Preparation method of fine particle size and low oxygen spherical titanium and titanium alloy powder

A technology of titanium alloy and fine particle size, which is applied in the field of preparation of fine particle size low-oxygen spherical titanium and titanium alloy powder, can solve the problems of unavailable, high centrifugal force, high cost, etc., and achieve strong process operability and short process flow , The effect of high powder yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

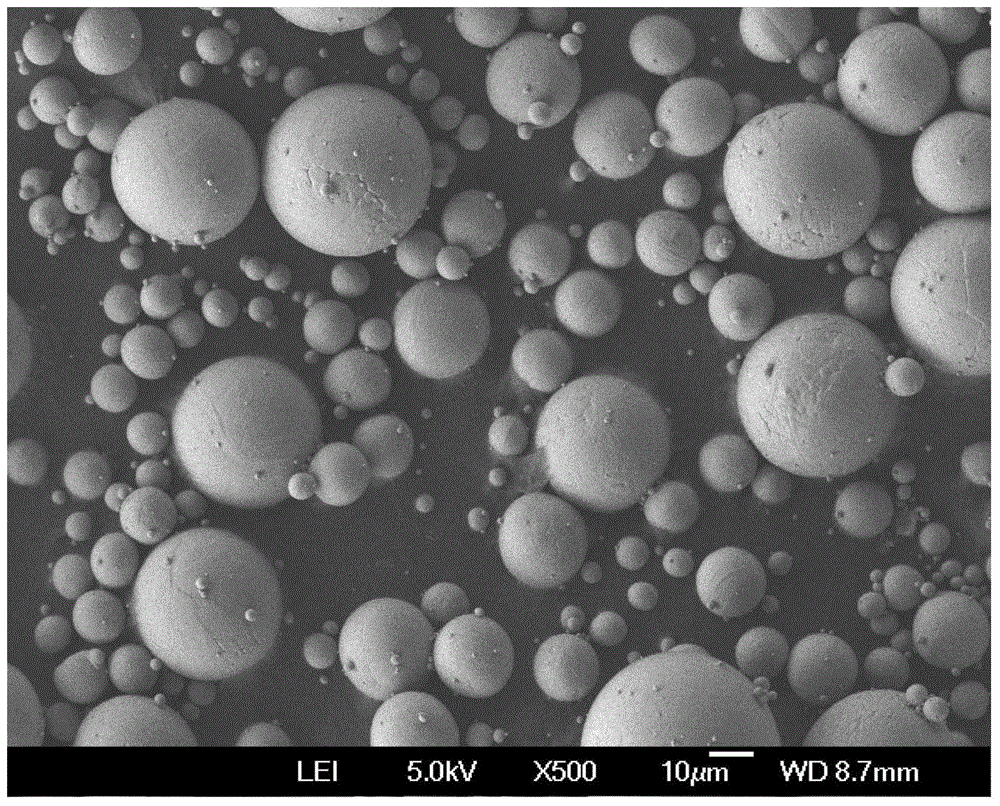

Image

Examples

Embodiment 1

[0021] Embodiment 1: The preparation method of the fine particle size spherical pure titanium powder of the present embodiment comprises the following steps:

[0022] 1. Using pure titanium ingots with high cleanliness to prepare 2mm diameter pure titanium coils by machining;

[0023] 2. Remove the oxide skin or impurities on the surface of the pure titanium wire by chemical pickling, clean and decontaminate and dry with alcohol;

[0024] 3. Put two discs of pure titanium wire into the wire feeding mechanism of the arc spray gun, and connect them to the positive and negative poles of the power supply respectively;

[0025] 4. Vacuum the atomization tower to 2×10 -3 Pa, and then filled with 0.4MPa high-purity argon.

[0026] 5. Turn on the power supply of the arc spray gun, adjust the arc current to 175A, feed two disks of pure titanium wire through the wire feeding mechanism and make them contact to generate arc melting, and the gas path is located 15mm directly above the ti...

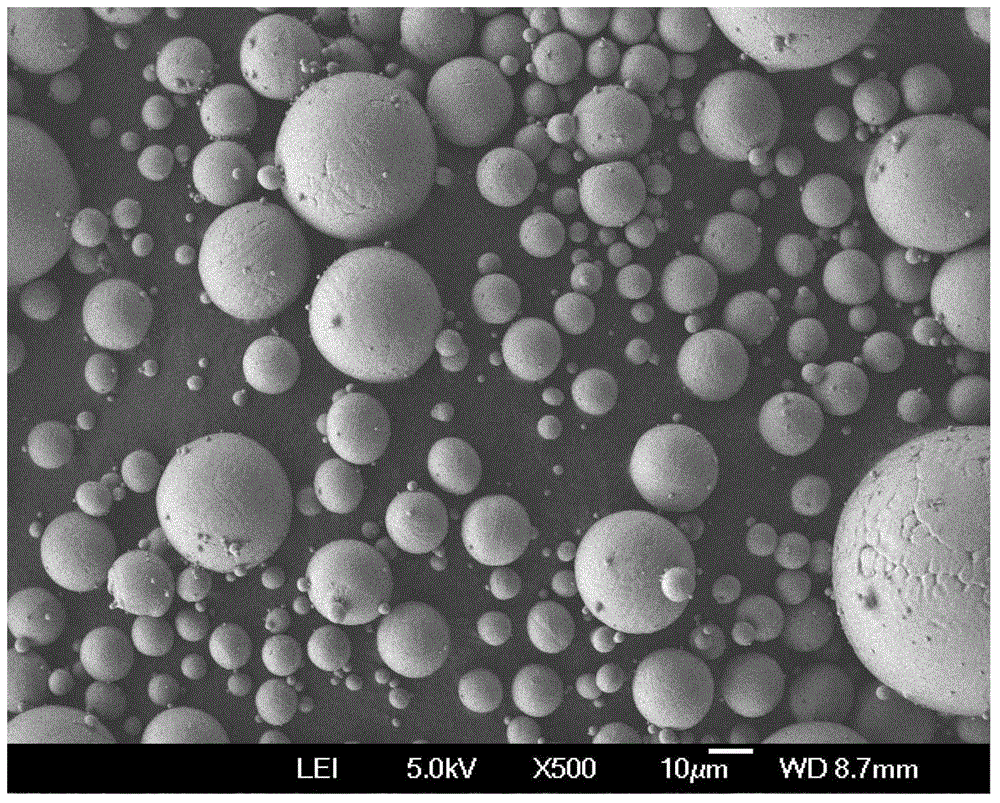

Embodiment 2

[0028] Embodiment 2: the preparation method of the fine-grained spherical Ti6Al4V alloy powder of the present embodiment comprises the following steps

[0029] 1. Using Ti6Al4V alloy ingot with high cleanliness to prepare 2mm diameter Ti6Al4V alloy wire by machining;

[0030] 2. Remove scale or impurities on the surface of Ti6Al4V alloy wire by chemical pickling, clean and decontaminate with alcohol and dry;

[0031] 3. Put two discs of Ti6Al4V alloy wire into the wire feeding mechanism of the arc spray gun, and connect them to the positive and negative poles of the power supply respectively;

[0032] 4. Vacuum the atomization tower to 2×10 -3 Pa, and then filled with 0.4Mpa high-purity helium.

[0033] 5. Turn on the power supply of the arc spray gun, adjust the arc current to 170A, send the two disks of Ti6Al4V alloy wire into contact through the wire feeding mechanism to generate arc melting, and set the air path at 15mm directly above the Ti6Al4V alloy droplet to set the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com