Preparation method of high-gel-strength fish scale gelatin

A technology of fish scale gelatin and high gel, applied in the field of preparation of fish scale gelatin, to achieve sustainable green development, reduce imports, and reduce application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

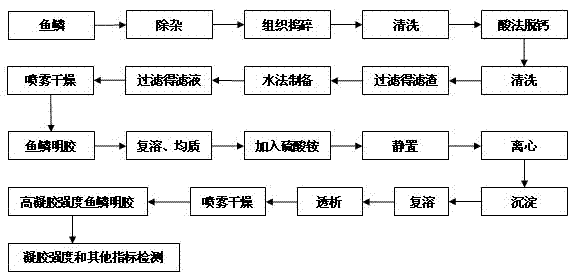

Method used

Image

Examples

Embodiment 1

[0014] 1. Preparation of initial fish scale gelatin: (1) Tissue pounding: After removing non-scale substances, use a tissue pounder to process fish scales for 6 minutes, and then wash until the water is clear; (2) Fish scale decalcification: Use hydrochloric acid to treat fish scales Carry out decalcification, the process is 0.5mol / L hydrochloric acid concentration, solid-liquid ratio 1:20, decalcification time 1h, after decalcification, the fish scales are cleaned to be close to neutral; (3) fish scale gelatin preparation: fish scales are prepared by hot water method Gelatin, the process is a material-to-liquid ratio of 1:20, a water bath temperature of 80°C, and a time of 3 hours; (4) Spray drying: the inlet air temperature is 180°C, and the outlet air temperature is 90°C to obtain the primary product of fish scale gelatin.

[0015] 2. Preparation of fish scale gelatin products with high gel strength: (1) Preparation of glue solution: Prepare fish scale gelatin into a 4% solu...

Embodiment 2

[0019] 1. Preparation of initial fish scale gelatin: (1) Tissue pounding: After removing non-scale substances, use a tissue pounder to process fish scales for 6 minutes, and then wash until the water is clear; (2) Fish scale decalcification: Use hydrochloric acid to treat fish scales Carry out decalcification, the process is 0.5mol / L hydrochloric acid concentration, solid-liquid ratio 1:20, decalcification time 1h, after decalcification, the fish scales are cleaned to be close to neutral; (3) fish scale gelatin preparation: fish scales are prepared by hot water method Gelatin, the process is a material-to-liquid ratio of 1:20, a water bath temperature of 80°C, and a time of 3 hours; (4) Spray drying: the inlet air temperature is 180°C, and the outlet air temperature is 90°C to obtain the primary product of fish scale gelatin.

[0020] 2. Preparation of fish scale gelatin products with high gel strength: (1) Preparation of glue solution: Prepare fish scale gelatin into a 4% solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com