Resource utilization method for oil-based drilling cutting ash residue

An oil-based drill cuttings and recycling technology, applied in the field of environmental engineering, can solve problems such as no compression molding reports, and achieve the effects of high burnout efficiency, improved combustion efficiency, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

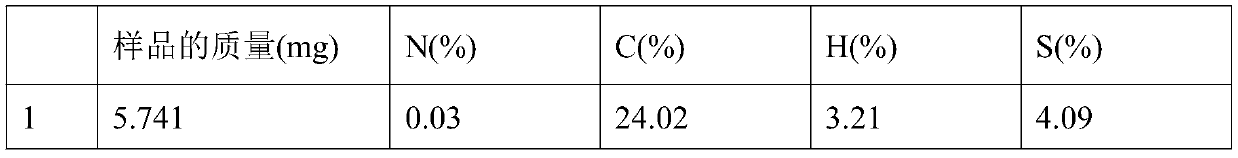

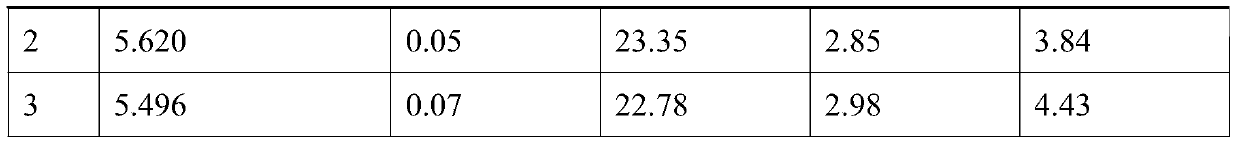

[0024] The oil-based drilling cuttings and ash produced by a drilling platform of Chongqing Fuling Jianghan Oilfield Company during the drilling process of oil and gas field exploration and exploitation are used as raw materials. The oil-based drilling cuttings and ash contain the following elements: C 24.02%, H 3.21%, N 0.03% , S4.09%, calorific value 10.5MJ / kg.

[0025] 70 parts of starch, 10 parts of carboxymethyl cellulose, 1 part of potassium permanganate, 10 parts of NaOH, and 9 parts of sodium tetraborate were mechanically mixed to obtain a composite binder; 60 parts of oil-based drilling cuttings ash, 22.5 parts The composite binder, 2.5 parts of magnesium acetate, and 15 parts of water are mixed mechanically, and then sent to a piston stamping molding machine to be compressed into a cylindrical hollow molding fuel with a diameter of 20 mm and a length of 50 mm under normal temperature.

[0026] After the molded fuel was dried, the shear force was measured to be 45.2N ...

Embodiment 2

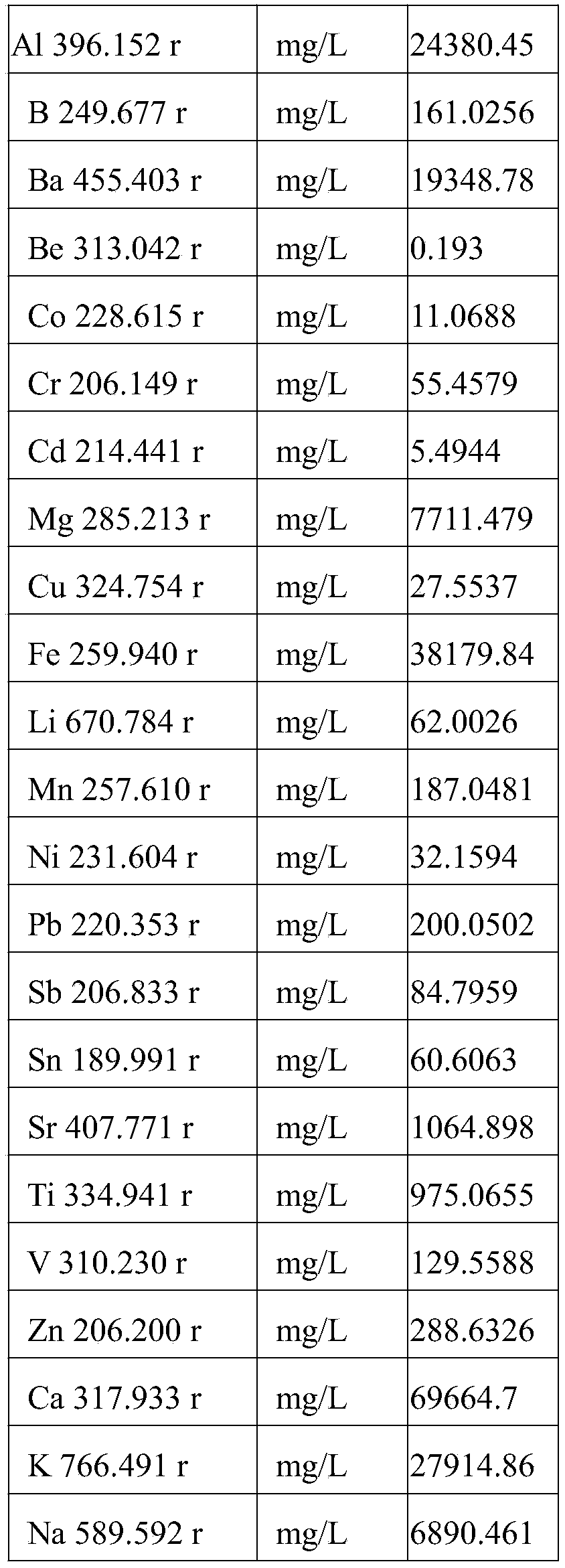

[0028] The oil-based drilling cuttings and ash produced by a drilling platform of Chongqing Fuling Jianghan Oilfield Company during the drilling process of oil and gas field exploration and production are used as raw materials. The oil-based drilling cuttings and ash contain the following elements: C 23.35%, H 2.85%, N 0.05% , S3.84%, calorific value 10.2MJ / kg.

[0029] 75 parts of starch, 10 parts of carboxymethyl cellulose, 2 parts of potassium permanganate, 9 parts of NaOH, and 4 parts of sodium tetraborate were mechanically mixed to obtain a composite binder; 65 parts of oil-based drill cuttings ash, 20 parts The composite binder, 5 parts of magnesium acetate, and 10 parts of water are mechanically mixed, and then sent to a piston stamping molding machine to be compressed into a cylindrical hollow molding fuel with a diameter of 20 mm and a length of 50 mm under normal temperature.

[0030] After the molded fuel was dried, the shear force was measured to be 41.3N by electr...

Embodiment 3

[0032] The oil-based drilling cuttings and ash produced by a drilling platform of Chongqing Fuling Jianghan Oilfield Company in the drilling process of oil and gas field exploration and exploitation are used as raw materials. The oil-based drilling cuttings and ash contain the following elements: C 22.78%, H 2.98%, N 0.07% , S4.43%, calorific value 9.9MJ / kg.

[0033] 80 parts of starch, 5 parts of hydroxypropyl methylcellulose, 1 part of potassium permanganate, 9 parts of NaOH, and 5 parts of sodium tetraborate were mechanically mixed to obtain a composite binder; 45 parts of oil-based drilling cuttings ash, 30 parts of composite binder, 5 parts of magnesium acetate, and 20 parts of water are mechanically mixed, and then sent to a piston stamping molding machine to be compressed into a cylindrical hollow molding fuel with a diameter of 20 mm and a length of 50 mm under normal temperature.

[0034] After the molded fuel is dried, the shear force of the fly ash is 46.3N measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com