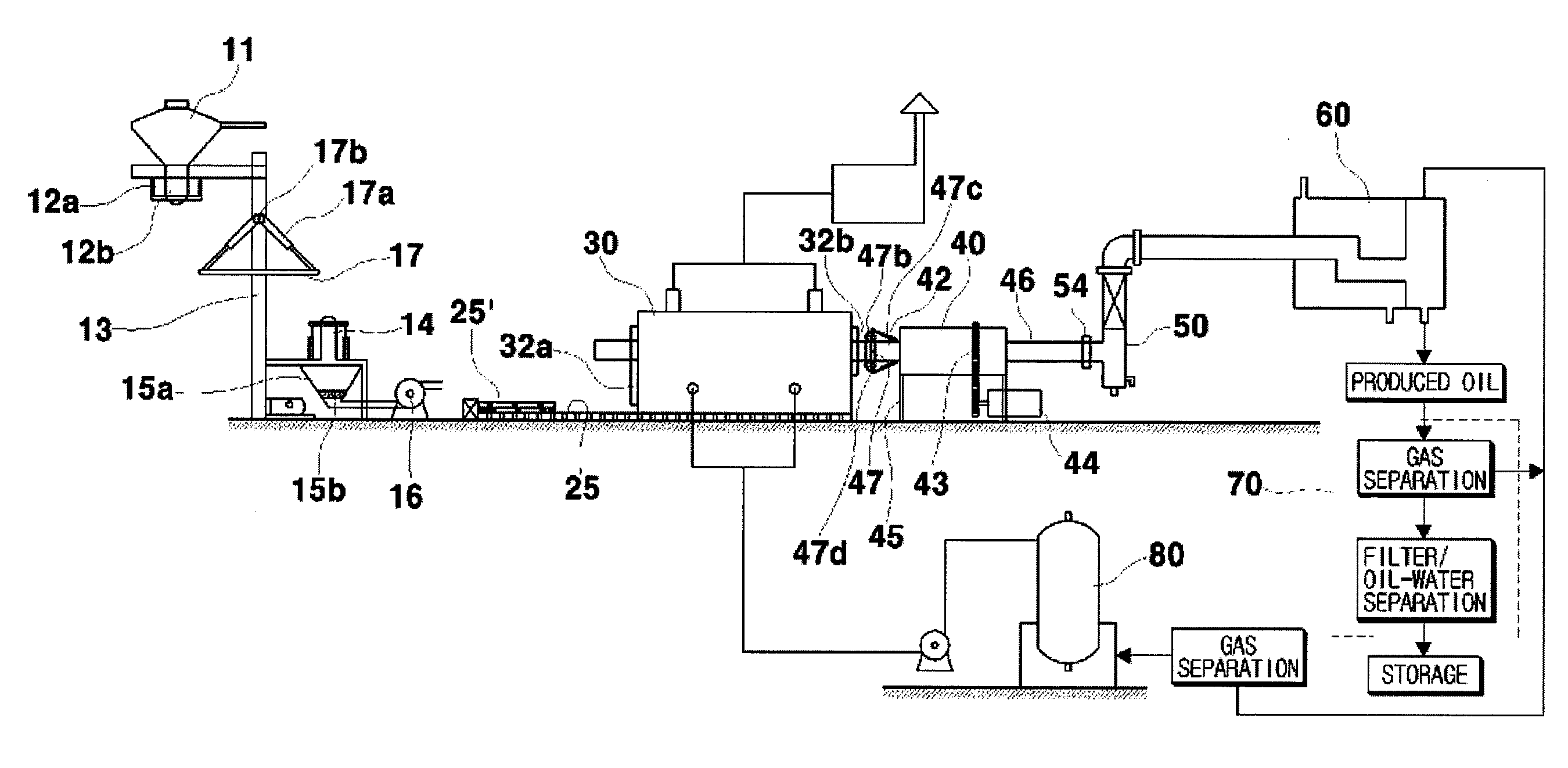

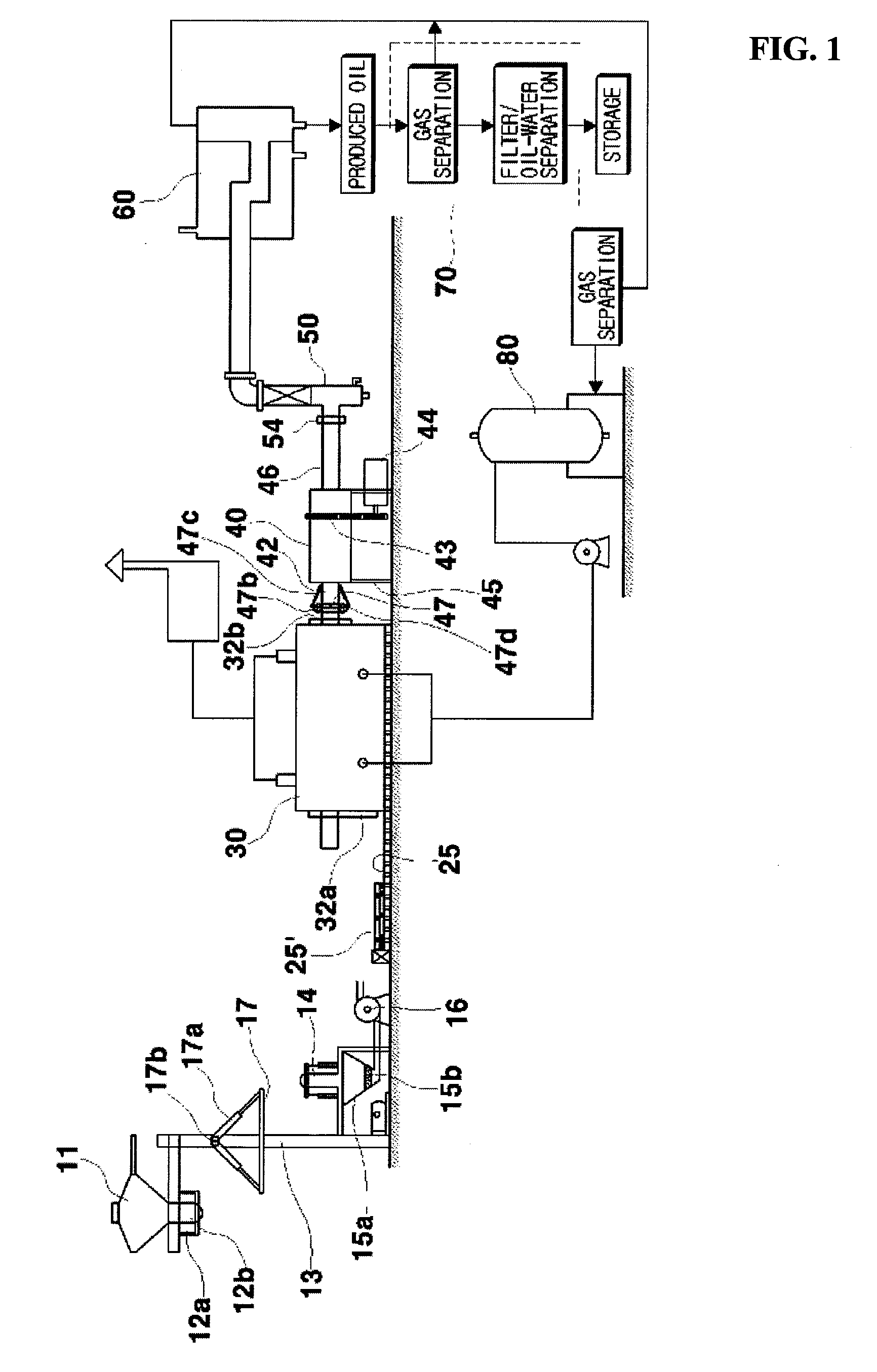

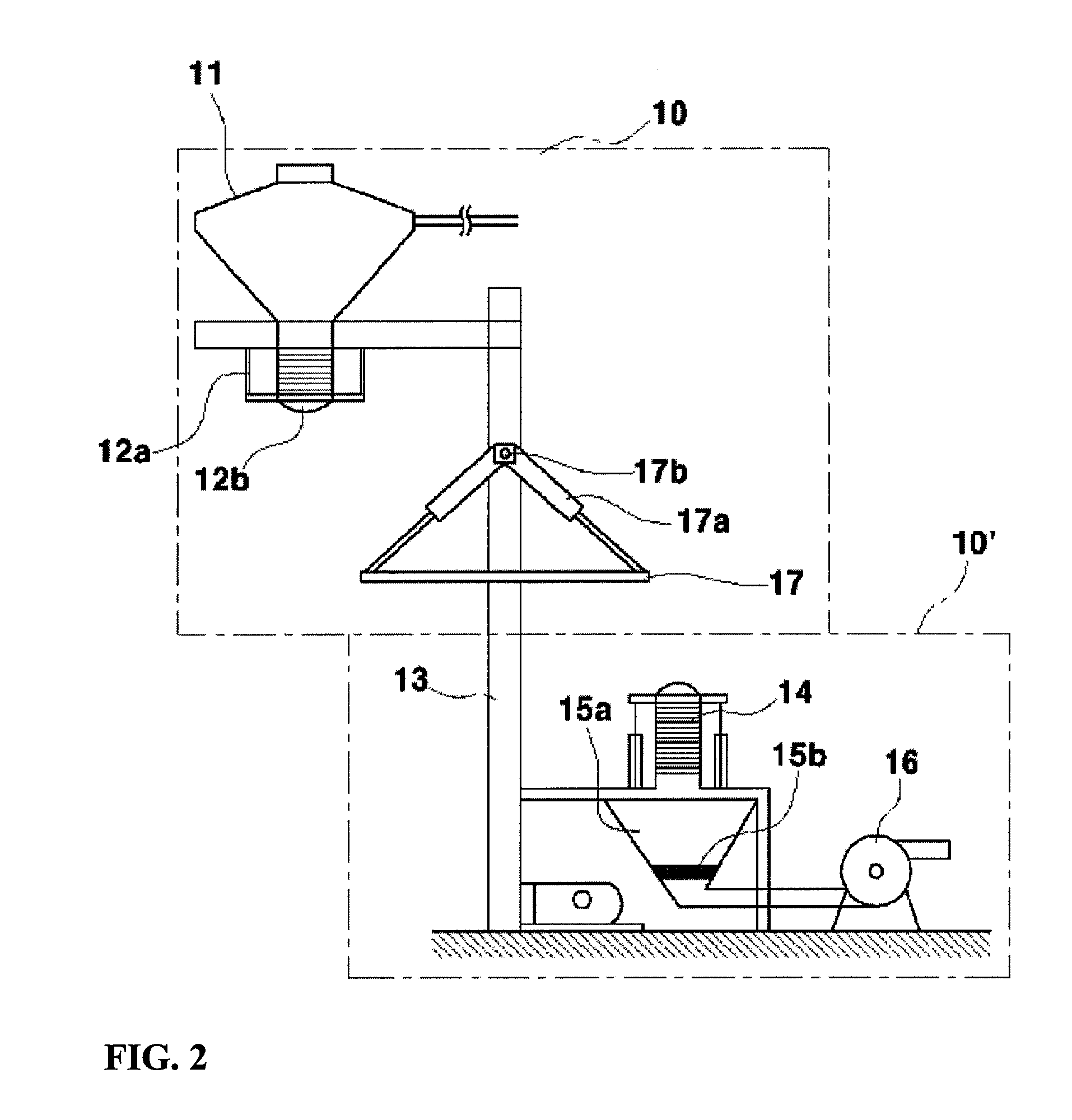

Oil extraction device for pyrolysis of plastics waste material and extraction method thereof

a technology of oil extraction device and plastic waste material, which is applied in the direction of lighting and heating apparatus, combustion types, separation processes, etc., can solve the problems of low economic efficiency, poor oil extraction yield, and the majority of conventional pyrolysis systems, so as to improve economic efficiency and efficiently collect the pyrolysis gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example

[0130]Volume of a reactor that may be filled with waste materials; 6.944 D,[0131]Filling ratio; 80%[0132]Weight of filled material; 0.1003×0.8×0.45 (specific gravity)=2.5 t (input weight)[0133]Composition analysis of product; oil: 60%, gas: 20%, carbide (char): 15%, and moisture: 5%, wherein oil is separated by an oil-water separator because oil and moisture are mixed together.

[0134]Amount of products is calculated as follows.[0135]Oil: 2.5 ton×0.6÷0.87 (specific gravity)=1,724 L[0136]Gas: 2.5 ton×0.2=500 kg[0137]Carbide: 2.5 ton×0.15=375 kg[0138]Moisture: 2.5 ton×0.05=125 kg

[0139]Accordingly, oil of 1,724 L is produced from 2.5 ton of waste materials and production efficiency is high.

[0140]Energy balance for producing oil is described as follows.

[0141][0142]Type of waste material: Waste tire[0143]Filling amount: 2.5 ton / batch (Specific gravity is applied.)[0144]Composition of product

[0145]1) Oil: 45%˜50%→Applied value: 50%

[0146]2) Gas: 10%˜15%→Applied value: 15%

[0147]3) Carbide: 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suction rate | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com