Horizontal type single boiler barrel multipurpose fuel boiler

A single drum and drum technology, applied in the field of boilers, can solve the problems of small combustion chamber space, insufficient volume, inability to maintain, etc., and achieve the effects of good overall structure, convenient production and manufacturing, and improved combustion environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

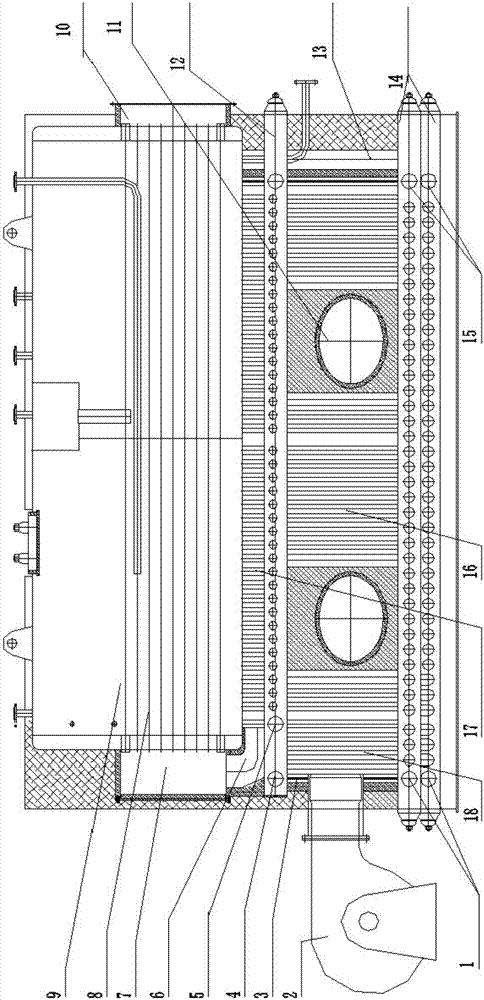

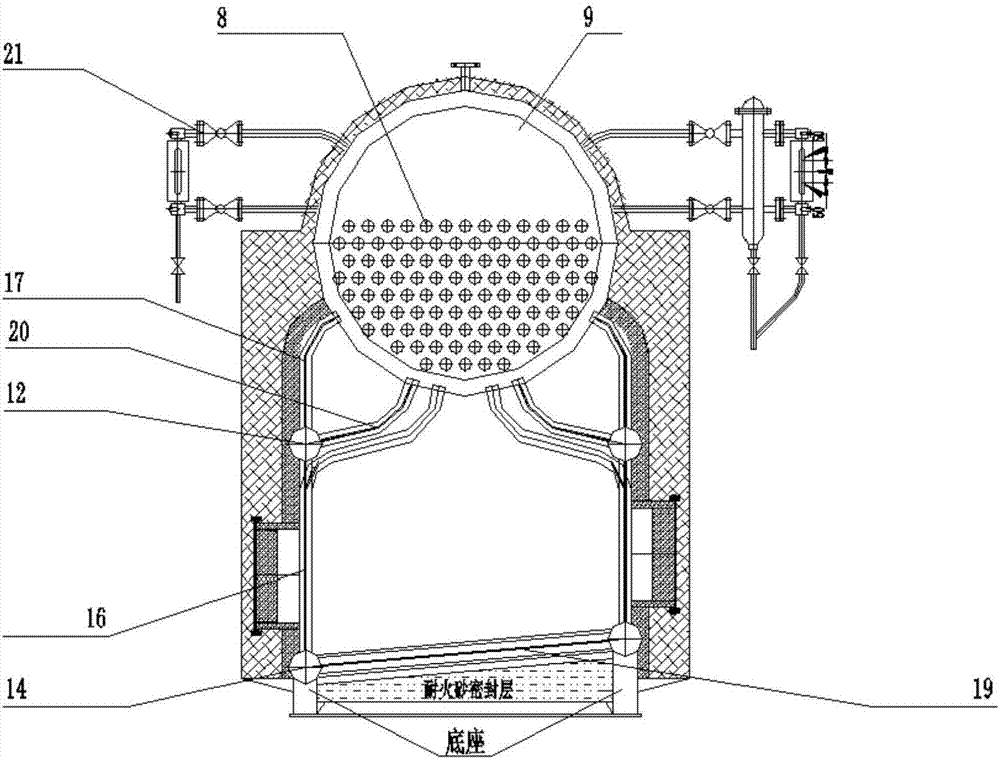

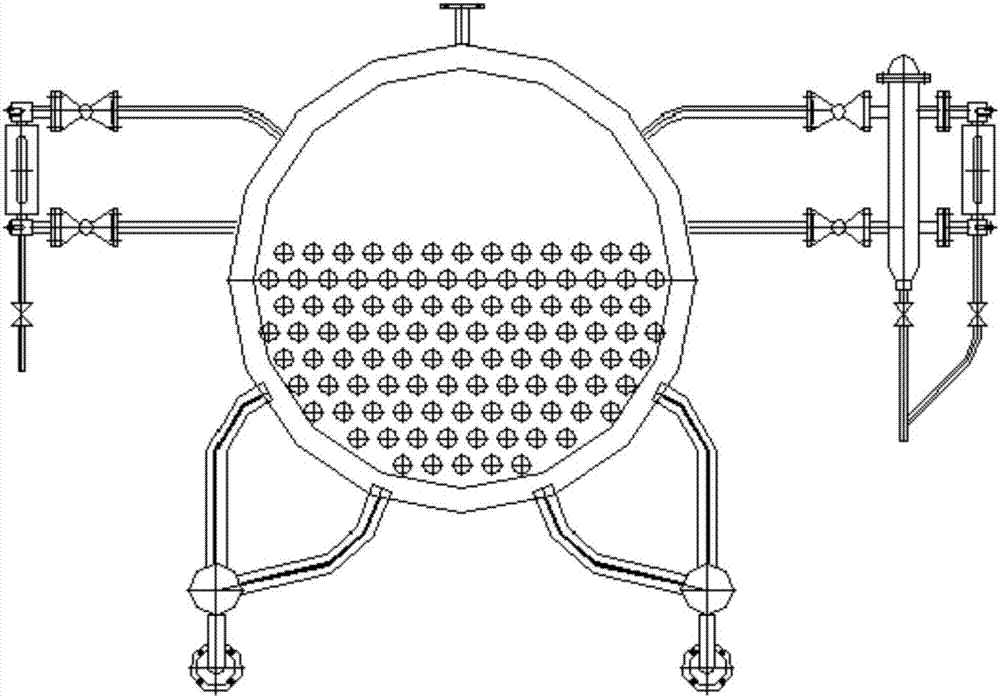

[0024] In the figure: 1 horizontal header under the front wall, 2 burner, 3 front wall pipe, 4 horizontal header on the front wall, 5 inner horizontal header, 6 connecting elbow, 7 front smoke box, 8 inner smoke pipe, 9 Drum, 10 rear smoke outlet, 11 maintenance port, 12 (left and right) upper vertical header, 13 downcomer, 14 (left and right) lower vertical header, 15 horizontal headers under the wall, 16 (left and right) wall pipes, 17 (left and right) upper wall pipe, 18 upper water pipe, 19 bottom wall pipe, 20 (left and right) inner wall pipe, 21 water level gauge, 22 rear wall pipe, 23 horizontal header on the rear wall, 24 burner interface.

[0025] A horizontal single-drum multi-fuel boiler, including a drum and a combustion chamber, a burner interface is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com