System for drying coal by using superheated steam

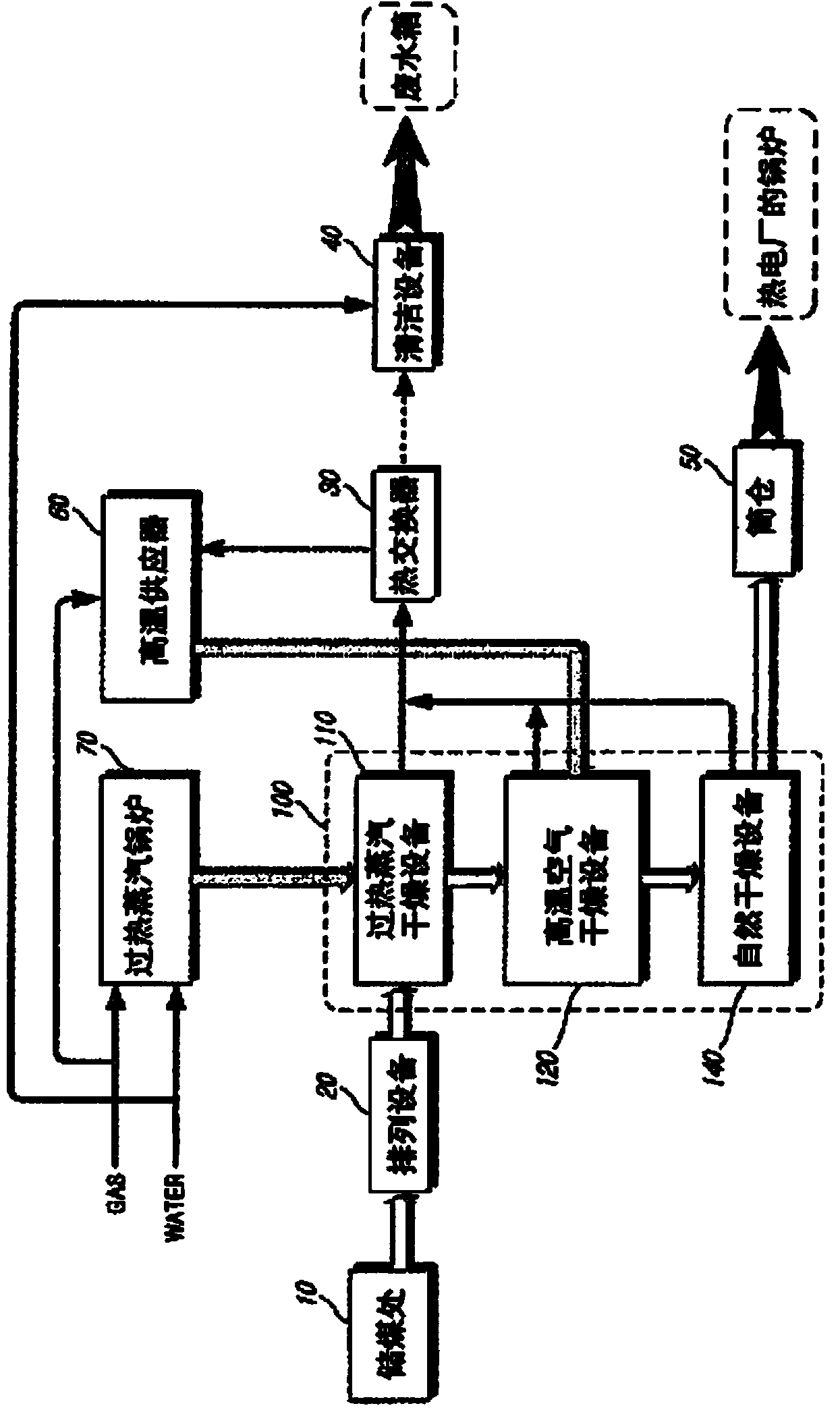

A technology of superheated steam and drying, which is applied in the direction of heating to dry solid materials, steam generation, and drying solid materials, etc., which can solve the problems of increasing coal thermal power plant construction plans, etc., to solve the problem of transmission path blockage, increase supply, and reduce emissions Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

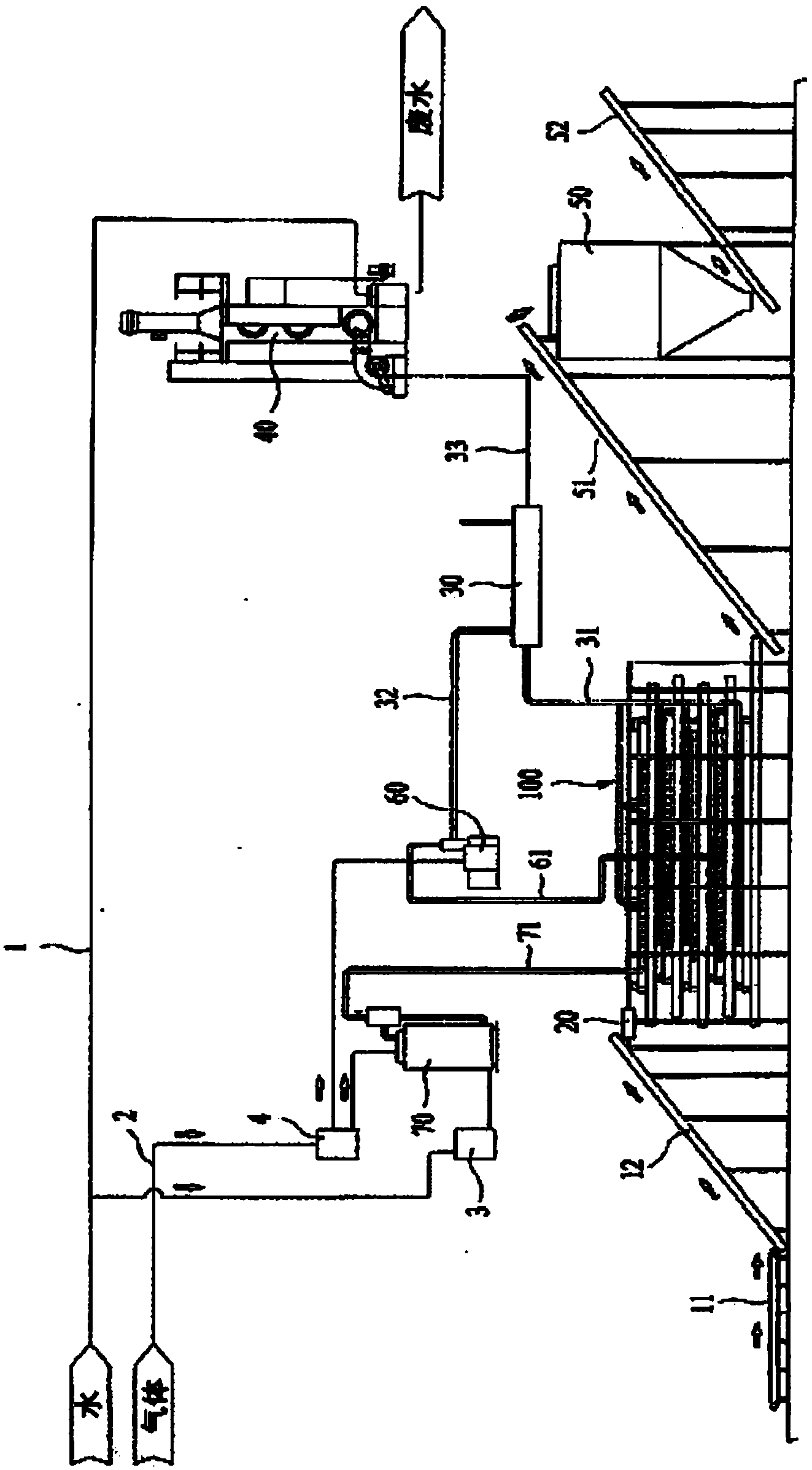

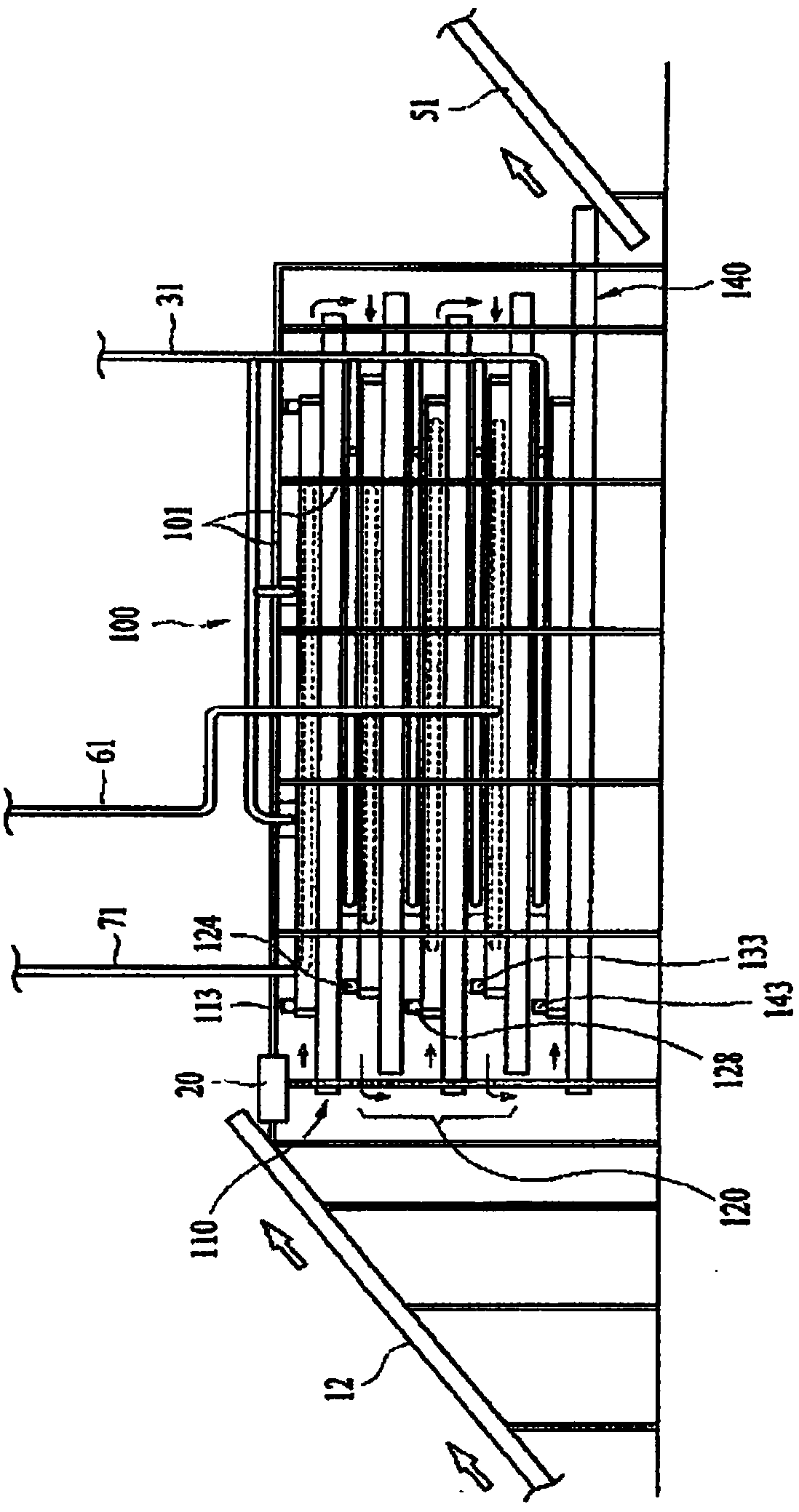

[0025] Therefore, specific embodiments of the coal drying device using superheated steam according to the present invention will be described in detail with reference to the accompanying drawings.

[0026] figure 1 , the coal storage place 10 is the place used to reserve and store fuel coal in the boiler of the thermal power plant. Coal includes surface pollination and internal pollination. Further, water is periodically sprayed on the coal stored in the coal storage place 10 so as to prevent the coal dust from spreading. The coal stored in the coal storage place 10 is transported to the coal drying system through a transport device, such as a transport system. In this case, the coal stored in the coal storage place 10 without moisture removal may be moved to a storage tank connected to the coal drying system and stored. The coal in the coal storage place 10 is transported to the alignment device 20 through the flat conveyor belt 11 and the concave conveyor belt.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com