Deodorization tower device capable of realizing dusty and oily damp and hot gas temperature regulation

A humid and hot gas, temperature regulation technology, applied in the direction of combination device, indirect heat exchanger, heat exchanger type, etc., can solve the problems of being unsuitable for microbial metabolic reaction, excessive wind resistance of pipelines, affecting the normal operation of equipment, etc. performance and treatment effect, reduce treatment pressure and failure factors, and reduce the effect of equipment replacement and maintenance investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

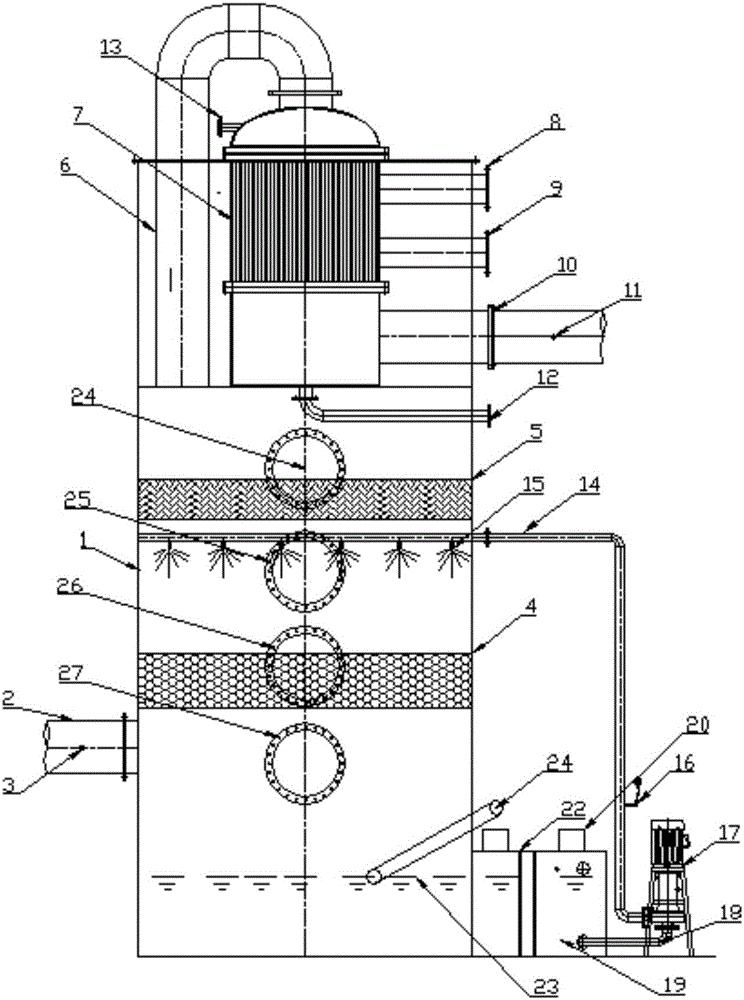

[0026] Below in conjunction with accompanying drawing and specific embodiment, the patent of the present invention is described in further detail.

[0027] System embodiment

[0028] The dusty and oily humid and hot odor is measured by the temperature sensor 3 on the exhaust gas inlet pipe 2 and enters the deodorization tower body 1. The gas moves upward along the tower body through the induced draft fan.

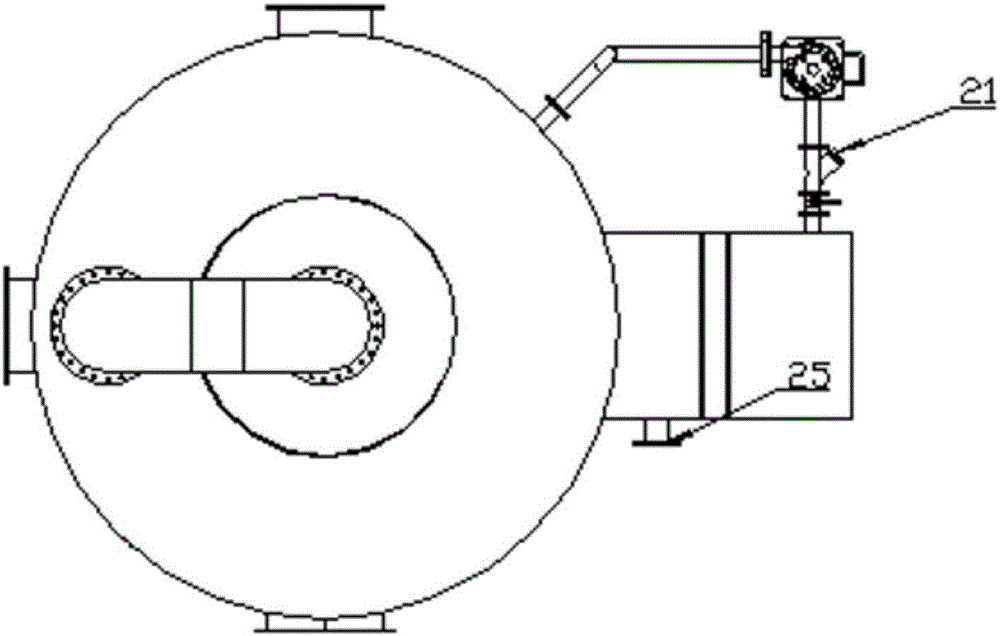

[0029] A spray atomizing pipe 14 and a nozzle 15 are arranged in the tower. Through the circulating water inlet pipe 18, the circulating spray water pump 17 pressurizes the water in the circulating water tank 19, passes through the Y-shaped filter 21 to remove impurities in the circulating water, and then transports it to the tower body through the spray atomizing pipe 14. squirt. The Y-type filter 21 can remove a small amount of particle impurities given in the circulating water, and prevent the small spraying and atomizing pipe 14 of the pipe diameter from clogging. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com