No water/graywater/selfsanitizing, valve toilet, waste recycling system

a waste recycling and toilet technology, applied in the direction of water closets, flushing devices, lavatory sanitory, etc., can solve the problems of polluting trillions of gallons of water a year, prior art also cannot utilize wastes as fertilizers, etc., to stop the use of net water, stop the cost involved, and ensure the natural recycling of was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

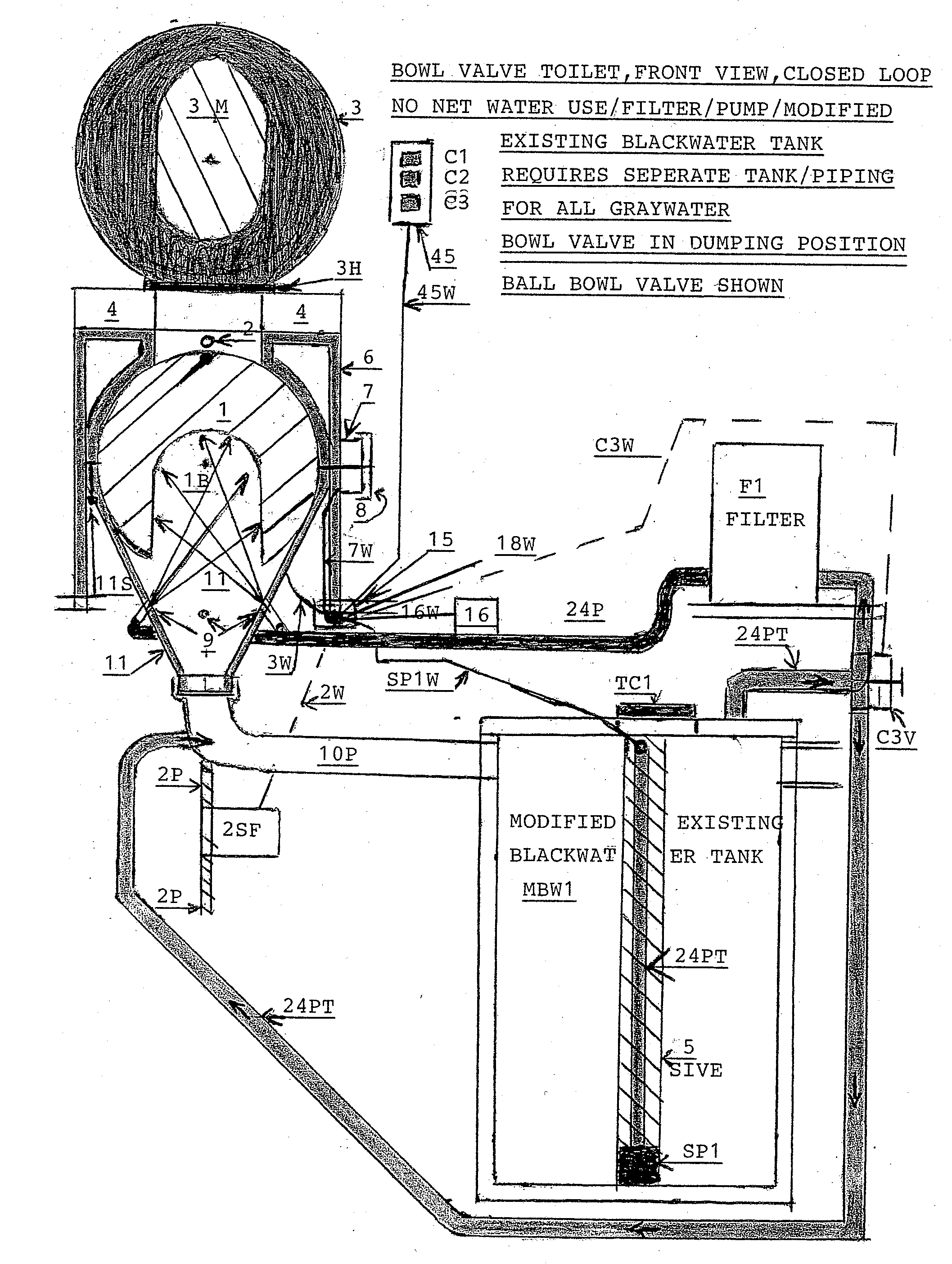

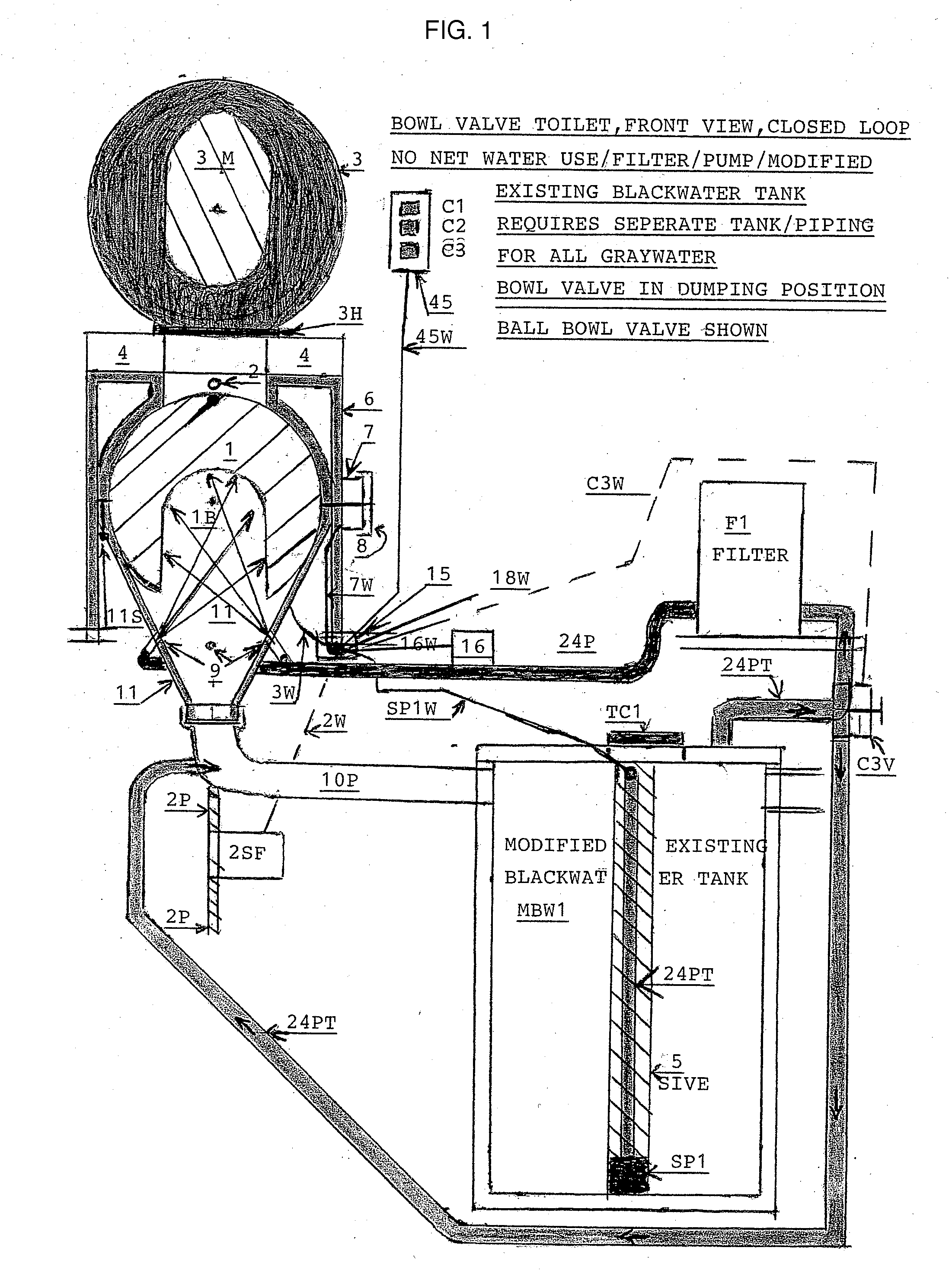

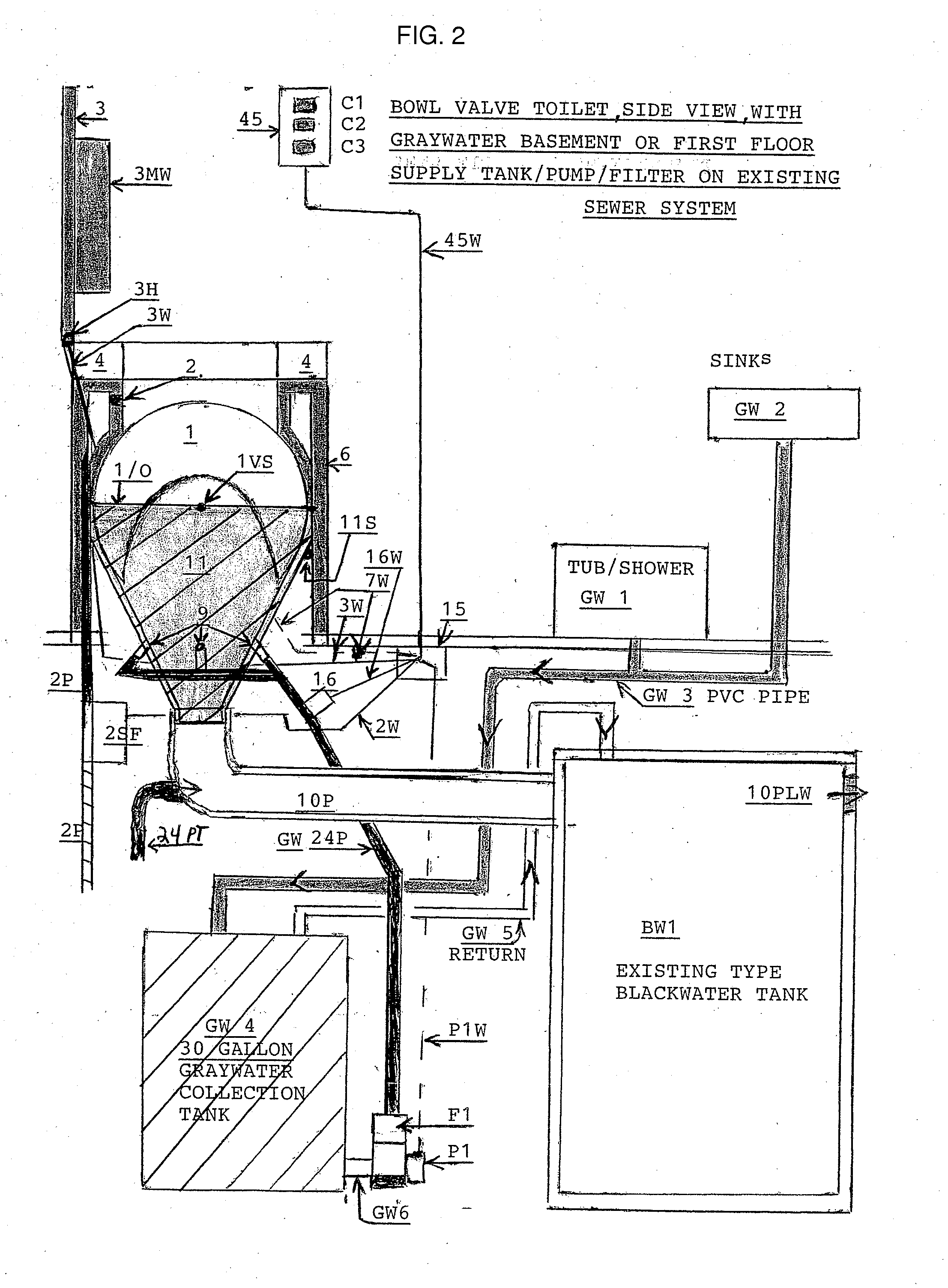

[0240]How to use bowl valve toilets & how they work

[0241]First, one lifts the toilet cover 3, which turns on a switch on the cover hinge 3H, which turns on air suction fan / motor 2SF sucking air from below seat 2 to outside via pipe 2P; at the same time the switch 3H activates the valve motor 7 via wire 7W connected to switch 3H via wire 3W@junction box 15 and turns the bowl valve 1 and its bowl 1B up to catch wastes. If electricity is off, the bowl valve is turned by hand 8.

[0242]Next one sets on the toilet seat 4, and excretes wastes in the bowl valves bowl 1B, at which time one must select cycle by pressing button one C1 (a rinse) for urinating, or cycle 2 for deficating (a full flush) (D.1,10,11) C2 when done activates an automatic line flush of sewer pipe cycle 3 C3. (C3 also has a manual over ride button that if held flushes said line) cycle selections are located in a wall box 45, which also contains the cycle timer that turns on and off the timed cycles. The timer / switch 45 v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com