Production plant and production method of rapid setting metal powder

A technology of solidifying metal and production equipment, which is applied in the field of rapid solidification metal powder production equipment, can solve the problems of inability to realize large-scale production and low powder strength, achieve stable line speed, high economic value, and ensure the effect of solidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

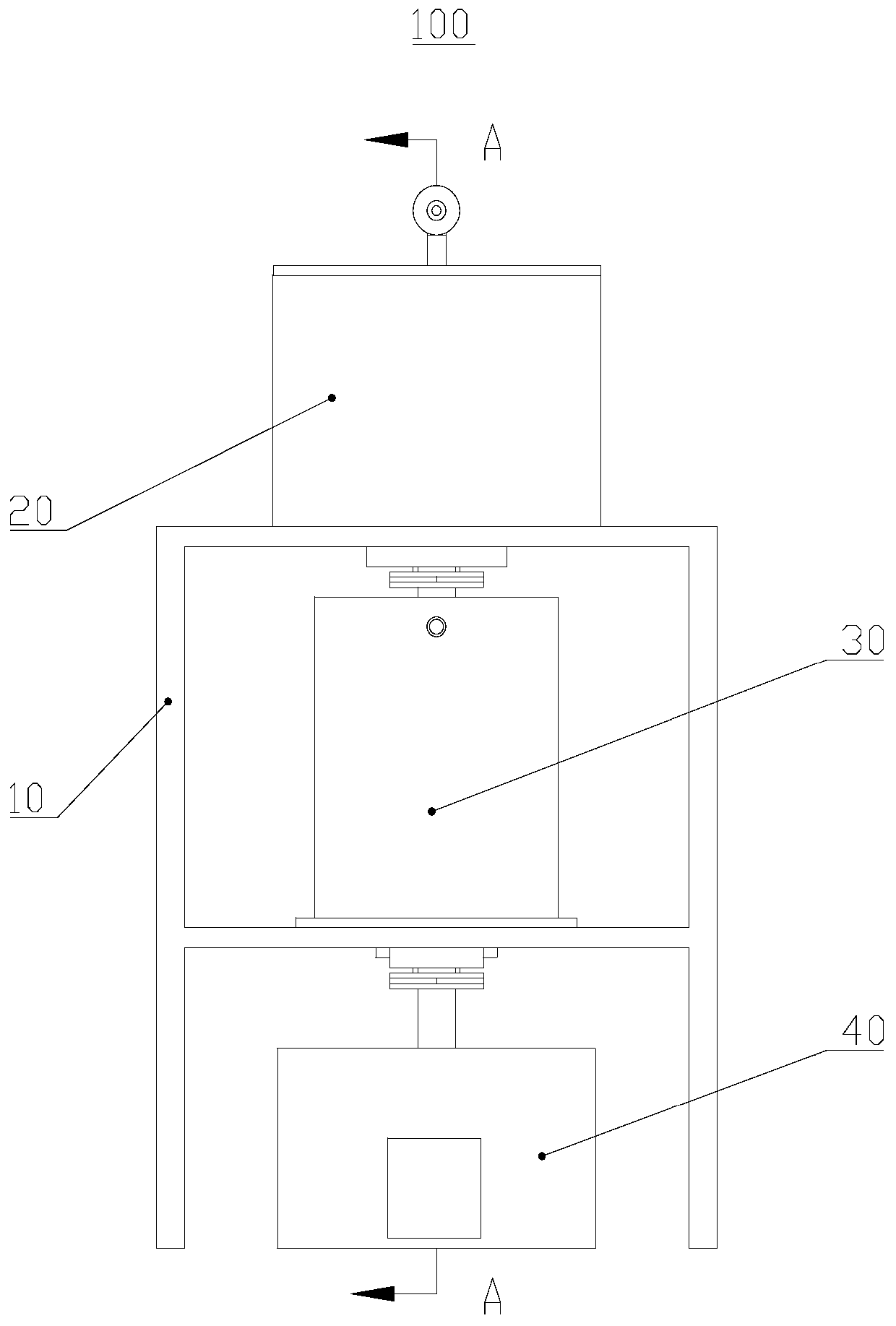

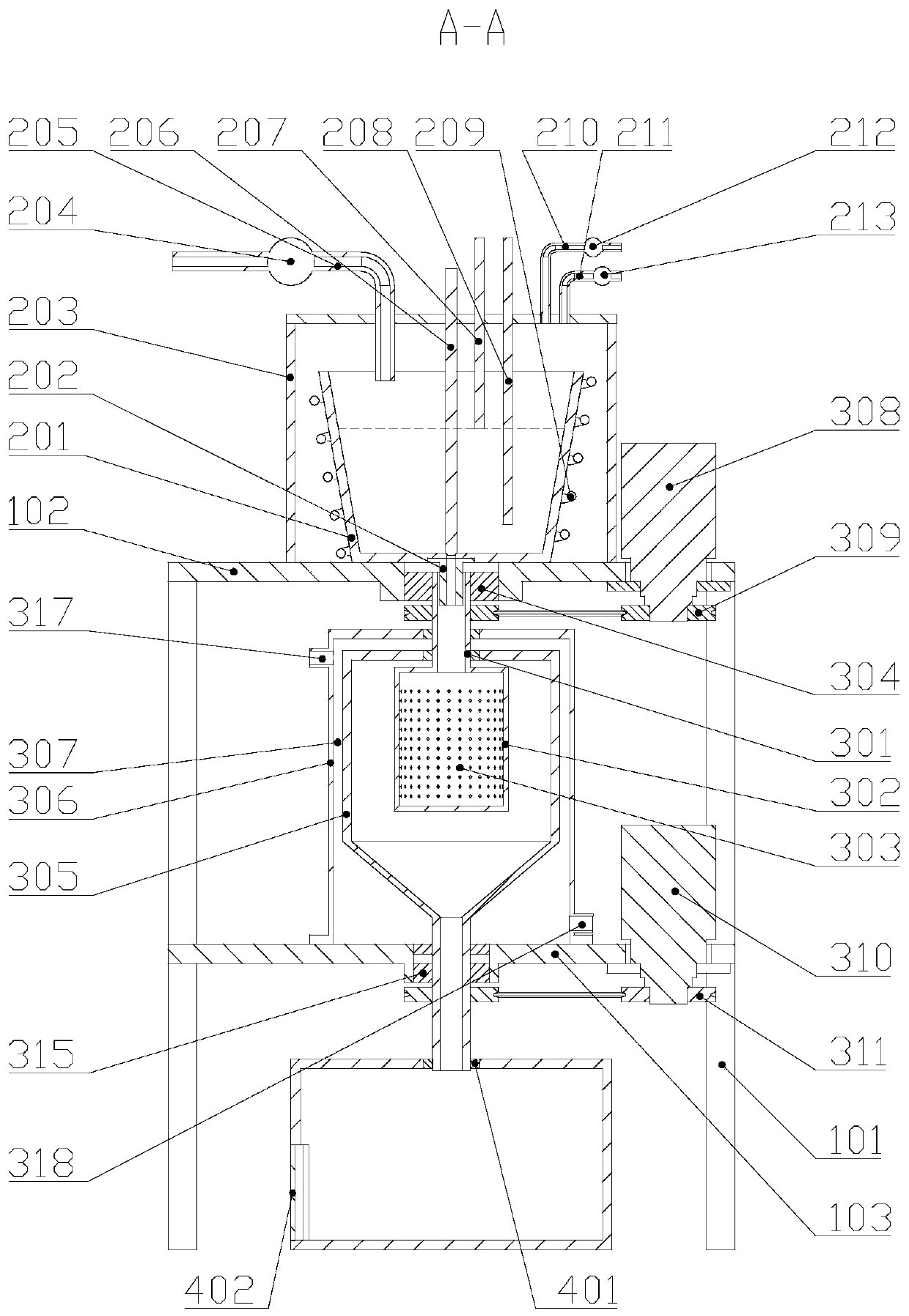

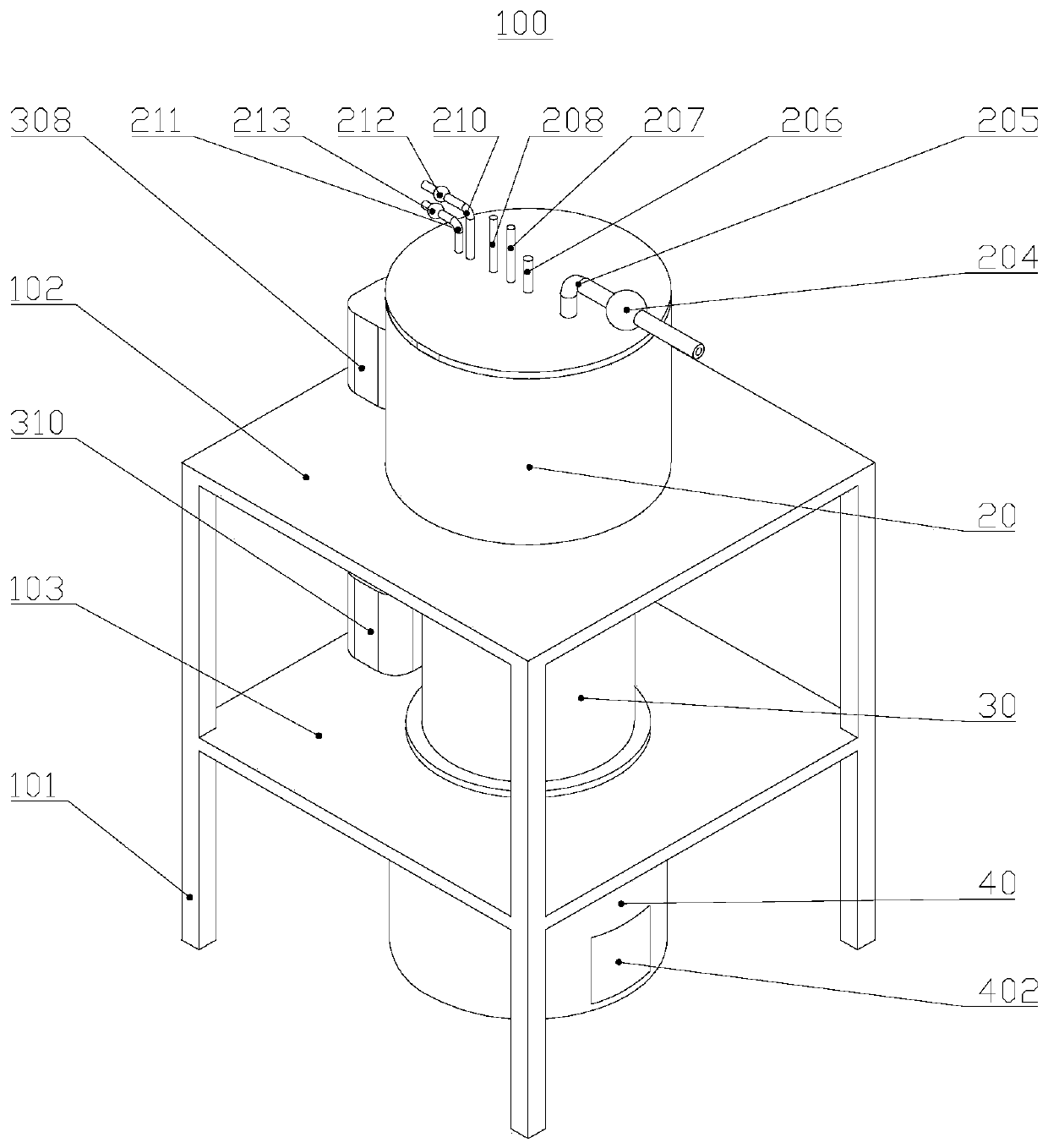

[0042] refer to Figure 1-4 , the production equipment 100 of rapid solidification metal powder according to the embodiment of the present invention includes: a support 10 and a holding furnace 20 , a quenching chamber 30 , and a powder collecting device 40 respectively arranged on the support 10 .

[0043] Please refer to Figure 1-4 , the bracket 10 of the present invention is used to install and fix the holding furnace 20, the quenching chamber 30, the powder collecting device 40, the driving group of the centrifugal atomizer and the driving group of the quenching wall, as the supporting member of the whole device. The bracket 10 of the embodiment of the present invention mainly includes a support leg 101, an upper support plate 102 and a lower support plate 103. The figure is only an embodiment of the present invention. Those skilled in the art can install the holding furnace 20, the quenching chamber 30, The powder collecting device 40 is for the purpose, and the structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com