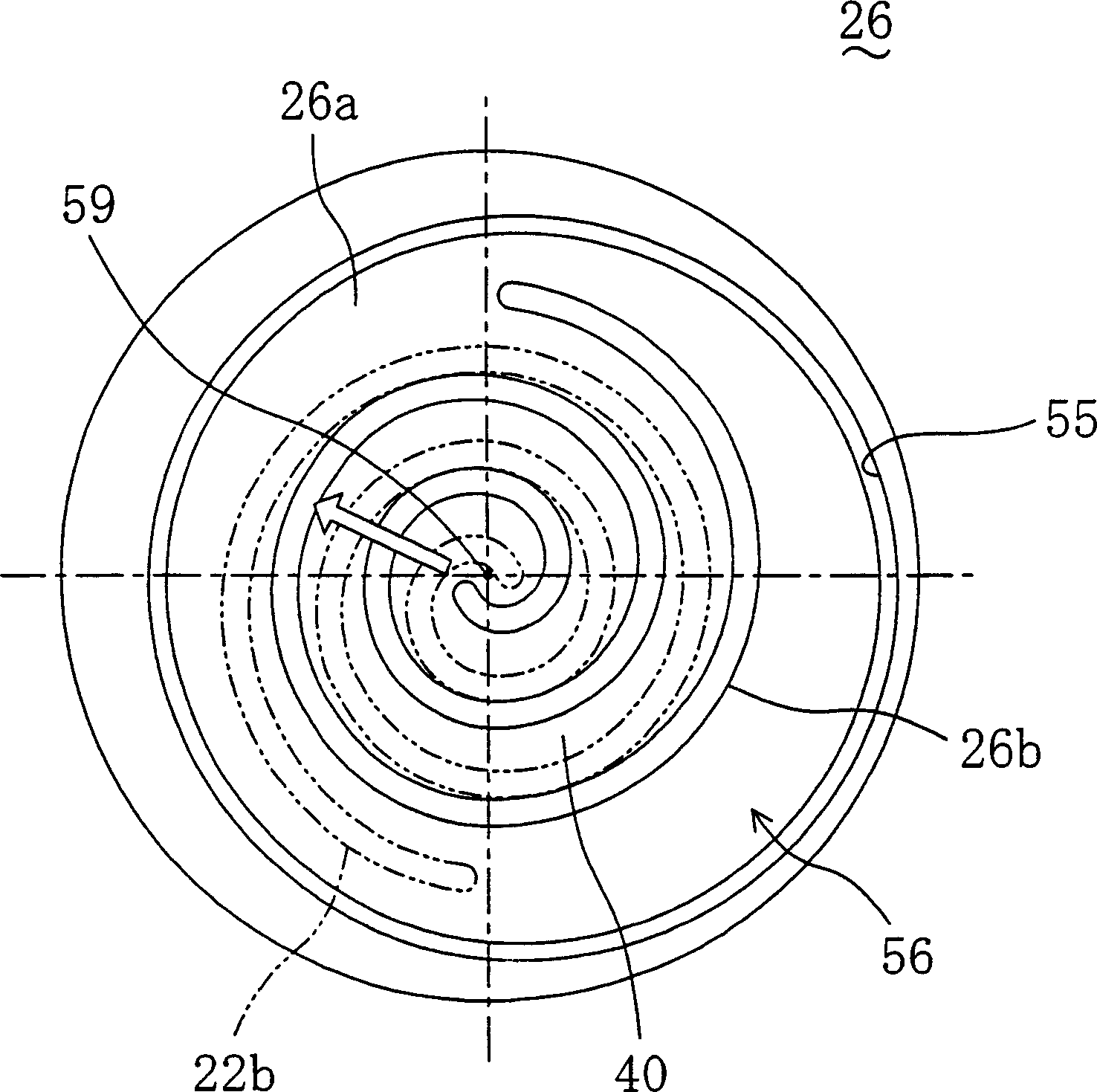

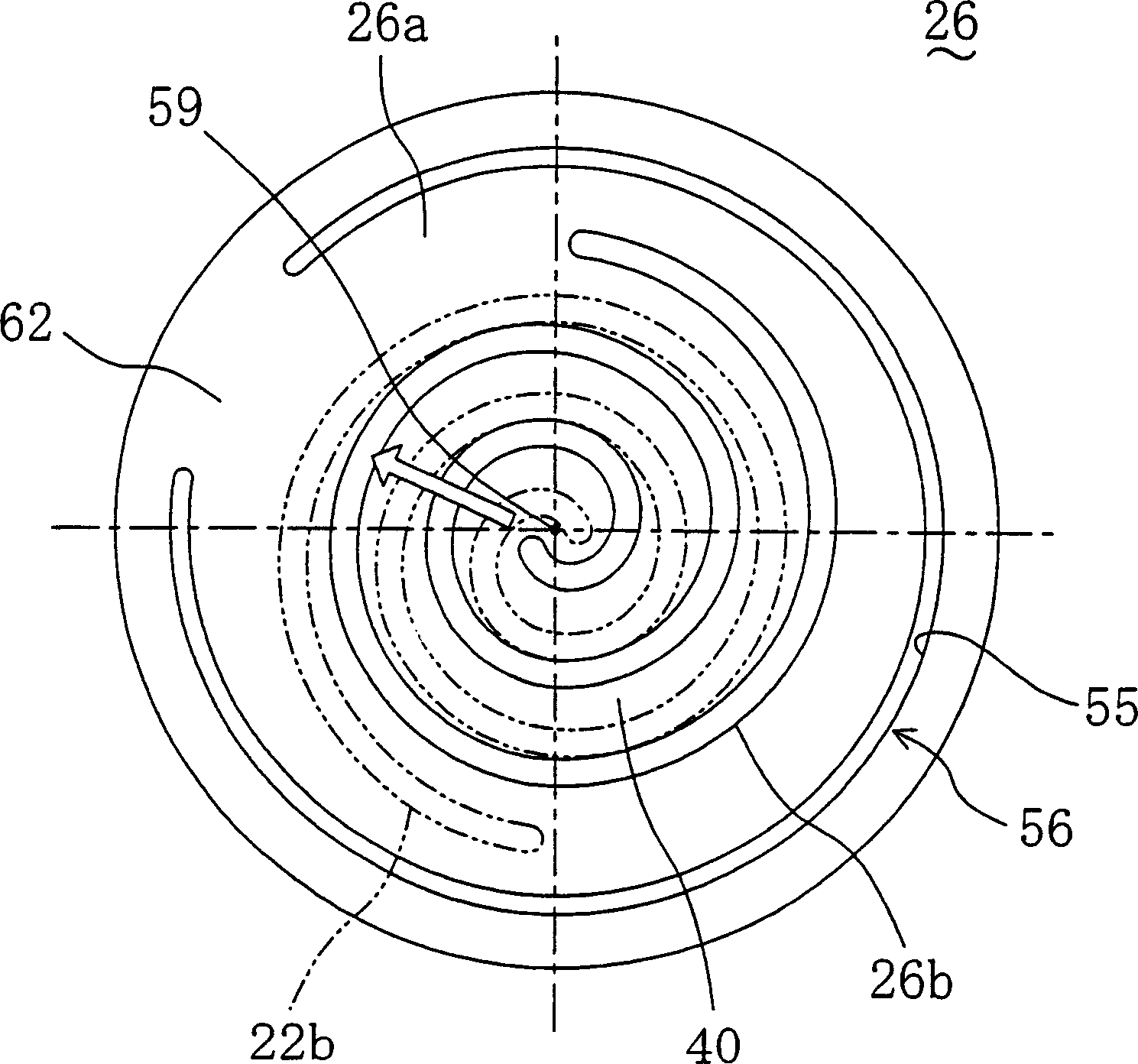

Scroll-type compressor

InactiveCN1592820APrevent leakagePrevent reduction in operating efficiencySealing arrangement for pumpsRotary piston pumpsMechanical engineeringEngineering

Owner:DAIKIN IND LTD

Method for treating chromic slag by acid pickling process

InactiveCN1635170AEliminate Pollution PotentialReduce processing costsSolid waste disposalProcess efficiency improvementAfter treatmentSlag

The invention relates to a method for treating chromic slag by acid pickling process. Wherein: mixing waste acid and chromic slag, leading supersonic wave into the acid tank by supersonic wave generator, discharging the acid liquor after treatment, deacidizing the hexavalent chromium ion in chromic slag to trivalent chromium ion completely by treating the acid liquor. The invention adopts resource method for treating chromic slag, and realizes innocuousness, resource-saving and economic benefit increasing.

Owner:刘克柱

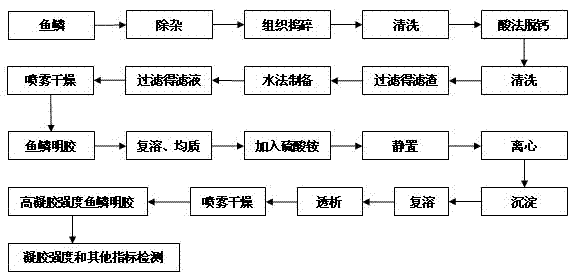

Preparation method of high-gel-strength fish scale gelatin

The invention relates to a preparation method of a high-gel-strength fish scale gelatin, which comprises the following step: performing ammonium sulfate salting-out on a fish scale gelatin, which is prepared from fish scale waste and used as an object, to prepare a high-gel-strength fish scale gelatin product. The preparation method provided by the invention has the following positive effects: 1, the fish scale waste is used as an initial raw material for gelatin preparation, thus realizing the high-value utilization of the resource, protecting the environment, realizing the sustainable green development, effectively reducing the gelatin production cost and reducing the gelatin import volume of China; 2, the fish scale gelatin is subjected to ammonium sulfate salting-out for the first time, thus preparing the high-gel-strength fish scale gelatin, reducing the consumption in the application process and further reducing the gelatin application cost; and 3, the method for preparing a high-gel-strength fish scale gelatin through ammonium sulfate salting-out can provide a practical and feasible basis for the preparation of a high-quality gelatin, thereby laying a foundation for the further study on the gelatin and making a little contribution for the quick development of the gelatin industry in China.

Owner:NANCHANG UNIV

Systems and methods for manufacture of dimethyl ether (DME) from natural gas and flare gas feedstock

ActiveUS9643906B2Enhance economic and energy securityEconomic benefitHydrogenEther separation/purificationNitrogen gasPetroleum

A unique design for a mobile system that reforms flare gas or natural gas, using air without steam, to directly produce dimethyl ether (DME), a diesel substitute, is disclosed. The system first reforms the air-methane mixture at ambient atmospheric pressures, and then compresses the resulting CO-hydrogen-nitrogen gas mixture to up to 600 psi, and feeds it through a combined reactor which reacts the gas mixture directly into dimethyl ether. The nitrogen is returned by the system back to the atmosphere. DME is an excellent diesel fuel, and can be used to displace significantly costlier and dirtier petroleum-based diesel fuel, while solving a critical problem with flaring. For example, the over 120 billion cubic feet per year that is currently flared in North Dakota could be converted into over 3 million tons of DME.

Owner:PIONEER ENERGY

Fermented feed raw material preparation as well as preparation method and application thereof

InactiveCN105360615AReduce importsIncrease serving sizeFood processingAnimal feeding stuffRapeseedSugar

The invention discloses a fermented feed raw material preparation as well as a preparation method and application thereof. The preparation is made from the following raw materials through beneficial microbial fermentation: 205-225 parts of soybean meal, 185-215 parts of cottonseed meal, 185-195 parts of rapeseed meal, 175-205 parts of bran, 185-210 parts of cassava residues and 5-10 parts of cane sugar honey. The invention aims to provide the fermented feed raw material preparation which is balanced in nutrition, low in cost, and capable of enhancing the immunity of bred animals, increasing the survival rate of the bred animals and reducing environmental pollution.

Owner:广州市天伟生物科技有限公司

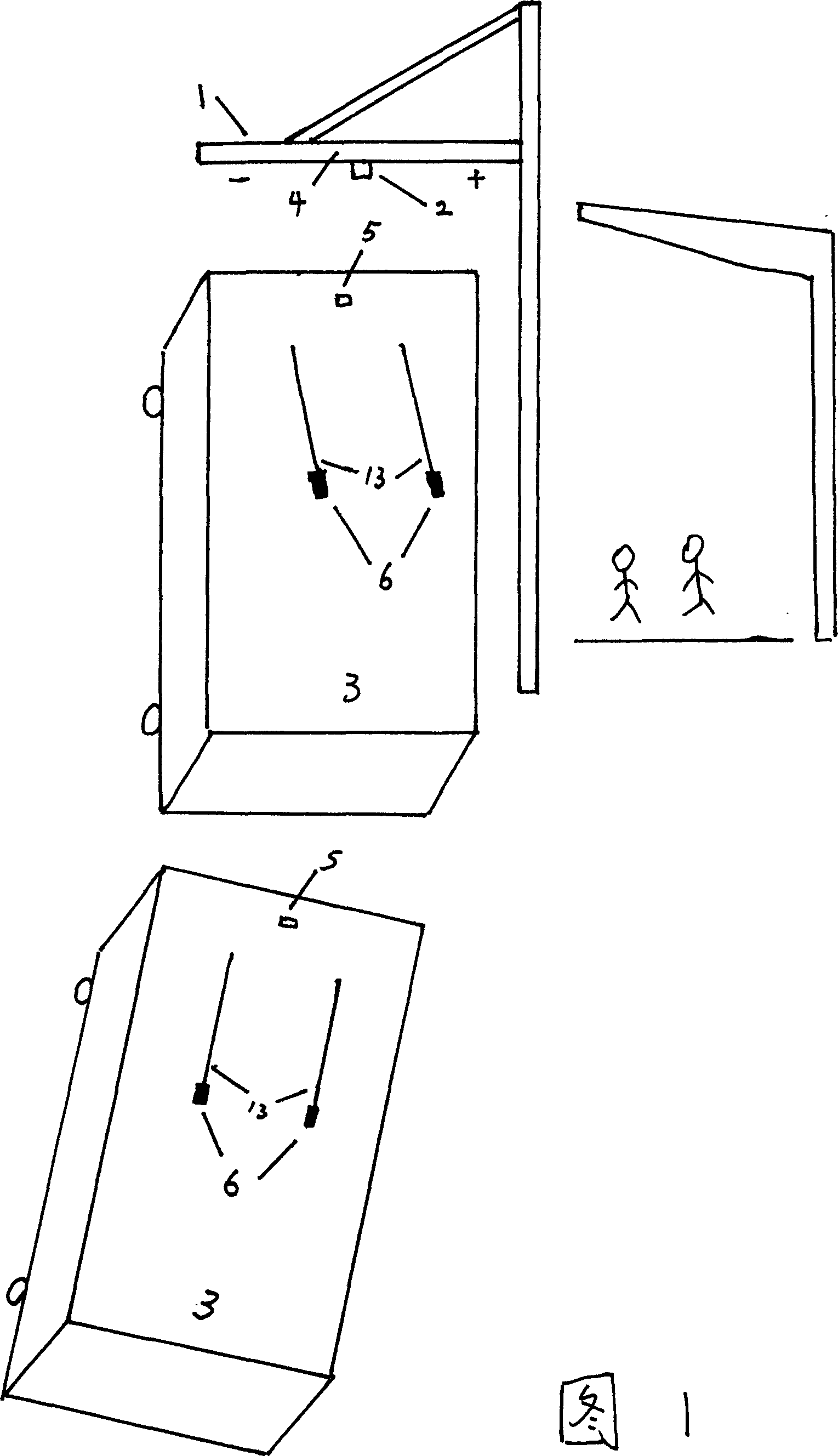

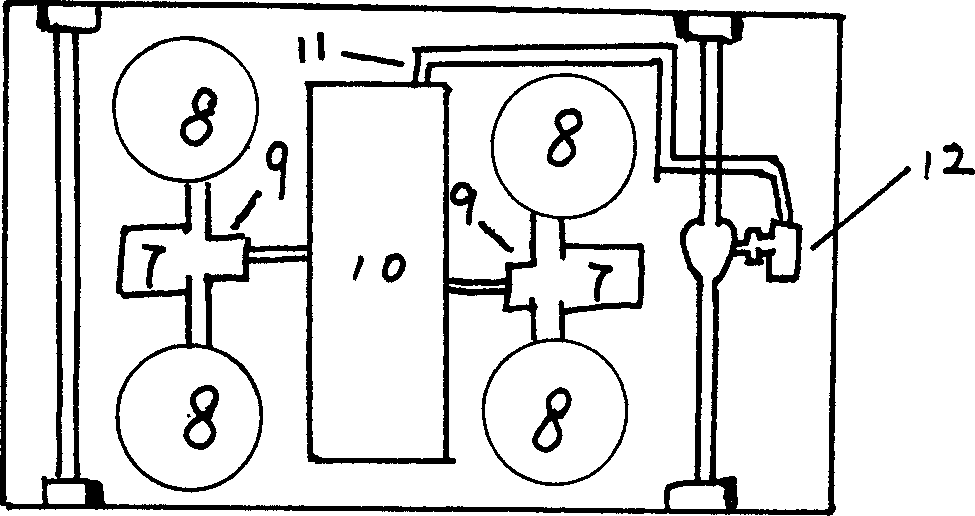

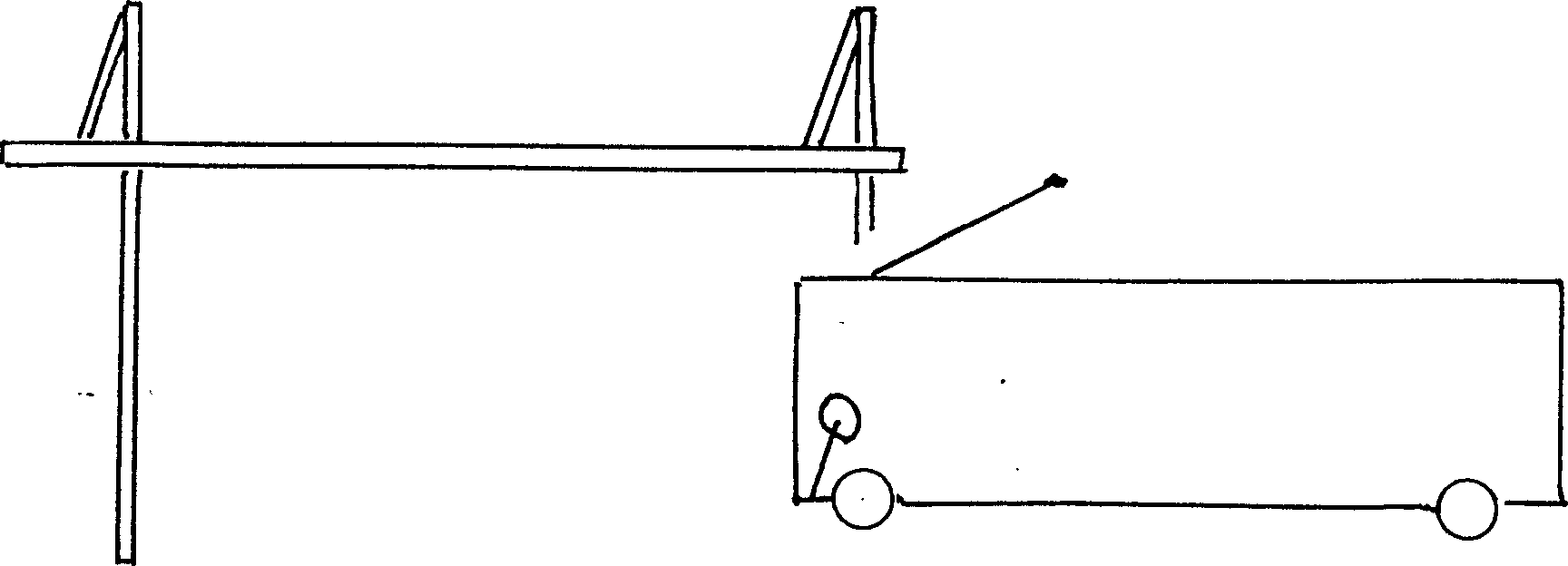

Technical project for urban electric power bus

InactiveCN1569510AReduce importsReduce pollutionPower supply linesElectric propulsionEngineeringInternal combustion engine

The invention is a technology scheme for cit electric public bus, which relates to a transmission method without gas engine. Through setting the electricity supplying platform connected to the city electric network, the system supplies electricity to the bus with electricity bow in times when the bus parking at the station, thus the carrying motor drives the energy storing flywheel and air compressor to act, the compressed energy drives the bus to the next station.

Owner:姚卫东

Magnetic separation and deinking method for waste paper

InactiveCN101736635AImprove deinking efficiencyReduce fiber lossPaper recyclingWaste paper working-upChemistrySodium silicate

The invention relates to a magnetic separation and deinking method for waste paper, comprising the following steps: (1) adding waste paper and magnetic seeds in a pulper, adding water, sodium silicate and NaOH for repulping, wherein the repulping conditions are as follows: the magnetic seed dosage is 0.05-0.2wt%, the dosage of sodium silicate is 2-10wt%, NaOH is used to regulate the pH value to be 7-10, and the pulp concentration is 10-15wt%; (2) adding water for diluting after water paper repulping until the pulp concentration to be 0.5-4wt%, adding flocculant which accounts for 0.01-0.1wt% of dry paper into the pulp after repulping for magnetic seed flocculation, enabling the deciduous ink particles to be adhered with magnetic seeds, wherein the pH value is 7.0-11.0, the time is 10-30min, and the stirring speed is 200-1000rpm; and (3) separating the flocculated ink particles from the pulp by a deinking device for size after magnetic seed flocculation. The method in the invention can obviously improve pulp whitness and fiber yield of water paper, and can be used for producing deinking pulp with high whiteness and high deinking rate and small amount of paper fiber loss.

Owner:有研资源环境技术研究院(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com