Coal loosening device for traveling grate stoker

A technology for chain grate and coal loosening, which is applied in the direction of grate, lighting and heating equipment, etc., can solve the problems of insufficient combustion, affecting fuel burnout, loose ash bonding, etc., and achieves simple structure, sufficient combustion, continuous stability and so on. burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

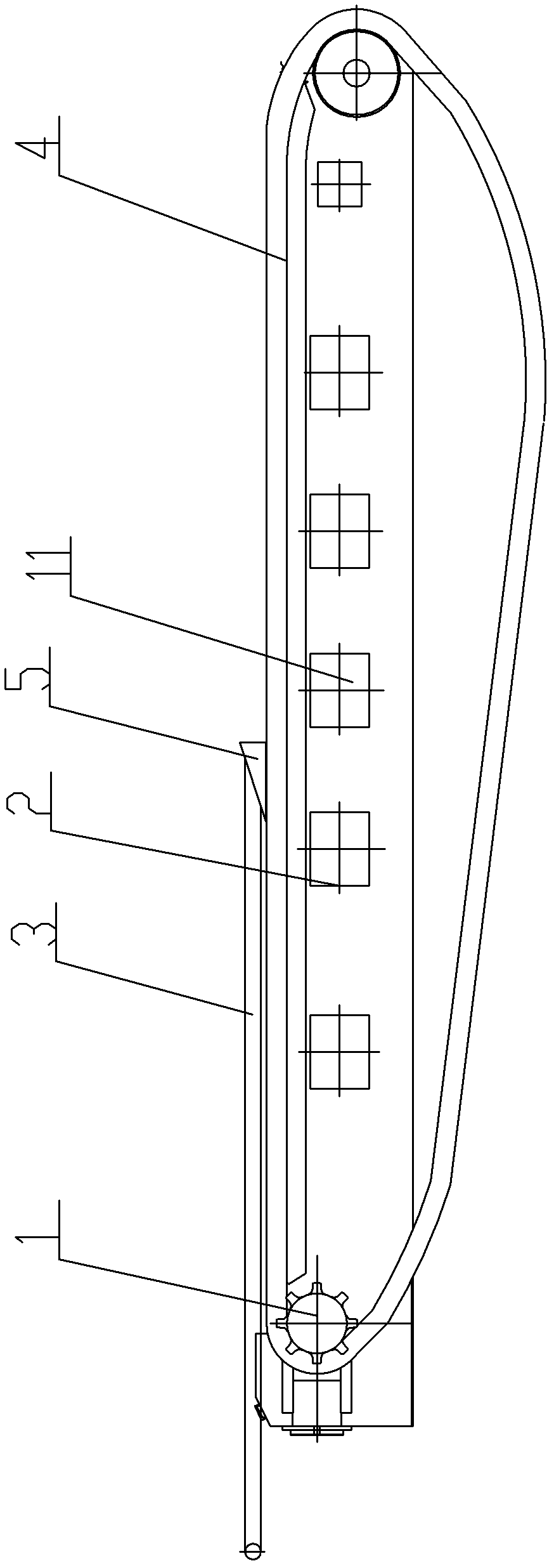

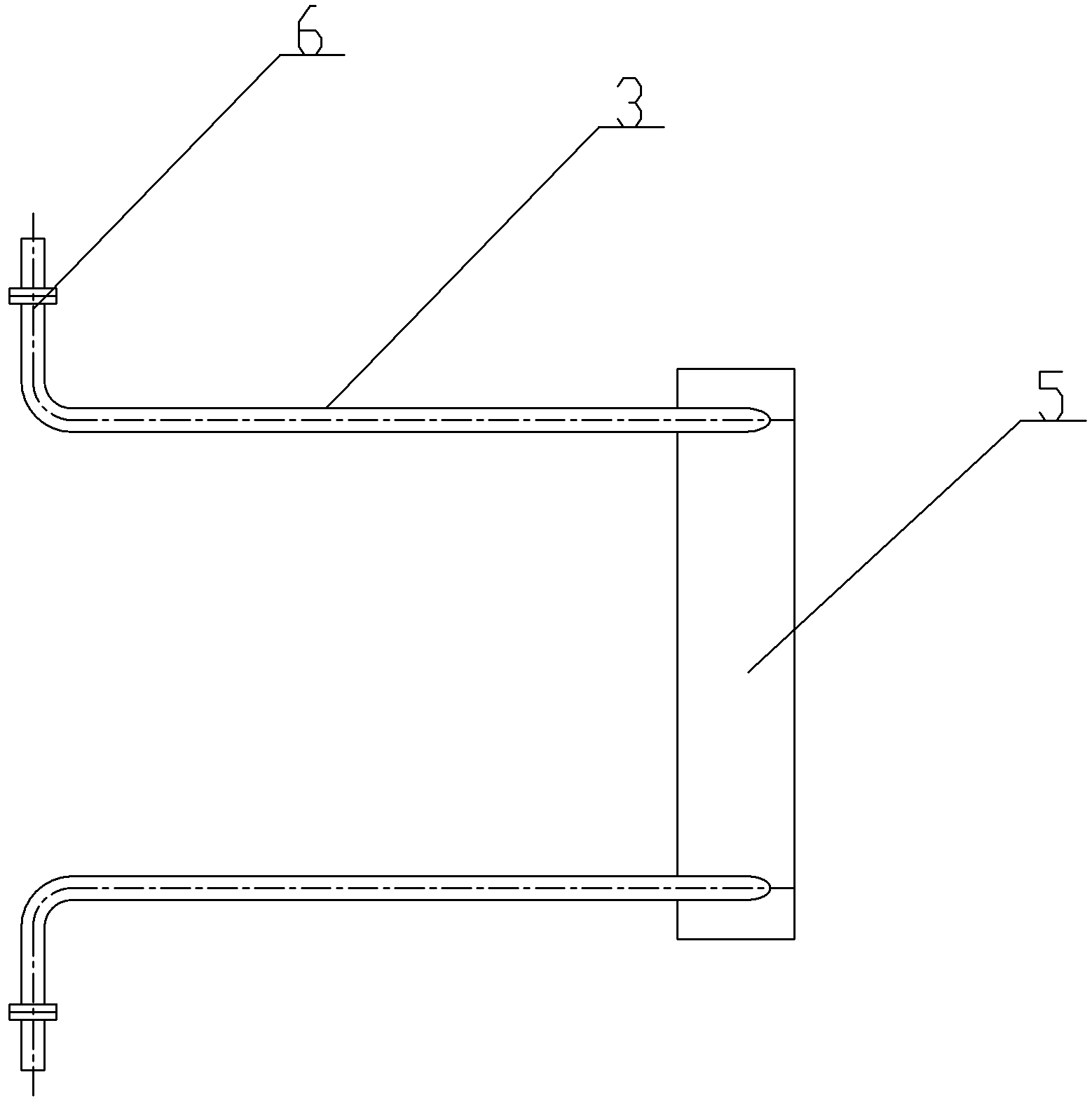

[0015] like Figure 1~2 As shown, the present invention mainly comprises coal loosening support 5 and cooling water pipe 3, and described coal loosening support 5 is placed on the grate surface 4, and installation position is positioned between the 3rd air supply chamber 11 and the 4th air supply chamber 2; The loose coal support 5 is connected with the cooling water pipe 3, and the pipe body of the cooling water pipe 3 is fixed on the coal hopper of the chain grate or the front windshield door by the Ω type clamp 6. Described cooling water pipe 3 leaves a section of length on grate surface 4, makes loose coal support 4 not blocked by coal block.

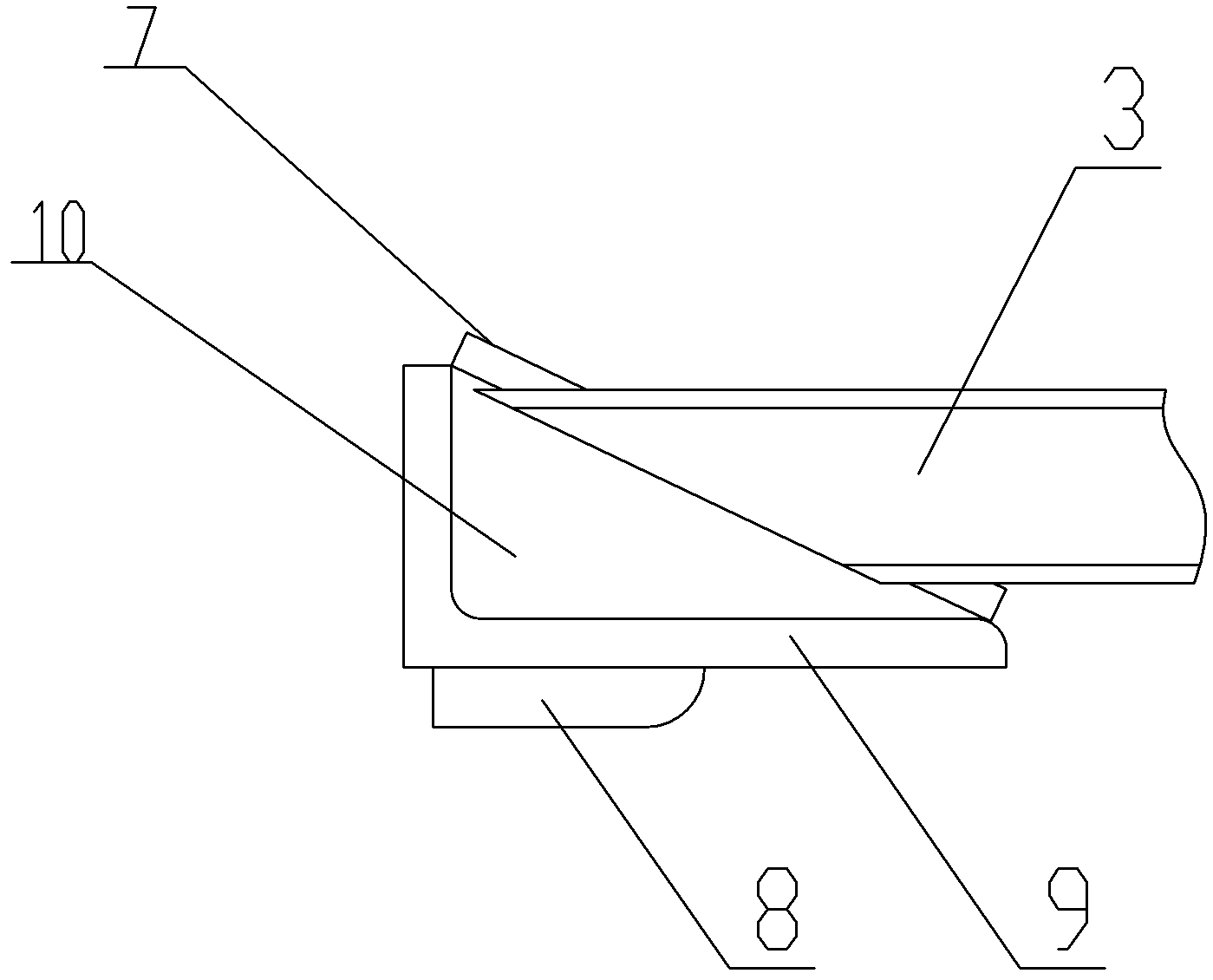

[0016] like image 3 As shown, the loose coal support 5 includes an upper coal plate 7, a backing plate 8, a support frame 9 and a side sealing plate 10, the support frame 9 is an L-shaped plate, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com