Gauge for detecting protruding volume of cylinder cover oil injector hole

A technology of injector holes and protrusions, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of time-consuming, cumbersome detection efficiency, and unsuitable batch detection, etc., and achieve the prevention of processing deviation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing

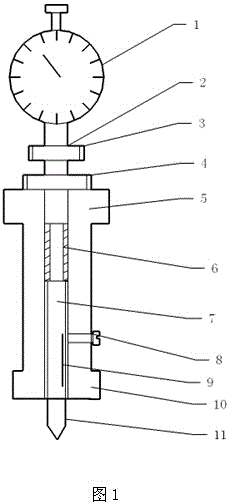

[0015] like figure 1 As shown, the dial indicator 1 is installed on the inspection body, and the nut is tightened on the inspection body 3, and the compression contact of the dial indicator contacts with the upper groove of the convex plunger shaft 7 inside the inspection body. During the inspection, the inspection body Installed in the hole of the injector is a compression inspection specific thimble to read the reading of the dial indicator.

[0016] The upper part of the inspection body fixes the dial indicator by tightening the nut 3 and the dial indicator locking seat 2; There is a "U" groove 9 on the plug shaft to the thimble, and by tightening the screw 8, the size of the positioning shaft 10 of the injector hole at the lower part of the plunger sleeve 5 of the inspection body, the size of the thimble 11 and the size of the cylinder head injector are designed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com