Industrial furnace comprehensive energy saving and emission reduction integrated system

An energy-saving emission reduction and integrated system technology, applied in the direction of indirect carbon dioxide emission reduction, furnaces, furnace components, etc., can solve problems such as increased power consumption of kiln tail fans, failure to meet emission standards, and unsuitability for industrial kilns, etc., to achieve increased Power consumption and operation and maintenance costs, scale reduction, and the effect of reducing equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

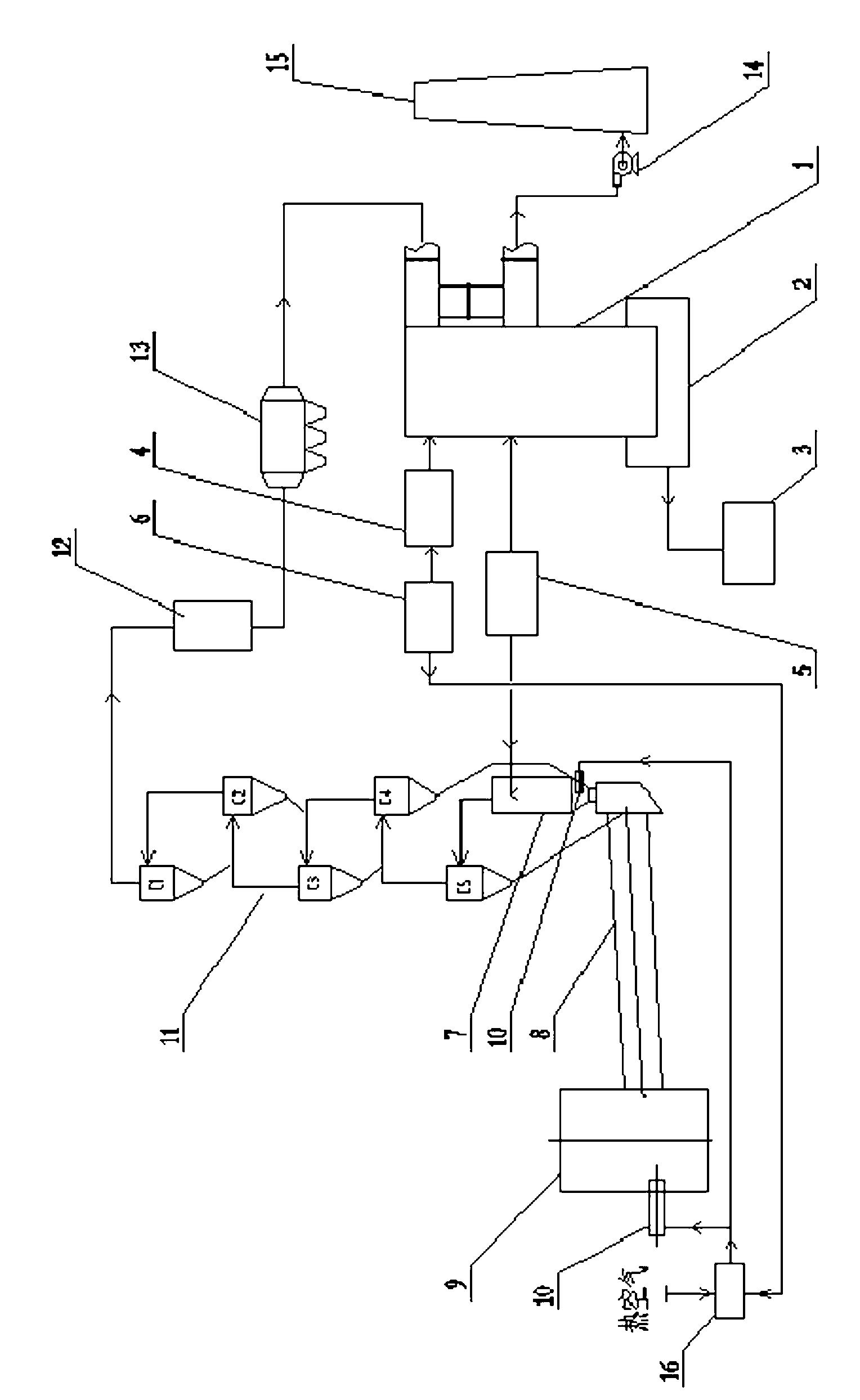

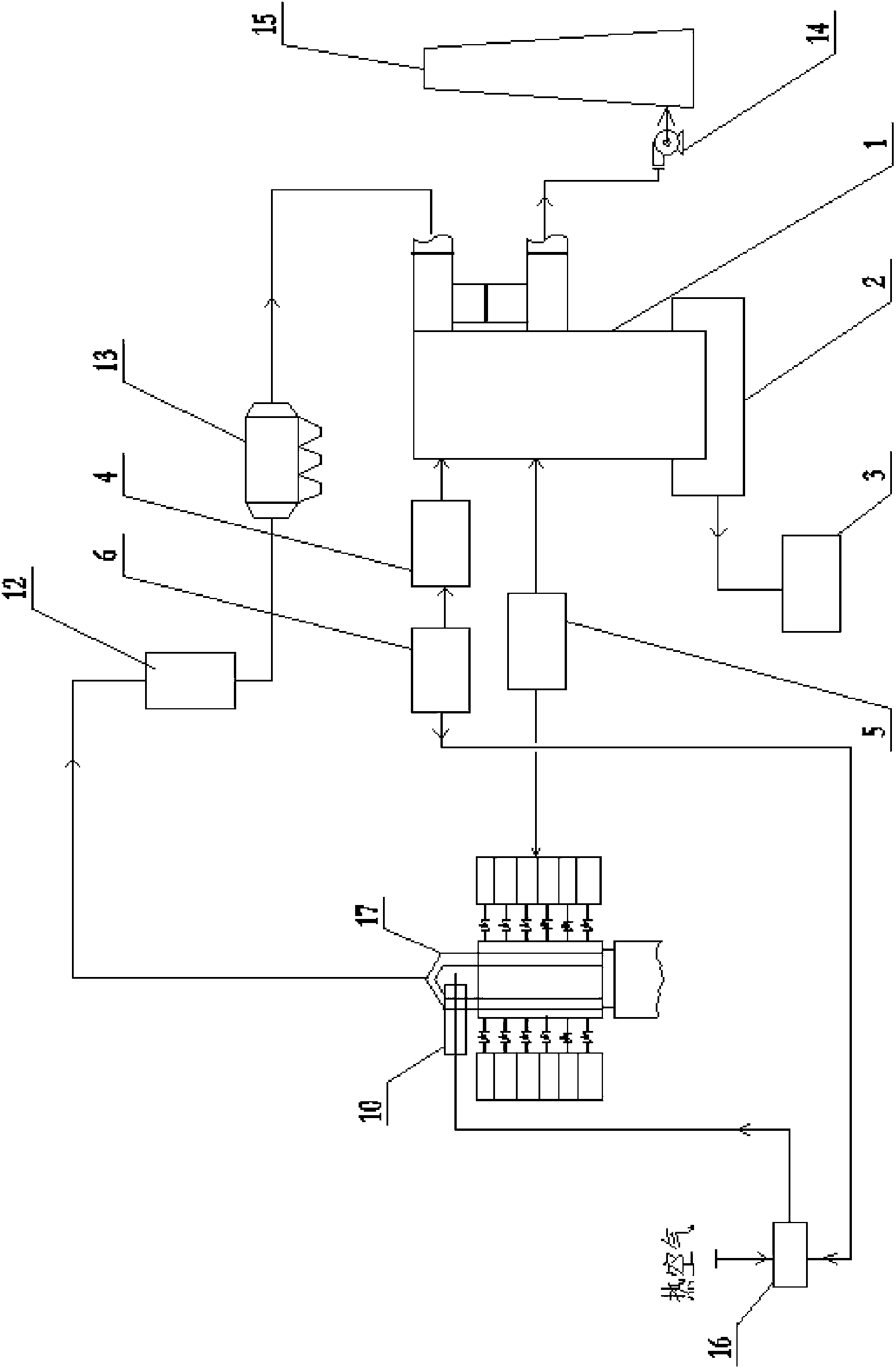

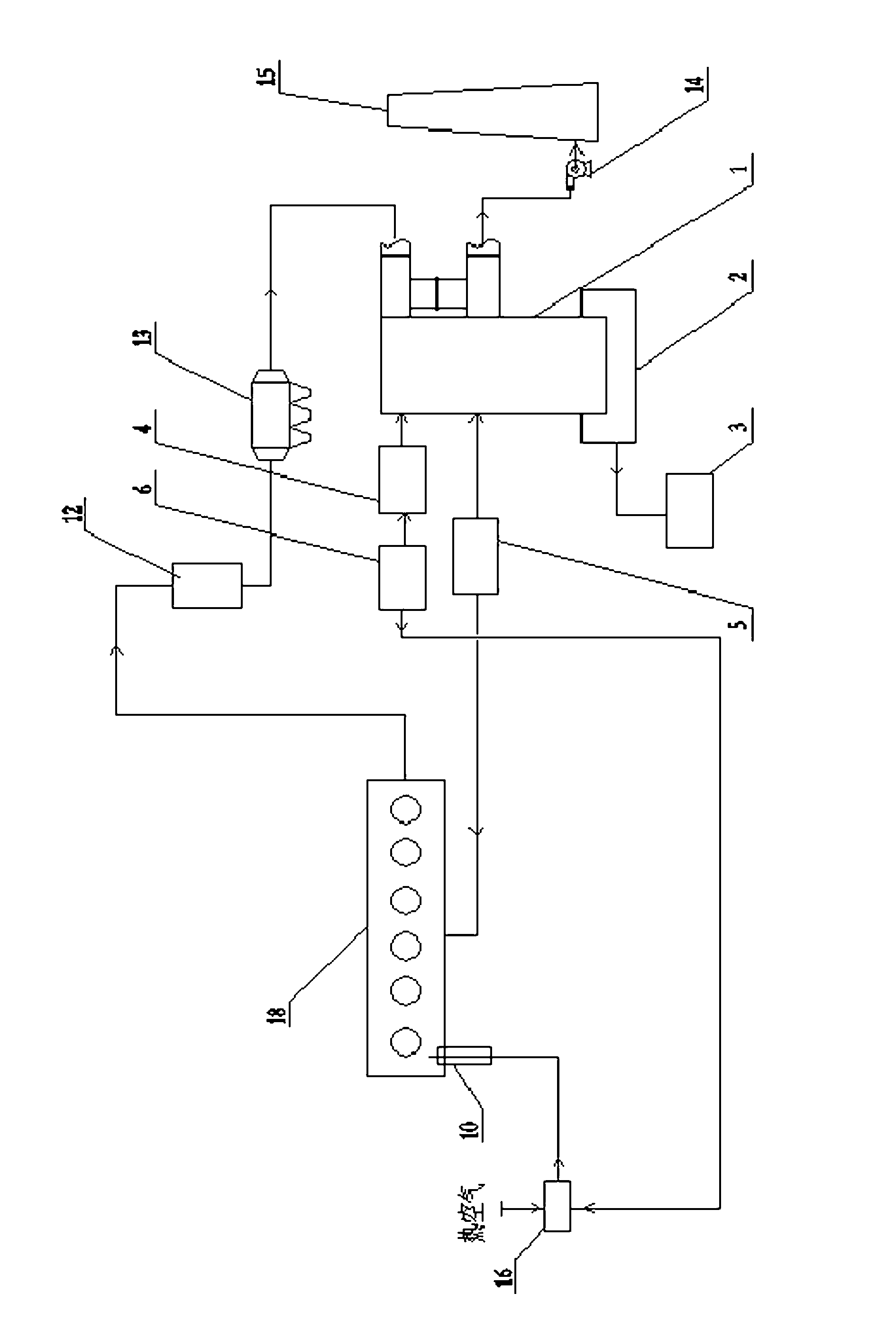

[0023] exist figure 1 In the schematic flow chart of the cement kiln comprehensive energy saving and emission reduction system shown, the cement kiln head is equipped with a burner at the front of the cement rotary kiln body, and the calciner is equipped with a burner at the kiln tail. The decomposition furnace is connected with the heat medium inlet of the cement raw meal preheater. The preheater is connected in series in multiple stages. The flue gas outlet of the last stage preheater is connected with the inlet of the dust collector. A waste heat boiler is set between the two. The outlet of the dust collector is connected to the inlet of the oxidation neutralization and denitration reaction tower, the outlet of the oxidation neutralization and denitration reaction tower is connected to the chimney, and an induced draft fan is arranged between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com