Compound burner

A burner and composite technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of high energy consumption, insufficient combustion of gas, etc., and achieve the effect of improving combustion performance and optimizing the combustion environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

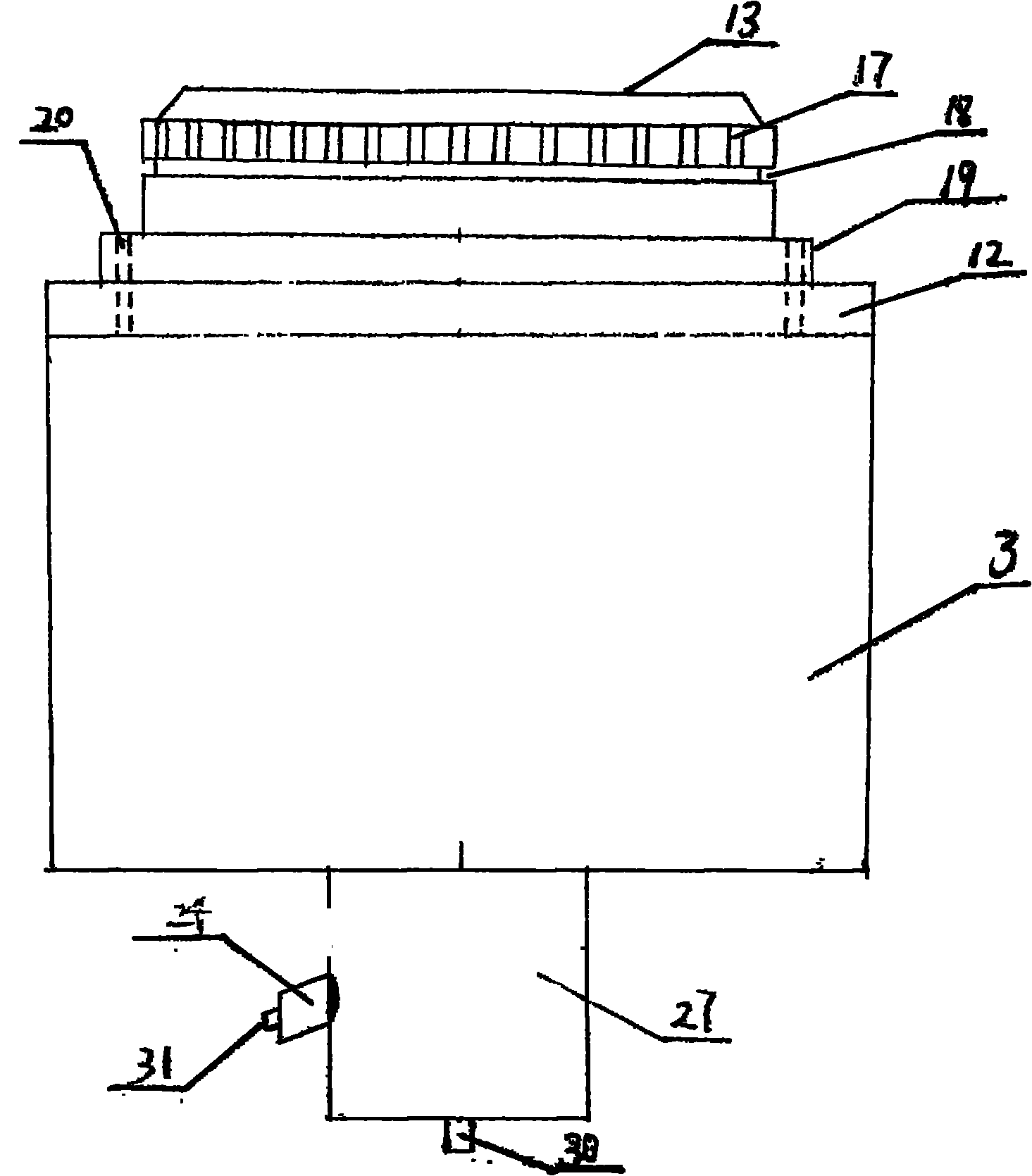

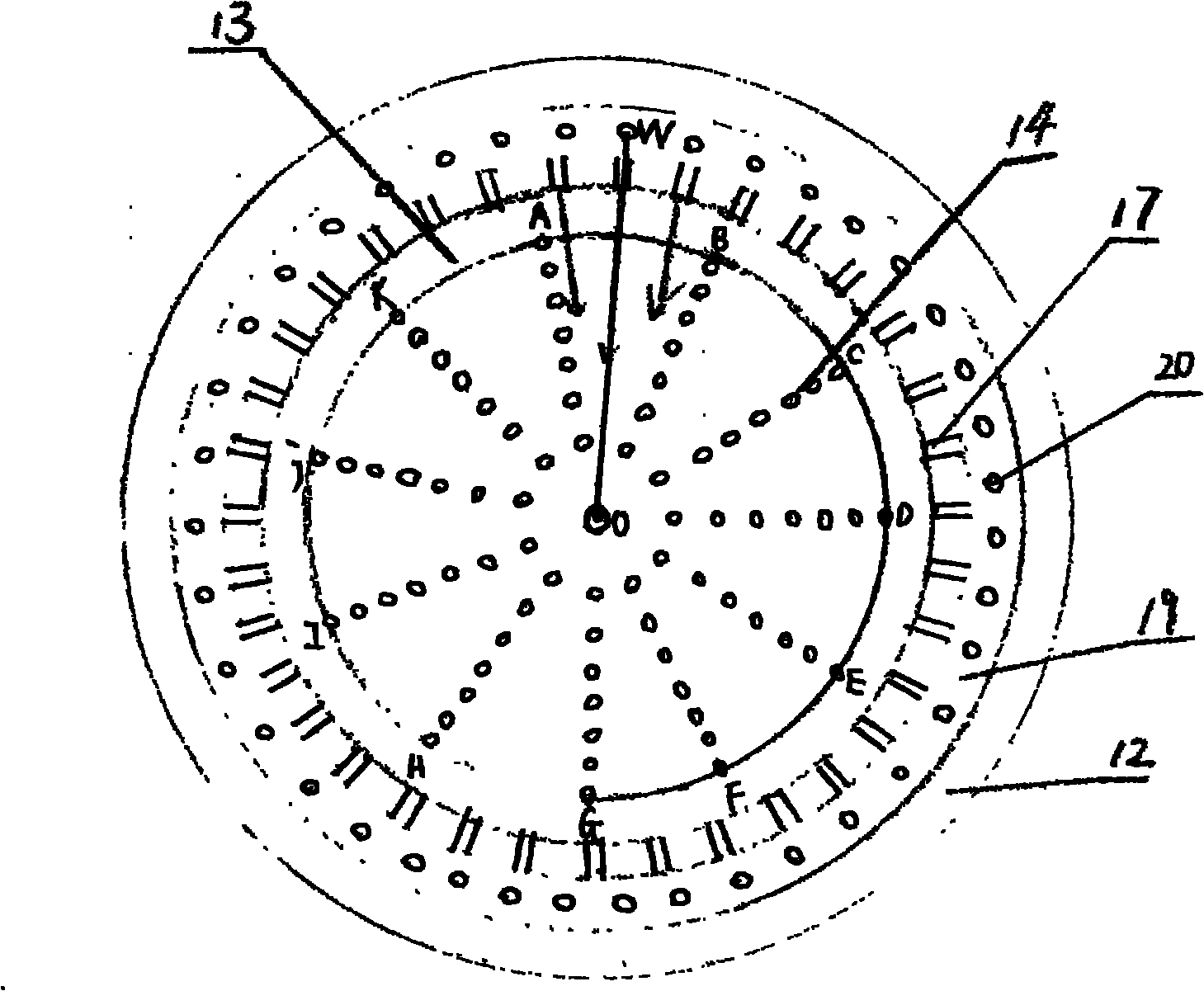

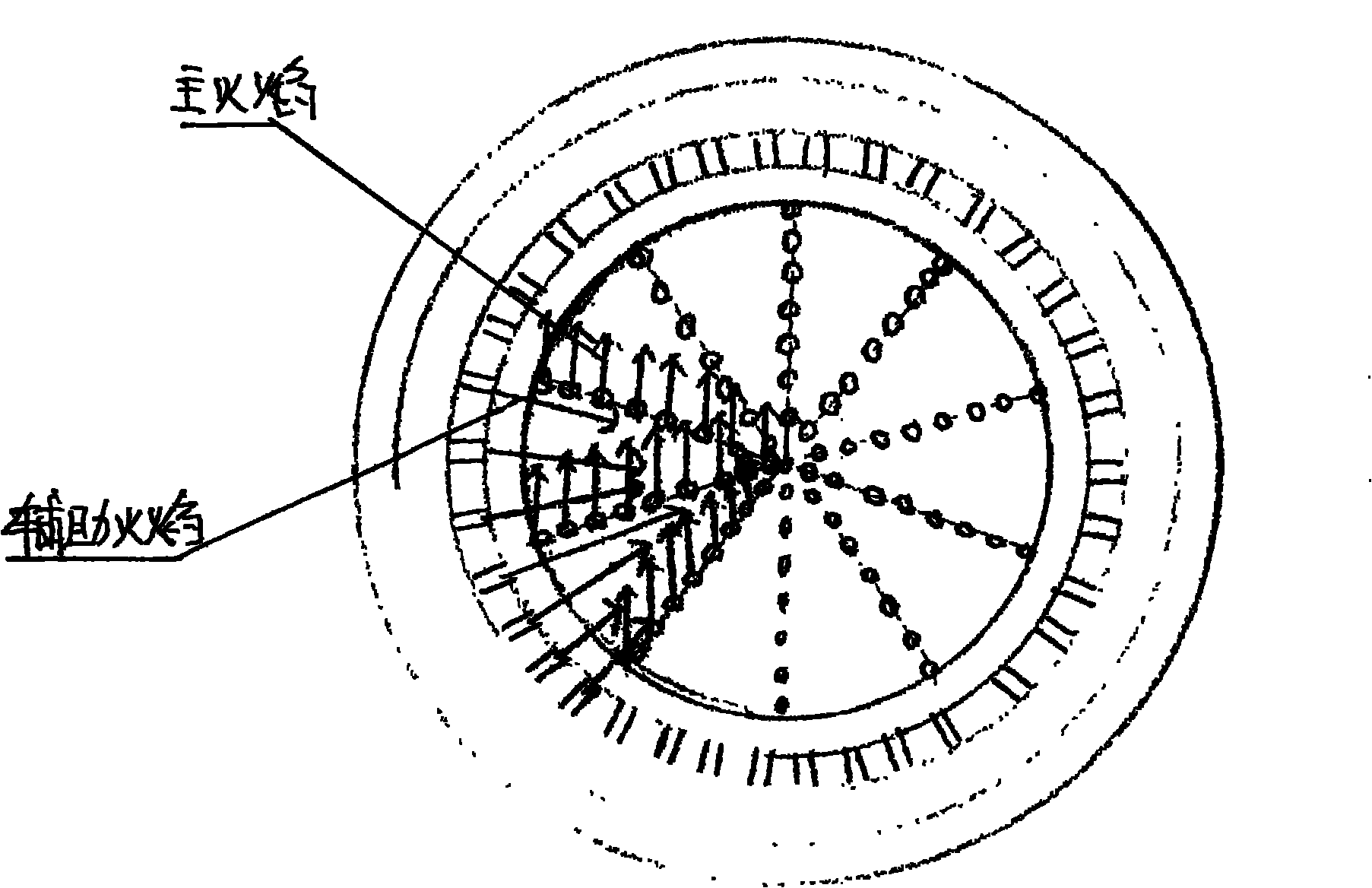

[0015] see figure 1 , figure 2 , image 3 As shown: the patent of the present invention is composed of an inner core 1, an upper cover 2, and a base 3, the inner core 1 is placed on the base 3, the upper end of the base 3 is provided with a protruding ring 11, and the lower end of the inner core 1 is also provided with a protruding ring 12 , the outer diameter of the protrusion 11 at the upper end of the base 3 matches the inner diameter of the collar 12 at the lower end of the inner core 1, so as to ensure that the inner core 1 can be placed firmly on the base 3, and several main combustion chambers are transparently provided on the upper end cover 13 of the inner core 1 The injection hole 14, the inner core 1 is hollow, the hollow part is the upper main gas chamber 15, the lower end of the inner core 1 is the lower main gas chamber 16, and a main gas premixing chamber is arranged between the upper main gas chamber 15 and the lower main gas chamber 16 Partition 28, the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com