Device and method for simulating influence of two-stage supercharging pressure end/vortex end bypass on spray characteristics

A technology of bypass pair and vortex end, which is applied in the field of devices that simulate the influence of two-stage pressurized pressure end/vortex end bypass on spray characteristics, which can solve the problem of invisible spray characteristics and achieve the effect of simplifying the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

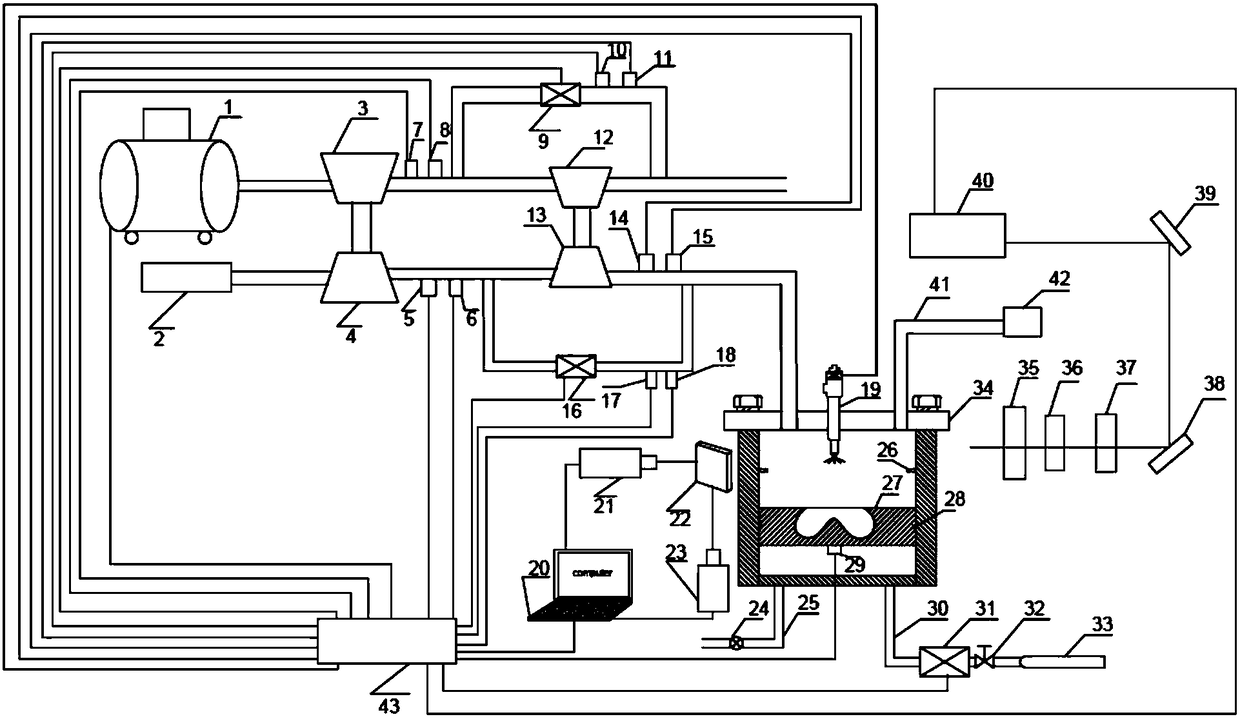

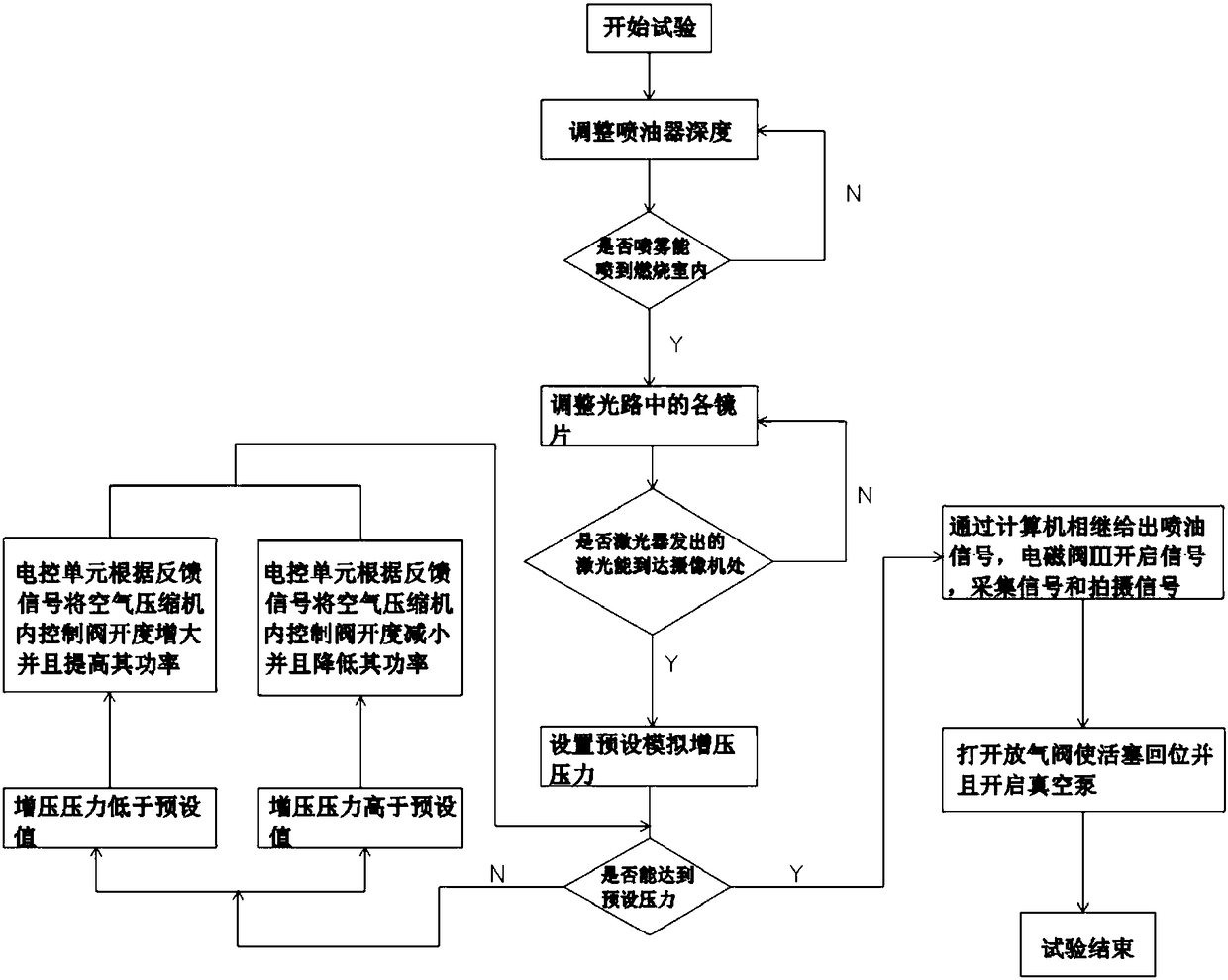

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, a device for simulating the influence of two-stage pressurized pressure end / turbine end bypass on spray characteristics includes a pressure end bypass simulation system, a variable volume incendiary bomb device and a spray shooting system.

[0034] The pressure side bypass simulation system includes an air compressor 1 , a low-pressure turbine 3 , a high-pressure turbine 12 , an air filter 2 , a low-pressure compressor 4 and a high-pressure compressor 13 .

[0035] The air outlet of the air compressor 1 is connected to the air inlet of the low-pressure stage turbine 3, and the air outlet of the low-pressure stage turbine 3 is connected to the air inlet of the high-pressure stage turbine 12, and a vortex temperature sensor is arranged near the air outlet of the low-pressure stage turbine 3 Ⅰ7 and vortex end pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com