Efficient and energy-saving environment-friendly high-pressure burner

An energy saving, environmental protection, burner technology, applied in burners, gas fuel burners, combustion methods, etc., to save energy, improve combustion efficiency, and ensure safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

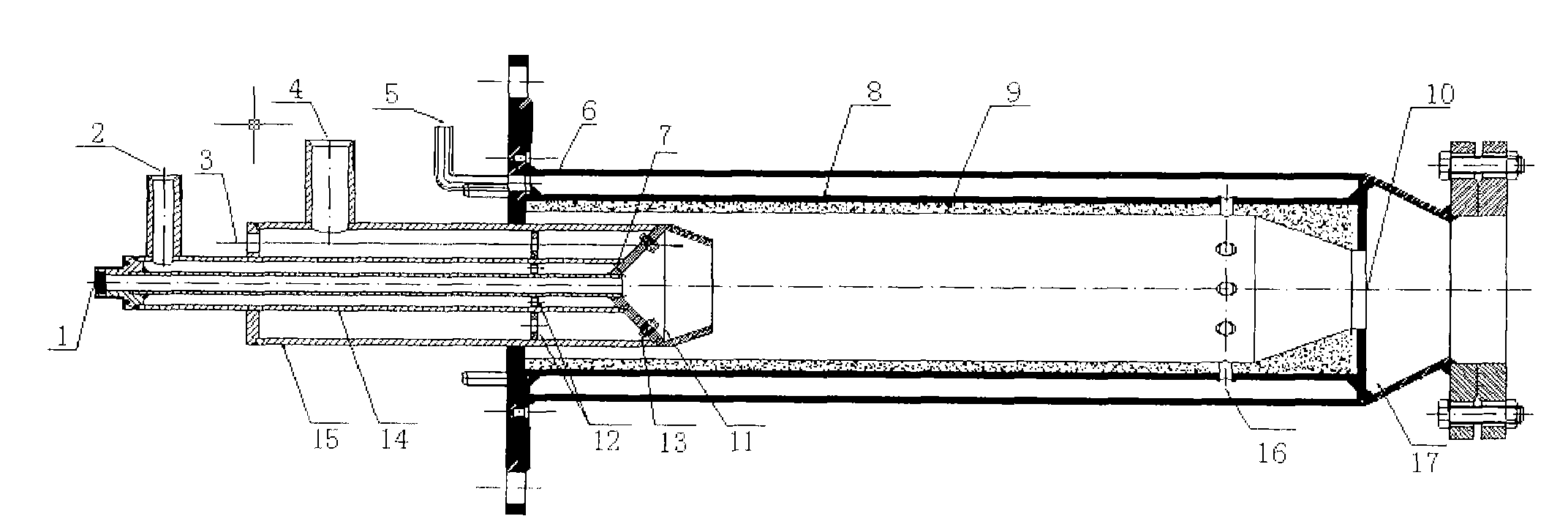

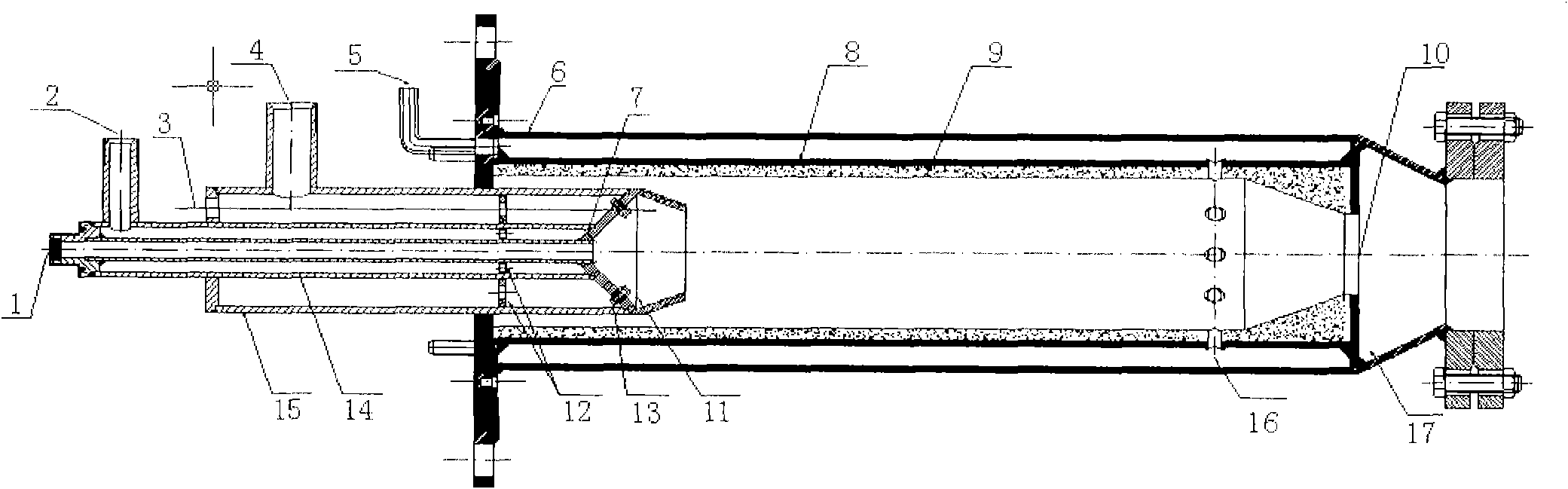

[0015] Such as figure 1 As shown, the burner in this embodiment includes a combustion chamber surrounded by the outer wall of the combustion chamber, and a refractory material 9 is poured on the inner wall of the combustion chamber. The end of the combustion chamber is provided with a smoke exhaust hole 10, and the outside of the smoke exhaust hole 10 is an expansion chamber 17. A conical nozzle is provided at the front end of the combustion chamber, and a gas injection inlet, a primary air injection inlet, and a high-pressure igniter are arranged on the conical nozzle, and a tapered conical flame stabilizer 11 is arranged behind the nozzle. Stream jets are good for flame stabilization. The axis of the combustion chamber coincides with the axis of the conical nozzle. The fuel gas pipe and the primary air distribution pipe coaxially arranged outside the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com