Apparatus and method for testing spray atomization performance

A detection device and performance technology, used in measurement devices, suspension and porous material analysis, particle size analysis, etc. The performance parameters such as drop particle size, uniformity and spatial density distribution can achieve the effect of low processing cost, easy operation and simple device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

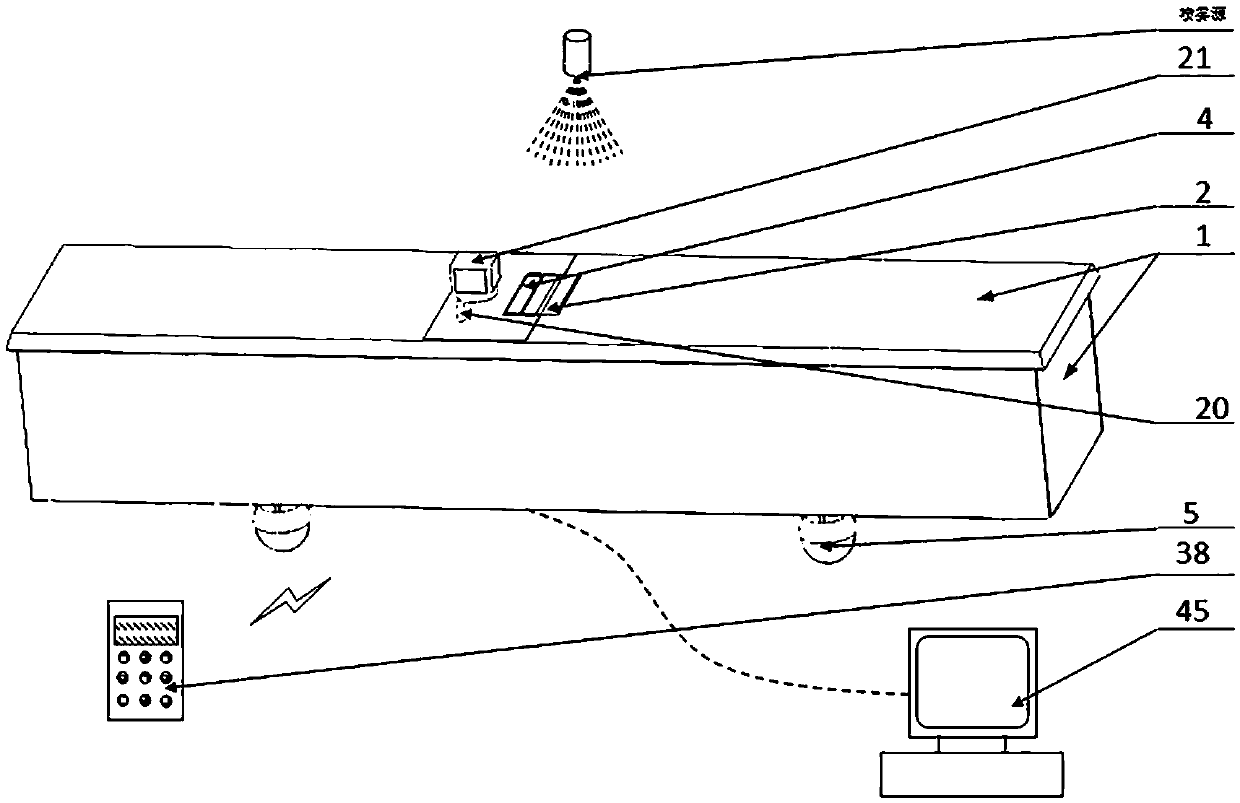

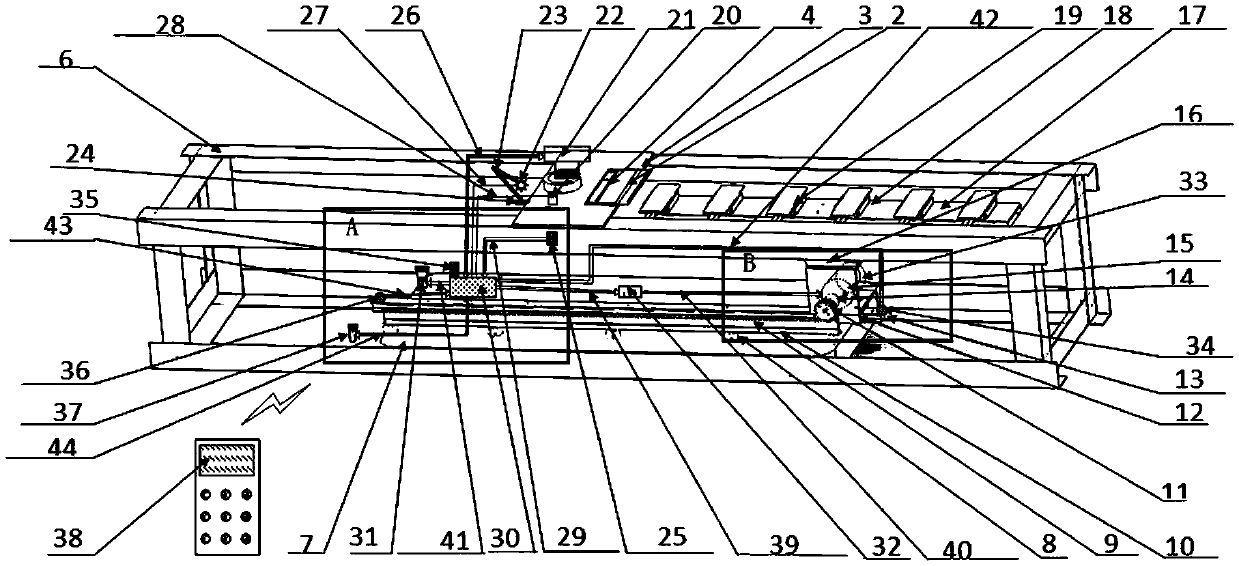

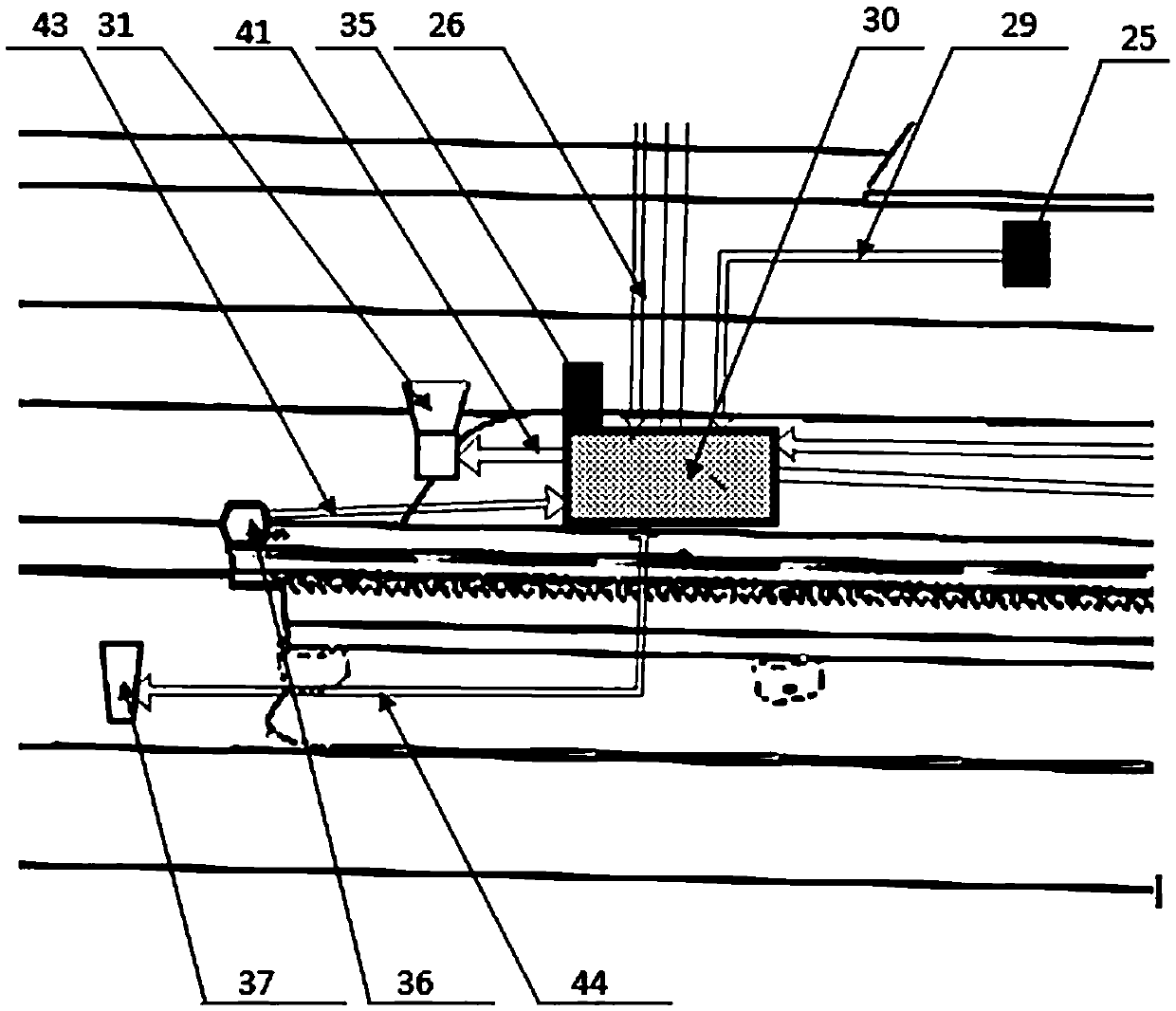

[0026] The structure diagram of the spray atomization effect performance detection device is as follows: figure 1 , figure 2 As shown, the device system is mainly composed of four major parts: mechanical part, camera part, control part and image processing part.

[0027] As the supporting platform of the whole system, the mechanical part mainly completes the movement of the stepper motor to drive the silicon analysis plate to realize the collection of spray droplets; including box body 1, push cover 2, upper plate cover 3, device frame 6, support plate 7, pad Block 8, rack 9, rack bracket 10, gear 11, slider 12, slide rail 13, coupling 14, motor support 15, adjustable bracket 16, support platform 17 and silicon analysis plate bracket 18;

[0028] The box body 1, the upper plate cover 3 and the support plate 7 are fixedly installed on the device frame 6, the push cover 2 is installed on the upper plate cover 3, and the upper plate cover 3 has a spray inlet window 4, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com