Low NOx rotational flow coal dust combustion device of industrial boiler

A technology for pulverized coal combustion and industrial boilers, applied in burners, combustion chambers, combustion methods, etc., can solve the problems of high pollutant emissions and low combustion efficiency of industrial boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

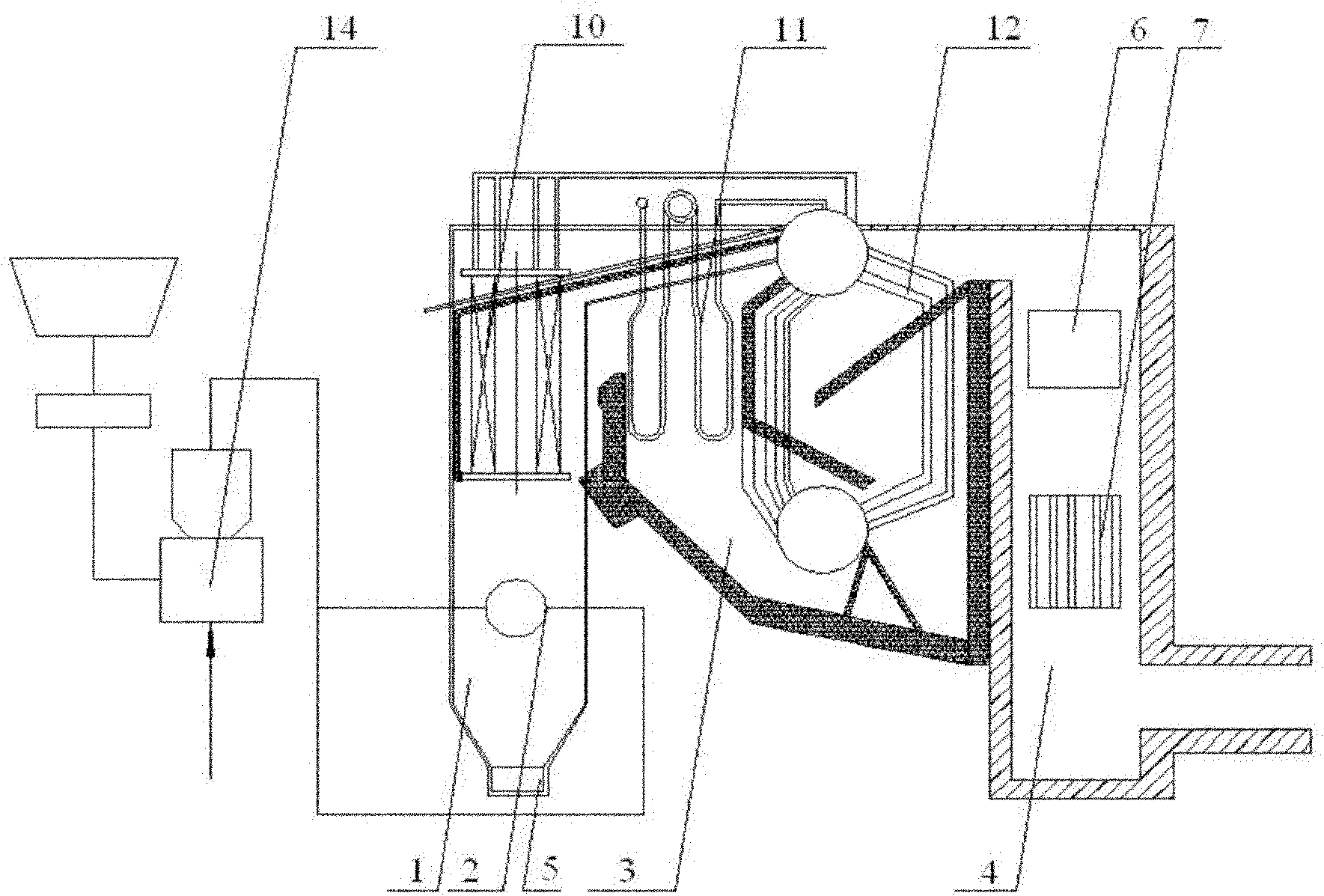

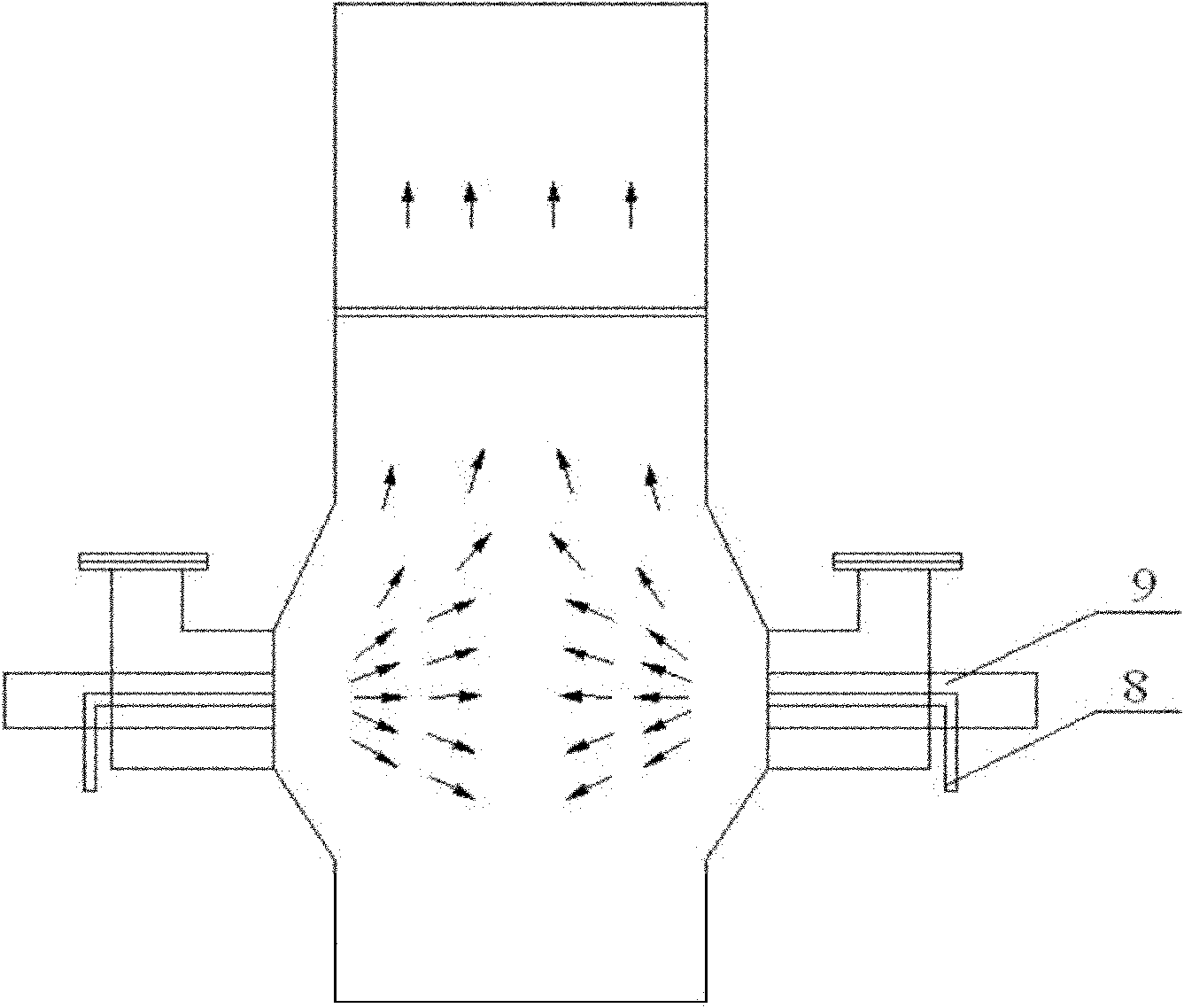

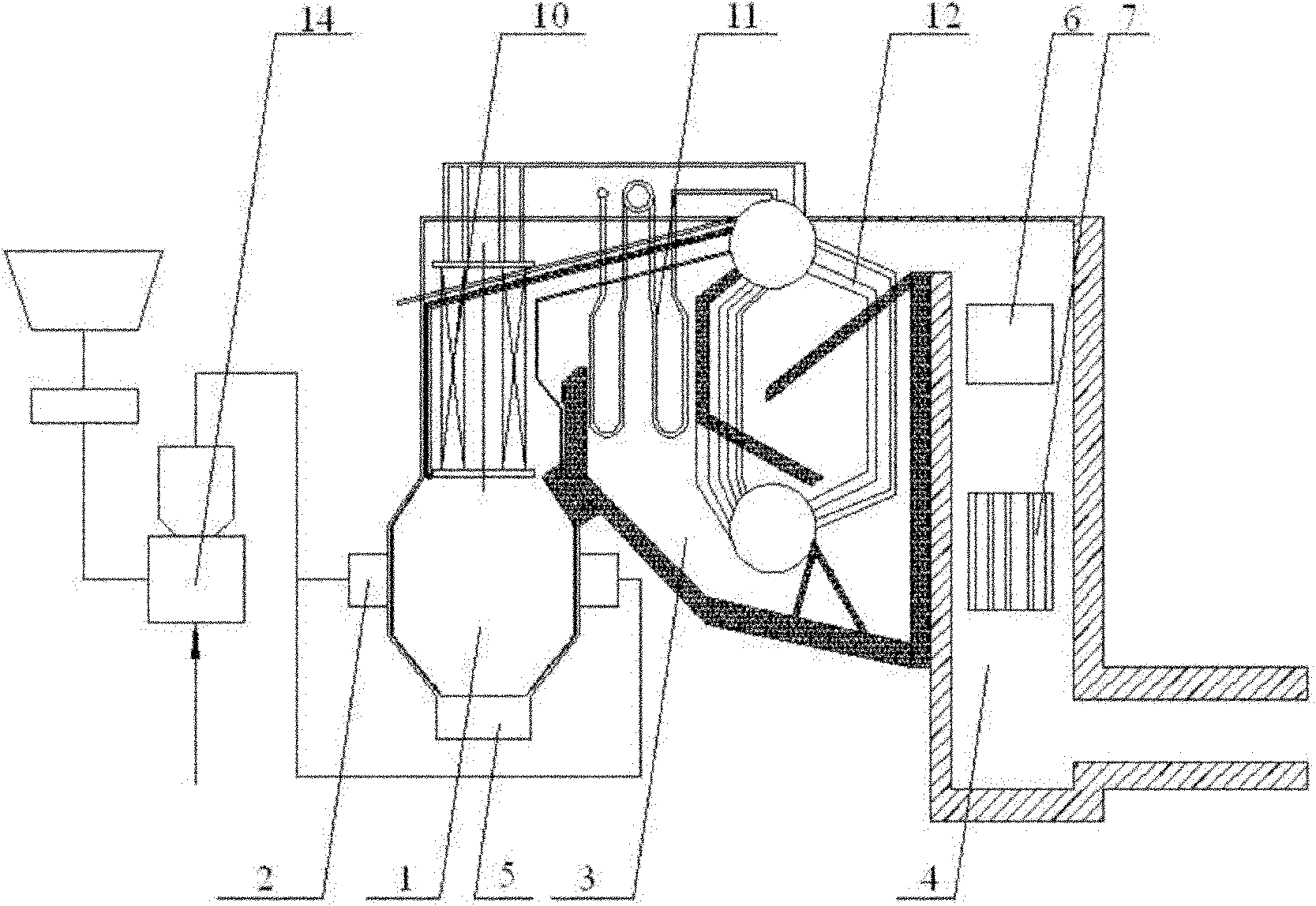

[0026] Such as figure 1 and image 3 As shown, this embodiment includes: furnace 1, swirl pulverized coal burner 2, burnout chamber 3, tail flue 4, ash hopper 5, economizer 6 and air preheater 7, wherein: furnace 1 is divided into The lower part of the adiabatic furnace 1 and the upper part of the water-cooled furnace 1, the adiabatic furnace 1 is located at the lower part of the furnace 1 and has a protruding structure on the front and rear walls or the left and right walls, the swirl pulverized coal burner 2 is respectively installed on the left and right walls of the adiabatic furnace 1, and the ash hopper 5 It is located at the lower part of the adiabatic furnace 1 to collect the ash after pulverized coal combustion. The water-cooled furnace 1 is equipped with a water-cooled wall 10 to absorb radiant heat and convective heat to heat the steam-water mixture from the economizer 6. The burnout chamber 3 is located in the furnace 1 The upper outlet of the upper outlet, the ta...

Embodiment 2

[0042] This embodiment includes: furnace 1, swirl pulverized coal burner 2, burnout chamber 3, tail flue 4, ash hopper 5, economizer 6 and air preheater 7, wherein: furnace 1 is divided into the lower heat insulation The furnace 1 and the upper water-cooled furnace 1, the adiabatic furnace 1 is located at the lower part of the furnace 1 and has a protruding structure on the front and rear walls, the swirl pulverized coal burners 2 are respectively installed on the front and rear walls of the adiabatic furnace 1, and the ash hopper 5 is located at the lower part of the adiabatic furnace 1 Collect the ash after pulverized coal combustion. The water-cooled furnace 1 is equipped with a water-cooled wall 10 to absorb radiant heat and convective heat to heat the steam-water mixture from the economizer 6. The burnout chamber 3 is located at the upper outlet of the furnace 1. The tail smoke The channel 4 is located at the outlet of the burnout chamber 3, and the economizer 6 and the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com