Turboprop recirculation combustion chamber and turboprop

A backflow combustion chamber and engine technology, applied in the direction of combustion chambers, continuous combustion chambers, machines/engines, etc., can solve the problems of large engine vibration and low concentricity, and achieve improved bearing performance, assembly accuracy and concentricity, The effect of realizing the installation requirements of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

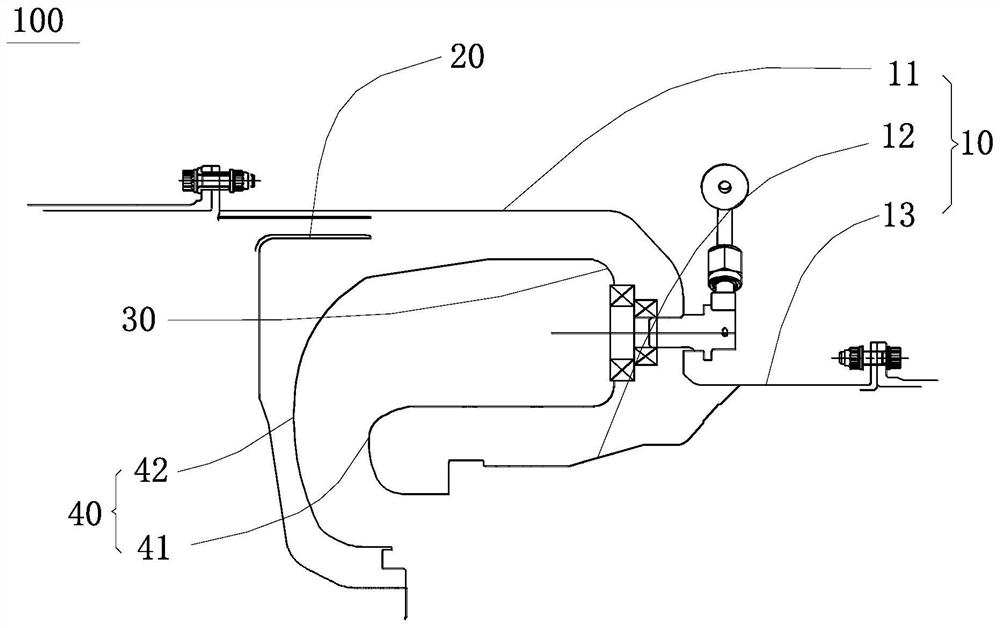

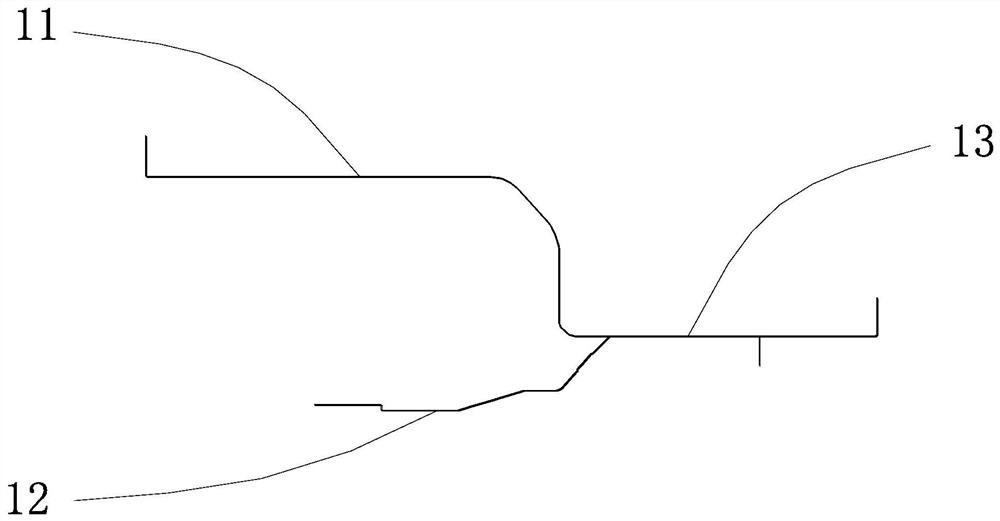

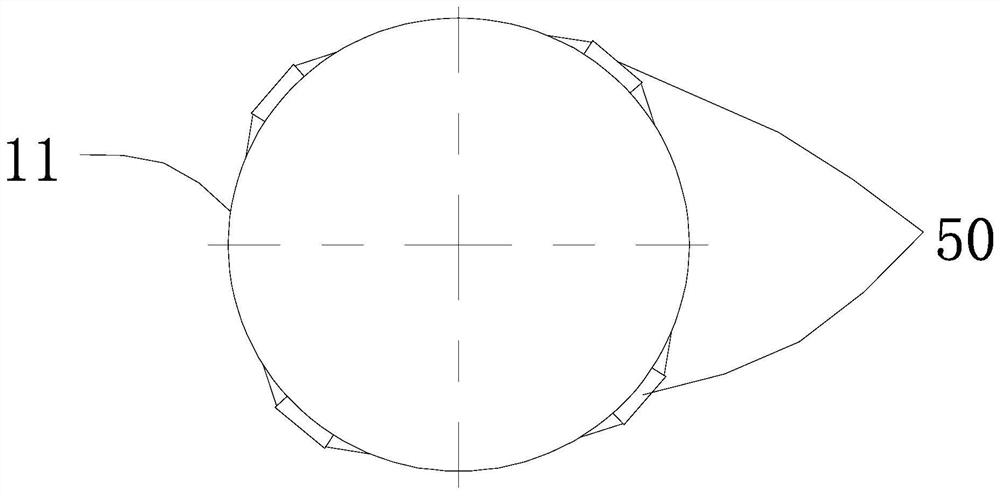

[0035] like figure 1 , figure 2 as well as image 3 As shown, the turboprop engine return combustion chamber 100 of this embodiment includes a combustion chamber casing 10, a diffuser 20, a flame tube 30, an exhaust elbow 40 and a mounting assembly 50. The combustion chamber casing 10 includes interconnected The combustion outdoor casing section 11, the gas turbine casing section 12 and the power turbine casing section 13, the flame tube 30 is accommodated in the cavity formed by the combustion outdoor casing section 11 and the gas turbine casing section 12, and the diffuser 20 is provided with It is upstream of the return combustion chamber and is used to provide high-pressure air for the flame tube 30. The exhaust elbow 40 is located at the airflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com