Automatic choke apparatus for engine

a choke apparatus and automatic technology, applied in the direction of mechanical equipment, engines, machines/engines, etc., can solve the problems of inability to mount the bimetal at a high-temperature portion of the muffler, the limitation of the mounting condition of the bimetal in the vicinity of the muffler, and the difficulty of opening the choke valve, so as to prevent the incomplete combustion of the engine caused by excessive fuel and suppress the temperature drop of the exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

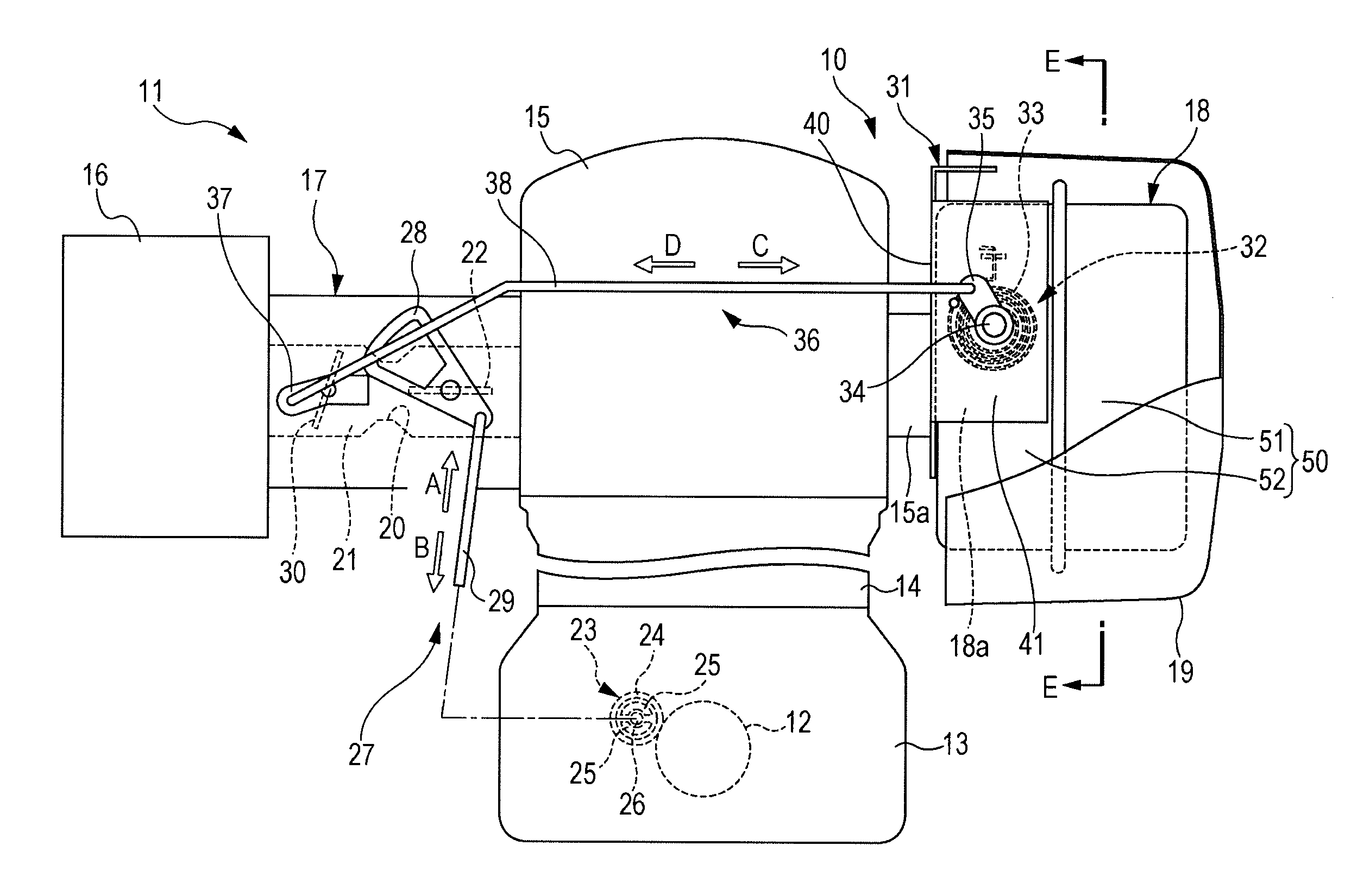

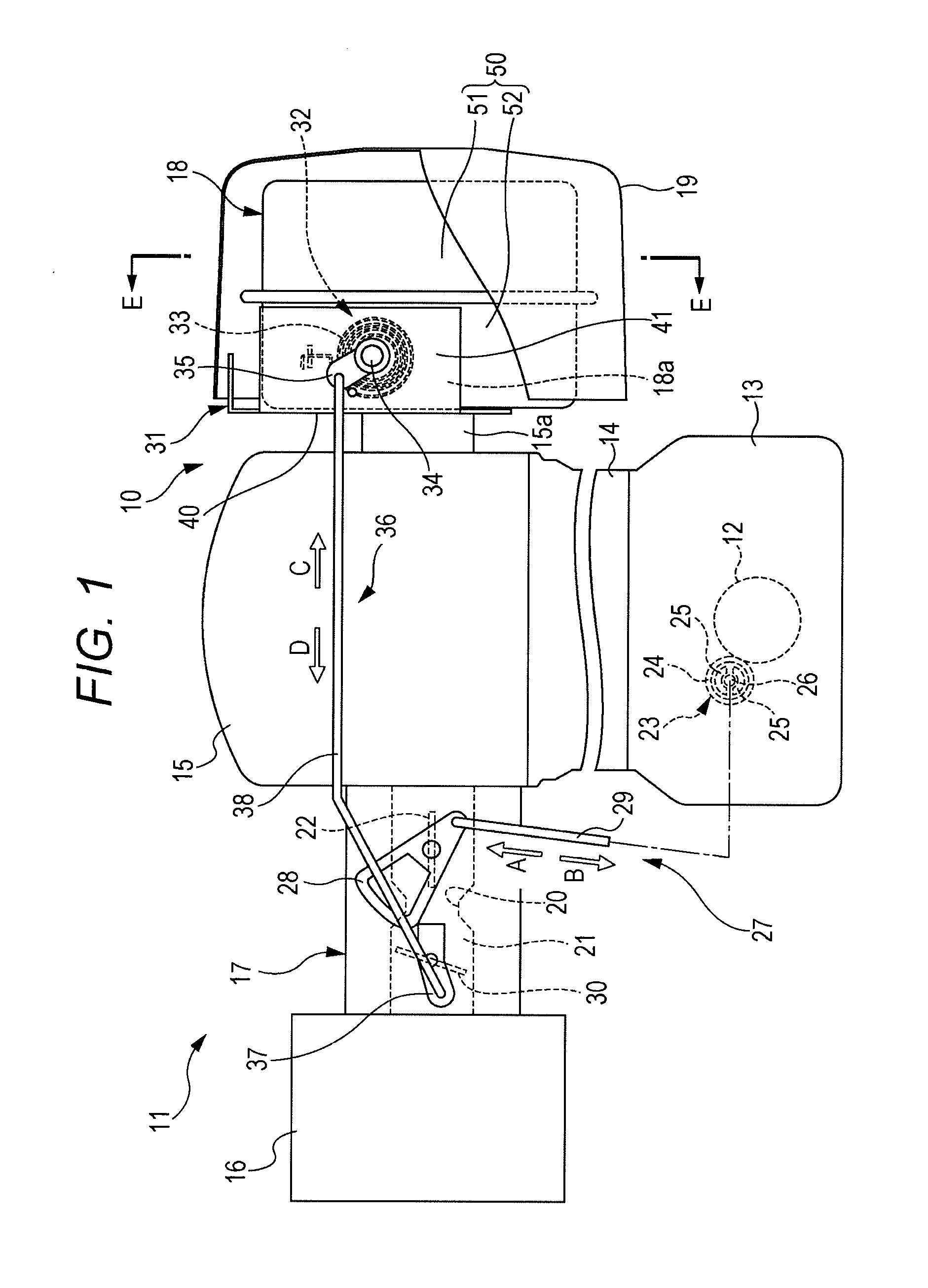

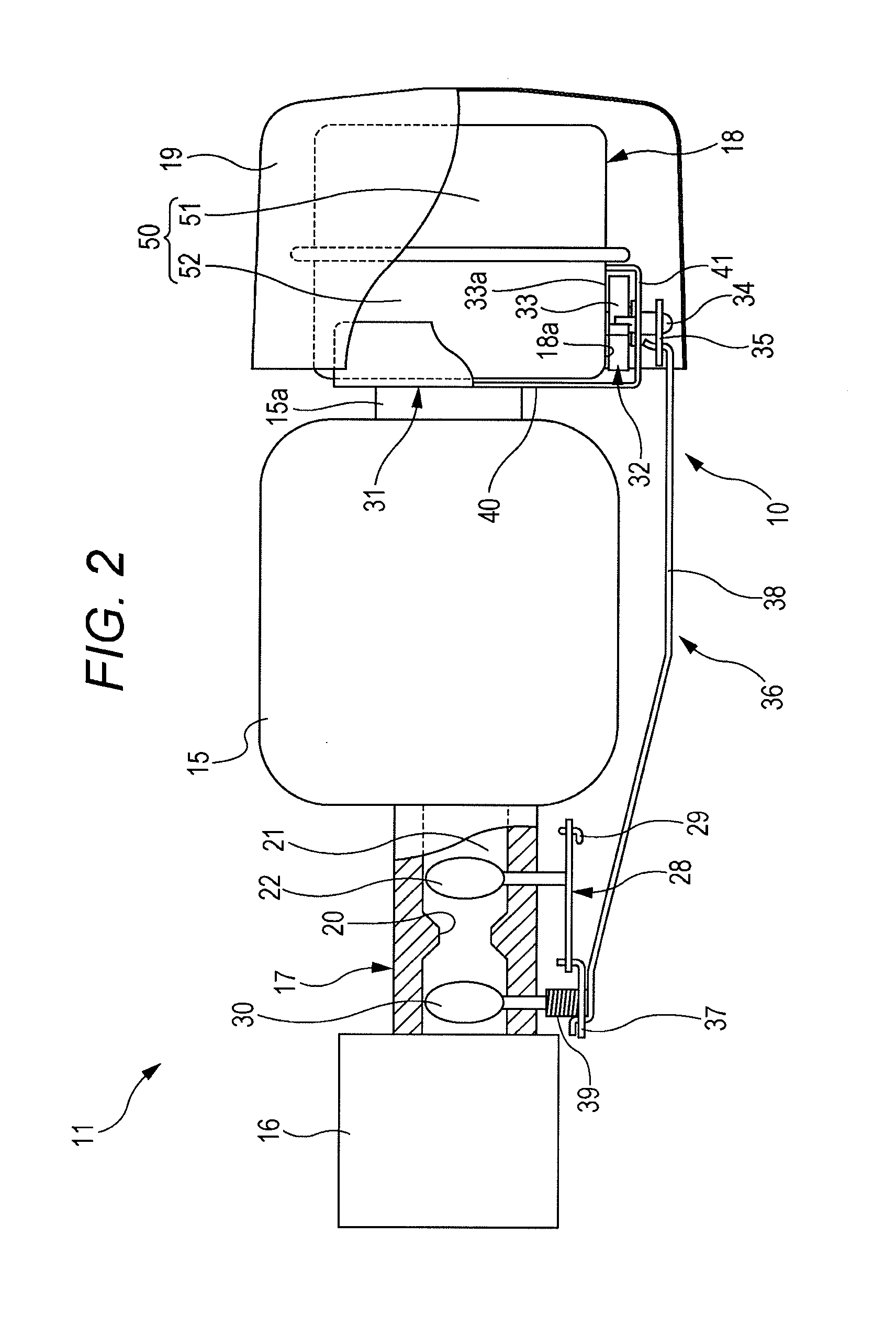

[0026]Embodiments of the present invention will be explained in detail below with reference to the drawings. FIG. 1 is a side view schematically illustrating an engine 11 provided with an automatic choke apparatus 10 according to one embodiment of the present invention. FIG. 2 is a plan view schematically illustrating the engine 11 in FIG. 1 as viewed from top. As illustrated in FIGS. 1 and 2, the engine 11 includes a crankcase 13 that stores a crankshaft 12. A cylinder 14 is attached at an upper end of the crankcase 13, and a cylinder head 15 is mounted to an upper end of the cylinder 14. An air cleaner 16 and a carburetor 17, which constitute an intake system, are connected to an unillustrated intake port of the cylinder head 15. Further, a muffler 18 constituting an exhaust system is connected to an unillustrated exhaust port of the cylinder head 15. A muffler cover 19 is attached to the muffler 18.

[0027]An intake channel 21 provided with a venturi portion 20 is formed on the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com