Internal combustion engine having fuel mixing means installed in intake port

A technology for mixing components and internal combustion engines, which is applied to internal combustion piston engines, building components, combustion engines, etc., and can solve problems such as inability to mix fuel and air, and disappearance of eddy or turbulent flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

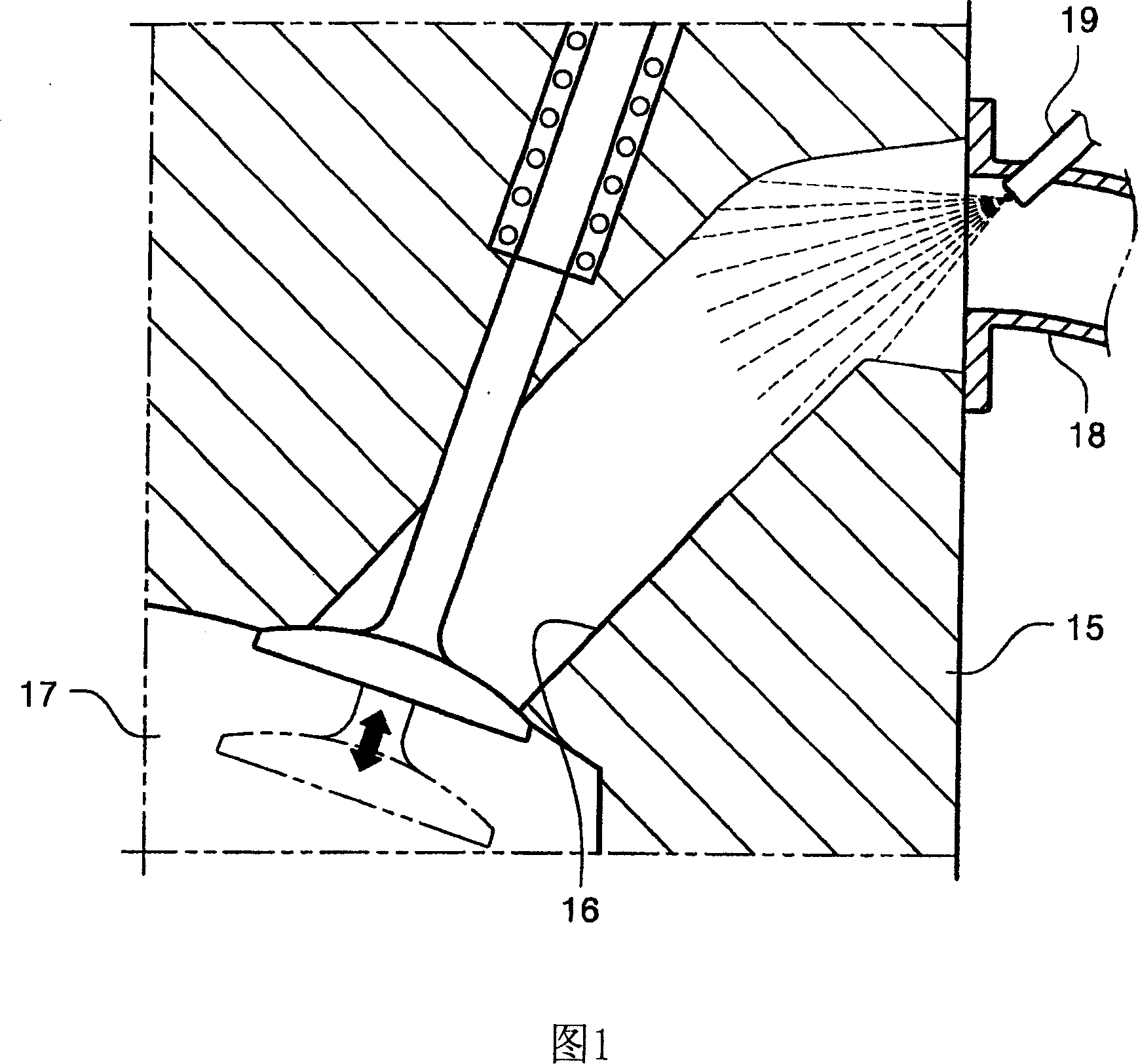

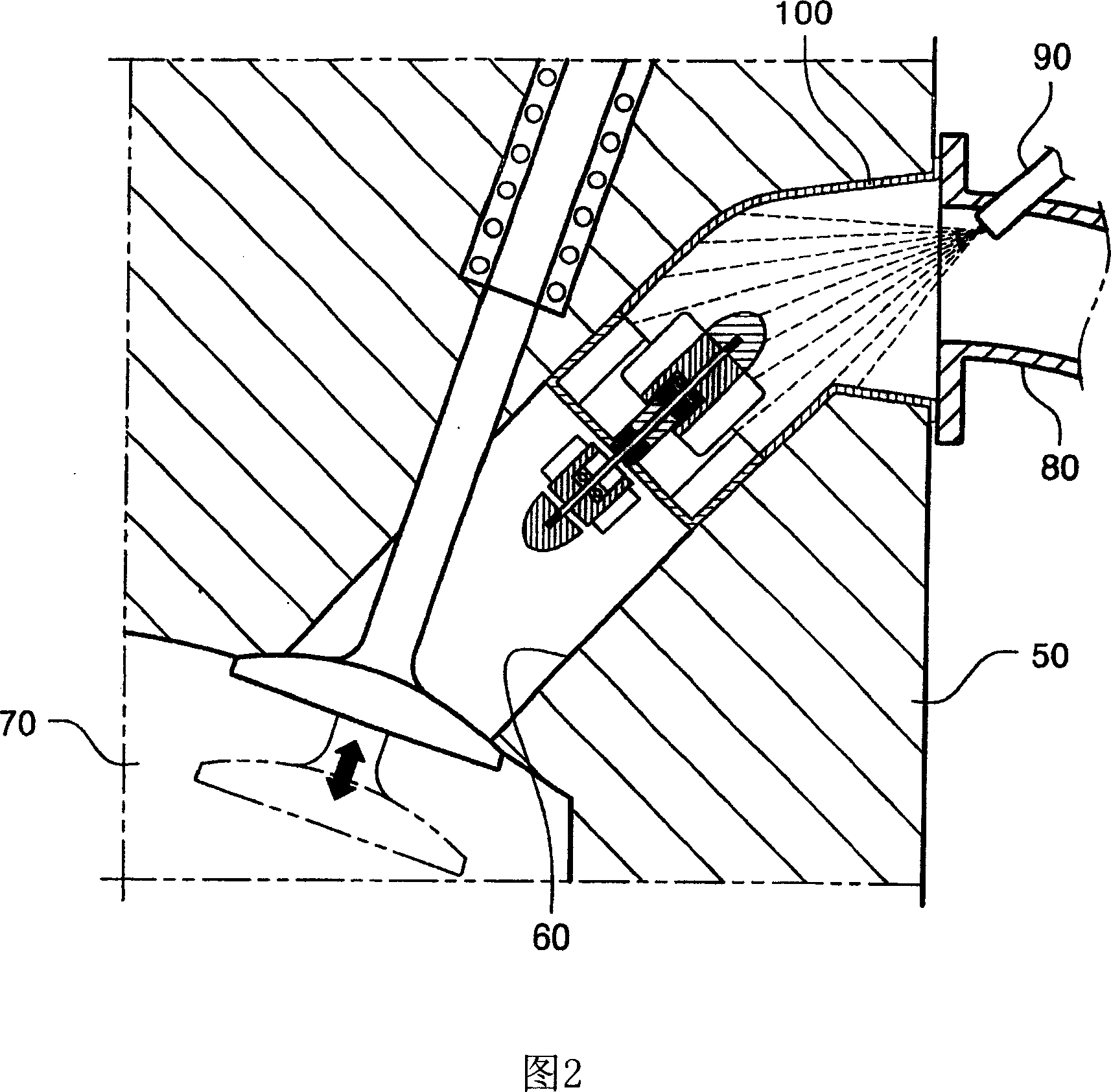

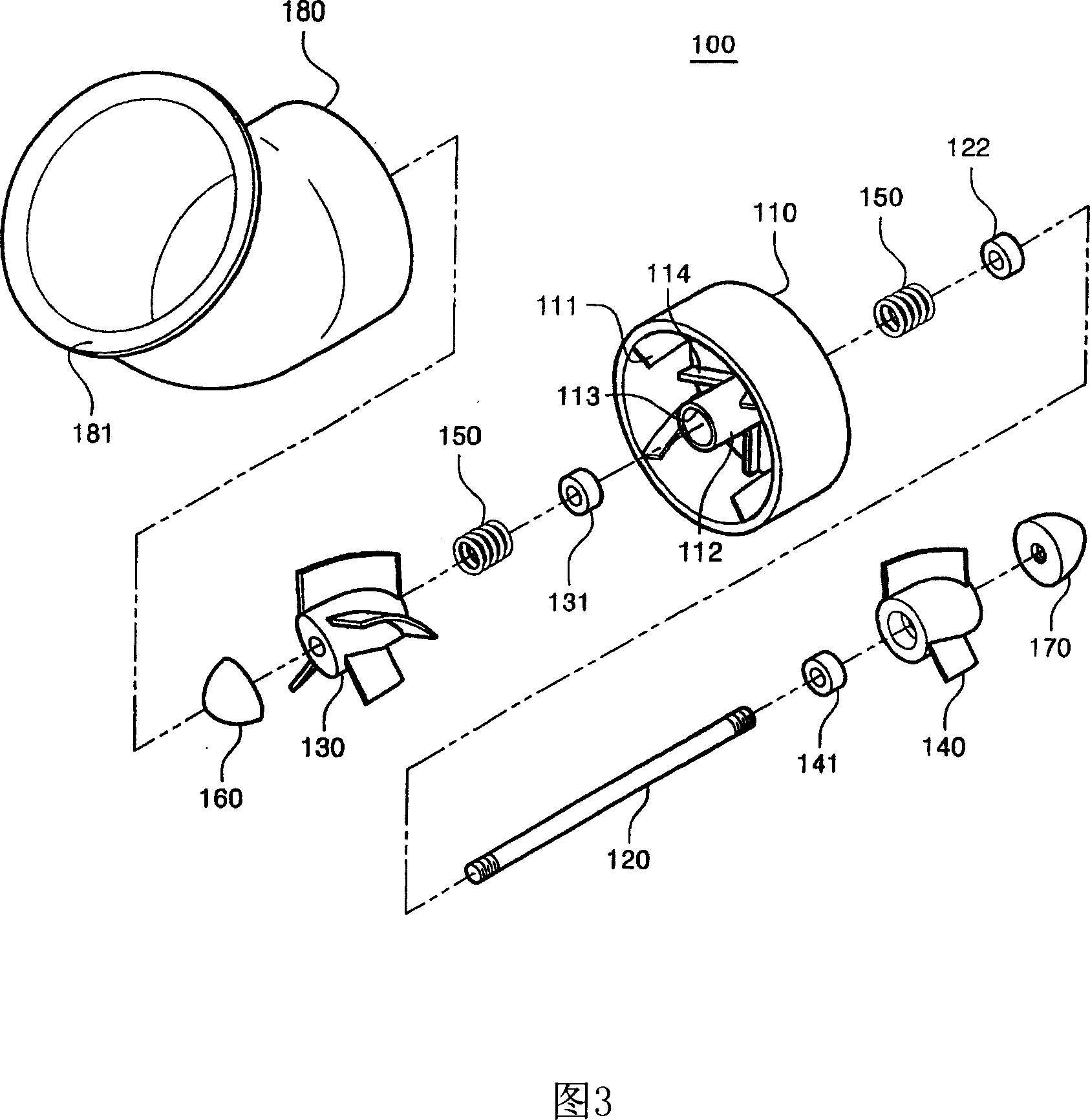

[0031] 2 is a sectional view of an intake port of an internal combustion engine according to a first embodiment of the present invention, FIG. 3 is an exploded perspective view of a fuel mixing member of the embodiment shown in FIG. 2 , and FIG. 4 shows the embodiment shown in FIG. 2 The perspective view of the assembled state of the fuel mixing member, and Fig. 5 is a cross-sectional view taken along line A-A of Fig. 4 .

[0032] The internal combustion engine of the present embodiment includes a fuel mixing member 100 fixedly inserted into an intake port 60 formed in the cylinder head 50 and serving as a passage for supplying a mixture of fuel and air into the combustion chamber 70 .

[0033] The fuel mixing member 100 includes a hollow cylindrical support ring 110 which is inserted into the intake passage 60 . Since the conventional cylinder head is made by casting, it is difficult to cut the intake port or change the shape of the intake port.

[0034] In consideration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com