Energy-saving heat exchange system with direct vapor-water mixing

A hybrid heat exchange and energy-saving system technology, applied in the direction of preheating, supplementary water supply, steam generation, etc., can solve the problems that the superiority cannot be fully exerted, affect the economy of the unit, and unfavorable heat transfer of the tube bundle, so as to increase the economy of heat recovery , Increase the effect of direct heat exchange and effective cold resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

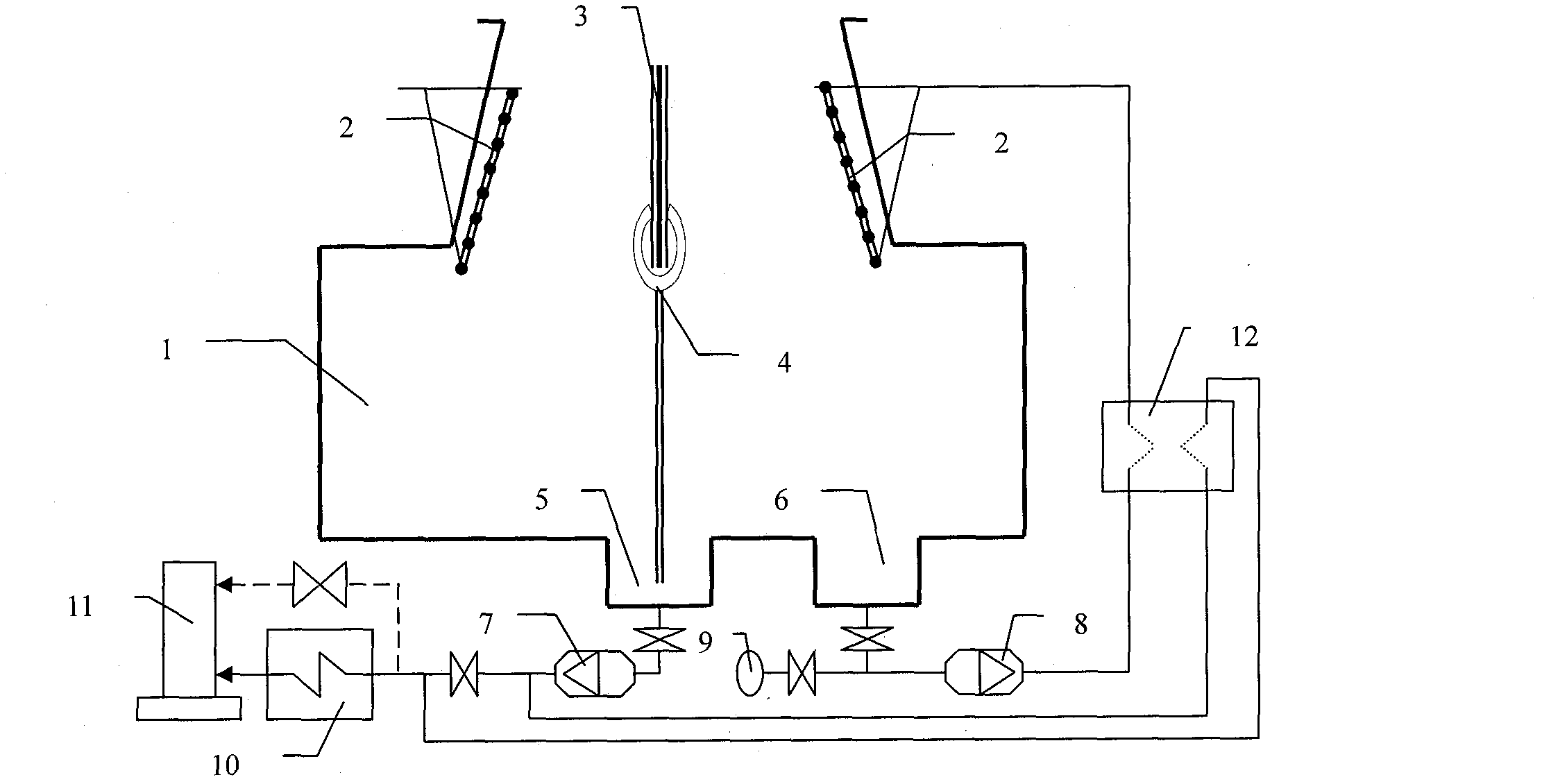

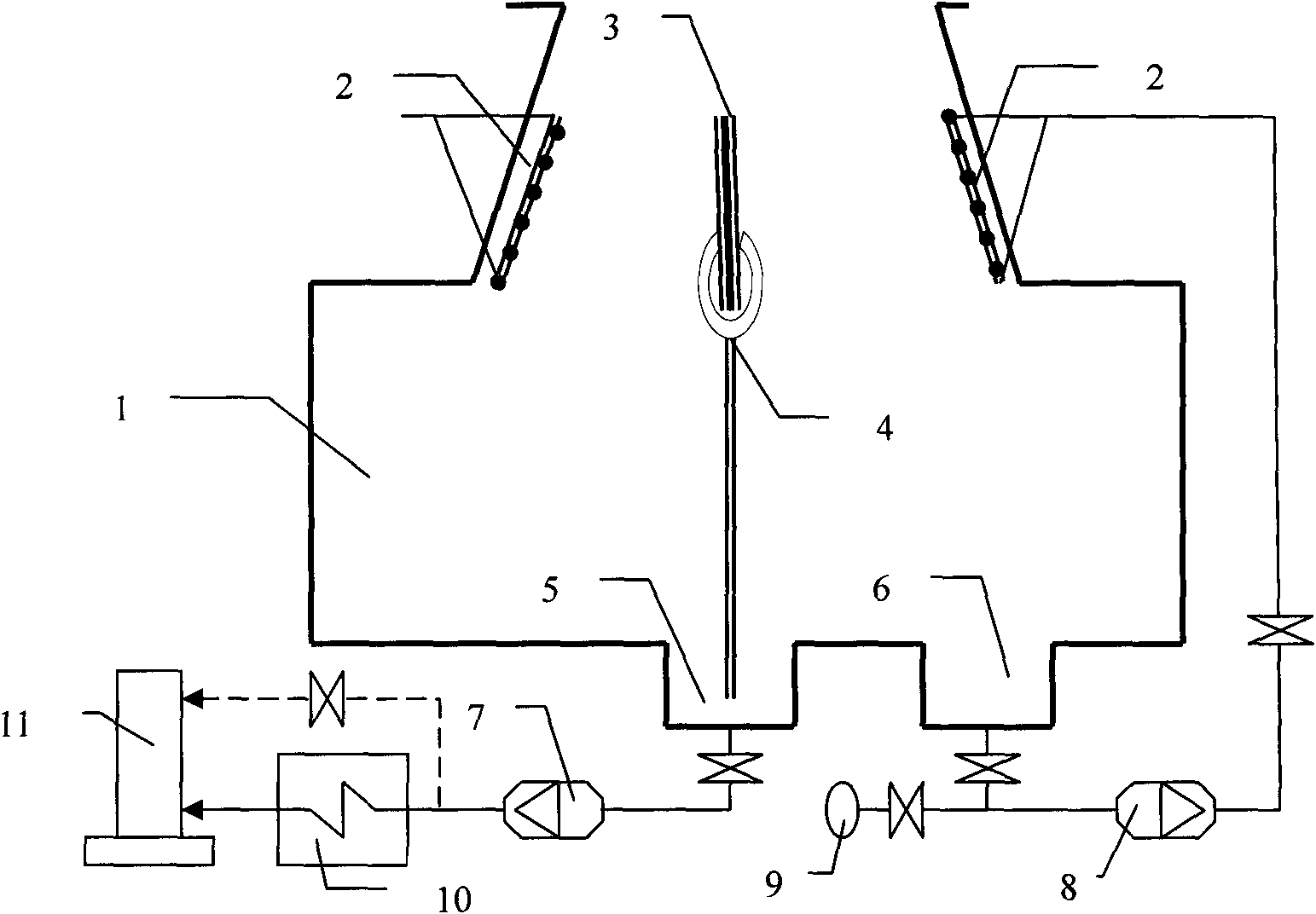

[0024] The present invention is further described by taking the accompanying drawings as an example

[0025] The steam-water direct mixing heat exchange energy-saving system of the present invention is as attached figure 1 Shown: Condenser (1), spray atomization heat exchange device (2), water collection device (3), diversion pipe fittings (4), high temperature water collection well (5), low temperature water collection well (6), Condensate water pump one (7), condensate water pump two (8), desalination make-up water (9) and deaerator (11) and other equipment. The main implementation technical features are:

[0026] At the high-temperature end of the throat of the condenser, a spray atomization heat exchange device and a water collection device are used to separate the high-temperature and low-temperature condensed water for separate treatment, so as to realize the heat-exchanged cooling cycle and the heating cycle of the condensed water. The process flow is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com