Ignition method for compound burner

A burner and composite technology, applied in the combustion method, the combination of multiple burners, burners, etc., can solve the problems of gas waste, slow combustion reaction speed, insufficient combustion, etc., to optimize the combustion environment, improve the Combustion performance, the effect of high-efficiency fully premixed combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the drawings and embodiments:

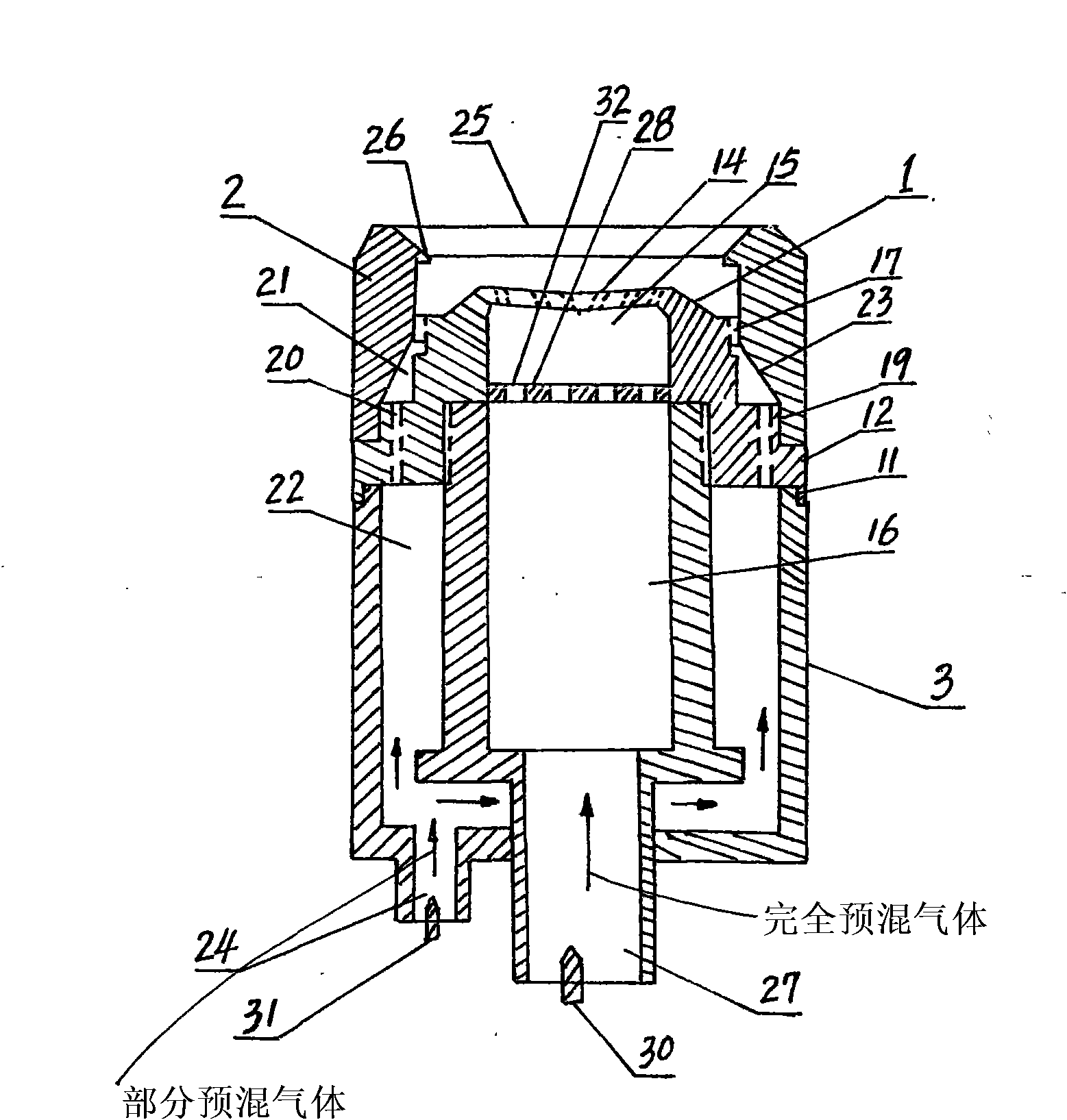

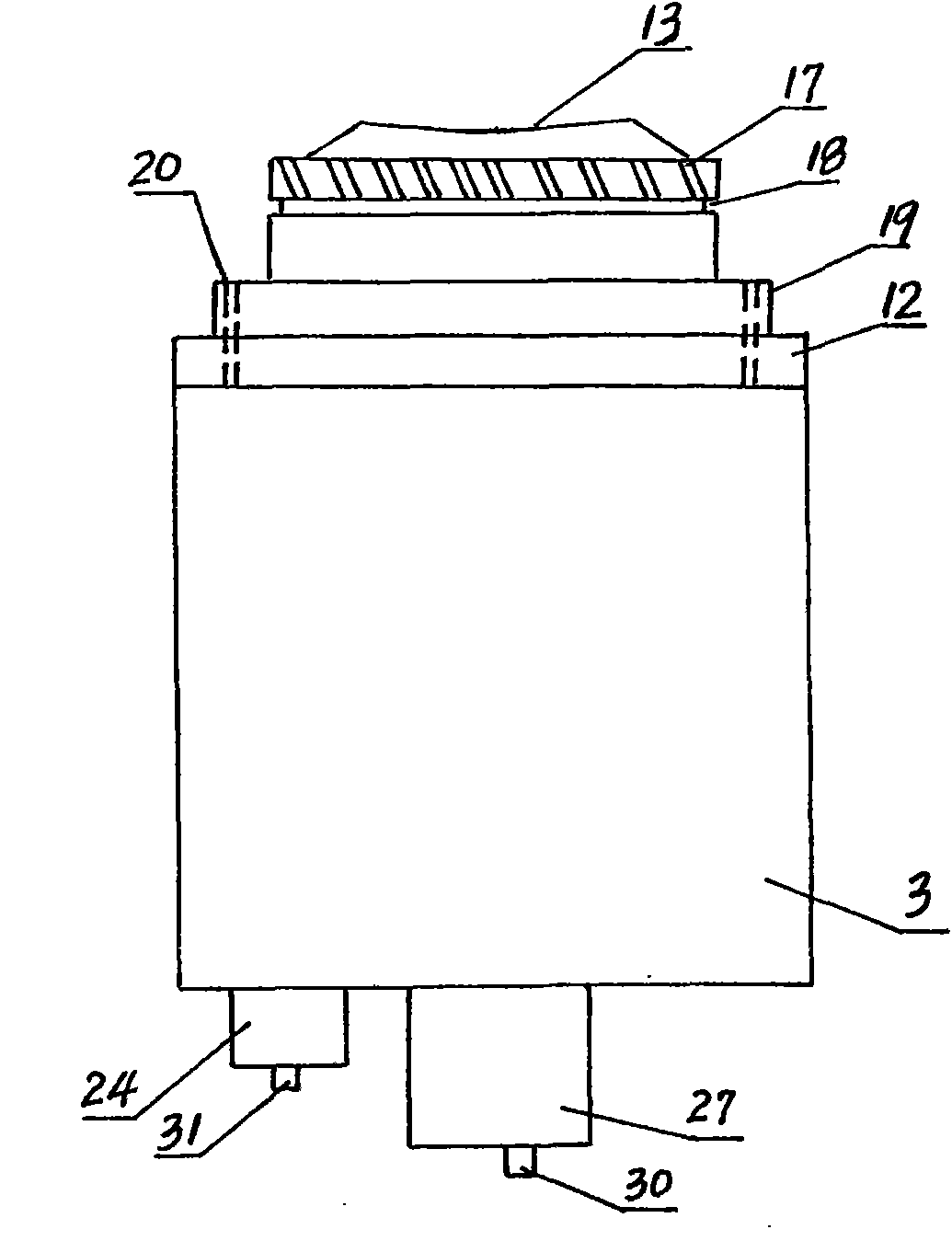

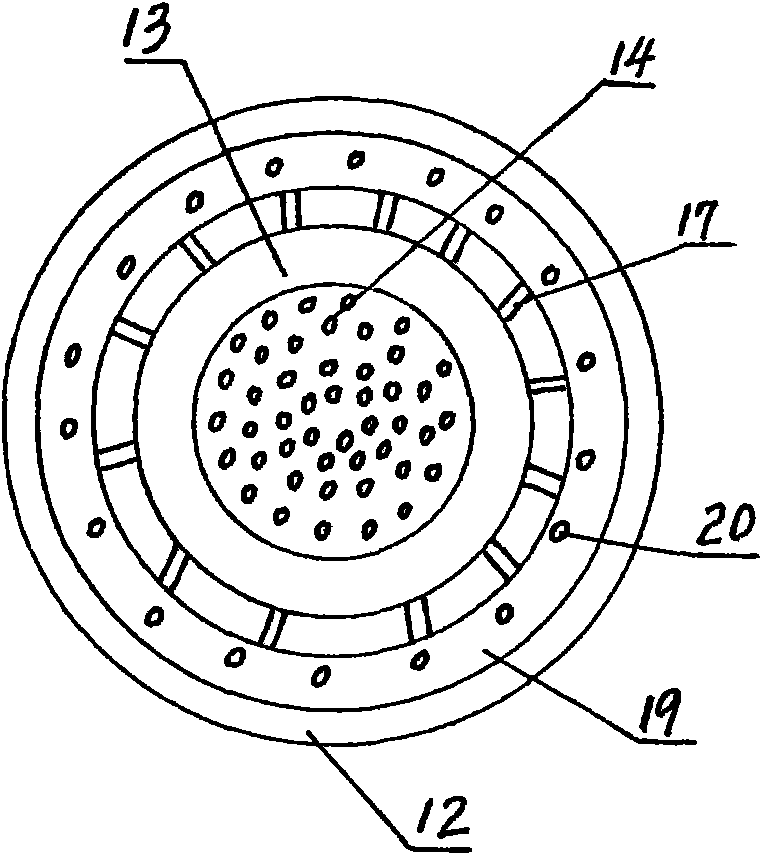

[0015] See figure 1 , figure 2 , image 3 Shown: The embodiment of the present invention is composed of an inner core 1, an upper cover 2, a base 3. The inner core 1 is placed on the base 3, the upper end of the base 3 is provided with a convex ring 11, and the lower end of the inner core 1 is also provided with a convex Ring 12, the outer diameter of the upper end convex ring 11 of the base 3 matches the inner diameter of the lower end convex ring 12 of the inner core 1 to ensure that the inner core 1 can be firmly placed on the base 3. The upper end 13 of the inner core 1 is transparently provided with several The main combustion nozzle hole 14 is arranged at a certain angle to the surrounding, the inner core 1 is hollow, the hollow part is the upper main gas chamber 15, the lower end of the inner core 1 is the lower main gas chamber 16, and the upper main gas chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com